The bathroom has the most difficult microclimate: constant dampness and heat. This contributes to the growth of mold and mildew on surfaces. It also often happens that water in considerable quantities falls on the entire surface of the floor. In order not to flood the neighbors, it is necessary to waterproof the bathroom floor under the tiles. You also need to protect other surfaces in the room from excessive dampness, since moisture is also destructive for wall ceilings.

Why do you need waterproofing in the bathroom

In conditions of constant humidity, especially in a small room where natural ventilation cannot cope with airing the room, over time, any, even the most moisture-resistant materials will begin to deteriorate. If the repair in the bathroom is not done very well, small drops of water penetrate between the tiles, the joints of panels, rolls of wallpaper, and eventually accumulate there, causing the formation of mold.

Consequences of improper waterproofing in the bathroom

Fungus is not just ugly black spots, a terrible smell. It is capable of causing allergic reactions, and then serious illnesses, but getting rid of it is not easy. Therefore, a high-quality waterproofing is necessary in the bathroom, it will not allow the parasitic fungus to settle in your bathroom, eliminating the need to make repeated repairs.

It looks like a fungus that has grown in a bathroom without waterproofing

What needs to be isolated

Ideally, all surfaces in the bathroom. You can leave the ceiling and the upper part of the walls alone, but the floor, the bottom of the walls in the "wet" areas - near the sink, bathtub or shower stall - is a must. No matter how carefully you and your household use the water, splashes fall on the floor and walls. In case of problems with plumbing, a burst of pipes, a blockage of the sewage system, leaks are inevitable.

Wall protection

It is considered mandatory to waterproof the wall in the immediate vicinity of the shower stall, near the bath, under the washbasin, near the toilet. It is mandatory to waterproof an area of at least half a meter from a source that creates high humidity. The walls of the bathroom must be protected to the same height. This will avoid the penetration of moisture under the tiles: over time, it can cause destruction of the cement composition on which the tiles are held.

Applying cement-polymer waterproofing to bathroom walls

In addition, water can make tiles or other materials used for wall decoration unusable or not aesthetically pleasing. Considering the cost of purchasing materials, the work of tile laying specialists, the additional costs are unlikely to please anyone.

Most often, the fungus appears at the junction of the wall and the shower or bath

Floor waterproofing

The entire bathroom floor must be protected from leaks: not only in "wet" areas, but also in "dry" ones. So you can protect yourself and your neighbors in case the water floods the room too much. For this purpose, in the case of coating waterproofing, protective sides are made that extend onto the wall to a height of at least 10-15 centimeters.

Sealing floor and wall joints with waterproof sealant

Particular attention should be paid to places in the immediate vicinity of water and sewer pipes - they suffer from leaks more often and more strongly.

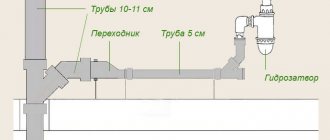

The process of installing waterproofing under the shower

Insulation for pasting

Rolled waterproofing, represented by canvases for pasting the base, perfectly fits under the tiles.This group of materials is made of polymers or fiberglass, one side of which is coated with a special adhesive, and the other has properties that ensure a high-quality connection of the canvas with the adhesive that holds the tiles.

This method is also suitable for wooden floors. Rolled sheets are flexible and elastic enough to ensure the integrity of the waterproof membrane in case of possible movement of wood. It is also convenient to use such canvases in cases where you have to work with large areas.

An important point in the manufacture of a waterproof coating is overlapping rolls with a margin of at least 10 cm.At the same time, the waterproofing of the walls in the bathroom under the tiles should extend from the floor to a distance of up to 20 cm.

All seams of the membrane during gluing must be rolled with a roller so that no air bubbles remain. Otherwise, the integrity of the coating will be difficult to maintain, and all work will be done in vain.

Types of waterproofing

There are three main types of waterproofing: coating, gluing and impregnating. They differ in their protective composition, appearance and method of application.

Okleechnaya

This type of bathroom floor protection is a coating of surfaces with a special film coated with a bitumen, rubber or polymer composition. This type of waterproofing includes familiar and modern coatings:

- Roofing material;

- Ecoflex;

- Isoplast;

- Isoelast.

