Autonomous heating of a private house up to 500 m2

Autonomous heating of premises over 500 m2 (roof boiler rooms)

Centralized heating in apartment buildings or non-residential premises of any size.

Why these three types?

Each version of this type of heating works according to different parameters and the composition of the coolant in the pipeline and radiators. Autonomous systems up to 500 m2 - the pressure in the system cannot be more than 3 bar (kilogram) and the coolant, if desired, can be filled without unnecessary chemicals that accelerate the aging process of the equipment.

Autonomous systems of more than 500 m2 - a roof boiler room for residential apartments in a multi-storey building, the pressure depends on the height of the building, but not more than 6 bar (kilogram) with a conventional heat carrier (tap water).

Centralized heating of apartment buildings and non-residential premises is the most problematic heating system throughout our homeland, the pressure in such systems reaches 9 bar (kilogram) with a coolant in which there are chemicals and a lot of dirt.

All of the above affects the durability of your batteries and supplies (pipes and taps) to them. Knowing the system and the factors of their problems, consider the heating devices themselves, and in the next article we will decide which pipes and taps to install. These devices are available to choose from: Cast iron - irrelevant, ugly and ineffective in terms of heat transfer 160 W per 1 m2. Aluminum - modern, beautiful, efficient 199 W per 1 m2 for breaking up to 25 Bar. Bimetallic - modern, beautiful, 187 W per 1 m2, but with a power reserve for breaking up to 40 Bar. Steel panel radiator - modern, efficient, reliable, but not always affordable. Cast iron batteries need no discussion! Aluminum radiators: The most common type of heating equipment today, so much has been said and written about them, but aluminum radiators are still worthy of attention. Their technical data, for all manufacturers, is almost the same if we consider the 500/100 model, since the property of aluminum is unchanged. A good manufacturer improves the design and convection of the appliance for more heat dissipation in each section. The working pressure of the radiators is 16 Bar (kilogram), the burst pressure is 25 Bar.

The heat dissipation of the battery and the price depends on three factors:

- Manufacturer.

- Model.

- Weight of one section.

The price is most influenced by the manufacturer, since goods from Europe are more expensive than ours or from China. The radiator model is 500/100, 500/85, 500/80, 500/70 as well as 350/100 and 350/80 and the smallest 200/80.

What does 500/100 mean - these are dimensions, where 500 is between the axial distance, and 100 is the depth of the product

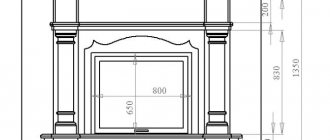

... See dimensions in millimeters from the photo:

- Total height under the letter, A

- Distance between the axes of the connection holes, B

- Section depth, C

- Front section width, D

The standard in our country is 500/100, cast iron batteries 500 mm along the axes of the pipeline. Other models 500/85 and so on, are made mainly to reduce the cost per section, due to less aluminum in it, and in appearance they look exactly the same, the manufacturer is disingenuous, visually passing off as a standard radiator.

And so we know that we need 500/100 with a heat transfer of 199 W per meter of heating area, with ceilings in a house no more than three meters in height and it is suitable for replacement in an apartment without additional parts, and then models 500/85, 500 are also suitable for us / 80 and 500/70, but their heat transfer is much less due to the reduced area of the radiator section, you need to look at the product data sheet, the price of such sections is cheaper than that of a standard 500/100 radiator.An important factor when choosing a heating radiator is production, cast aluminum radiator or extrusion. Cast radiators naturally pour into molds under high pressure and are a one-piece piece, which means maximum reliability. Extrusion - the radiator is welded by welding and three parts, which reduces the cost of the production process, worsens the quality of reliability, this will definitely not withstand the pressure testing of the system in apartment buildings. Today, extrusion is rarely found in stores. The third factor is the weight of one section, good and at the same time real Italian or, so to speak, real aluminum radiators 500/100 have a weight in one section from 1.2 to 1.4 kg. Less weight affects heat dissipation, service life, withstands lower working pressure.

Each person wants to buy at a cheaper price and sell at a higher price, see the product passport, there is indicated the manufacturer, model, power and all other technical data for the heating equipment that you want to purchase. For example, you need a heating device for an apartment where there is a high operating pressure and the pressing pressure and the coolant does not always correspond to the standard temperature, it is preferable to purchase a real heavy radiator with a standard size. It's another matter if you need to heat a private house with the available minimum pressure and constant heat flow from your own boiler, here you can save on the quality of devices, in a private house there are practically no factors for the rapid destruction of sections of the device. I hope you will be able to choose the most profitable variant of the heating device for yourself.

