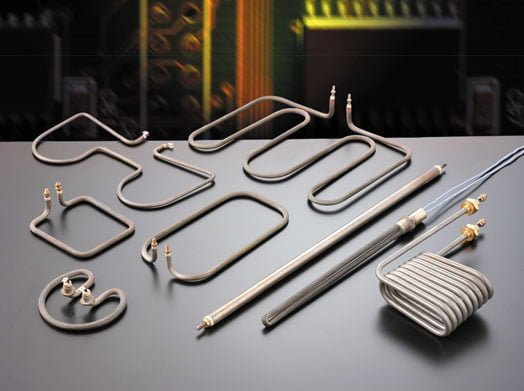

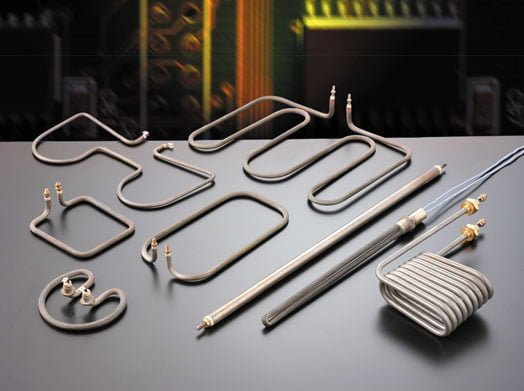

From the article you will learn what a heating element is, for what purposes it is used, how it is connected. You will also learn about what kind of design it has. In short, this is an electric heating device, and the abbreviation itself stands for quite simply. It is a tubular electric heater. It bears this name for the reason that often these elements are made in the form of ceramic, glass or metal tubes. Now let's take a closer look at all the components of this electrical appliance.

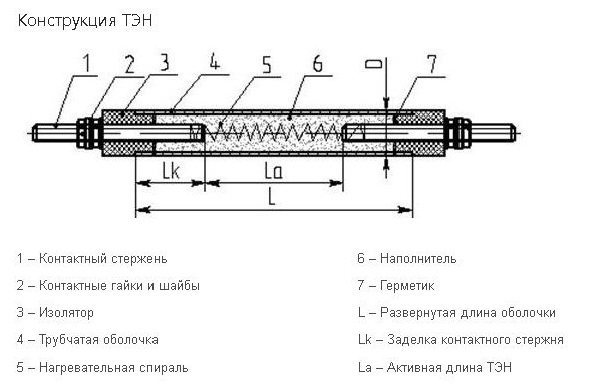

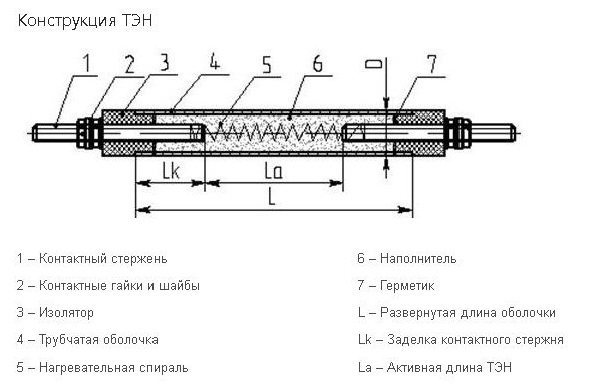

Element design

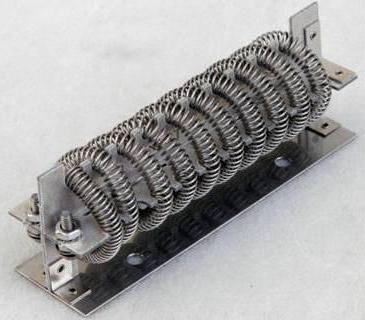

The article shows a diagram of a heating element. The most important component of any heating element is the heater itself, made of nichrome thread, which is located inside the tube along its entire length. The ends of the thread are attached to the output pins. The nichrome thread has a certain resistance, when a current begins to flow through it, it heats up, and gives off heat to a metal or ceramic holder.

It should be noted that the material from which the tube is made must have a high current resistance. Therefore, it is made from alloys that include constantan or nichrome. The resistance of the heating element depends on how much power the device needs to develop.