Laying roofing material under the floor tiles in the bathroom

In fact, all of them are based on a bitumen coating with a filler applied to a fiberglass or polyester base.

Laying isoplastic on the bathroom floor

Pros and cons

The advantages of such a waterproofing coating are:

- No need to wait for the material to dry completely - you can walk on it right away;

- Durability;

- Good waterproofing properties.

Rolled waterproofing adheres tightly to the surface, does not require drying and allows you to immediately continue repair work

However, such a coating requires special care when laying, in addition, the process is quite laborious, so it is better to invite specialists to properly perform waterproofing work in the bathroom.

The application of glued waterproofing requires special knowledge and experience.

In addition, before laying the protective film, thorough surface preparation and leveling are required - only differences of no more than 2 mm are allowed.

Coating

It is a mortar based on bitumen, rubber or synthetic ingredients, which is applied directly to the floor, bathroom walls, before laying the tiles. It is used more often than other waterproofing methods.

Moisture-proof waterproofing is applied to the surface from one millimeter to several centimeters

Advantages of coating

Unlike pasting waterproofing, the coating composition can be applied to any surface without first leveling it. In addition, it does not require preliminary drying - and the waterproofing solution is easily applied to a damp surface after plastering without losing its properties.

Due to its liquid consistency, the composition is applied in an even layer, has no joints and fills in all cracks and irregularities. Due to this, it gives the surface of the walls, floor in the bathroom increased moisture resistance.

Applying a waterproofing layer in the bathroom

Among the advantages, it should be noted that such a composition is inexpensive, and it is easy to apply it yourself, without having experience and special skills. In addition, it does not have an unpleasant odor, unlike a roll coating.

Treatment of a bathroom with a liquid coating solution

Types of coating waterproofing

The main types of waterproofing compounds are bituminous and cement mastics. The former include:

- Bitumen;

- Rubber crumb, latex fillers, plasticizers;

- Solvent.

Application of polymer coating waterproofing

The result of the combination of such components is a durable elastic composition that reliably retains moisture, preventing it from penetrating inside. In addition, this waterproofing is able to withstand both cold and hot temperatures.

Important! Reinforcement of the surface requiring waterproofing avoids cracking, which leads to a decrease in the protective properties of the coating.

Carrying out reinforcement before applying the coating waterproofing

Cement waterproofing compounds are a mixture of cement, water, mineral filler. The mastic is easily applied to the surface and has high adhesive properties. It is more resistant to temperature changes than bitumen.

A paint roller is used to apply cement-based coating waterproofing.

Useful video on waterproofing wet rooms

Times viewed: 321

Interesting article on the topic: Types of floor tiles: classification and technical characteristics

Excellent article 0

Author rating

The author of the article

Oleg Grishin

The flooring specialist with 10 years of experience. Oleg has something to share with our readers

Articles written

103

- Even more interesting:

- Types and characteristics of ceramic tiles

- Tile cutting: instructions for DIY lovers

- What are interactive tiles?

Surface preparation

Bathroom waterproofing is carried out during a major renovation. The preparation of a bathroom for waterproofing begins with cleaning the surfaces - old paint, tiles, and plaster are removed from the walls. The floor and walls are cleaned down to the concrete base. The walls and floor are leveled as much as possible, debris and dust are removed.

Before applying the waterproofing layer, level the surface of the walls and floor

Before starting work in the bathroom, you need to tap all the walls - if there are voids, cracks - embroider them, remove the screed, plaster, seal all the seams.

Primer

Priming is the first stage of work after cleaning. The primer is applied if there is no need to carry out a leveling screed. Apply it with a roller in several layers, applying each layer perpendicular to the previous one. So there will be no gaps. In this case, the primer itself will become an additional waterproofing impregnation.

The primer can be applied with a brush

Pay attention to the type of primer: it must be compatible with the selected type of waterproofing.

Important! The bathroom floor must be below the floor level in the rest of the apartment, otherwise a high sill will have to be installed.

Moisture-proof primer will protect against excess moisture in the bathroom

Preparation of problem areas

These include wall and floor joints, corners, pipe joints. They need additional processing: they are usually glued with sealed tape, and tight rubber plugs are put on the pipes.

Use cases

Let's figure out how coating or roll moisture protection can be used if the bathroom is being repaired with our own hands. First of all, you need to figure out how best to place the waterproofing - over or under the screed. Each option has its own merits.

