Whether or not to use foil in the bath is up to you. Previously, in Russian baths, foil was not used, they simply tried to build a bath from thick coniferous logs and heat it well. Now they build baths as they can: from logs, from ready-made timber, from bricks, from foam blocks and the frame method of building a bath. All these walls have a different thermal conductivity coefficient. And with the advent of various insulation materials and the sale of foil in stores, it became possible to use them intelligently to insulate any structures in the bath.

Conversations and discussions about the benefits of using foil are still ongoing. From the practice of those people who use foil, it is known that the loss of heat loss in a non-insulated bath is greater. And the foil used as a heat insulator gives positive results and retains heat well.

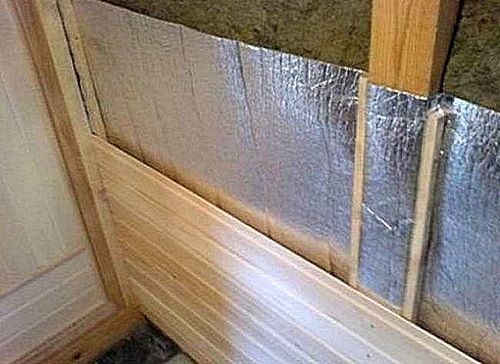

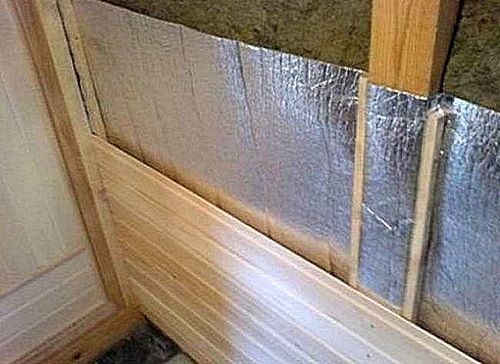

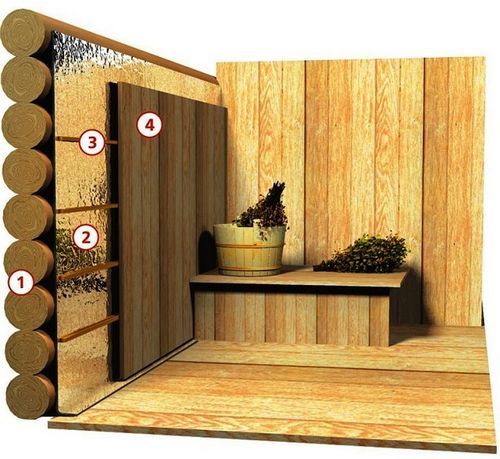

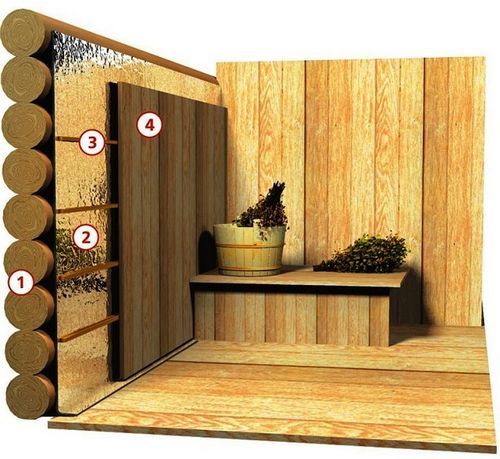

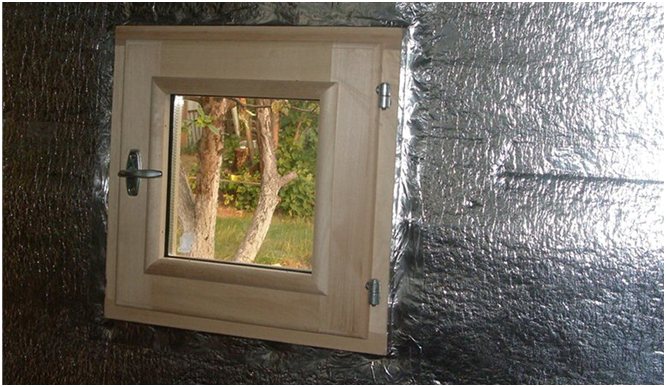

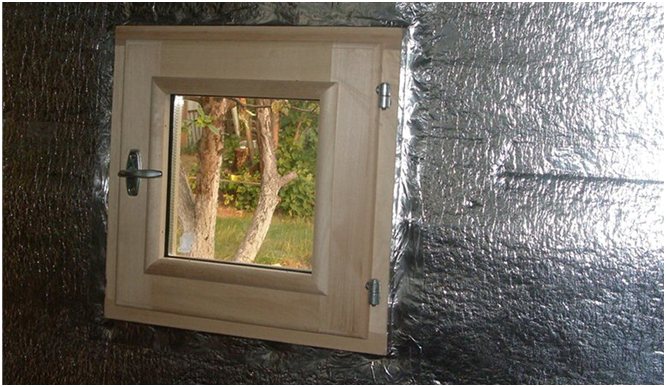

The picture shows an example of thermal insulation of bath walls using foil. The use of foil is now widely used in baths, saunas and the installation of underfloor heating.

Foil reflects heat well and does not transmit it through walls, that is, the heat is contained inside the room. And the physical qualities of the foil make it very easy to use. The foil is flexible, thin, easy to carry, measure, cut and fasten.

The foil is made of aluminum, and it does not corrode. Therefore, it is called as "aluminum foil" with distinctive characteristics:

- Reflectivity - not less than 97%

- Melting temperature - from 300 degrees.

- Vapor throughput - 0.01 g / m3 per day

- Does not release toxic substances when heated

- does not deform at high air temperatures

How to properly apply foil for a bath

And if you properly insulate your bath with foil, you will get the "thermos effect" - this is the way to quickly accumulate heat and maintain the desired temperature for a long time. The use of foil is especially necessary in the sauna room. Where the foil is applied to the ceiling and walls.

The pictures show that there must be an air gap between the clapboard and the foil layer, which means that the insulation system and the walls of the bath must breathe.

First, the ceiling is insulated in the steam room and only then they move on to decorating the walls of the room. If the insulation is mineral wool, then paper is first glued to the ceiling, then a crate of wooden bars is nailed and mats are inserted between them. To prevent the mats from falling, they are fixed with slats.

Then, neatly, or better together, they overlap the foil. Try not to tear it.

If broken, cover with aluminum duct tape. All foil overlaps, also glue with tape. The main loss of heat goes through the ceiling, so the insulation process must be thorough and the use of foil for the bath has had a positive effect. Watch the video about the use of foil

So that there is no leakage of heat and steam, the foil is laid down to the walls and ceiling by 5-10 cm. On top of the foil layer, more bars are nailed to create an air gap of up to 2 cm for air convection. And already the last finishing layer or linden paneling.

To use foil with insulation in the bath or without it, different people still have their own opinions, so look at how the author discusses this topic

Thus, all the steam remains in the steam room, does not accumulate in the insulation and does not condense on the inner surface of the load-bearing walls. The bathhouse will stand for a long time, without repair.

The nuances of installing foil and foil insulation in a sauna

In the process of work, a thin soft sheet of foil is easily crushed and torn, therefore new technologies for its application have appeared.

Its other name is paper-based laminated foil for a bath. It is an elastic and dense material and has excellent vapor barrier characteristics. It is produced in two types: foil plus kraft paper and foil plus paper plus polyethylene.

Foil paper is able to withstand 130 degree heat. Resists compressive loads. It holds its shape and is easy to cut. The standard strip width is 120 centimeters. Self-tapping screws, construction staples and nails are used for its fastening. The material is used for cladding baths from the inside. It is not recommended to use laminated foil for the surface of the walls adjacent to the oven.

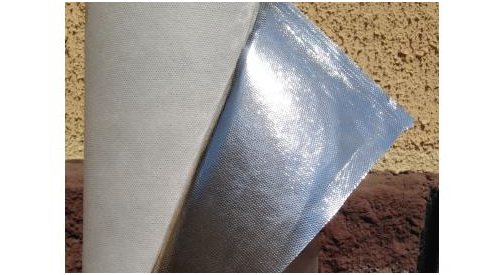

This soft two-layer material is made from fiberglass and foil. The thickness of the foil fabric is in the range of 0.12 –3 millimeters. The canvases must be fastened end-to-end. Foil fabric is used to insulate bath rooms, it can be used to sheathe the walls near the heating unit.

Its main characteristics:

- the ability to withstand temperatures up to 500 degrees;

- resistance to mold and other harmful microorganisms;

- good moisture resistance.

Insulation is made on the basis of expanded polystyrene and covered with the thinnest layer of aluminum foil. The material is produced in sheets 1.2x0.6 meters in thickness 2-10 centimeters. They are used for the purpose of warming the premises of a bath building from the inside. The sheets are equipped with stepped locks that prevent the formation of cold bridges.