Heating elements of the Swedish company Electrolux

The Swedish company Electrolux uses heating elements of its own production and products of the Italian plant Thermowatt. High-quality products are produced in a large assortment, are reliable and do not overgrow. Heating elements for Electrolux heaters become unusable due to the following reasons:

- a metal tube bursts from prolonged temperature overheating or high voltage;

- corrode attachment points;

- there is no magnesium anode;

- the heater is not completely submerged in water.

All cases of failure of heating elements are associated with violations of the rules for operating the device.

Calculation of heater parameters

According to Ohm's law, the power is calculated, which is equal to the product of the current strength and the voltage of the electrical network. In other words, in order for the heating element to have a power of 1000 W, you must first calculate the current strength. There are two known parameters - power and voltage (in the household network - 220 volts). The current will be equal to the power divided by the voltage. If 1000/220, we get a current strength equal to 4.55 A.

In order to determine the resistance of the thread, it is necessary to divide the voltage by the current strength. As a result, we get the resistance of the heating element winding, expressed in ohms. More precisely, we divide 220 by 4.55 and we get that the resistance of the nichrome thread should be equal to 48.4 ohms.

It should be noted that resistance directly affects the power of the heating element. The lower the resistance value, the greater the power of the heating element. It is necessary to pay attention to the fact that almost all the power will be spent on heating the thread. Therefore, the efficiency of most heating elements is almost 100%. In other words, the more powerful the heating device, the faster and more it warms up.

Tips & Tricks

Before purchasing a water heater, any consumer asks the question, a device with which type of heating element would be the best option. To choose a more suitable type of part, it is worth familiarizing yourself with the specific features of each variety, as well as taking into account the existing advantages and disadvantages.

- Flange elements are standard parts of the water heaters. According to experts, as a result of their operation, the maximum contact of the heating element with the liquid is achieved.However, corrosion and deposits will negatively affect heater performance over time. Many manufacturers resort to additional developments that help slow down the accumulation of plaque on the surface of the part, but open types of elements still fail much faster. In addition, the maintenance of wet heating parts is difficult.

Apartment owners are constantly faced with interruptions in the supply of hot water. Residents of private housing construction independently provide themselves with hot water for household needs. For those and others, the way out will be the purchase and installation of a water heater or boiler. There are two types of boiler on sale. For the consumer, each type is described separately and a comparative characteristic is given for the heating element. Depending on which heating element for the boiler: dry type or wet type is installed, the consumer will make an informed choice.

Insulator and tube material

Between the tube and the nichrome thread is an insulator that can withstand very high temperatures. In order to make a tube for heating elements, it is necessary to choose materials that do not corrode. It is these tubular electric heaters that are most often used in industry and everyday life.

Enclosed in a glass tube are used, as a rule, in very aggressive environments, for example, in chemical laboratories, in which it is necessary to heat various mixtures. But you can also find them in household heaters. As a rule, they are used in devices using infrared type radiation. Ceramic tubes in heaters are used very rarely today.

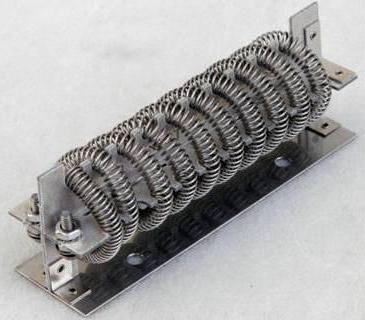

Advantages and disadvantages of air heating elements

These heaters have many advantages. They are not focused on testing with threats of corrosive damage, but contact with aggressive gas-air mixtures made them resistant to other operational factors. The advantages of products include their increased physical strength, thermal protection, as well as the ability not to lose their basic qualities under the influence of high loads and vibrations. In addition, the air heating element is distinguished by a variety of configurations, which is confirmed by both finned models and flexible versions.

Air heating elements also have disadvantages. They are expressed in the complexity of maintenance and the need for a detailed study of working environments in order to select the best suitable element.