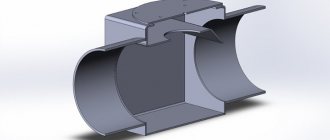

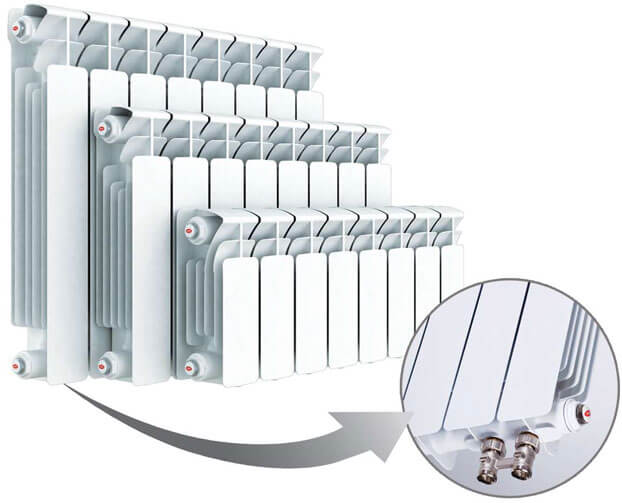

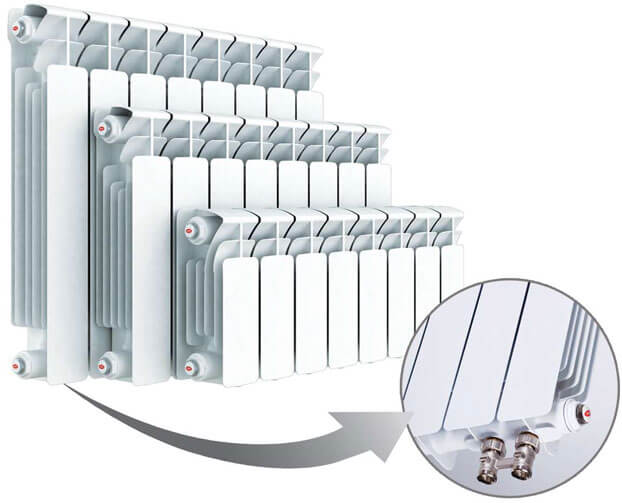

Bimetallic radiators - This is an outwardly ordinary aluminum battery, the difference is in the inner steel tube through which the heating fluid flows, that is, water, the tube consists of three parts, welded together to form a through channel and is filled with aluminum on top using a special technology. The coolant flows through the steel tube without touching the aluminum and without producing a chemical reaction that destroys the aluminum. All chemical reactions in pipelines occur very slowly, the time of destruction by a harmful chemical reaction for aluminum has not been investigated and the service life can be even 20 and 30 years. Bimetallic batteries are very good, they have a huge margin of safety in terms of a burst pressure of 40 bar and a constant working pressure of 25 bar. The reliability of such radiators in the heating systems of an apartment building is undeniable, but all these data refer to radiators produced at a plant in Europe, and their cost is two, three times higher than that of an aluminum radiator of the same brand (brand) for example GLOBAL.

Heat dissipation of a bimetallic radiator up to 180 W and an aluminum radiator up to 199 W. With all the laudatory reviews of bimetallic radiators, the advisability of installing it is money down the drain or full awareness of an impenetrable heating device in the form of a battery. Rather, the pipes will burst. Let's compare the parameters of heating systems and radiators:

Autonomous heating system:

| Technical data | Aluminum | Bimetallic |

| Working pressure in heating systems 3 - 6 bar (kilogram) | ||

| System pressure test maximum 12 bar | ||

| Temperature range maximum 85 degrees |

District heating in apartment buildings:

| Technical data | Aluminum | Bimetallic |

| Working pressure in heating systems 14 Bar (kilogram) | ||

| System pressure test maximum 9 bar | ||

| Temperature range maximum 90 degrees |

The heat carrier is water, the chemical reaction is unknown.

Aluminum is interesting in that it opens up wide opportunities for energy saving due to the high thermal conductivity of the metal. Aluminum batteries heat up the room faster than steel radiators. This means less hot water consumption and faster response to changing room temperature requirements. Radiators of this type can reduce up to 10% of the annual heating consumption.

The main technical characteristics of aluminum heating batteries include:

- heat transfer (power);

- working and pressure testing;

- dimensions;

- center distance;

- mass and capacity (internal volume) of one section;

- the maximum permissible temperature of the heating medium.

In this article:

Medium size

This parameter characterizes the distance between the manifolds (the centers of the upper and lower holes) of the device.

The standard provides for three standard sizes for the center distance:

- 500 mm;

- 350 mm;

- 200 mm.

But on the market you can also find non-standard radiators, the center distance of which can vary in the range from 200 to 800 mm.

The distance between the axes of the collectors plays an important role when choosing a heating device: the overall overall size of the radiator depends on it

.

Parameters of aluminum radiators from Torex

The Italian company of the same name offers aluminum sectional heating devices, which are manufactured by casting. Their peculiarity lies in the presence of unusual light transitions on the front. For models that have a center distance of 350 millimeters, the depth is 78 millimeters. But for batteries with a gap between the axes of 500 millimeters, the depth of the radiators can be 70 or 78 millimeters. They can have one or an even number of sections. The mounting kit must be purchased separately.

Main parameters of Torex aluminum radiators:

- the permissible operating pressure is 16 bar, and when testing the device - 24 bar;

- limiting temperature - no more than 110 ° С;

- the required pH of the water is 7-8 (6.5 - 8.5 is acceptable).

For Torex B 350 models, according to the official sources of the manufacturer, with a distance of 350 millimeters between the axes, the height is 420 and the depth is 78 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at least 130, and at the maximum - 1820 watts. The number of sections can be from one and then an even number up to 14.

Torex radiators of the B 500 series have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 78 millimeters. At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 172 watts, and the maximum is 2408 watts. The number of sections can be from one and then an even number to 14.

Torex radiators of the C 500 model range have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 70 millimeters. At the same time, the minimum length of the devices is 75, and the maximum is 1050 millimeters. With regard to heat transfer, its minimum value is 198 watts, and the maximum is 2772 watts. The number of sections can be from one and then an even number to 14.