Foil polystyrene foam has the following qualities:

- does not absorb moisture;

- reflects about 98% of thermal energy;

- differs in vapor barrier properties;

- resistant to chemical attack;

- safe for health;

- has a long service life.

This insulation roll with a thickness of 2 to 10 centimeters has a one-sided or double-sided foil coating. It is used in the arrangement of thermal insulation of the internal premises of the baths.

This material is able to withstand temperatures of no more than 100 degrees. It is not used for cladding surfaces near the furnace.

It is produced in rolls or in the form of mats of various thicknesses. Possesses excellent thermal insulation properties. Ideal for insulating frame sauna buildings. Using rolls or mats with foil makes finishing work easier and more convenient.

If work is carried out in a log house, then, as a rule, foil insulation is used. The material can be attached directly to logs (beams) using a stapler with the aluminum side inside the room. Depending on the thickness of the cladding, butt joint or overlapping is used. The joints are glued with metallized tape.

Air gap between foil and clapboard

To drain condensate, it is planned to release foil-clad material from the ceiling to the wall, and from the wall to the floor. On top of the foil insulation, slats with a thickness of at least 3 cm are attached. They perform two functions: they serve as a crate for the finishing cladding and form an air gap between the foil and the lining. The gap is important to prevent direct heat transfer from the lining through the aluminum layer.

The arrangement of baths in rooms with brick or concrete walls has only one, but very significant difference from work in log cabins: the contact of the foil material with the load-bearing wall is categorically unacceptable. First, the main insulation is made with heat insulators that have a sufficient thickness.

We suggest that you familiarize yourself with: What is more profitable than firewood or fuel briquettes

Another important note for all types of baths and saunas, equipped according to the principle of a thermos with the use of foil: in such rooms, high-quality ventilation should be provided.

As a 100% vapor barrier, aluminum promotes condensation.Only intensive air exchange between bath sessions can promote the natural evaporation of accumulated moisture.

The choice of foil-clad heat insulator depends on the material from which the bath is built. In some cases, just aluminum foil is enough, while in others it is recommended that sheathing be done only with the use of insulation.

If the walls of the bath are made of thick logs, then covering them with foil is a waste of money. Here, the quality of caulking is more important, and it is simply pointless to insulate the log house additionally. In this case, there will be little positive effect from the thermal insulation layer.

In a log sauna, foil insulation should be used only for lining the ceiling. Above, there will be at least some sense of it, especially if the ceiling is made thin and without an insulating layer on top.

You can also cover the walls around the stove with aluminum foil without a backing. Such a screen will reflect heat in the form of infrared radiation into the steam room, instead of wasting it on unnecessarily heating the wall behind the stove.

Thick foil makes an excellent screen for a sauna stove.

When lining the ceiling, foil-clad insulation is laid with a reflective layer downward, with an overlap and with a small, 5–10 cm, approach to the walls. The joints must be glued with special aluminum tape. It is very important to create a sealed layer without the slightest trapdoor for steam.

After installation, the foil can be left as is. So condensation will definitely not accumulate on it. But from an aesthetic point of view, it is better to cover it with clapboard. To do this, you need to fill a crate of 40x40 mm bars, to which wooden planks will be nailed.

If the walls of the sauna are made of bricks or frame technology is used, then they will have to be insulated with foil-clad thermal insulation material without fail. Otherwise, the heat in such a bath will not last long.

Installation diagram of foil insulation on the walls and ceiling in the bath

The sequence of work in this case is absolutely identical to the technology used in a log cabin. Only sheathing with foil is made around the entire area of the walls and ceiling, so that a thermos is obtained. It is necessary to block all possible ways of heat release to the maximum.

Advice! When insulating a bath with aluminum foil, special attention should be paid to windows and doors. The material to be laid should be securely nailed to the jambs and glued with tape.

Ideally, the lathing for the lining should be made independent, with a gap between the frame and the foil. The larger the space, the better the ventilation and less condensation. And this is the most important point in the insulation of the steam room.

Overview of foil insulation

From the information above, it became clear that aluminum foil is used both with and without insulation. In the first case, the foil is applied to the insulation, and in the second - to the timber or log.

On sale you can find:

- Polished aluminum foil in accordance with GOST 618-73 in rolls or sheets

- Foil Kraft Paper

- Insulation with a foil layer

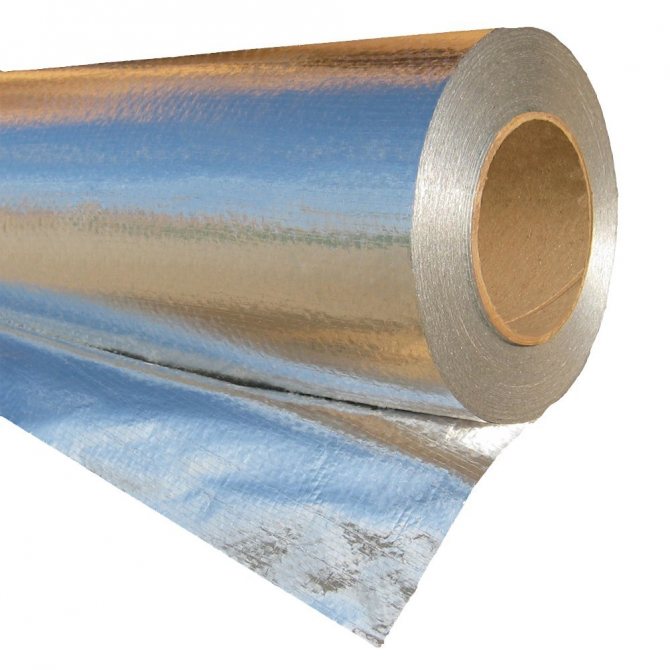

Let's consider all the varieties separately, in more detail. The picture shows foil rolls.

1. Depending on the thickness, the foil is sold in sheets or in rolls. Annealed (soft) foil is marked with the letter M, and unannealed foil is designated with the letter T. The thickness of the foil is from 0.007 to 0.2 mm and more, the width is usually 1 to 1.5 m.

Rolls of thin foil often consist of five pieces of linen, and thicker ones - of three.

In stores, it has a specific purpose - for baths and saunas.

2. Foil paper is a high strength paper with cellulose and a thin aluminum coating. The product is attached to the walls using nails, screws or construction brackets.

It is ideal for thermal insulation of building structures in hard-to-reach places.

A roll with a width of 1 m consists of 30 m of linen. Price for 1 m2 = 420 rubles.

This type of coating can withstand temperatures from - 50 to + 120 degrees. FROM

3. This foil insulation is specially designed for the decoration of rooms with high humidity.

Penotherm NPP LF is a heat-insulating material made of expanded polypropylene with aluminum foil. It is reflective thermal insulation as it uses polished aluminum foil. It is mainly used for thermal insulation of walls and ceilings in baths and saunas.

Penotherm NPP LF can be easily cut with a clerical knife, can be mounted using a furniture stapler, glued with tape.

Main characteristics: application temperature from - 50 to + 150 degrees. C, good thermal insulation, good vapor barrier, good sound insulation, does not rot and corrosion, environmentally friendly material.

In brick or block saunas, it is recommended to insulate not only the steam room, but also the sink.

Penotherm NPP LF is produced in different thicknesses and therefore prices will also be different:

- thickness = 2 mm costs 134 rubles / m2

- thickness = 3 mm costs 145 rubles / m2

- thickness = 4 mm costs 154 rubles / m2

- thickness = 8 mm costs 244 rubles / m2

- thickness = 10 mm costs 278 rubles / m2 (prices are indicated for the city of Perm)

Let's go back to point 1 - to aluminum foil in rolls to get acquainted with the prices:

- thickness = 0.04 mm costs 570 rubles / roll

- thickness = 0.08 mm costs RUB 950 / roll

- thickness = 0.1 mm costs 200 rubles / m2

- thickness = 0.2 mm costs 300 rubles / m2

- thickness = 0.8 mm costs 450 rubles / m2

Knowing the prices of foil insulation and the material of the walls of your bath, you can compare them with your money and it is already better to choose it and buy it.

And when the material is purchased and delivered, you can edit it the way the author of this video did.

Thanks to the foil insulation, bathing procedures will be a joy and pleasure. Good luck!

You built a bathhouse, invested energy, money, knowledge, dreamed of a pleasant and very useful procedure for the human body, and as a result you got a hut with an ice ceiling and so on. Warming errors are evident. Those who build such objects without the involvement of specialists, ignore technology, pay excessive attention to the study of opinions about the uselessness of using this or that material, in particular, foil - make a serious mistake.

Which foil for a bath is better to choose - varieties and basic methods of application

Which foil for a bath is better to choose, and is it needed at all? This question arises for all owners of suburban areas who decide to acquire their own steam room.

Experts consider foil to be one of the most important materials for decorating bath rooms, since they must quickly gain the required temperature and keep warm for a long time.