Tube diameter

The tubes can have any diameter, but elements with a diameter in the range of 6-24 mm are widely used. In addition to the fact that the insulator must have high insulating properties, it is necessary that it effectively transfers heat from the heating coil to the tube. Now let's talk about what a heating element is and how it works.

The power supply to the heating element is supplied using the terminals, which are located on the inserts with insulators. Terminals can be located at one end or both. There are varieties of tubular electric heaters that are equipped with built-in fuse protection. As a rule, such elements are installed in dishwashers or washing machines.

Dry heating element

Such an element is not in direct contact with water. It is located in a sealed flask (see photo), which can be filled with:

- By air;

- Oil;

- Sand;

- Other materials.

During operation, a dry heating element heats the surrounding material, liquid or gas. They transfer heat to the walls of the flask, which heats up water, air or coolant. Most often, the dry version is supplied complete with the flask, but it can be collapsible.

Dry heating elements of different sizes.

For air heating

For such heating elements, the temperature can reach 450 degrees. These tubular devices are used to heat the air in domestic and industrial premises.Such heating elements are the basis for the manufacture of convectors, various designs of drying chambers, air curtains. These heaters have smooth or finned tubes. What is a heating element for heating air, we will consider further.

The fins of these heaters are made from steel straps that are attached to the tube. Thanks to the use of ribs, it is possible to increase the surface area of the element, therefore, the load on the nichrome thread is significantly reduced, and the resource of the element also increases. At the same time, heat transfer increases significantly.

Influence of the thermostat on the service life of the heating element

Water heaters have mandatory overheating protection. When the critical temperature is reached, the device turns off. The temperature in the water heater is controlled using a thermostat. In this case, the temperature sensor is;

- a rod lowered into the vessel parallel to the heater;

- a capillary device, in which the membrane closes in contact with an increase in the volume of liquid;

- electronic node.

Thermostats are simple and programmable, overhead and mortise. They cannot be repaired, they are replaced during installation with similar ones.

Heating elements for a water heater with a thermostat operate in a gentle mode. If an economical heating mode is used up to 55 degrees, the conditions for the deposition of hardness salts are not created and the heating element remains clean for a long time, which means it does not overheat.

In addition, a heating element with a thermostat is very convenient to use, simply by heating water in any container.

Water heaters

When replacing the heating element of the washing machine, you can see that its design is completely sealed. Very often, such heating elements can be found both in washing machines and in boilers, heating appliances. Water can be heated in them to the boiling point, which is 100 degrees Celsius. If the volume of water is very large, block type devices are used. Quite often, together with the heating element, a temperature regulator is installed for the boiler.

With the help of a thermostat, it turns out to disconnect the heating element from the power supply when the liquid reaches the required temperature. As soon as the water cools down, the thermostat turns on the power again, and the coil begins to warm up. Such heating elements are used for heating boilers, boilers, in washing machines.

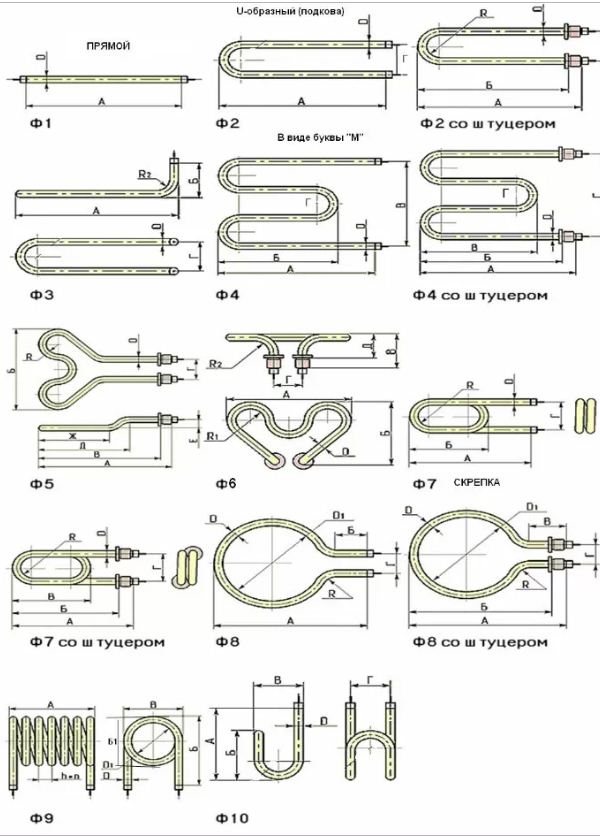

Construction of tubular electric heaters (TEN)

It is possible to manufacture TEH with a diameter of 8, 8.5, 10, 12, 13 mm with other contact devices, as well as equip with threaded fittings M22 × 1.5, M18 × 1.5, M16 × 1.5, M14 × 1.5 , М12 * 1.5 and washers, nuts.