Under the screed

This option is used most often, that is, it is this technology that is standard. For waterproofing the floor, this option is better, because this technology provides increased coating strength. An additional plus of this technology is that it is possible to use any type of waterproofing material.

However, this technology also has a negative point. So, if water spills on the floor, the screed will get wet.It will take a long time for the screed to dry and there will be increased dampness in the room throughout the drying period, which can lead to mold growth.

Over the screed

This option for waterproofing the bathroom floor is used less often. The fact is that the waterproofing coating does not provide a high level of adhesion to the tile adhesive.

The positive aspect of using this technology is that the screed will remain dry in the event of water hitting the floor. If this method of waterproofing is chosen, then it is better to choose either cement-polymer mastic or roll materials.

Combination

To ensure a high level of waterproofing, it is best to use a combined moisture protection method:

- the first layer (about 3 cm thick) is placed under the screed;

- the second layer (about 1.5 cm thick) is applied over the completed screed.

Laying waterproofing

Installing or pouring waterproofing materials in the bathroom can only be done after the primer has dried well. Each layer of waterproofing coating in the bathroom should be at least two millimeters, at least four millimeters at the pipe exit points.

Applying mastic to the floor

In building markets, waterproofing mastic can be sold ready-made or in the form of a dry semi-finished product. The dry mixture must be diluted before use according to the manufacturer's recommendations. Sometimes, not water is used to prepare the solution, but a special emulsion.

As a result, the finished composition should be similar in consistency to molten plasticine - viscous and elastic - in this form it is convenient to apply it to the surface, and it hardens faster. Apply mastic near the openings of the sewage system and the water supply - the outlet of the water pipes. It is more convenient to work with a brush in hard-to-reach places.

To make the waterproofing of the bathroom correctly, you should follow the technology:

- They start processing from the corners, which are coated especially carefully.

- Then the joints of the walls and the floor are processed, after which a waterproof rubber tape is applied to them.

- The mastic is applied to the floor in several layers. Each layer is applied after the previous one has completely dried. Thus, it will take you 2-3 days to process the bathroom.

Important! It is necessary to apply the mastic in several layers, carefully smearing the entire surface so that there are no untreated areas left.

Wall waterproofing

When processing the bathroom floor, you need to smear the walls too - at least 15-20 cm from the floor, and better even higher. Here the disadvantages of bituminous mastic appear - it flows, therefore, when choosing such a waterproofing for the floor of the wall, it is better to treat it with a cement moisture-protective composition.

After the floor and walls are dry, they are primed again. If bitumen mastic was used, you need to make a screed for laying the tiles. When using acrylic or cement mixtures, the screed can be omitted.

Recommendations

Before starting work on the manufacture of waterproof structures, dry the room well and treat the most humid places with an antiseptic. Make vertical membranes only where they are needed. Treat areas of the room where there is no excessive moisture, treat with hydrophobic solutions. If you change the water pipes, try to make sure that there are no threaded connections under the tiles and in other hard-to-reach places. For the bathroom to be well ventilated, the room door must have a gap or a special ventilation hole.