Operating pressure

This parameter indicates at what coolant pressure the radiator can be operated.

- There are two types of aluminum radiators available:

- up to 6 atm (normal);

- up to 16 atm (reinforced).

In private houses equipped with an autonomous heating system, the average value of the coolant pressure in the network usually does not exceed 1.4 atmospheres. In houses with central heating, this parameter is in the range of 10 - 15 atm. But in the heating main, the working pressure is much higher: it can reach 30 atm.

Obviously, for the installation of aluminum radiators on central heating, devices with a higher working pressure should be chosen.

Some manufacturers indicate in the passport the working pressure not in atmospheres, but in MPa. To convert mega Pascals to atmospheres, multiply the parameter by 10 (for example, 1.5 MPa corresponds to 15 atm.).

Why is the radiator volume important?

Calculating how many liters are in one section of an aluminum radiator is important for several reasons:

- When the device is mounted on wall brackets, it is necessary to provide not only its weight, but also the heat carrier inside. It is easy to calculate how much water weighs by checking the data sheet of the product. If it states that the volume, for example, of a section of an aluminum radiator with a center-to-center distance of 500 is 0.27 l, then 270 ml of water is placed in it.

- Knowing the volume of the battery will allow you to select a boiler of the required power. This is especially important when the coolant is antifreeze. Having a sufficiently high viscosity, it needs a good "pusher", otherwise the slow advance of the carrier through the system will make its work ineffective.

- The choice of an expansion tank, on which many consumers save when installing aluminum batteries, also depends on the amount of coolant in the heating system. He takes over any pressure drops, which "saves lives", both heaters and pipes. As the water heats up, it increases in volume by 4%, and if you do not provide it with additional space for this, then the rupture of the integrity of the system is only a matter of time.

- The way the coolant flows through the network sometimes depends on the volume of the radiator. For example, batteries with a large capacity are well suited for natural circulation.

Considering how many factors are affected by the volume of heating batteries, this parameter should be taken into account when choosing aluminum products.

Pressure test

Heating system pressure testing

Before the start of the heating season, the central system is checked for leaks - that is, pressurized. This operation consists in supplying a coolant at a pressure 1.5 - 2 times higher than the operating pressure.

Standard values of the pressure test are from 20 to 30 atm.

If the radiator is not designed for such a pressure, it may fail during testing of the heating system.

If you have central heating in your house

, be sure to pay attention to this parameter when buying a battery: according to the passports of many models, it is only 18 atm. Such models are only suitable for autonomous heating systems.

Dimensions of the section of aluminum radiators from Rifar

The company manufactures aluminum batteries of BASE models with a distance between two axes of 200, 350, 500 millimeters. ALP products have an improved design, increased heat dissipation and a center distance of 500 millimeters. Alum models are specially designed devices that can be used both in standard heating systems and as an electric oil heater. The unique design of Flex allows you to give the device the desired radius of curvature.

The main characteristics of radiators made of aluminum Rifar:

- permissible working pressure is 20 atmospheres;

- limiting temperature - no more than 135 ° С;

- the required pH of the water is 7-8.5.

Other parameters

Aluminum radiator in the interior of the room

Weight

matters when choosing the mountings for the heater.

The passport indicates the mass of one section. To determine the total weight of an unfilled radiator, this parameter must be multiplied by the number of sections. Depending on the dimensions, the weight of one section can be from 1 to 1.47 kg.

Water volume

in the radiator is also calculated from the parameters of one section, which must be multiplied by the number of sections.

The capacity (internal volume) of a section depends not only on its dimensions, but also on the thickness of the shell. The average value of the capacity of one aluminum section is in the range of 250 - 460 ml. The internal volume of the radiator is taken into account when calculating heating systems and has the most direct effect on the volume of the coolant required to fill them.

Maximum allowable coolant temperature

for aluminum radiators it is standard and is 110 degrees.

How much water is in one section of a cast-iron heating radiator

Cast iron batteries differ in section height, depth, power and weight. For example, the MC 140-500 model has a height of 50 mm and a depth of 140 mm.Basically, the height of the radiator affects the volume of water in the cast iron section of the radiator.

The most common is the MC series. Depending on the manufacturer, the volume of the coolant may vary, so there is a small variation.

Volume of one section of MS brand (in liters)

- MS 140-300 0.8-1.3;

- MS 140-500 1.3-1.8;

- MS-140 1.1-1.4;

- MS 90-500 0.9-1.2;

- MS 100-500 0.9-1.2;

- MS 110-500 - 1-1.4.

The cast iron batteries of the ChM series are very popular. Model markings indicate the number of channels, the height and depth of the section. For example, ChM2-100-300 has a height of 300 mm, a depth of 100 mm, and water circulates in it through two channels.

The volume of water in one section of the CHM brand (in liters)

- ChM1-70-300 - 0.66;

- ChM1-70-500 - 0.9;

- ChM2-100-300 - 0.7;

- ChM2-100-500 - 0.95;

- ChM3-120-300 - 0.95;

- ChM3-120-500 - 1.38.