An example of a designation when ordering:

| Heating element | 100 | BUT | 13 | ABOUT | 220 | R30 | F2 | G1 / 2 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

Designations of positions in the marking:

- Tubular electric heater.

- Unfolded length 100 mm.

- Contact rod length (table 1) (A = 40, B = 65, C = 100, D = 125, E = 160, F = 250 (mm)).

- Diameter 13 mm, the following diameters are available: 8, 8.5, 10.11, 12, 13 mm.

- Heating medium (table 2)

- 220-voltage

- R30-bend radius 30 mm.

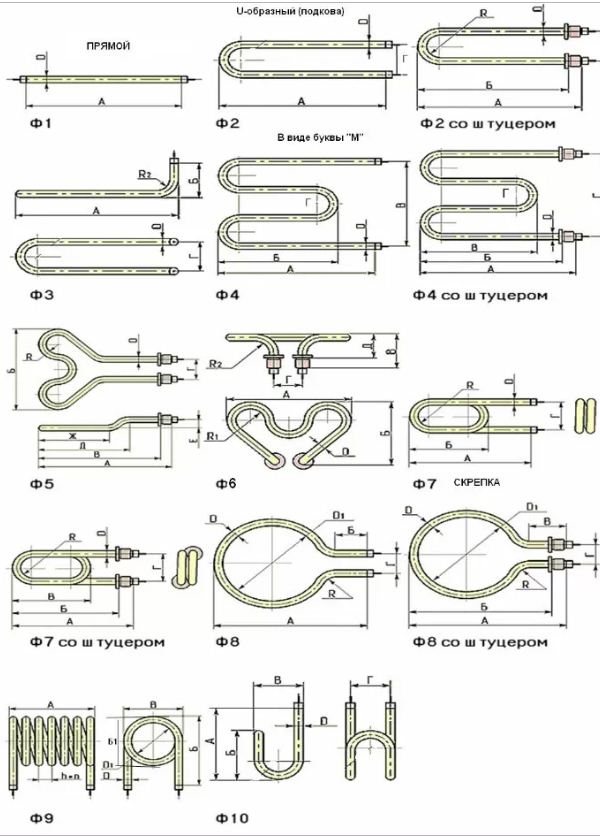

- F2-typical form (table 3)

- G1 / 2- Presence of threaded unions G1 / 2.

Table 1. Designation and nominal length of the contact rod in the termination for pipe diameters from 10-12 mm

| Length designation | BUT | IN | FROM | D | E | F | G |

| Length in mm | 40 | 65 | 100 | 125 | 160 | 250 | 400 |

Table 2. Designation of heated medium, sheath material

| Symbol | Medium to be heated | Heating behavior | Sheath material |

| J | Water, weak acid solution (pH 5 to 7) | Heating, boiling with a maximum temperature on the casing of 100 ° C | Stainless steel |

| P | Water, weak alkali solution (pH 7 to 9) | Heating, boiling with a maximum temperature on the casing of 100 ° C | Carbon steel |

| S | Air, gases and gas mixtures | Heating in a calm atmosphere to a temperature on the heating element sheath of 45 0 ° С | Carbon steel |

| T | Air, gases and gas mixtures | Heating in a calm gas environment with a temperature on the heating element sheath over 450 ° С | Stainless steel |

| O | Air, gases and gas mixtures | Heating in air moving at a speed of 6 m / s to a temperature on the heating element sheath of 450 ° C | Carbon steel |