Foil for a bath which is better to choose

For this purpose, insulation is mounted on the surface of the walls and ceiling, which will block the exit paths for the generated heat outside the bath. Almost always, the traditional insulation "cake" created on the inner surfaces of this structure includes aluminum foil, produced in different versions.

However, we have to admit that this material, which is welcomed by some users, is completely denied by others, and there is an irreconcilable dispute between these "camps". Therefore, it is worth figuring out how necessary this thermal insulation material is, or you can do without it. At the same time, let's see how the installation should be done so that the created insulation layer works properly.

Do you need a foil layer?

To insulate bath rooms, a thin layer of aluminum foil is usually used, the thickness of which is on average from 30 to 300 microns.It can be applied on kraft paper, directly on the insulation material, or it can be separated from them and used with other thermal insulators in combination.

There are both supporters and opponents of the use of foil for warming baths

Opponents of the use of foil argue that there is no benefit from it, since aluminum has a high thermal conductivity and therefore is not able to retain heat in the room - it will freely go outside. In their opinion, it turns out that the purchase and installation of foil-clad material is a waste of money and effort. It should be noted that to some extent this is completely true, since the foil will "work" only if its installation is carried out according to all the rules.

- The high thermal conductivity of aluminum foil will manifest itself negatively if it is attached directly to a cold wall, built of materials such as brick, concrete or foam concrete, without an additional insulation layer between them.

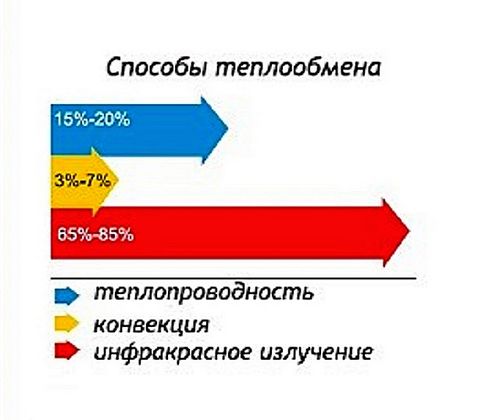

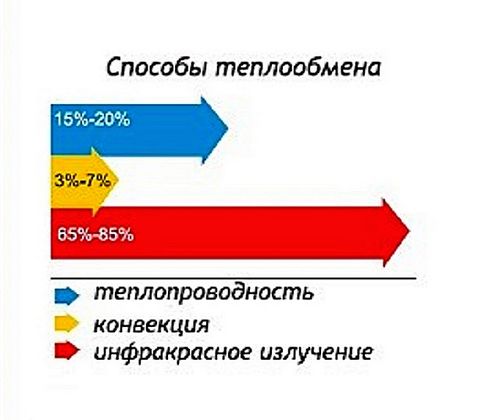

The "lion's share" of thermal energy given off by bath stoves falls on infrared radiation.

- Secondly, in addition to the high thermal conductivity of the material due to its structure, which is unable to keep the heated air inside the premises of the bath, there are other methods of heat transfer - this is convention and infrared radiation. Thus, a hot stove gives off the generated heat to rooms mainly in the form of infrared rays, which heat the surfaces when absorbed.

When heat rays hit a layer of aluminum foil, they are not absorbed by it, but are reflected from it back into the room. Thus, the thermal energy is not wasted on heating the walls, but is useful inside. Therefore, it follows that the foil retains heat not due to its thickness or the structure of the material structure, but due to the creation of a reflective surface. Moreover, it should be noted that it is capable of reflecting up to 97% of the heat released by the furnace.

- Thirdly, foil is an excellent vapor barrier for insulation laid on the surface of the walls. It creates an airtight, moisture-proof coating, therefore, prevents heated steam from escaping through the walls and ceiling. This not only contributes to the preservation of heat in the room - the vapor barrier does not allow the insulation to be saturated with moisture and from this lose its thermal insulation qualities

Therefore, the steam room of the bath, sheathed with insulating material and supplemented with a foil layer, heats up quickly and retains heat longer. The logical conclusion is that in such a room it will be more comfortable to take bath procedures, despite the fact that the cost of fuel or energy will be much less.

Criteria for choosing a foil for a bath

Foil for a bath must be chosen "wisely"

To determine the choice, first of all, it is necessary to take into account some factors that affect the efficiency of the material, the ease of installation of the canvases and the durability of operation. These criteria include the following points:

- Foil with a backing is much easier to attach to the crate, since the likelihood of damage becomes much lower. Therefore, purchasing such material is much more practical.

Materials such as mineral wool, foamed polyethylene or kraft paper can be used as a substrate for this thermal insulator. In addition, a foil reinforced with fiberglass mesh is available for sale, which has a slightly thicker thickness than material without a base.

Glass fiber reinforced aluminum foil

- For the bath conditions, it is very important that the wall decoration is resistant to high temperatures. This indicator should not be lower than + 100 degrees. The material for the bath must be resistant to sudden changes in temperature, and rolled foil, even without a base, or having one, fully meets this criterion.

- High-quality foil-clad material should be distinguished by high reflectivity, amounting to at least 95 ÷ 97%, since the preservation of heat in the premises of the bath will directly depend on this parameter.

- If the foil is initially combined with some kind of thermal insulating material, then high thermal resistance values should also be assessed.

- The vapor permeability of the foil layer should not exceed 0.01 g / m² in 24 hours.

- The strength properties of the material are important from the point of view of the ease of installation.

- A very important criterion is the environmental friendliness of the foil material. When heated to high temperatures, it should not emit toxic substances.

- Of course, the durability of the foil-clad material should be assessed - what guarantees the manufacturer gives for it, and how consumers respond about it.

Varieties of foil-clad materials for thermal insulation of a bath

So, there are many varieties of foil and foil materials that differ in their properties. The table below shows the most popular of them:

| Illustration | Name and main characteristics of the material |

| Unsupported roll foil is a thin material that is not particularly tear-resistant. It is produced in thicknesses from 0.007 to 0.2 mm, in rolls of 5, 10 or 20 meters, in widths from 1000 to 1500 mm. Base foil is used for installation on the walls of bath rooms, on top of previously installed insulation. The fabrics of the material are fixed with an overlap, and their joints are necessarily glued with metallized tape, forming a sealed reflective surface. The operating temperature limit for foil reaches +650 ° C. The ability to reflect thermal radiation is up to 97%, so the foil is able to provide rapid heating of the steam room and maintain a comfortable temperature in it for a long time. The material is resistant to corrosion and does not emit toxic substances when heated. | |

| Kraft foil is produced on a paper basis, as well as in a three-layer version consisting of foil, kraft paper and polyethylene - this material is called Izolar. Kraft foil has good strength characteristics and can be used for fixing on well caulked timber walls without additional use of insulation. Kraft foil is an environmentally friendly material, as it does not emit toxic fumes when heated. The thickness of this insulator ranges from 0.03 to 1.0 mm. Working temperature - up to 100 degrees. With proper installation and gluing the joints with metallized tape, the material creates an airtight, well-reflecting heat layer - the reflectivity reaches 95%. The material is more convenient to install in comparison with base foil, since it is less wrinkled and tear-resistant. | |

Folar is a vapor barrier consisting of one or two layers of aluminum foil, between which a fiberglass mesh with 4 × 4 mm cells is laid, which is an element reinforcing the canvas. Thanks to such strengthening, the foil insulator retains its qualities even in the temperature range from -60 to 300 degrees. Folar is an environmentally friendly material that does not contain carcinogens and allergens, withstands high loads, including mechanical ones. Such material is produced in three types:

Standard roll parameters - length 50 m, width 1000 mm. | |

"Folgoizolon" is a foamed polyethylene with a foil coating. It is produced and marketed in rolls or sheets, depending on its thickness.This insulation has high strength, shock absorption and sound insulation characteristics. Since such canvases (sheets) can have a fairly large thickness, they are often fixed to the surface without additional thermal insulation materials, provided that certain conditions are met during the arrangement of the room. "Folgoizolon" is used to insulate log surfaces, as the main heat insulator, or concrete and brick walls, as an additional layer to the main insulation, installed between the lathing bars under the clapboard sheathing. Material sheets have the following parameters:

Rolls:

Operating temperature range - up to + 100 ÷ 125 degrees. The material does not deform, it is easy to cut and fixed on a wooden crate with staples and a stapler, and on a metal profile using double-sided tape. | |

| Foil mineral wool is produced in rolls and slabs with a thickness of 5 to 100 mm. The material can have different lengths and widths - these parameters can vary from manufacturer to manufacturer. The reflectivity of the material reaches 97%, the working temperature is from -60 to 300 degrees. There are many varieties of foil mineral wool, and one of the most popular in the Russian market from this line of materials is the basalt heat insulator for baths "ISOVER Sauna", which has all the qualities necessary for such specific operating conditions. |

Video: foil mineral wool slabs "ROCKWOOL Sauna Butts"

How to carry out the insulation correctly?

Before moving on to insulation measures, you need to find out how to carry them out correctly, and what should be foreseen in this case.

