Rank: 951

Heating convectors, like any other development for a heating system, are highly efficient in use. Do-it-yourself installation of heating convectors may differ depending on what is used as a heating medium.

The carrier of heat can equally be both water in heating, and electricity or gas. The place of installation of heating convectors is highly dependent on the method of operation. The gas convector should preferably be placed vertically. Modern electric convectors are placed on the floor or suspended on the wall, as is the case with a device that works on water. Further in the article we will talk about how the installation of heating convectors of various types is carried out.

What is an economizer and what is it for

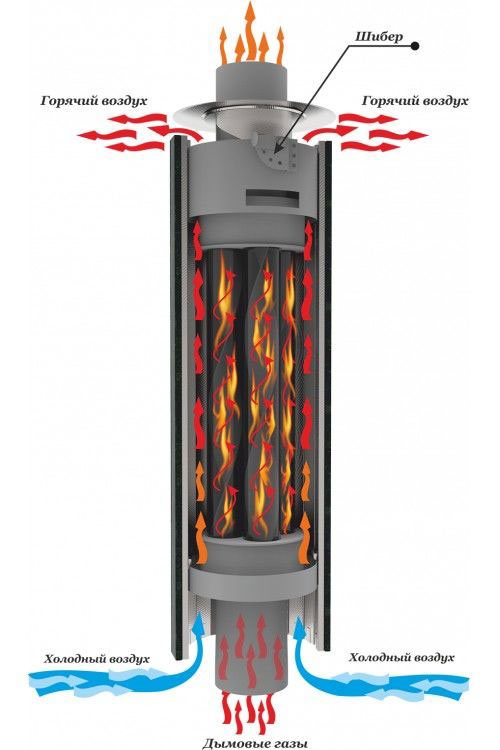

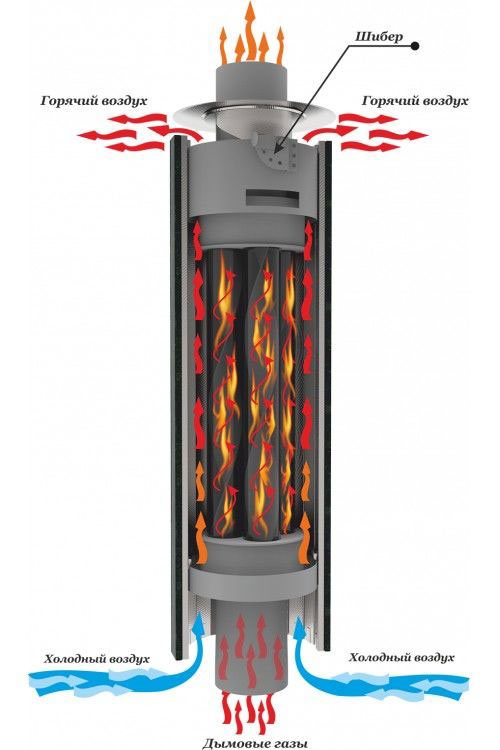

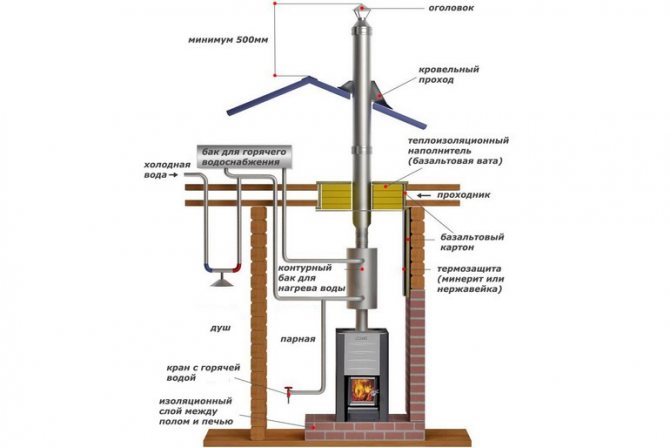

Convection chimney is a heat exchanger made of high-alloy heat-resistant steel, installed directly on the pipe of a heating boiler or sauna stove and used to increase the heating rate of the main space and efficiently supply warm air to adjacent rooms.