| K | Air, gases and gas mixtures | Heating in an air moving at a speed of at least 6 m / s with a temperature on the sheath of the heating element St. 450 ° C | Stainless steel |

| L | Foundry molds, molds | The heating element is inserted into the groove, there is guaranteed contact with the heated metal, the temperature on the heating element sheath is up to 450 ° С | Carbon steel |

| Z | Fats, oils | Heating in baths and other containers, temperature up to 250 ° С | Carbon steel |

| W | Low-melting metals and alloys | Heating and melting in baths and other containers with a temperature on the heating element sheath up to 450 ° С | Carbon steel |

| D | Saltpeter (double shell) | Heating up to a temperature of 600 ° С | Stainless / black steel |

| H | Saltpeter | Heating up to a temperature of 600 ° С | Stainless steel |

Table 3. Designation of the form of heating elements

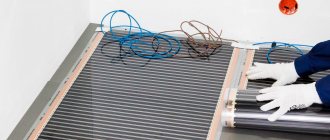

Flexible type devices

Such designs have found application in systems with hot channels, in molds. They are convenient when you need to shape the contour in a hot channel system. The sizes of electric heating elements can be any. A kind of flexible electric heating element that is familiar to almost every homeowner is a self-regulating cable for a warm floor. Such a heating element is very often used in the manufacture of a space heating system.

A separate type of device is a cartridge device, in which the terminals for connecting to the power source are on one side. The length of the heating element can be a maximum of 3.5 m. The main difference from all other types of devices is that it has a compact body, most often made of stainless steel with leads.

Cartridge heating elements have a very high power density, heat from the heating element is transferred both by convection and contact. Typically, such heaters are often used in the industry to heat oils of various shapes made of metal. Quite often, devices can be found in the automotive industry, footwear, food, and foundry.

Features of flexible air heating elements

Flexible elements demonstrate a high-tech approach to organizing the heating function. They differ in that even with their hands without the use of a special tool, the user can give the product one or another shape. It is important to emphasize that the flexible structure does not in any way diminish the working qualities of the device - the heating element may well compete in terms of thermal resistance and power with traditional models, including liquid ones. Electric air heating elements are used in special hot runner equipment and molds. That is, the specifics of the operation itself led to the need for a flexible structure. In some respect, contour heating of the target area is obtained.