In order for the aluminum layer to participate in maintaining the required microclimate properly, as intended by the manufacturer, the following points must be taken into account:

- Compulsory arrangement of ventilation of the room. Otherwise, all the insulation layers will be saturated with moisture and lose their thermal insulation qualities, and the foil will become simply useless.

- Compliance with the parameters of the thickness of the insulation in relation to the thickness and material from which the walls are removed.

- Correct fixing of layers of insulation and foil material and sealing of joints between sheets.

- Formation of ventilation gaps between layers of insulation and decoration.

We must not forget that failure to fulfill even one of the listed conditions is fraught with the fact that all the efforts made during the installation of materials will be wasted, as well as the vapor barrier and heat-reflecting qualities of foil insulation will be reduced to zero.

Bath room ventilation

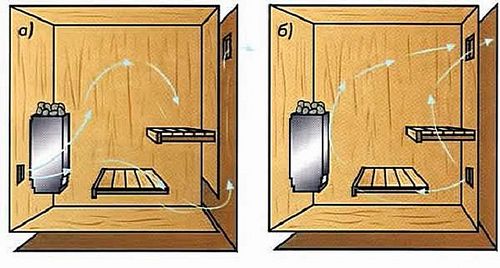

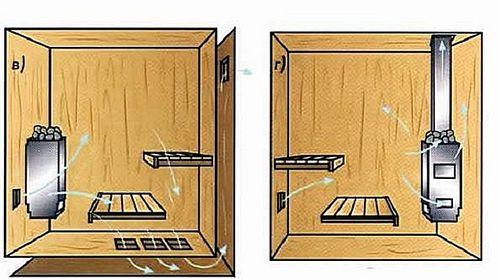

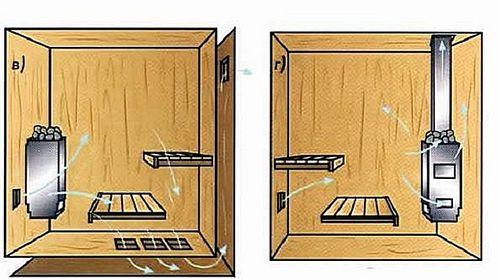

Correctly organized ventilation system of the steam room is one of the basic conditions that are necessary for the correct functioning of thermal insulation. Ventilation is planned in advance, before starting insulation operations. There are four main schemes for the location of ventilation openings in rooms with high humidity and, accordingly, the distribution of air flows, with a prerequisite for maintaining an optimal temperature regime.

Organization of ventilation of the bath room: schemes "a" and "b"

- The first option, shown in the diagram under the letter "a", is a natural ventilation system. For her, holes are arranged on opposite walls of the room:

- in the lower part of the wall, next to the stove, an inlet is made;

- on the opposite wall, in its upper part - an exhaust window. It is advisable to place the exhaust window behind the partition, so that a direct draft does not arise in the steam room.

Both windows must have doors regulating the air inflow and outflow.

This option can be called the easiest to set up, but not effective enough. The air stream entering the inlet heats up immediately, passing by the stove, and then it immediately rises to the ceiling and goes into the hood. As a result, there is no proper ventilation of the room, since the air masses move along the same path, not covering the far corners of the steam room. That is why it is better to place the exhaust window behind the partition.

It will be necessary to strengthen such ventilation after the adoption of procedures at the expense of an open door.

- The second diagram (b) represents a ventilation system in which both the inlet and outlet openings are on the same wall, and the oven is installed near the opposite one. Such ventilation is usually arranged if the bath has one external wall, in which ventilation windows are mounted. In this version, the ventilation system is strengthened by a fan, which is installed in the lower intake opening, therefore it is called forced. The fan makes the air flow into the room more intense, so its flows are divided and cover most of the steam room.

A more efficient way to ventilate the steam room: the inlet is at the bottom behind the stove, the exhaust outlet is on the wall opposite, but not at the top, but below. In this case, the exhaust outlet must be equipped with a fan. With this arrangement of vents in the steam room, cold air heats up from the stove, rises up, cools down there and goes down.

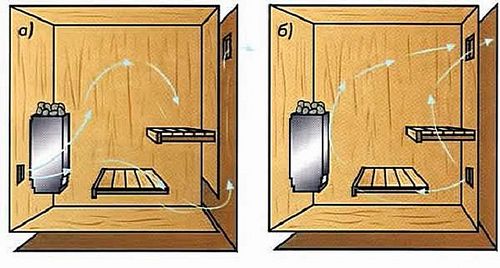

Organization of ventilation of the bath room: schemes "c" and "d"

- The third option (c) is implemented during the construction of the bath, as it involves the passage of air under a "clean" floor. In this case, the ventilation windows are located in the same way as in the first version, that is, on opposite walls, but the fan is installed in the upper exhaust ventilation window. In addition, the air flows are separated by the holes in the floor and the gap between the opposite wall and the “clean” floor surface, since this design creates additional traction. Such a system can be called effective, since the fumes do not have time to settle in large quantities on the walls and ceiling.

- The fourth system (d) will work only during the heating of the furnace. When arranging it, only one inlet is made, which is located on the wall opposite the stove. In this version, hot air from the stove rises up, then, cooling down, goes down, mixes with the incoming cold air, and is discharged through the blower door.

There is another system in which the exhaust air is removed through the blower. In it, the stove is positioned so that the blowing hole is below the level of the "clean" floor, and an air inlet is arranged in the upper part of the foundation, which will be located in the space between the "black" and "clean" floors. So, the air entering through the hole in the foundation will provide ventilation not only for the underground space, but also for the gaps between the foil and the facing material of the bath room.

Ventilation windows must be sized in proportion to the area of the steam room. So, on 1m² of the ventilated area, the window must have at least 24 cm².

Correct ventilation of the bath is the key to its long-term operation!More detailed information about all the nuances of the arrangement ventilation in bath rooms can be obtained from a special publication of our portal.

Thickness of walls and applied insulation

The effect of the foil-clad material will also depend on how correctly the thickness of the insulation for the walls of the bath is chosen. In order to determine this parameter, you can use this table:

| Wall material | Steam room wall thickness, mm | Insulation thickness (recommended), mm |

| Concrete, brick | 350 ÷ 370 and more | 80÷100 |

| Concrete, brick | 250÷350 | 100÷150 |

| Wooden blockhouse | 100÷150 | 60÷80 |

| Wooden blockhouse | 150÷200 | 40÷60 |

| Wooden blockhouse | More than 200 | 20÷40 |

It should be understood that the specified thickness of insulation is precisely for a bath, that is, for a short-term reception of bath procedures, and with the obligatory use of a foil reflective layer directed inside the premises. For premises of permanent residence of people, the criteria for choosing the thickness of the insulation will be different. And there you can no longer do without calculations.

How to determine the thickness of the insulation of the outer walls of a residential building?There is a very accessible and convenient algorithm for calculating the thermal characteristics of a wall. With all the details, it is set out in the article of our portal dedicated to insulation for the outer walls of the house... There is also a convenient calculator for independent calculations.

Thermal insulation of bath walls using foil-clad materials

Correctly mounted on the walls and ceiling of the bath "insulation pies" directly affect how comfortable the atmosphere will be in the premises. In addition, a violation of the technology of thermal insulation can render not only the insulation itself unusable, but also the walls of the building.

The order of installation of the insulation system may differ slightly - depending on the material from which the walls of the bath are built.

Thermal insulation of a bath - a wooden frame

Wood has a low thermal conductivity and a high ability to keep warm inside a log house, provided that the joints of logs or beams are well caulked. Therefore, there is a technology for insulating a bath from this material.

The diagram shows the layer-by-layer fastening of materials to log walls.

1 - Log wall.

2 - Foil-clad polyethylene.

3 - Lathing from a bar.

4 - Finishing material - wooden lining or tongue-and-groove board.

Work on securing materials is carried out in the following order:

| Illustration | Brief description of the performed operation |

| Foamed foil polyethylene or even base foil is stretched on the walls insulated with caulking and fixed with a stapler and staples. The canvases of the material are fixed with a reflective coating inside the room with an overlap of 150 ÷ 200 mm. If a heater is chosen that has a sufficiently large thickness - 10 ÷ 15 mm, then in this case, the sheets are fixed end-to-end, without gaps. | |

| When fixing the foil-clad material, it is necessary to constantly monitor its integrity, since even slight damage can disrupt the intended effect of insulation and vapor barrier. If the material is accidentally damaged, it must be immediately sealed with special foil tape. In the next step, all the canvases along the line of overlaps or joints are glued with the same tape, so as to create an airtight coating over the entire area of the wall. | |

| From above, on foil insulation, slats with a section of 30 × 50 mm are fixed. They can be installed vertically or horizontally, depending on how you plan to mount the lining boards: in any case - perpendicular to the inner lining. | |

| Finishing is attached to the arranged lathing. There must be a ventilation gap between it and the foil surface, which, in fact, is set by the battens of the lathing - 30 mm. |

All operations on the internal insulation of the bath rooms are carried out only after the log house has shrunk and the secondary caulking is performed, otherwise deformation of the finish and insulation rupture may occur.