Table with characteristics of some models

| Specifications | GREEN HP 350 (Faral, Italy) | Alux 200 (ROVALL, Italy) | Alum 350 (Rifar, Russia) |

| Distance between axles, mm | 350 | 200 | 350 |

| Working pressure, bar | 16 | 20 | 20 |

| Power (coolant temperature - 70 degrees), W | 136 | 92 | 139 |

| Section capacity, l | 0,26 | 0,11 | 0,19 |

| Weight, kg | 1,12 | 0,83 | 1,2 |

| Dimensions (H / W / D), mm | 430/80/80 | 245/80/100 | 415/80/90 |

The data given in the table are taken from the official sources of the manufacturers.

In the process of replacing and repairing the heating system in an apartment or house, you have to solve a lot of various issues of a rather specific nature. One of them: the selection of heating devices or, more simply, batteries. That is, first of all, you need to figure out if these are aluminum heating radiators, then which ones are better to choose? And in what cases will their installation be more justified and rational? Or is it better to prefer more expensive bimetallic options or standard cast iron ones?

On the modern construction market, there are several types of these products made from various materials, for example:

Steel radiators

There are two types:

- panel radiators, which are solid-type heat-conducting surfaces.

- tubular radiators, consisting of sections in the form of vertically arranged pipes and produced in various design options.

Production material: low-carbon steel with high anti-corrosion resistance, coated with powder-type enamel.

Cast iron

Classic "accordions" with a long service life of up to 50 years, notable for their low cost and good wear resistance.

Aluminum radiators

Lightweight, compact and elegant batteries with improved heat dissipation.

Bimetallic radiators

They are made in two ways:

- Coated steel frame with aluminum.

- Steel reinforcement of the vertical ducts for better resistance to pressure within the system. The connection of the radiator sections is made using steel nipples.

Features of aluminum radiators from Faral S.p.A.

This company, exclusively for the Russian market of heating equipment, produces durable radiators FARAL Green HP (Italy), capable of withstanding a working pressure of 16 atmospheres. In their manufacture, the injection method is used. The outer and inner surfaces are covered with a zirconium protective layer that penetrates deeply and is not washed off during operation. As a result, no gas evolution occurs when the device comes into contact with water. The possibility of electrochemical corrosion is excluded.

The Green HP batteries are 80 millimeters deep, while the Trio HP batteries are 95 millimeters deep. The distance between the axes is 350 or 500 millimeters. The separately sold instrument mounting kit contains: a bleeder valve; brackets; adapters with plugs; self-tapping screws with plugs and silicone gaskets.

The main parameters of FARAL aluminum radiators:

- operating pressure up to 16 bar is allowed, and when testing devices - 24 bar;

- limiting temperature - no more than 110 ° С.

All models of FARAL Green HP 350 devices, according to information from the manufacturer's official data, with a distance of 350 millimeters between two collectors, have a height of 430 and a depth of 80 millimeters. Moreover, the length is from 80 to a maximum of 1120 millimeters. The power can be at least 134 watts, and at the maximum - 1904 watts. The number of sections is from 1 to 14.

The radiator models FARAL Green HP 500, with a distance of 500 millimeters between the axles, have a height of 580 millimeters and a depth of 80 millimeters. In this case, the length of the devices is from 80 (minimum) to 1120 millimeters (mausimum). In turn, heat transfer can be at a minimum of 180, and at a maximum of 2520 watts. The number of sections is from one to 14.

FARAL radiators of the Trio HP 500 model range have a center-to-center distance of 500 millimeters, the height of the devices is 580 millimeters, and the depth is 95 millimeters.

Types of aluminum radiators

In turn, aluminum heating batteries are divided into two types, depending on the technology used in their production:

Cast

For their manufacture, all sections of the device are cast from a special alloy based on aluminum with the addition of silicon, which gives the material special strength under high pressure conditions. The individual parts of the radiator structure are interconnected by welding in an inert gas atmosphere.

Their strengths:

- Durability and tightness of the joints, guaranteeing high quality and efficiency of products.

- The ability to create radiators of various lengths and capacities by changing the number of sections.

Disadvantages:

- High cost compared to extrusion type radiators.

Extrusion

In the production of radiators of this type, parts are not cast, but are squeezed out under conditions of increased pressure, and then pressed with upper and lower manifolds made by casting. In some cases, composite glue is used to mount individual parts of the battery, which makes these products even cheaper.

Their advantages:

- Slightly higher heat dissipation compared to cast batteries.

- Less volume of sections, due to which they require less heating medium.

- Less weight of the radiator due to the thinner fins.

- Low cost.

Disadvantages:

- Impossibility of repair and disassembly of the radiator.

- The likelihood of a leak in the area of the collector-section connection. This may be due to insufficient quality of the adhesive or wear of the O-rings made of rubber or Teflon.

- The presence of crackling sounds arising from temperature differences during the operation of the devices.

Useful advice - when choosing radiators made of aluminum, it is better to opt for options made by casting. They have thicker walls and are better able to withstand high operating pressures in the system. If, when purchasing, the low weight and cost of these products is of decisive importance, then it makes sense to choose extrusion aluminum heating radiators, the price per section of which is much lower than injection-type batteries.

What is the effect of the dimensions of aluminum heating radiators

One of the most important parameters is the gap between the axes of the radiators. Most often, you can find aluminum devices on sale, in which the distance between two collectors - the lower and the upper one - is 350 or 500 millimeters. True, there are products with an indicator equal to 200, 400, 600, 700 and even 800 millimeters.

The dimensions of aluminum radiators are practically unlimited in length. The longer the battery, the higher its capacity. To reach the required power level, it is necessary to purchase a certain number of heating sections.