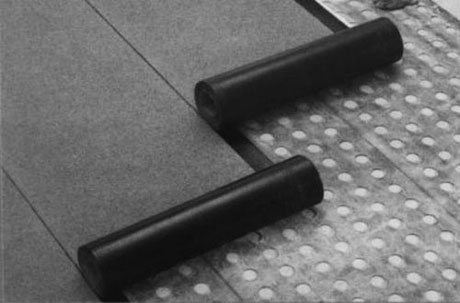

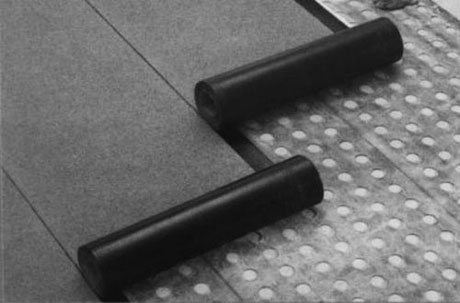

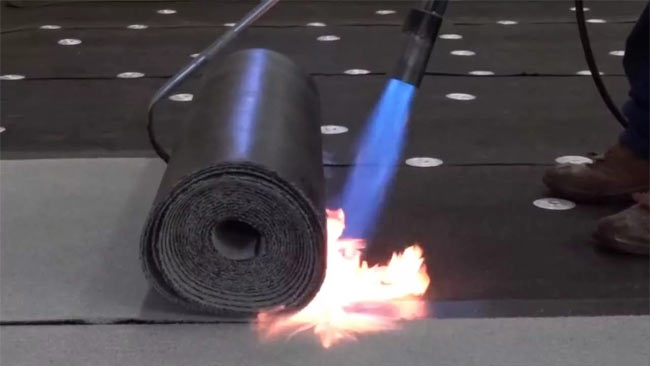

Laying roll waterproofing

This method will cost more - both the water-resistant material itself and the work on its installation. All roll-up protective materials for the bathroom are divided into self-adhesive and weldable. As the name implies, the former have an adhesive layer, while the latter will require a gas burner.

Adhesive waterproofing

Laying such a film is simple:

- The protective coating is removed from the adhesive side;

- The roll spreads out, capturing part of the wall;

- The next layer is applied side by side, slightly overlapping.

The peculiarity of this method of waterproofing the bathroom is that it is necessary to lay layer by layer very carefully - it will be impossible to correct the error. In order for the film to lie flat on the floor, you need to roll it with a wide roller for better adhesion to the surface.

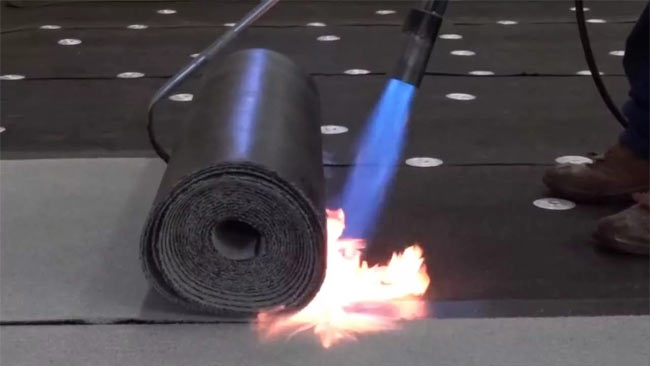

Deposited waterproof film

Such a waterproof material for the bathroom consists of shale dressing, bitumen polymer applied to glass fabric (elastic polyester). The waterproofing "cake" is completed by a film that burns out when heated.

A gas burner is required to install the waterproofing. It is undesirable to use it in an apartment, especially in a limited, poorly ventilated room. Therefore, it is advisable to invite experienced specialists to carry out the work.

The moisture-proof "sandwich" is laid in this way: the roll is rolled out, the bitumen layer is heated with the help of a gas burner, which ensures its adhesion to the concrete floor surface. Here, too, mistakes are not allowed - it is impossible to tear off the cover.

The subtleties of laying roll waterproofing

Before laying the rolled waterproofing, it is necessary to treat all joints, corners, and pipe exit points with bitumen-based mastic. Where you have to bypass engineering communications, you need to make holes in the film for them with a smaller diameter than the pipe - then you can organize small sides.

In addition, it is advisable to use rubber seals and first coat all joints with mastic, and then strengthen with a waterproof tape. Having finished laying the waterproofing layer, you can make a screed for laying the tiles.

Important! After laying the tiles, treat the joints with a sealant, and only then grout them. The more waterproofing layers will be made in the bathroom, the quieter you can live without fear of leaks.