Video: using foil to insulate a wooden bath

Thermal insulation of brick or concrete walls of the bath

Insulation of cold walls made of bricks, concrete, as well as foam concrete blocks is somewhat different from similar operations with wooden structures, and is carried out as follows:

| Illustration | Brief description of the performed operation |

| At the first step, the walls are marked, and the lathing bars are fixed on them, with a sectional thickness equal to the thickness of the insulation, since it must stand flush between the timber.Moreover, if it is planned to install the lining vertically, then the bar is also attached vertically, since to fix the sheathing after fixing the foil, another row of counter-lattice bars will be installed, perpendicular to the already installed ones. The bars of the frame guides are fastened at a distance from each other, which will also allow the plates of insulation material to be placed as tightly as possible between them. | |

| If ventilation windows or openings are installed on the walls, it is imperative to fix bars of the same cross-sectional size as the other elements of the crate around them, since foil will also need to be fixed around them. | |

| Further, an insulating material is installed between the bars. For the bath, modified hydrophobic basalt wool is most often used, for example, the vapor-permeable and water-resistant Rockwool insulation. | |

| The next step is to close the insulation with one of the varieties of foil-clad material - it can be ordinary foil without a backing or foamed foil-clad polyethylene. The fixing of the foil to the lathing bars is carried out using staples and a stapler. If the foil canvases are fixed horizontally, then its installation starts from the floor. If the foil has a small thickness, then its second strip is superimposed on the lower one with an overlap of 150 ÷ 200 mm. When the thickness of the foil material is 10 ÷ 15 mm, the canvases are mounted end-to-end, as when mounting on a wooden wall. | |

| Foil should also be well secured around ventilation openings and windows by nailing it to pre-assembled blocks. If possible, it is advisable to hermetically glue the edge of the foil around the holes or windows with tape. | |

| Foil sheets are fastened together at the joints with metallized tape. If the surfaces of the walls and ceiling are insulated, then it is recommended that a part of the sheet, about 200 ÷ 300 mm, mounted on the ceiling, be lowered onto the wall so that the joint between the two planes is hermetically closed. | |

| On top of the foil, slats with a thickness of 20 ÷ 25 mm, a width of 40 ÷ 50 mm are fixed, which will fix the foil and insulation, create a gap between the foil and the cladding, and also serve as a crate for further installation of the lining. | |

| In the next step, the lathing is sheathed with clapboard, but you need to make sure that a distance of at least 20 ÷ 25 mm is maintained between the clapboard and the foil. This space is necessary to ensure effective ventilation and evaporation of condensate that forms after each bathing procedure. |

In conclusion, I would like to note again that foil will become an excellent barrier against moisture penetration into wall structures and ceilings, will help maintain a comfortable temperature in the steam room, but, of course, if all technological rules for its use are observed when insulating the walls and ceiling of the bath. Therefore, there is absolutely no need to doubt its necessity.

What is the main thing in a good bath?

A good bath is one that heats up quickly and does not cool down for a long time. If the first problem is solved by a high-quality stove, then the insulation system is responsible for the problem of preserving heat. The material of the building does not matter much here. Do not close up the cracks and holes - there will still be loopholes for the formation of cold bridges. Proper insulation should create the effect of a thermos, this function is performed by foil.

Thermos room - good steam room

Foil for a bath, without touching the walls lined with clapboard, blockhouse, reflects heat, not allowing it to go outside the steam room, works like a mirror. The material, in fact, serves as a heat reflector and more. Another important function is to ensure the tightness of the room, does not allow water and steam to pass through. The steam, while remaining hot, does not condense, it remains inside the room, which also contributes to the retention of heat. A steam room, in which insulation is foil, heats up much faster and accumulates heat.

Such functions are relevant for all other premises of the bath.It is also important to maintain heat and tightness in the shower, pool, recreation room.

The best material for bath insulation

The peculiarities of the bath rooms are that inside you will need to provide not only high temperature, but also create the necessary humidity. For this, multilayer structures from various materials are used.

One of the recommended layers of thermal insulation in a bath is building foil for a bath, which reflects up to 90% of the incoming heat. Which one is better to choose from its varieties, let's figure it out further. Manufacturers offer several types of material, which are used based on the design features of the steam room.

An ideal sauna building should warm up as quickly as possible and retain thermal energy for a long time. For this, the walls and ceiling are insulated in it. A heat insulator such as aluminum foil for a bath is one of the most demanded materials, as it is resistant to high temperatures and humidity.

Foil is produced both in rolls and in sheets. Roll material can have a thickness of 0.007 to 0.2 millimeters, a width of 10-1500 millimeters. The percentage of aluminum in it is up to 99.5%.

Depending on the type of surface, foil is:

- smooth, without additional finishing;

- for finishing;

- finishing.

Depending on the manufacturing method, foil is distinguished:

- soft (annealed), marked "M";

- hard (unannealed) - the letter "T" is assigned to it.

A quality product is called a canvas that does not have folds, spots, tears and other inclusions on the surface. When viewed through the light of a thin canvas, it should be free of gaps and the smallest holes. Thick foil allows the presence of a small number of holes, which is regulated by the technical parameters of the equipment used.

A thin web is wound on sleeves of different diameters. Thick foil is produced in sheets.

Before starting work on insulation, developers are interested in how much foil for a bath costs. Domestic rolled products will cost less than imported material. With a roll length of 25-30 meters, the price will be approximately $ 20-30.

To determine which foil to use for the bath is better, you need to take into account what material the structure was built from and the conditions for its operation. If the building is a log building with carefully poured walls, then a foil heat insulator is not required for it.

In the case when the bath is built of natural wood, but large in area and does not warm up well, experts recommend sheathe the ceiling and walls from the inside with thin foil, and then close it with clapboard. You can use a foil cloth for the surface behind the heating unit, as a result of which the steam room will warm up faster.

Despite the fact that a foam concrete bath building is considered warm, it requires high-quality vapor barrier, so the use of foil will be justified, but it is better to opt for laminated products.

Frame and brick buildings must be insulated. For this, heaters for a bath with foil based on expanded polystyrene and mineral wool are ideal (read: "How to insulate a frame bath - nuances from a master"). The type of this material is chosen for ceilings, taking into account the thickness of the floor and the absence / presence of thermal insulation in the attic.

In addition, the operating conditions matter. If the bath is used infrequently and the procedures are taken for a short time, there is no need to insulate it with foil. When the steam room is used often and are in it for a long time, high-quality thermal insulation will save fuel, and the room will quickly warm up and cool down for a long time.

Since the cost of energy resources is constantly growing, the owners of baths and saunas are forced to look for ways to save costs for the operation of the steam room.When erecting a new building, it is necessary to use materials that have heat-saving characteristics. Baths built of bricks, foam concrete, cinder block and other building materials, except natural wood, need additional protection from heat loss.

When arranging a steam room, you should be especially careful when deciding which foil is best for a bath, since the material must be environmentally friendly and reflect heat well. All these requirements are met by heaters with aluminum foil coating.

Advantages of foil insulation:

- The material is versatile, since it is used for walls, ceiling and bath floor.

- Foil-coated heaters have good light reflection.

- Products are produced in a wide range.

- They are used in humid rooms, while they do not need to be treated with fungicidal compounds.

- They have high hygienic properties. The inherent properties of aluminum do not create a breeding ground for the growth of fungi and mold.

- They do not deform or melt in the steam room at elevated temperatures.

- The material is easy to use. It is easy to mount and fix on different planes: vertical, horizontal and inclined.

Baths insulation tips:

- If the bath building is not for commercial purposes, wall decoration with 3 mm foil in rolls will be sufficient.

- For commercial enterprises, the solution to the problem of which foil is better for a bath will be the use of laminated products based on basalt mineral base.

When insulating a bath located inside a capital building, it is necessary to take into account the functioning of the central heating, since it heats the air additionally.

A good bath is one that heats up quickly and does not cool down for a long time. If the first problem is solved by a high-quality oven. then the insulation system is responsible for the problem of keeping warm. The material of the building does not matter much here. Do not close up the cracks and holes - there will still be loopholes for the formation of cold bridges. Proper insulation should create the effect of a thermos, this function is performed by foil.

Thermos room - good steam room

Foil for a bath, without touching the walls, lined with clapboard. blockhouse, reflects heat, not allowing it to go outside the steam room, works like a mirror. The material, in fact, serves as a heat reflector and more. Another important function is to ensure the tightness of the room, does not allow water and steam to pass through.

Such functions are relevant for all other premises of the bath. It is also important to maintain heat and tightness in the shower, pool, recreation room.