The use of an economizer is preferable in the case of regular operation of the hearth as the main heating device. In this case, the device will be able to take over the function of radiator heating, significantly increasing the efficiency of the entire heating system. The maximum efficiency during the operation of the chimney-convector can be achieved when it is installed on the pipe of a solid fuel boiler.

Convector-type chimneys are effective in organizing heating in bath rooms. In such cases, models are used with the possibility of overlapping convection channels in order to direct all the energy generated by the hearth to quickly warm up the steam room.

Electric convectors

Equipment that uses electricity is as efficient and convenient as water-based equipment. Do-it-yourself installation of electric heating convectors is a fairly simple matter, you can even do it yourself. You just need to follow the instructions, which are quite simple.

The procedure is as follows:

- The purchased unit must be properly unpacked.

- Then you need to remove the protective film with a gentle movement.

- It is, of course, important to find the most advantageous location for mounting the unit.

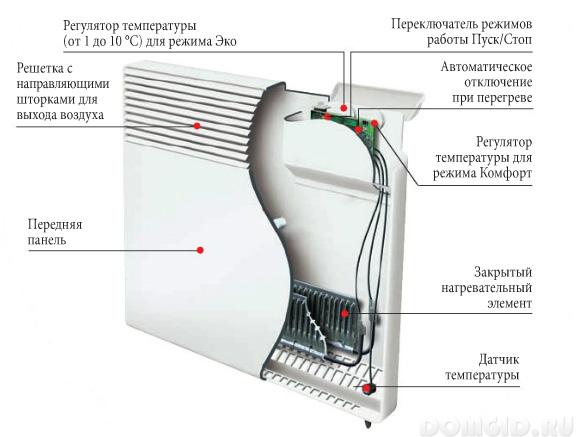

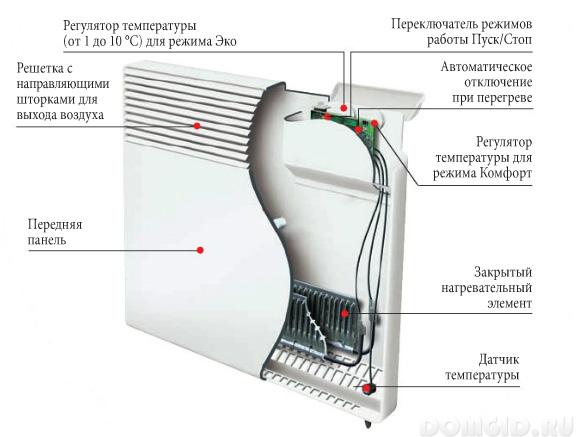

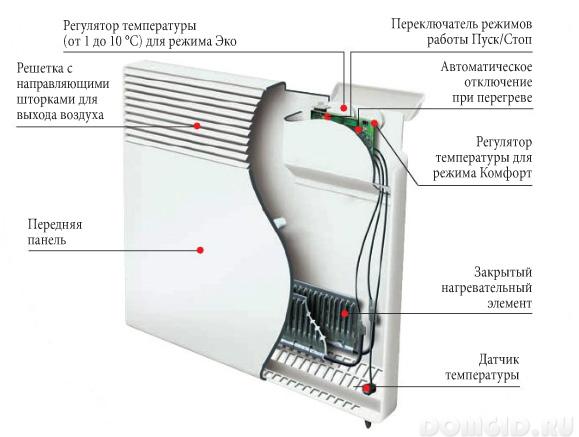

Electric convector device

Before proceeding directly with the installation of electric convectors, you need to familiarize yourself with the following nuances:

- The device must be suspended at a height of at least 0.2 m.

- Space is also required between the walls and the device, but not exceeding a quarter of a meter.

- Hanging too high is also not worth it. You need to leave at least half a meter of space and more.