The total length of the device depends on the power required to heat the room, on the dimensions of the heating batteries, sections and heat transfer.

To dock individual elements of an aluminum radiator with pipelines of a heating structure, use a mounting kit for installation, which includes:

- special brackets for hanging the battery on the wall in the amount of 2-4 pieces;

- Mayevsky crane - a device for bleeding air that has entered the system;

- key for the crane;

- straight through radiator plugs with a diameter of 3/4 or ½ of the right or left type;

- plugs for the heater, they are also called blind plugs;

- sometimes dowels are also provided to secure the brackets.

Depending on the type of manufacture of an aluminum alloy radiator, the heater can be cast or extrusion:

- thanks to the molding, the battery becomes durable and reliable. In this case, the sections are made up of separate parts, cast as a whole and then assembled into a single heater. Its lower part is welded very last;

- in the process of using extrusion equipment, the heated aluminum alloy is pushed through a special metal plate with holes. This method allows you to make a long aluminum profile of the required shape. When it cools down, it is divided into segments that correspond to the dimensions of the device. Only then the top and bottom of the battery are welded. In this case, it is impossible to adjust the length of the radiator, and sections cannot be added or subtracted to it. Extrusion devices are rarely found on the market.

Pros and cons of aluminum radiators

As an indisputable argument in favor of buying and using aluminum batteries, you can cite their positive characteristics, including:

- Low weight, not more than 1.5 kg per one section of the device, and compact dimensions, allowing aluminum batteries to fit well into rooms of any area.

- Good thermal conductivity and fast heating period (1.5 times faster than cast iron radiators).

- Excellent heat dissipation, making these devices as efficient and economical as possible.

- Possibility to change the number of working sections if necessary.

- Temperature control function (on batteries equipped with thermostats).

- Attractive radiator design and aesthetics.

At the same time, aluminum radiators also have some disadvantages, for example:

- Sensitivity to the pH level of the heating medium. It is desirable that it be in the range of 7-8 units, since if it is exceeded, aluminum can corrode, which over time will lead to damage to the battery.

- The need to install an air vent to prevent rupture of sections due to the threat of gas formation.

- The need to connect an aluminum radiator to pipes made of the same material or to plastic, since otherwise (in particular, in contact with copper pipes) it may be damaged as a result of the resulting electrochemical corrosion reaction.

- The ability of the radiator to withstand relatively low operating pressure.

Calculation of aluminum radiators from Global

Global radiators from the company of the same name (Italy) can be installed in apartments of multi-storey buildings, and in their own houses. Their distinctive characteristics are elegant and original appearance. The most popular are the ISEO and VOX models with a center distance of 350 or 500 millimeters. A mounting kit is standard and sold separately.

Main parameters of Global aluminum radiators:

- the maximum working pressure is 16 bar, and when testing the device - 24 bar; the limiting temperature of the heated water is no more than 110 ° С.

For Global VOX 350 models, according to the manufacturer's official sources, with a distance of 350 millimeters between the axes, the height is 440 and the depth is 95 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at a minimum of 145, and at a maximum - 2030 watts. The number of sections varies from one to 14.

Global radiators of the VOX 500 series have a center-to-center distance of 500 millimeters, the height of the devices is 590 millimeters, and the depth is 95 millimeters.

At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 193 watts, and the maximum is 2702 watts. The number of sections can be, depending on the power, from one to 14.

For Global ISEO instrument models, according to the manufacturer's official sources, with a distance of 350 millimeters between the axes, the height is 432 and the depth is 80 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at a minimum of 134, and at a maximum - 1976 watts. The number of sections varies from one to 14.

The Global radiators of the ISEO model range, which have a center-to-center distance of 500 mm, have a height of 582 mm and a depth of 80 mm.

At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 181 watts, and the maximum is 2534 watts. The number of sections can be, depending on the power, from one to 14.

Technical and consumer qualities and features

In addition to its practicality, visual appeal and low cost, the technical characteristics of aluminum heating radiators are a very decent set, which includes:

| Parameters | Indicators |

| Working pressure level | 6-25 atm. |

| Heat transfer of one section (heat output) | 150-212 W |

| Maximum allowable coolant temperature | 110 ⁰C |

| Section volume | 250-460 ml |

| Section weight | 1-1.47 kg |

| Center-to-center distance (the gap between the upper and lower collectors) | 200-800 mm |

| Life time | 10-15 years old |

Please note that the most common sizes for aluminum radiators are:

350, 500 and 200 mm. They indicate the value of the center-to-center distance between the collectors. But on sale there are models with a distance between the axes that differ from the standard. It can be from 200 to 800 mm. And in order to calculate the height of the aluminum radiator, 80 mm must be added to this value.

One of the most important indicators characterizing the quality and efficiency of aluminum batteries is their operating pressure. However, in the passport of these devices, the pressure test is also indicated, which has a slightly increased value. This characteristic of radiators is very important, since it is used in tests when starting the heating system after draining it. The standard value of the pressure test is 20, 25 or 30 atm.

In our separate article, you will learn to use. There you will find their characteristics, prices and the names of reliable manufacturers.

Pros and cons of flow and storage type water heaters

Instructions for making a shower tray yourself can be studied by following the link

Design features and classification

The material for the manufacture of the aluminum radiator section is not pure aluminum, but its alloy with silicon additives. This gives the new appliance greater strength and resistance to corrosion, extending its service life. The initial raw material undergoes special processing, then passing through a high-pressure press to obtain the elements of future apparatus.