An ideal sauna means that the steam room will warm up quickly and keep it warm for a long time. To achieve this, one has to either install a log house with thick walls, or additionally insulate the walls with a ceiling. The second method is cheaper, but not every thermal insulation material is able to withstand the bath conditions. Traditional heaters will not work, but aluminum foil for a bath is exactly what you need. However, there are pitfalls here.

In addition to the usual roll foil, there are a lot of different foil materials designed for wall insulation. But not all of them are applicable in a bath, where the temperature and humidity are high. It is extremely important here to choose the right and harmless heat insulator, otherwise a visit to the steam room can lead to health problems. An additional layer makes the foil more durable or increases its thermal insulation characteristics.

- kraft foil (paper-based);

- foil-clad fabric (on fiberglass);

- foil insulation (on foamed polyethylene).

The first option is a complete analogue of standard aluminum foil, only with a reinforcing layer of paper. The second is the most durable and fire-resistant of all, and the third, thanks to polyethylene foam, creates an additional layer of classic thermal insulation.

Advice! Experienced craftsmen recommend sheathing the walls and ceiling of the bathhouse near the stove exclusively with foil on fiberglass. It is durable, harmless and can withstand temperatures up to several hundred degrees.

We suggest that you familiarize yourself with: Which door to put in the steam room? Species overview

The polyethylene backing easily transfers the heat of the steam room. But near the firebox, this foil material should not be sewn onto the walls. In the heat of a red-hot stove, it will inevitably begin to melt.

Folma-fabric (folar, foil on fiberglass) - an ideal heater for a bath

There are also mineral wool-based foil insulation on sale, but it is not recommended to use them in a bath. Some of them contain formaldehydes, which begin to be released when the temperature of the material rises, while others, when wet, lose all their thermal insulation properties.

Even thick aluminum foil without a backing can be easily damaged during installation. It should be used in a bath only as a last resort. It is best to choose the option on fiberglass, produced in three types:

- "A" with one-sided foil (operating temperature from -40 to 150 ° C).

- "B" with foil on both sides (operating temperature from -40 to 300 ° C).

- "C" with an adhesive base and one layer of foil (operating temperature from -40 to 80 ° C).

All of these materials are sold in rolls of various sizes and thicknesses. They can be easily cut to the required size. And their fastening in the bath is done with galvanized nails or staple staples.

The foil, being a continuous metal layer, is a guaranteed barrier to steam and air currents. Thus, in addition to the infrared mirror, the materials of this group provide high-quality convection sealing and vapor barrier of the steam room in the bath.

In addition to considerations related to the physics of heat transfer and infrared reflection, the choice of the type of substrate is associated with the ease of installation and the mechanical strength of the two-layer material. The foil tears easily during installation, which requires additional investment of time to seal the gaps with special tape. Paired with a substrate, the material becomes much more reliable, which makes it easier to attach it with a stapler to the wooden battens of the battens.

Foil insulation for baths

As a reinforcing and / or heat-insulating layer, the following is industrially glued to the foil:

- Mineral wool. The material is produced in rolls 5 - 100 mm thick. However, not all foil wool is suitable for arranging baths. In order to increase the hydrophobic properties, mineral fibers are impregnated with special compounds that are unsafe for human health when the material is heated. You should use only heaters without these impregnations with a direct indication of the purpose in the name. For example, "ISOVER Sauna" or "ROCKWOOL Sauna Butts".

- Kraft paper. The main commercial names of the material are Kraft Foil, Foil Paper, Alukraft and Izolar. In Izolar, a third element is added to the aluminum layer and paper - a polyethylene film, which increases the strength and serves as a water barrier for the paper layer. The thickness of kraft paper is in the range of 0.3 - 1.0 mm.

- Foamed polyethylene (PPE). The most popular material in the group of foil insulation. It is produced under the names "Folgoizol", "Folgoizolon" in rolls with a thickness of 2 - 10 mm and plates (20 - 110 mm). Rolled foil insulation is usually used for equipping baths and saunas in log cabins without additional thermal insulation. It is produced in large quantities and is distinguished by good assembly and operational qualities, combined with a reasonable price.

- Fiberglass mesh. As an infrared screen, a three-layer material "Folar" is sometimes used, containing a reinforcing layer of a mesh with a mesh of 4 × 4 mm. The original purpose of the folar is a vapor barrier.

We isolate the joints with special tape

Photo of a roll of foil

Benefits of application

Aluminum foil, GOST 618-73, is a rather fragile material that is necessary to create an insulating cake for baths and saunas; it is used either in the form of a conventional aluminum film or in conjunction with a substrate.

A heat insulator is necessary to improve the efficiency of the bath. The benefits of its use are as follows:

- promotes rapid heating of the room;

- retains heat, not allowing it to go outside;

- protects walls, a layer of insulation from the destructive effects of moisture and steam;

- protects against the formation of mold, mildew;

- withstands high temperatures and their drops;

- extends the life of the building as a whole.

Environmentally friendly foil is non-corrosive, non-toxic, ecologically perfect, meets all sanitary and hygienic requirements.

On a note! The use of foil is useful, the consumption of energy (electricity, wood) is reduced by at least a third! The life of the bath is extended twice! The material is inexpensive, easy to install.

The benefits of the application are obvious, it is only important to choose the right material for the steam room and other premises of the bath, sauna.

Material advantages

Taking into account the peculiarities of the operation and microclimate of the bath room, a number of requirements are imposed on the used foil:

- good moisture, steam and water resistance;

- high refractory qualities;

- good anti-corrosion properties;

- high reflectivity (within 95-98%), achieved through special polishing of the top layer;

- significant thermal conductivity.

Excellent vapor barrier properties help prevent hot steam from escaping from the room, which will not accumulate in the coating. In addition, aluminum foil has the following advantages:

- complete absence of deformation and loss of original consumer properties;

- high ductility of the coating upon prolonged exposure to high temperatures;

- lack of release of substances and vapors harmful to humans;

- UV resistance;

- protection against excessive condensation, mold and pathogenic microorganisms;

- ease of installation;

- durability;

- hygiene;

- resistance to chemicals;

- protection of adjoining or adjoining rooms, if the bath is located inside the house.

With careful installation, even thin paper-backed sheets will not tear or deform. But it should be remembered that such material should be bought with a small margin of 5-7%.

Aluminum foil can withstand temperatures up to 145 ° C, which, in combination with its high reflectivity, helps to keep the heat inside the steam room in comparison with other heaters for 2-2.5 hours longer, providing the so-called thermos effect. It is a universal insulation material suitable for walls, floors and ceilings of steam rooms, baths and saunas and does not require special treatment of premises with fungicidal substances.

Types and characteristics

Conventional roll foil is known to everyone. There are other foil materials, but they are used for thermal insulation of the bath, should be selective. An additional layer in such materials is needed to strengthen, stiffen the aluminum layer. Foil is used for the bath:

- regular roll, rolls 10-30 m long, 1.2 m wide, 30-100 microns thick;

- paper-based (kraft foil);

- on fabric (fiberglass);

- on foamed polyethylene (foilizolon), rolls or sheets with a thickness of 20-110mm.

It is worth noting that foil-clad fiberglass has increased fire resistance characteristics, and foil-insolon enhances the thermal insulation properties of the room.

On a note! The walls around the oven are sheathed with glass cloth foil. This is ideal. The material is able to withstand temperatures up to 250 °. The best option for a steam room is foil fiberglass.

Foil on fiberglass - the best heat reflector for a bath

Folgizolon, cannot be used near the firebox.The polymer will melt with all the ensuing consequences, but you can mount it on the walls of the steam room, where the shelves are located. This material is good for a shower, a pool, a rest room, its only drawback may be the price. Those who want to save money can upholster the rest room with ordinary roll foil or craft foil, this will be quite enough.

For a brick and concrete bath, foil mineral wool is sometimes used. Produced in rolls or plates with a thickness of 8-10 mm, it provides excellent thermal insulation, withstands temperatures up to 125 °. True, the use of this material is not always justified, when overheated, the material releases formaldehydes into the air, the mineral layer can get wet and collapse. In addition, the surfaces around the firebox, sheathed with such a heat reflector, require additional asbestos insulation.