- The equipment should not be in the immediate vicinity of power supplies. Observe a distance of 0.35 m or more.

The procedure for self-installation of an electric convector is as follows:

- First you need to turn the device over and build on it something like supporting legs that can be moved using the built-in wheels. To make something like this, you need bolts from the standard kit.

- In general, that's all. The device is ready for use, you can start working and customize it to suit your personal needs.

How the convector works

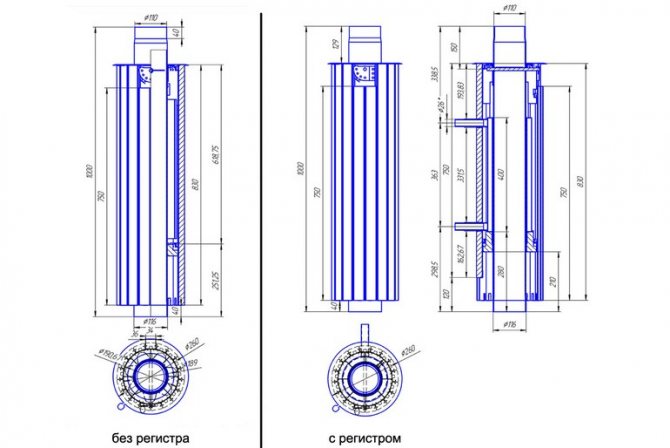

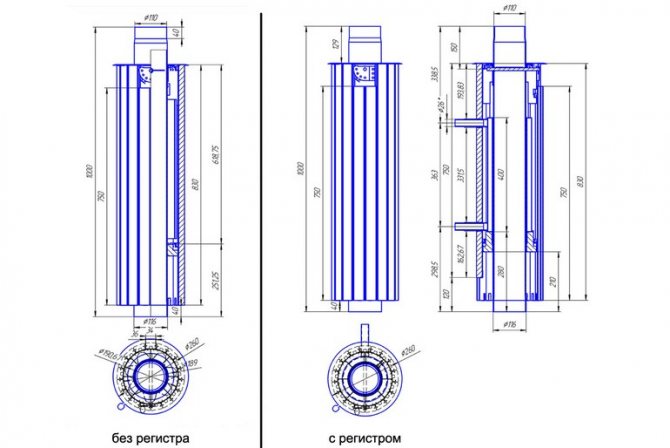

The economizer has a modular design consisting of two steel pipes of different diameters.The outer tube acts as a casing for the heat exchanger and is made of 0.5 mm hardened steel sheet. The internal flue gas module is made of 1 mm thick steel and ensures the passage of incandescent gases.

Some models are equipped with an upper casing made of artificial or natural stone, designed to accumulate and evenly distribute heat in the heated space. The design of such a chimney completely excludes the ingress of carbon monoxide into the room: only heated air circulates in the external module of the convector, other gases remain inside a completely sealed core.

The materials used to create the oven convector have a high degree of heat resistance, corrosion and oxidation resistance.

Pluses of converter devices

Such chimneys have many advantages that many have already appreciated. These include:

- Simple installation. The convector is connected to the pipe on one side, on the other - to the chimney leading out.

- Safe operation. Through the main chimney, the combustion products go out into the street without lingering in the room.

- Benefit. The room heats up very quickly, spending very little energy on it.

- Some purchased models are endowed with the function of blocking the chimney, due to which the intensity of heat release can be adjusted.

- When the device is made of quality materials, there is no doubt about its durability.

In general, the chimney-convector is really an inexpensive design that you can do yourself. It has many advantages, thanks to which it is widely used for heating baths, residential buildings and other premises.

DIY chimney heat exchanger:

The chimney-convector is a hollow metal structure that is connected to the outlet pipe of the boiler or the combustion chamber of the furnace. Its function is to remove waste gases and fuel combustion products, as well as additional heating of the room through the use of secondary thermal energy.

The design can be easily done by yourself, using basic skills of working with a welding machine and having a general knowledge and understanding of the principles of operation of furnace equipment.