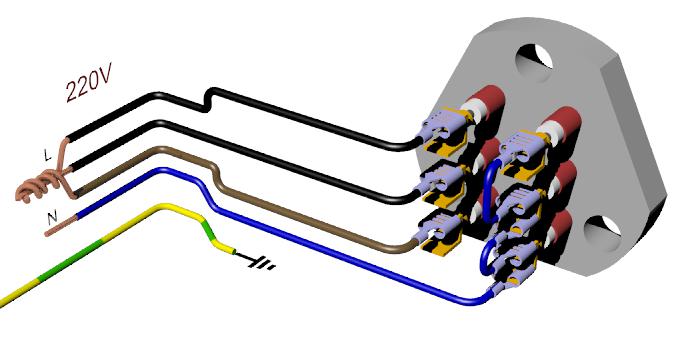

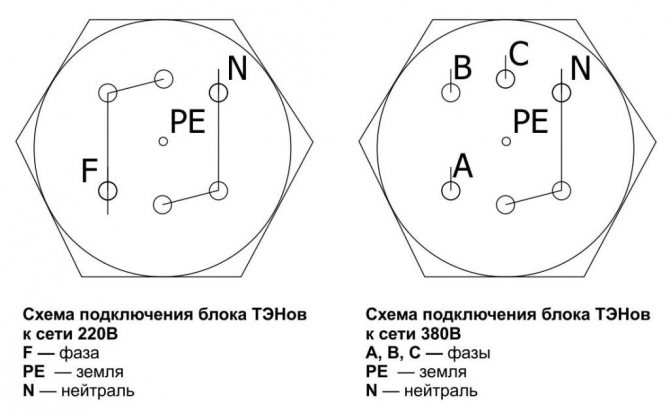

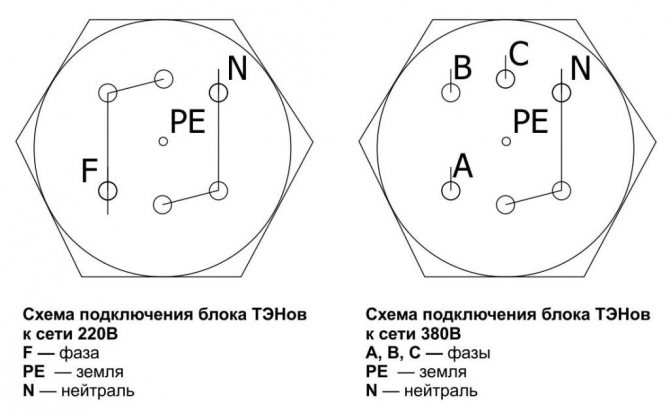

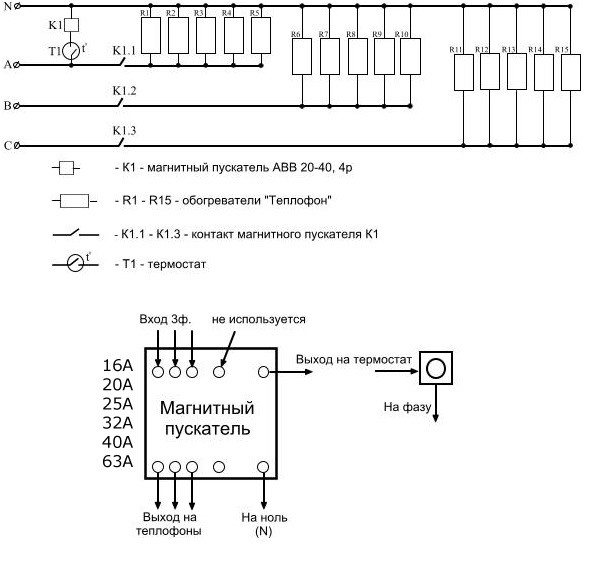

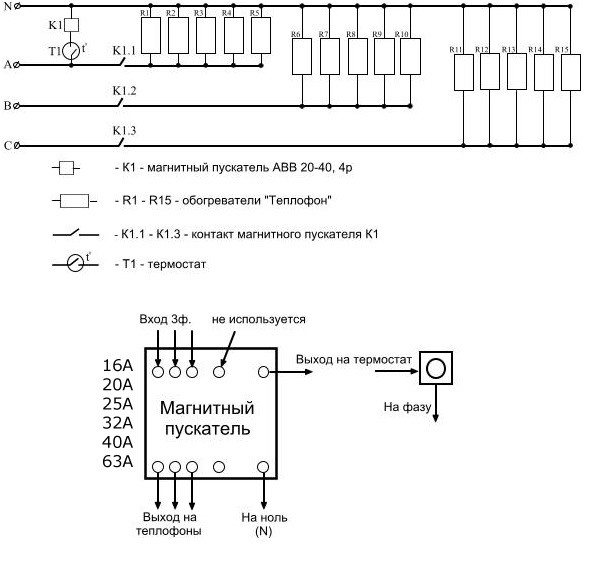

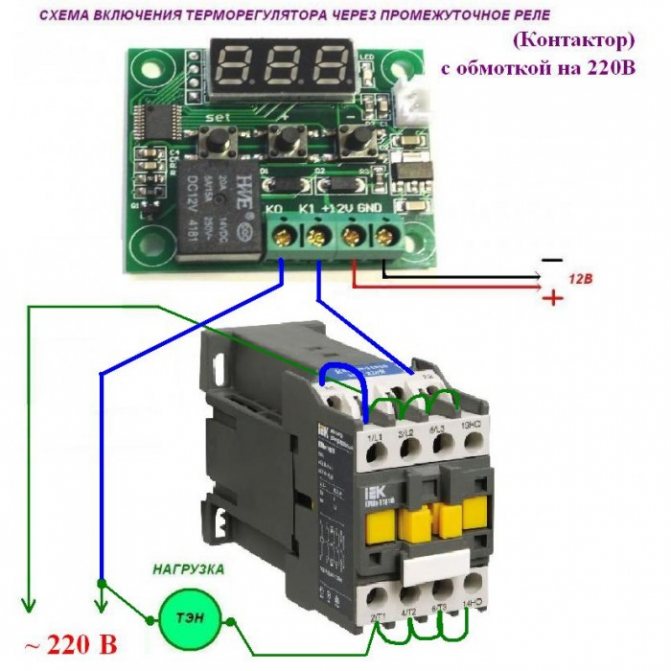

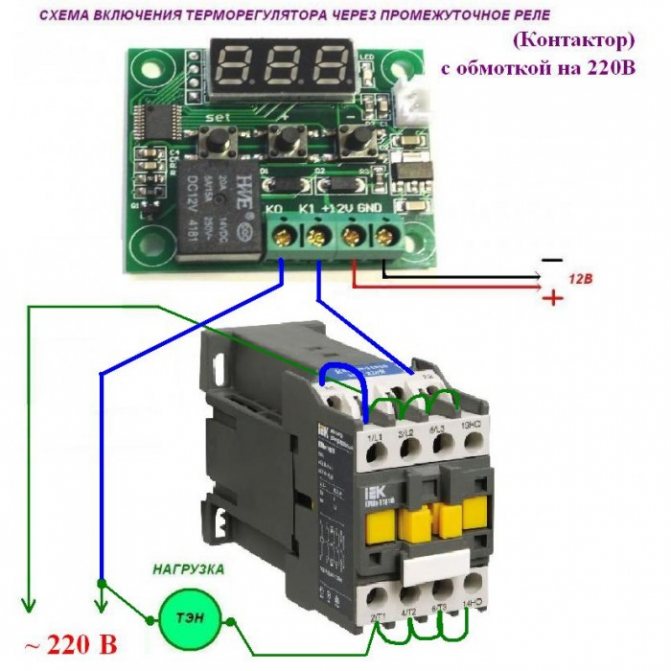

Connecting devices

In order to connect the device to an alternating voltage network, you must use the diagrams given in the article. Be sure to install protection - a circuit breaker. In addition, you can install a magnetic starter to switch the circuit or an electromagnetic relay. If you need to adjust the temperature, install a special regulator - it is allowed to use both electronic and mechanical, operating on the principle of a thermostat. Now you know what a heating element is and what its types are, and most importantly, you have familiarized yourself with the connection diagrams.

The procedure for replacing heating elements in water heaters

To clean or replace the heating element in the water heater from scale, it is necessary to provide access to the device by emptying and draining the container. In this case, it is necessary to ensure equalization of the pressure in the vessel.

During the work being carried out, the water heater is not only disconnected from the outlet, but the machine on the line is turned off.You can assemble the circuit and turn on the water heater after water flows from the drain cock.

To ensure inspection and repair of the device, it is necessary to turn over and dismantle the flange with the attached heating element. Disconnect power. First, you need to sketch or photograph the wiring fastening on the flange in order to assemble the circuit correctly after replacing the node. At the same time, the anode rod must be replaced or cleaned of sediment.

Heating element for a washing machine, what is it. How to choose a heating element for a washing machine

How to choose a heating element (heating element) for a washing machine by brand of technology.

Seat

The most important thing when selecting a heating element is that the seat fits. Almost all heating elements have the same place. The exception is heating elements on old washing machines, which are more than 12-13 years old.

The presence of a pile

The presence of a shoulder must be taken into account. If instead of a heating element, which did not have a collar, you put a heating element with a collar, then this heating element can fly out of the tank during washing. In principle, you can put a heating element without a collar, instead of a heating element with a collar, but it is not desirable.

Sensor hole

Some heating elements have a special hole for the sensor. On all heating elements that come with a sensor, this sensor can always be pulled out, even if it seems that it is sealed. Instead of a heating element without a hole, you can put a heating element with a hole using a special plug. There are models on LG washing machines that have heating elements with a sensor, but nothing is connected to the sensor. In this case, you can put the heating element without a hole.

Heating element length

After that there is a difference in length. Heating elements are short, medium and long. It is desirable to take into account the length, but if the new heating element is a little longer or shorter than the old one, then it's okay. You can also put a short heating element instead of a long one, but a long heating element will not fit in the place of a short one (it may not fit).