Foil types and coating features

The building materials market offers customers several types of foil with different properties and characteristics.

| Cover type | Dignity | Application type | Application type |

| High strength, shock-absorbing and noise-insulating properties, the ability to lay the material directly on the surface without additional thermal insulation. | Suitable for log walls, as well as surfaces with battens or clapboard. | The thickness of the material in sheets is from 20 to 100 mm, the dimensions of the canvas are: length -120 cm, width - 600 mm. The thickness of the roll material is from 20 to 110 mm, the standard length is 25 or 30 m, the roll width is 100 or 120 cm. The range of withstanding temperatures is from 100 to 125 ° C. | |

| Environmentally friendly material. | Foil material is used on any surfaces, but in combination with a heat-insulating coating. | The thickness of the sheets ranges from 0.03 to 1 mm, the temperature range is 50-85 ° C. | |

| High degree of vapor and moisture insulation. | Suitable for use on concrete and brick walls as well as all types of wood surfaces. | Thickness 8-10 mm, maximum withstand temperatures: from + 100 to +125 ° С. | |

| Good insulating properties and easy installation. | The same as for roll materials. | Similar to the previous ones. | |

| Low cost, accompanied by tears and deformation of the material during installation. | Only on refractory heat-insulating material with obligatory fastening with metal brackets. | The sheet thickness is 0.01-0.5 mm, the roll width is 1500 mm, the temperature range is from -50 to +75 ° C. |

To obtain a high-quality coating when carrying out laying work, it is recommended to strictly adhere to the thickness of the foil insulation.

| Wall material | Steam room wall thickness | Recommended layer of foil insulation |

| Brick, concrete | 35-37 cm and more | 8-10 mm |

| Brick, concrete | 25-35 cm | 10-12 mm |

| Wooden blockhouse | 10-15 cm | 6-8 mm |

| Wooden blockhouse | 15-20 cm | 4-6 mm |

| Wooden blockhouse | more than 20 cm | 2-4 mm |

Experts remind that aluminum foil or foil coatings are not able to reflect back inside the premises all the heat that has gone, therefore they work best in steam rooms insulated according to the “pie” principle, while basalt or glass wool, as well as similar ones, should be used as an additional heat-insulating material. mineral heat insulators. This is especially true in baths and saunas built of brick or concrete and other frame structures. With a sufficient thickness of the external walls of wooden log cabins, additional thermal insulation can be neglected, but thin sheets of kraft foil should not be preferred as foil-clad material.

How to sew correctly?

The main installation condition is overlapping fastening with a grip of 10-20 cm, the joints should be glued with special tape, then there will be no loopholes for steam, condensate will fall to the floor without penetrating the insulation layer.

Aluminum tape - a guarantee of tightness

The use of foil in a log bath differs from the technology of insulating a building made of brick and concrete. Walls made of logs should be carefully dug. If the tree looks aesthetically pleasing, the frame is well-built and the rooms (except for the steam room) are not supposed to be clad with clapboard, then the use of foil for the walls is not necessary. The ceiling is sheathed with a heat reflector without fail.

On a note! To get the effect of a thermos - it is necessary to sheathe the steam room with foil, walls, floor, ceiling.

- It is necessary to sheathe the wall around the stove with thick ordinary foil, the heat will not get behind the wall with the stove.

- On the ceiling, installation is carried out with a reflective layer downward, with an overlap and an allowance of 5-15 cm on the wall.

- Walls are also sheathed, floor overlap is required.

- The floor is set up last.

Work with the floor is carried out after the lining is sewn onto the ceiling and walls, the correct installation of which assumes the presence of a gap between the frame and the heat reflector layer.

Air gap is required

The same procedure for installing a foil layer of brick-concrete structures. With the difference that all rooms (walls, floors and ceilings) are sheathed there, without exception.

On a note! The joints with window and door openings should be especially carefully upholstered. Nail the foil with tape, glue it with tape, checking for cracks.

Correct cladding of a window opening

In conclusion, a few words about ideal insulation. Foil materials perform the function of a heat reflector, in fact, they are not insulation. For high-quality insulation, the installation of a pie is required, the top layer of which is the material for vapor barrier, then the insulation itself, and only then a layer of foil-clad material. In this form, the bath will be functional, healthy, pleasant for the body and soul.

Foil has been used in construction for several decades, and during this time it has shown itself to be a good thermal insulation material. Foil for baths and saunas is used as a heat insulator and as a protection against steam (vapor barrier, vapor barrier membrane).

It is glued to the ceiling and walls and must be covered with an external finishing layer (for a bath, this is a natural wooden board). The service life of such protection turns out to be significant - not less than 10 years.

Coating installation

For the most effective and high-quality coating and to ensure a comfortable stay in the steam room, a number of tips should be followed when laying the material.

- When laying foil-clad materials in steam rooms of non-commercial baths and saunas, it is sufficient to use roll or craft foil with a thickness of at least 3 mm.

- Foil on a mineral or basalt base is suitable for large steam rooms.

- When placing a sauna inside a house or in a basement, it is important to take into account the central heating and the location of its sources, if possible using it for additional heating of the steam room air.

- Before starting work, it is necessary to provide for condensate drainage by making a small withdrawal of the canvas from the ceiling to the walls, as well as from the walls to the floor. To do this, the foil material is laid with an overlap of 15-20 cm and glued with foil tape.

Important! To create a "thermos" effect, a gap of 13-18 mm must be left between the foil coating layer and the finish to ensure ventilation and maintain a healthy microclimate.

A gap of 1-2 cm will allow the condensate to dry out in the period between the heating of the bath Ventilation gap on the ceiling

The foil installation process takes place in several stages; rolls or sheets with a width of 60 cm or 1.2 m are most convenient to use.

- On the walls of the steam room, you need to make a crate with beams with a section of 5x5 cm. The distance between adjacent strips depends on the width of the material. For rolls of 600 and 1200 mm, this is 60 cm, for foil materials with a width of 1000 mm and 1500 mm - 50 cm. The bars are fixed with self-tapping screws of a suitable length.Lathing Fastening the battens to the ceiling Fastening the battens to the floor

- A layer of mineral insulation is laid between the planks so that it does not protrude beyond the level of the beams. Measurement of the distance between the battens of the sheathing Fastening the insulation boards to the ceiling. In the photo - the use of foil-clad insulation. The insulation plate is tightly inserted between the lathing bars. For the inner walls, you can use the insulation 50 mm thick. For outdoor use, a 100 mm slab is suitable or 50 mm thick slabs can be laid in two layers

- A foil-clad material is fixed on top of the insulation layer with the obligatory placement of a reflective layer inside the steam room. The joints of adjacent canvases or sheets can be glued with metal tape, but it should be remembered that under the influence of high temperatures, the glue can soften, and the panels will disperse, breaking the tightness.

Fixing the foil with tape

It is best to fix the foil with staples or nails, nailing them directly onto the beams. With a large width, the foil material is fixed not only at the edges, but also in the middle.

- The laid foil is sewn up with clapboard, leaving a one and a half centimeter air pocket, the main function of which is to reduce the heat-conducting properties of the foil layer and to maximize the reflection of all rays that hit the foil back into the steam room. An air pocket will allow you to create a lathing under the lining. Choose strips with a thickness of 10-20 mm and fix them with self-tapping screws. Fastening the lathing under the lining Installation of the lining Wall and ceiling lined with lining

Sometimes the order of arrangement of materials can be changed - a layer of foil is stuffed onto a layer of insulation placed between the battens of the lathing, staples or nails, which is fixed on top with thin slats, placed strictly on top of the lathing with self-tapping screws of sufficient length.

Bath wall decoration

In some cases, it is allowed to stuff a wooden crate over a layer of insulation, laying foil over the entire area of \ u200b \ u200bthe walls, incl. and on the uneven bars. Then it is impractical to leave air pockets, and the lining is fixed directly on the crate. But, as practice shows, the purchase of combined heat-insulating materials with a foil layer is not only economically more profitable, but also greatly simplifies the entire installation process.

Fastening the battens to aerated concrete walls Correctly fasten the bar to the concrete walls through spacers 2-3 mm thick to leave a ventilation gap. Level the bars. avoid contact with the floor The distance from the unprotected steel chimney during the passage of the ceiling must be at least 50 cm Installation of foil over the insulation Fastening the lining

Mineral wool prices

mineral wool

Where is used

It should be noted that the thermal insulation effect of foil is not based on the same property as that of other thermal insulation materials. Aluminum foil for a bath, on the other hand, conducts heat very well, but its effectiveness is based on the reflection of heat rays.

In any household infrared heater, electric fireplace, air heater, an aluminum heat reflector is used. To remove the disadvantages of high thermal conductivity of aluminum and low strength of the foil, manufacturers produce composite materials.

They have a layer of foil (reflective layer) and a layer of heat insulating material such as polyethylene foam. There are also many options where the foam layer is replaced with plastic wrap and / or kraft paper.

Product range of possible foil-clad insulation products

Knowing the basic requirements for foil materials, you should consider in detail the varieties of thermal insulation products.Finishing the bath with foil will take less time if you study the whole variety of the insulation market in advance. Below is a list of the most common ones:

- Aluminum foil for a bath. This thermal insulation product is sold in rolls. Rolls in the markets are presented in a wide range. Rolls can be of different widths and lengths. The layer thickness can also vary.

Foil rolls have no base. It is used for mounting on top of an existing mineral insulator. You can use aluminum foil for a bath up to 650 degrees. At the same time, the owner himself can choose the thickness of the insulation, it is important to remember that the final strength depends on this. The reflectivity of an aluminum sheet is usually at least 95%.

Pros and cons

The use of foil in a bath is due to its ability to reflect heat and retain steam. For a bath, these are important qualities, they are not possessed by so many materials. When deciding whether you need foil in a bath, you should take into account that it will serve as a good additional insulation system, but not the main one.