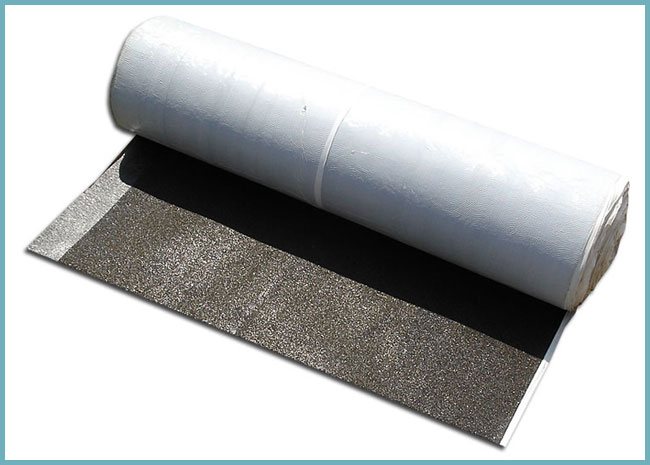

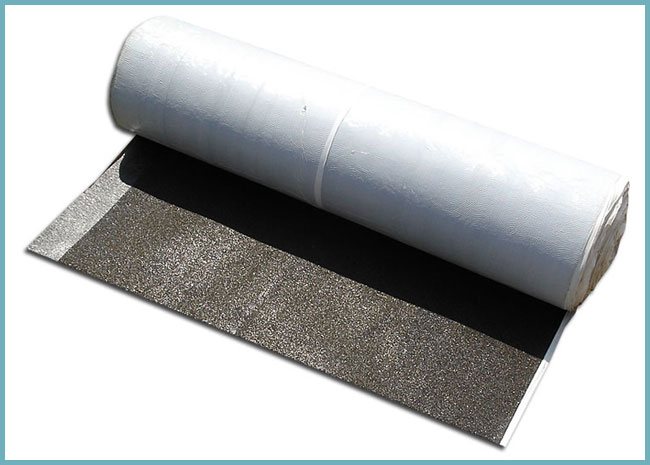

Roll-up waterproofing materials

Materials for roll waterproofing are made on the basis of polyester or fiberglass. On the underside, the web is covered with a layer of adhesive that provides adhesion to the base, and on the top - with a component that improves adhesion to tile adhesive.

Roll waterproofing is placed on a previously prepared, cleaned and leveled surface. Height differences are allowed within 2 mm per 2 running meters. In the list of their advantages, one can note the affordable price, the strength of the attachment to the subfloor and the ability to start cladding almost immediately, without observing a long technological break.

Roll waterproofing material

In addition, roll materials are suitable for waterproofing wooden floors. They are quite elastic, withstand the movement of wood and at the same time maintain solidity. It is advisable to use the roll method of sealing on large areas.

The canvases of the material must be laid with an overlap of at least 10 cm on top of each other and overlapping the walls. The joints are carefully glued with a roller. It is important to remove all air bubbles, if the slightest gap remains, it can be considered that all the work was done in vain.

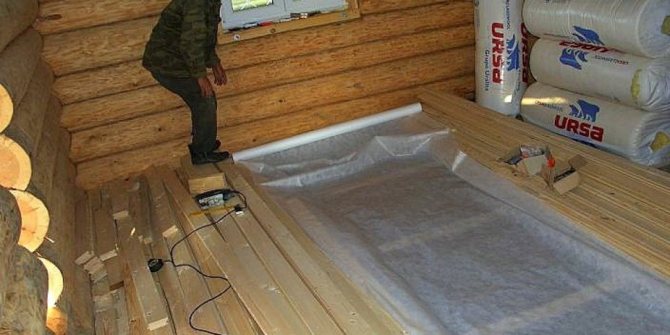

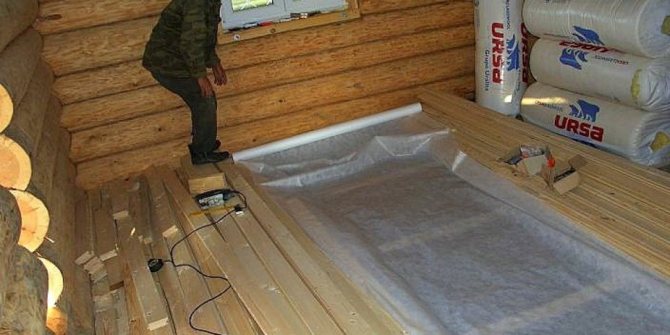

Features of waterproofing a wooden floor

Such a floor, and sometimes the walls of the bathroom, require some preparation. The bituminous composition is unsuitable here - it is fluid and will penetrate the wooden floor. It will take many layers of mastic before it stops absorbing. This is very expensive.

Preparation

Waterproofing technology in a bathroom with a wooden floor consists of several stages:

- Cleaning the floor from dirt;

- Laying lags, then a vapor barrier film;

- Plates of insulation are laid next - for example, expanded polystyrene;

- The joints are treated with a sealant.