Aluminum radiators offered in heating equipment stores have different external characteristics. They are distinguished:

1. In general appearance:

- panel,

- tubular.

2. By the structure of one, separately taken section:

- one-piece, ready-to-use (cast),

- extrusion, which are composed of individual elements using internal bolting with silicone and paronite gaskets.

3. By dimensions:

- Having standard dimensional characteristics. The dimensions of standard aluminum radiators are as follows: width - about 40 cm, height - about 58 cm.

- Low aluminum radiators can be as little as 15 cm high to fit even in very confined spaces. Now some companies even offer so-called "skirting" aluminum batteries with a height of only 2-4 cm.

- Tall, or vertical.With a small width in height, they can reach 2 - 3 meters. Their working position in the height of the room makes it possible to heat a large volume of air, and the original look also adds a decorative function to them.

Tubular instrument

Attention! The service life of the aluminum heating radiators you bought does not depend on how many elements the device contains, what its dimensions and internal volume are. The quality of the device is determined only by the quality of the raw materials and the conscientiousness of the manufacturer.

Review of popular models and manufacturers

Another question that worries consumers who choose aluminum heating radiators: which are the best companies? Traditionally, it is believed that the best quality and reliability are aluminum batteries from Italian manufacturers, although many domestic models are not inferior to them in many respects. Reviews on aluminum heating radiators of these brands also speak of their quality and reliability.

The most famous brands include:

| Brand | Model | Center distance, mm | Dimensions (height / width / depth) of the section, mm | Max. Working pressure, bar | Thermal power, W | Section capacity, l | Weight, kg |

| Faral, Italy | GREEN HP 350 | 350 | 430/80/80 | 16 | 136 | 0,26 | 1,12 |

| GREEN HP 500 | 500 | 580/80/80 | 180 | 0,33 | 1,48 | ||

| TRIO HP 350 | 350 | 430/80/95 | 151 | 0,4 | 1,23 | ||

| TRIO HP 500 | 500 | 580/80/95 | 212 | 0,5 | 1,58 | ||

| Radiatori 2000 S.p.A., Italy | 350R | 350 | 430/80/95 | 16 | 144 | 0,43 | 1,4 |

| 500R | 500 | 577/80/95 | 199 | 0,58 | 1,6 | ||

| ROVALL, Italy | ALUX 200 | 200 | 245/80/100 | 20 | 92 | 0,11 | 0,83 |

| ALUX 350 | 350 | 395/80/100 | 155 | 0,11 | 0,82 | ||

| ALUX 500 | 500 | 545/80/100 | 179 | 0,23 | 1,31 | ||

| Fondital, Italy | Calidor Super 350/100 | 350 | 407/80/97 | 16 | 144 | 0,24 | 1,3 |

| Calidor Super 500/100 | 500 | 557/80/97 | 193 | 0,30 | 1,32 | ||

| Rifar, Russia | Alum 350 | 350 | 415/80/90 | 20 | 139 | 0,19 | 1,2 |

| Alum 500 | 500 | 565/80/90 | 183 | 0,27 | 1,45 |

That is, the main criteria by which aluminum heating radiators are assessed: technical characteristics and price.

And in accordance with these criteria, one of the best in the middle price range can be called domestic brands Rifar and Thermal, which have excellent physical and technical qualities and have a cost that is 1.5-2 times lower than their foreign counterparts.

Dimensions of aluminum radiators from Fondital

The Fondital company (Italy) produces Calidor Super aluminum batteries adapted for the climatic conditions of Russia and the CIS countries (see photo). In their manufacture, European standards are taken into account, such as EN 442 and Russian, according to GOST R RU.9001.5.1.9009.

The method of their manufacture is high pressure casting. Painting is carried out in two stages: initially, one layer of enamel is applied using anaphoresis as a protection, and then, using powder enamel, the product is given a decent appearance. You will have to buy a mounting kit for the radiator separately. It includes: adapters; brackets; blind plugs and Mayevsky's tap.

The distance between the axles is:

- 350 millimeters for the S4 model, which has 4 side ribs and a section depth of 97 millimeters;

- 500 mm for models S4 and S3 (3 ribs and 96 mm depth).

Main parameters of Calidor S aluminum radiators:

- allowable working pressure - 16 bar, and when testing the device - 24 bar, maximum breaking limit - 60 bar;

- limiting temperature - no more than 120 ° С.

Radiator models Calidor Super 350 S4, with a gap of 350 millimeters between the two axles, according to the manufacturer's official sources, have a height of 428 millimeters and a depth of 96 millimeters. At the same time, the length of the devices is minimum - 80, and maximum - 1120 millimeters. In turn, heat transfer can be at a minimum of 145, and at a maximum - 2036 watts. The number of sections is from one to 14.

The dimensions of aluminum heating radiators Calidor Super 500 S4 with a center-to-center distance of 500 millimeters are as follows: height 578 millimeters, section depth - 96 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at the minimum 192, and at the maximum - 2694 watts. The number of sections varies from one to 14.

All models of Calidor Super 500 S3 devices with a distance of 500 millimeters between the axes have a height of 578 and a depth of 100 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the minimum power can be 178, and the maximum - 2478 watts. The number of sections varies from one to 14.

Varieties of heating batteries

It is necessary to consider all possible options and the number of coolants placed in them.