A common myth works against foil that to insulate a steam room or the entire bath, it is enough to paste over it with a thin layer of foil. It's not like that at all. The bath should be insulated exactly as if the foil was not used in it at all.

It plays only an auxiliary role, enhancing the insulating qualities of existing heaters. Before sheathing the bath from the inside with foil, it should already be well insulated, and the entire insulation should be well protected by waterproofing. Also communications, water, lighting must be divorced, a stove must be installed.

Which one to choose

The foil is based on a thin metal sheet. It is made only of aluminum. This is due to its technological feature, which allows aluminum to be rolled into very thin sheets. Not all metals have such a coefficient of plasticity.

Copper is on a par with aluminum, but when rolled into thin layers, it oxidizes. Only aluminum remains suitable, so there are no options for metal. Aluminum already has excellent performance properties. Insulation for a bath with foil can be produced by the manufacturer in a variety of options.

The main types of foil insulation used in baths

- Foil + foamed polyethylene (Folgizolon), one-sided and two-sided coating, different thickness of the polyethylene layer;

- Foil mineral wool. The aluminum coating is only double-sided.

- Foil for a bath, reinforced with kraft paper (kraft foil). It has no insulation layer.

- Foil + fiberglass mesh (Folar). It is heat resistant.

- Regular building foil without backing. Requires neat adhesion and good protection, followed by a finishing coat.

The choice of which foil is best for the bath is made according to the project documentation, the construction budget and the availability in the local construction market. If the requirements for safety and environmental friendliness are the highest, then paper-based foil for a bath or without a base at all is optimal.

If the quality requirements are standard, then foil thermal insulation for a bath can be any, if only from a certified manufacturer.

If the bath already has a good layer of insulation, then there is no point in purchasing foil on foamed polyethylene or mineral wool.

It is for such options that foil is made on kraft paper for a bath or fiberglass mesh.

These additional materials are added to the foil not for insulation, but for strength.

There are a lot of specific brands of foil: Alufom, Resource Megaflex, foil for a bath of any brand should be with a uniform surface. It should be free from spots, stripes, thinned or not glued areas. This is the main indicator of quality.

Foil is not difficult to manufacture and aluminum has a low melting point.That is why there are so many manufacturers of foil and foil materials. It is recommended to pay attention to certified products.

Which is better to use

When wondering what kind of foil to use for a bath, evaluate the various options. To calculate the required quantity (and, therefore, the price), exactly the same scheme is used as for the wallpaper.

In shops with wholesale prices, you can buy at least one roll. For thin materials, it is more than enough for the entire bath. Thick foil insulation is purchased in several rolls.

Thickness

Aluminum allows you to make any sheet. From a few micrometers to centimeters. In construction, variants of 30-300 microns are used. Foil for a bath of 100 mkr is the most durable, and differs slightly from thinner options in cost. It is easier to work with a solid version, but still the installation must be done very carefully.

The thickness of the foil layer is always indicated in the material characteristics. With a limited budget, you can choose the smallest thickness. The smaller the thickness, the more carefully you need to carry out the installation. The thickness of the foil does not significantly affect the efficiency of heat reflection.

Do not think that thickness is a decisive factor in which foil is best used for a bath. On the contrary, it affects only the strength, and not the thermal insulation characteristics. Despite the inertness of aluminum, it still oxidizes to some extent from water.

In some manufacturers, especially in those materials where thin foil is used, it is protected by a polymer film or by spraying.

These are usually more expensive.

Their advantages are noticeable only after many years of operation.

It is justified to use them only for the pair ward.

Heaters

Foil insulation for a bath can have either a porous polyethylene base, or mineral wool or basalt. The option of foil foam rubber, foam crumbs on a mesh is possible, but these are all specialized heaters intended for refrigerating chambers.

In construction practice, they can be encountered very rarely. Foil bath insulation is widely available in only two versions: polyethylene and mineral wool. Their main advantages are:

- foil on polyethylene foam is a safe material, both components are widely used not only for insulation, but also for packaging food products;

- mineral wool or basalt does not burn, but when working it requires care, as in handling glass wool.

Foil selection. What to look for

When buying foil for a bath, you should thoroughly make a decision on the question: which one is better to choose. The purchase must be made based on the compliance of the product with a number of important criteria, among which ease of installation and durability in operation can be distinguished. In this regard, special attention should be paid to the following nuances.

Aluminum sheet, due to its technical features, is a raw material that is very sensitive to mechanical damage, therefore, it should be purchased on a substrate and, preferably, in a reinforced form. This solution will significantly reduce labor costs during installation due to the absence of time wasted on unnecessary sealing of damaged areas.

Among the most common types of substrates are:

- kraft paper,

- foamed polyethylene,

- mineral wool.

A very important detail that makes foil insulation for a bath an irreplaceable product is its reflectivity. 95% for this characteristic will be sufficient for the product to perform its function. The higher the reflectivity, the less heat the room will lose.

Separately, attention should be paid to the environmental friendliness of thermal insulation.During operation, foil-clad insulating substances will be repeatedly heat treated. These processes should not become a catalyst for the release of harmful, toxic substances into the air.

Durability and reliability are also important criteria. Before making a purchase, you should read reviews of thermal insulation products on information sites, as well as inquire about the warranty periods of operation from manufacturers or distributors.

Vapor barrier

Even a thin aluminum sheet of a dozen micrometers does not allow water vapor to pass through. This property is very important for baths and saunas. Foil vapor barrier for a bath is produced by many manufacturers, and it is very convenient. You are applying a universal layer that will perform two functions at once:

- Reflective thermal insulation for a bath is a layer that effectively reflects infrared rays;

- Vapor barrier made of safe food grade material.

The ability to effectively reflect even the thinnest foil sheets, such as food grade foil, is easy to test. Look at the leaf in the sun for a light. It shouldn't show through at all.

At the same time, much thicker and more reliable foil is used for construction than for the food industry. The thickness of the aluminum foil for vapor barrier in a sauna (in a sauna, a vapor barrier is always more powerful than in a bath) can be any.

In doing so, you should only use construction foil, not food grade. The quality of the vapor barrier is more influenced by the accuracy of the installation and the absence of cracks provided by it, and not by the thickness of the material.

Areas of use

The choice of a foil-clad reflector is influenced by the type of material from which the bath is built, as well as the conditions of its operation. For buildings made of logs, it is not used. In an ordinary wooden steam room, a thin foil layer is used, it can be fixed directly behind the stove to speed up the heating process of the steam room.

A room made of aerated concrete needs additional insulation and vapor barrier. For ease of installation, laminated foil is used.

A thermal insulating layer based on mineral wool or expanded polystyrene is used in frame and brick baths. For the ceiling, a vapor barrier is selected taking into account the thickness of the floors, the presence or absence of an attic space.

The advantage of aluminum foil is the ease of installation, it is convenient to attach it to any surface. The material is able to create a favorable microclimate inside the steam room, the main thing is compliance with the technology of mounting the foil layer.

Installation

The bath is covered with foil at the stage when the main layer of insulation on the frame from the inside is already laid. Moreover, this stage of readiness should be for the ceiling. Foil in a ceiling-mounted bath is even more important for reflecting heat, as the warm air rises straight up. On the ceiling and on the walls, the covering must be continuous and without gaps. Only in this case will it be effective.

Any aluminum foil for baths and saunas is mounted on acrylic glue. There is no point in using toxic epoxy. Its strength is overkill for such a task. The same applies to polyurethane and other solvent-based polymer adhesives. Acrylic glue is bought in cans, and construction tape is also covered with it. Masking tape should not be used.

Foil properties

Among the characteristics that foil for baths and saunas has, the most important is the ability to reflect about 97% of infrared rays. If this material is used for continuous sheathing of the steam room, the thermal energy will be retained as much as possible. The fact is that the IR rays are not absorbed by the walls, but are reflected towards the room.

Foil for a steam room is ideal because:

- the material is able to withstand temperatures up to 300 degrees and even higher - this property depends on its type;

- does not emit substances harmful to the human body;

- has a low specific gravity.

In addition, aluminum foil has the following advantages:

- moisture resistance;

- plasticity;

- durability;

- vapor tightness;

- resistance to corrosive processes.

When using this material, almost all the heat remains in the steam room, while the insulation for the bath with foil on the walls will be reliably protected from condensation. The fastening process is simple, the main thing in the work is not to allow deformation, and not to leave gaps between the canvases.

To achieve a greater effect, foil heaters for a bath are sheathed not only on the walls, but also on the ceiling surface, since steam and hot air first of all rise up.

Steam room sheathing

Foil for steam rooms is usually purchased on kraft paper or polyethylene. It is not recommended to use foil mats with mineral wool due to their low moisture resistance.

Safe and environmentally friendly kraft paper is ideal. The steam room differs from other premises of the bath in high temperature and humidity. This imposes corresponding requirements for all finishing materials.