Heating element power

Next comes the power. Power doesn't matter. If the heating element is more powerful, then it will heat the water a little faster, and if it is less powerful, then it will heat up a little longer. The difference will not be noticeable.

Heating element form

Another point is the form of the heating element. Almost all heating elements are straight, but sometimes curved ones are found. This must also be taken into account.

Heating element coverage

Some models of washing machines are equipped with heating elements with a ceramic or other coating. It is of no fundamental importance; it may last a little longer.

Heating element manufacturers

- Thermowatt (the best in quality, these heating elements are embossed "made in Italy")

- IRCA (second in quality, but these heating elements come with a fuse)

- Blackmann (worse heating elements, very rare)

The manufacturer does not matter, the main thing is that the heating element is suitable for other parameters.

Selection process by brand

- Samsung, Indesit, Ariston - short heating elements with a hole, without a shoulder. On some samsungs, ceramic heating elements are installed. Instead of them, you can put ordinary short heating elements with a hole.

- LG - short heating elements without a hole. Some models come with heating elements with sensors.

- Bosch, Siemens - medium heating elements with a shoulder, with a hole.

- Candy - long heating elements without a hole, with a collar.

- Electrolux, Zanussi - long heating elements with a hole, with a shoulder.

- Ardo - sometimes there are curved heating elements with or without a hole.

- Older models of the brands listed above may have other heating elements. Basically, long heating elements were previously installed. There may or may not be a sensor hole.

This list is indicative only. Discrepancies possible!

Signs that the heating element burned out

- The washing machine does not heat the water

- The washing machine draws water and stops or turns off after 5 minutes

- Knocks out plugs 5 minutes after starting the washing machine

- The smell of burning

- Washing machine does not wash well

- The washing machine is electrocuted

In our catalog of spare parts for washing machines, you can choose a suitable heating element for your washing machine according to the brand or size of the heating element. You can order a spare part on our website, or by calling.

What is a heating element in the oven. Communicate with ovens in the same language

When a hostess gets to know a new oven, the first thing she encounters is the need for translation. And not in the sense from one language to another, but more often from the names inherent in each company, to generally accepted terms.

What is it for? It's simple, you can compare one oven with another only when the object of comparison is clear. Therefore, we avoid pretentious, and most importantly, incomprehensible expressions such as "turbo-blowing", "maxi-grill", "intense hot air", "thermocirculation" or "3-0-convection". And if the description contains any function like "slow baking" or "gratin", we strive to "shake out" the whole truth about how it works from the brand department.

Therefore, the technical characteristics in the manufacturers' catalogs look much brighter and more seductive than our boring, but understandable data for everyone. We will not deviate from this rule now, therefore we assign the same names to the modes, which you will see on the following pages of the review.

Remember to warm up

At the beginning of the story - a few general tips. In the instructions for ovens (which we actively use), for the successful preparation of dishes, it is recommended to preheat them to the required temperature (while focusing on the thermostat indicator lamp, it should go out).

Only for very fatty meat can an exception be made and put in a cold oven. In this case, the cabinet can be turned off a few minutes before readiness, the residual temperature will be sufficient for the successful completion of the process. It is advisable to open the door as rarely as possible, and observe the "behavior" of the products through the glass (for this, the backlight often does not turn off while cooking is in progress).

Pros and cons

Tubular electric heaters contribute to uniform and complete heating of the heating system. The installation of such devices has many advantages:

- safety of use;

- ease of installation;

- profitability of use;

- the ability to install additional options;

- reliability;

- long term operational;

- relatively low price for the product.

Along with the advantages of heating elements for heating batteries, they have their disadvantages:

- When TENA is connected, the high speed of liquid circulation in the radiator does not allow increasing the level of heat transfer. Thus, the operation of the heating system prevents uniform heating of the device.

- When using the heating element as the main heating device, the consumption of electrical energy is significantly increased.

Among the advantages of heating elements for radiators is a low cost

The cost of the heating element itself is low, but when purchasing the necessary additional equipment to automate the workflow, the costs increase significantly. The complete set has a price several times higher than a convector powered by electricity.