Types of radiators

The most popular among the total number of convectors are three types:

- Aluminum radiator;

- Cast iron battery;

- Bimetallic radiator.

If you know which convector is installed in your home and are able to count the number of sections, then it will not be difficult to make simple calculations. Next, calculate the volume of water in the heating radiator, the table and all the necessary data are presented below. They will help you calculate the amount of coolant in the entire system as accurately as possible.

Average water volume liter / section

Aluminum

Although in some cases the internal heating system of each battery may be different, there are generally accepted parameters that allow you to determine the amount of liquid placed in it. With a possible error of 5%, you will find out that one section of an aluminum radiator can hold up to 450 ml of water.

It is worth paying attention to the fact that for other coolants, the volumes can be increased.

Calculating the amount of liquid that fits in a cast iron radiator is a little more difficult. An important factor will be the novelty of the convector. In new imported radiators, the voids are much less, and due to the improved structure, they heat no worse than the old ones.

The new cast-iron convector holds about 1 liter of liquid, the old one will fit 700 ml more.

Bimetallic

These types of radiators are quite economical and efficient. The reason why the filling volumes can change lies only in the features of a particular model and the pressure variation. On average, such a convector is filled with 250 ml of water.

Possible changes

Each battery manufacturer sets its own values for the minimum / maximum permissible standards, but the volume of the coolant in the inner tubes for each model may change based on considerations of increasing pressure. Typically, in private houses and new buildings, an expansion tank is installed on the basement floor, which allows the fluid pressure to stabilize even when it expands when heated.

Parameters also change on outdated radiators. Often, even on non-ferrous metal tubes, build-ups are formed due to internal corrosion. Impurities in the water can be a problem.

Due to such build-ups in the pipes, the amount of water in the system must be gradually reduced. Taking into account all the features of your convector and the general data from the table, you can easily calculate the required volume of water for the heating radiator and the entire system.

Long heating

Let's compare the heat transfer, which is inherent in one section of a cast-iron battery (this is an average of 110 watts) and a similar indicator of radiators made of aluminum from steel. It turns out that the latter, having the same dimensions, require less hot water and give one and a half times more heat. However, the convection-air heating method for aluminum and bimetal, where only the core is heated, and not the casing, loses to the beam method for steel and cast iron.

They are heavy

Not everyone can lift a clumsy and weighty cast-iron battery alone - after all, only one section weighs an average of 5-6 kilograms. But after all, few of the owners of apartments and houses carry these batteries - usually a plumber is invited to install and remove them. It’s for them that they don’t like cast iron. And it should also be noted that these radiators have a lot of weight because of the thick walls, thanks to which they keep heat for a long time and serve for at least fifty years.

Well, yes, an average of 0.9 liters of hot water is poured into the cast-iron section, and only 0.4 liters into the aluminum section. Note that in this case, the overall dimensions of these two types of batteries are different - aluminum is much smaller.

They are not beautiful

Standard cast iron radiators, which were ubiquitous in Soviet times, they, of course, do not shine with beauty. They warmed well, but I just wanted to hide them out of sight.

So the owners of the apartments closed them with all sorts of screens and screens that take away the heat.

Today, aesthetic artistic cast iron products have appeared. On their surface, there are patterns in a variety of styles.Such batteries (German, English, Turkish, French, Chinese) are expensive, but they look simply luxurious. Domestic radiators, of course, are not so beautiful, but cheap. Still, their design is quite attractive, and the flat surface looks neat.

Artistic cast radiators in a retro style.

Before purchasing a heater, you should also study the quality characteristics of various models, showing the design features and manufacturing technology.

Heat carriers

The technical passport for the product must indicate with which heat transfer fluids its operation is allowed. The allowable range of values of the pH value of the coolant can also be specified. If an aluminum radiator is supposed to work with non-freezing liquids (antifreezes), special intersection gaskets are used in its design.

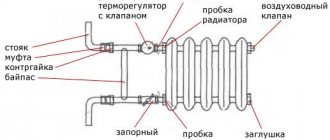

Connection diagrams for aluminum radiators.

Connection methods

The standard aluminum radiator section has top and bottom manifolds, allowing one of the known side connection methods. Some models of heaters are equipped with a collector with a lower connection pipe, which allows a bottom connection, which is convenient when installing a collector heating system.

The flow diagram of the coolant at the bottom connection.

Manufacturing method

Sections can be made by injection molding or extrusion. Extrusion is a pressure treatment method that produces a billet of increased density. Radiators manufactured by this method have a higher strength, which allows them to withstand increased pressure.

Aluminum radiators of various standard sizes.

Aluminum sectional radiators have proven themselves well in individual heating systems, when the homeowner has the opportunity to independently choose the type of heat carrier and control its quality. Such devices are characterized by high thermal performance, outperforming bimetallic models due to their lower cost. Technical characteristics of aluminum heating radiators give the buyer the opportunity to choose the best model among a number of analogues.

We offer you to familiarize yourself with Automation for long-burning boilers

How many kilowatts are in one section of a cast-iron radiator, and what dimensions should the entire battery have? These questions are important enough.

Performance

| Marking | Withstanding pressure, atm. | Thermal power, kW | Heating area of the 1st section, m2 |

| MS-140 | 9 | 0,12-0,16 | 1,11-1,45 |

| World Cup1 | 9 | 0,075-0,11 | 0,66-0,9 |

| World Cup2 | 9 | 0,1009-0,1423 | 0,7-0,95 |

| World Cup3 | 9 | 0,1083-0,1568 | 0,95-1,38 |

Now, knowing how many kW in one section of a cast-iron radiator, it is easy to determine the required amount.