When mineral wool is used instead of expanded polystyrene, the "pie" will become even thicker - waterproof plywood is placed on top of the mats.

Waterproofing

To protect the wooden floor from moisture penetration, liquid rubber is taken, which is mixed with an activating compound and quickly applied by rolling with a roller. Particular attention should be paid to the joints of the floor and walls, cracks, which must be filled with a sealed hydro-resistant compound as much as possible.

After waiting for complete drying, you need to carefully inspect the surface - so that there are no non-oiled areas. The floor should be flat and uniform. For confidence, it is best to apply a second coat. Then a screed is made - a reinforcing mesh is laid. When using rubber compounds as waterproofing, it is necessary to make a screed - the tile adhesive does not adhere well to the rubber-impregnated surface.

If it is planned to leave the floor wooden, the so-called thermal tree, treated with steam in special vacuum boxes, is chosen. Instead of conventional waterproofing, parquet varnishes, stains, primer varnishes are used. In this case, all cracks, joints must be carefully missed. This method can be used in particularly humid rooms, such as a bath.

Optimal waterproofing under the tiles

When preparing the base for tiles for a bathroom, on a balcony, in a kitchen or other rooms with high humidity, you can use various waterproofing materials, but which ones are better to choose:

- For a bathroom or kitchen, where the humidity level is not very high, you can use glued waterproofing.

- If the house is built of concrete blocks, it is better to use penetrating insulation in the premises. It not only guarantees a high level of protection against moisture, but also creates a stronger and more reliable base.

- For the "warm floor" system, you should use glued bitumen-polymer or coated cement-polymer waterproofing.

Whether the subfloor is wood, concrete or cement, a layer of waterproofing material should be applied before laying the tiles. This will reliably protect against moisture penetration.

How long does waterproofing dry

If you have chosen a roll-up waterproofing for a bathroom under a tile, you do not need to wait until it dries. It dries instantly - after laying the rolls, you can walk on the floor.

The mastic takes longer to dry - in about a day. Considering the need to install two or three layers of waterproofing to better protect the bathroom, it will take several days before continuing with the renovation. It is undesirable to walk on the bathroom floor until it dries completely. Do not put anything on it, do not spill water. After complete drying, you can install plumbing in the bathroom, supply water to it, lay tiles on the walls and floor.

Waterproofing a bathroom is an important renovation step that cannot be ignored. No one is insured against leaks, gusts. Even daily water procedures can, over time, not only spoil the carefully made repairs, but also create a favorable atmosphere for the development of a pathogenic fungus.

Proper waterproofing will help protect tiles from the negative effects of moisture and steam, and neighbors from unpleasant streams from the ceiling. Having completed it once in compliance with all the rules, you can forget about possible "wet" problems for a long time.

How to choose the right one

It is not a problem to buy waterproofing for the floor in the bathroom and toilet, the assortment on the market is very large. But here you need to choose the one that is best suited for your room, and for this you need to know its intricacies. There are the following types of waterproofing:

- Polymer and bituminous bathroom mastic is now the most popular material due to its ease of application and effectiveness with a rather long service life.Universal formulations are cheaper than specialized ones, but can also be used for bathrooms without loss of quality.

- Impregnations are also easily and easily applied with a regular brush or roller. With proper application and use, they can last as long as the material they are processing, which after that only becomes stronger and more durable.

- Membrane material. There are many varieties of it, and each has its own scope of application, here, the main thing is not to be mistaken. In your case, the product labeling should contain a clause stating that it is suitable for interior work in bathrooms. You should not take a dense membrane, which will give higher protection, since it is more difficult to work with it due to the fact that it is not so elastic.

- Expanding cement expands after drying. This is what allows you to carefully close even the smallest cracks and crevices. The moisture protection is resistant and durable.

Floor covering

Almost all waterproofing materials are suitable for such work. The main thing is that their service life is not less than that of the finish. If you plan to level the floor with a cement screed, then roll or coating material can be used under it. The latter is more convenient to apply and its consumption is less than that of a roll one. And if you also apply it over the screed, then you don't have to worry about moisture protection for many years.

The tandem of coating and impregnation works well. The latter increases the hydrophobic properties of the building material, and the coating forms the final water seal. This is almost 100% protection from the flood and scandal with neighbors because of it.