Tip: if calculating the number of sections of a cast-iron radiator by yourself is difficult, then you can always use one of the online calculators available on the Internet, where you just need to enter the dimensions of your room and indicate the selected battery model.

Visual demonstration of the effectiveness of different methods of connecting pipes

As you can see in the figure, the most effective is the double-sided pipe connection. In this case, it is necessary to feed from the top on one side, and the outflow from the bottom on the other, which fully corresponds to the school physics course, from which everyone remembers that a warm liquid rises and a cold one falls. That is, the hot coolant will enter from above, cool down and exit through the lower hole, giving up its heat as much as possible.

Heat dissipation in single-sided batteries

Here we see a cold corner that significantly reduces the heat dissipation of the system.

But this is not the end of the important technical characteristics of the cast-iron radiator section. We calculated the number of sections, but you still need to have an idea of the weight and volume of the structure.

Weight and dimensions

| Marking | The volume of one section of a cast-iron radiator, l | Linear dimensions of one section, mm | Weight of one section, kg |

| MS-140 | 1,11-1,45 |

| 5,7-7,1 |

| World Cup1 | 0,66-0,9 |

| 3,3-4,8 |

| World Cup2 | 0,7-0,95 |

| 4,5-6,3 |

| World Cup3 | 0,95-1,38 |

| 4,8-7 |

Knowing the size of the section of a cast-iron radiator, you can calculate its total area at any time, which will give an idea of the place it occupies on the wall.

To do this, do the following:

- To do this, first, the area of the cast-iron radiator section is found, by multiplying its height and width with each other.

- Then we multiply the resulting number again, but this time by the number of sections, which most often amounts to 7-12 pieces.

Let's substitute the values of the ChM1 brand: 370 × 80 = 29600 mm2, which is approximately 0.03 m2. Let's say the battery consists of seven sections, then: 0.03 × 7 = 0.21 m2. It is such a section of the wall that will be required to place the cast-iron radiator in question.

It is better to calculate the wall area intended for the installation of the battery in advance.

The weight of a working cast-iron radiator is also needed in order to choose the right brackets for its fastening. Let's take the same brand and the average value of the mass of one section: 4 × 7 = 28 kg. But taking into account how much water is in one section of the cast-iron radiator (again we take the average value), we recalculate and get: 28 7 × 0.8 = 34.

| Inches | Millimeters |

| 1/2 | 12.7 |

| 3/4 | 19 |

| 1 | 25.4 |

| 1 1/4 | 31.7 |

| 1 1/2 | 38.1 |

- they can be placed under a low sill;

- they have maximum heat transfer per unit area.

Panels and convectors

Why know the amount of coolant in the battery

The calculation of the volume of the coolant in the battery is done in order to:

- choose the correct radiator mount. It must withstand not only the weight of the product, but also the weight of water, which fills the entire interior space. The weight of the liquid is equal to the volume;

- select a boiler of the required power. If it is weak, it will create little pressure and the water will move slowly;

- select an expansion tank of the required volume. Many are rejecting this element. However, it is better to use it, since it compensates for the pressure created by the heated coolant increased in volume. For example, when heated, the volume of liquid increases by 4%. If she has nowhere to go, then the pressure on the batteries and pipes increases. Sooner or later, thermal expansion will "please" with a leak;

- determine the total need for a coolant. To do this, it is necessary to take into account the internal volume of pipes with low hydraulic resistance, as well as the volume of the heating boiler, capable of creating the required pressure;

- maintain the correct concentration of antifreeze. This applies to cases where water will mix with antifreeze. This can be done, and in some cases the formed liquid for heating radiators freezes at lower temperatures than 100% antifreeze;

- select the type of circulation. The coolant can move naturally (from top to bottom) or move under the pressure generated by the pump. The natural type of circulation is chosen in the case of batteries with a large internal volume and low resistance to the heated liquid. As for the second type, the size and weight of the batteries does not matter.

Calculation of the volume of the heating system

Calculation of the volume of the heating system is necessary to determine the volume of the expansion tank, select a heating boiler or determine the required amount of coolant.

Content

The procedure for calculating the volume of the heating system Calculation of the volume of the coolant in heating radiators Calculation of the volume of the coolant in the heating pipes Example of calculating the volume of the heating system

It is quite simple to calculate the volume of the heating system, for this it is necessary to sum up the internal volume of all elements of the system... The problem arises precisely in determining the volume of internal elements, in order not to re-read GOSTs and passports for heating devices, this article contains all the necessary information. It will greatly simplify the calculation of your heating system.

Features of installation and care

When installing an aluminum radiator in the heating system and subsequent use, you need to remember that:

- When planning a heating device, you will need to calculate the number of sections. It is individual for each type of battery, so you will need information about how much power your chosen device has.

- Installation of a radiator requires compliance with some numerical parameters: the distance to the window sill is at least 10 cm, and to the floor - at least 6 cm.

- The device should not touch the wall; there should be at least 3 cm to it.

- Possibility of water hammer, because Excessive heating medium pressure can damage the device.

- Various connection methods (top, bottom, diagonal, side).

Attention! Do not forget that with a lower and especially one-pipe connection, the heat transfer of the device is reduced by 10-20%.

In the interior

plusteplo.ru