The chimney-convector is a component of the stove or boiler heating system in a house or a bathhouse, operating on the principle of convection.

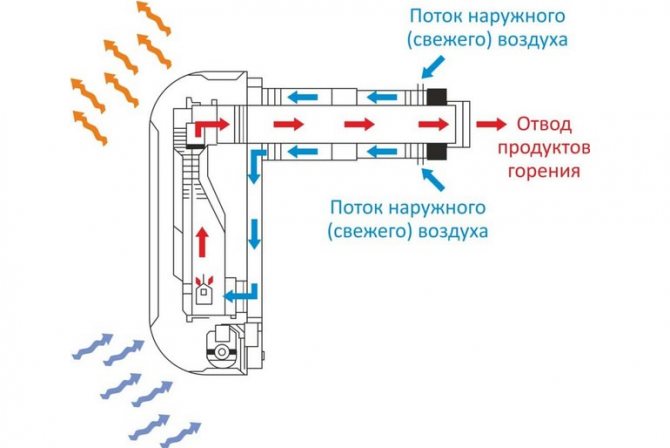

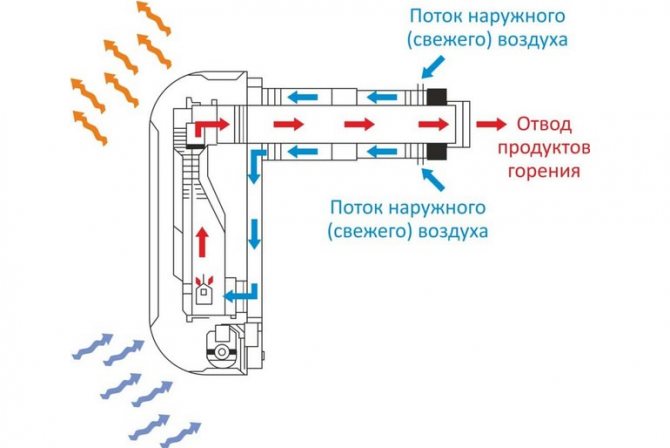

In fact, it is a coaxial pipe, consisting of two pipes, one of which is located inside the other. The outer tube acts as a convector and a protective cover that absorbs infrared radiation. The inner part of the structure serves to remove exhaust gases and combustion products, while the outer one is designed to supply fresh air to maintain the combustion process in the combustion chamber.

The operation of such a chimney is based on the principle of convection: passing through the inner pipe, hot smoke, gas and water vapor heats up the metal pipe.

The increased area of the metal casing, like a radiator, promotes heat exchange and heating of the air as it passes through the air pockets. Due to the large surface area of the metal, the convector effectively transfers internal heat to the air, thereby heating the room.

The main purpose of installing a chimney-convector is to increase the productivity of boiler or furnace equipment, as well as to save energy.

Note! Due to the more efficient use of the thermal energy of fuel combustion, the metal structure allows you to double the heating power of one room, as well as additionally heat adjacent rooms on the basis of one source.

Principle of operation

During the combustion of fuel in the furnace, a large amount of incandescent gas is emitted, which is discharged outside the heated room by means of a pipe. The economizer allows you to use the gas discharged from the hearth for the purpose of additional heating.

The chimney convector works on the principle of the simplest heat exchanger with natural convection of air masses. The cooled air is sucked into the convection holes of the outer tube of the product and, being heated from the incandescent chimney, gradually rises upward, spreading throughout the room. Slowly cooling, the air masses descend, and their path repeats again.

Types and designs

The design of the oven convector can be varied depending on its functional purpose:

- With two connections. Used to heat one living space.

- With four or more nozzles. They are used when it is necessary to heat two or more adjacent rooms.

- For baths. They are distinguished by the possibility of blocking ventilation openings in order to increase the heating rate of the steam room and increase the maximum air temperature in the heated space. Some models of sauna economizers are equipped with a special steel mesh for placing stones.

Designs of economizers to ensure uniform heating of living quarters have convection holes on the outer part, which provide cooling of the gas outlet pipe and effective circulation of heated air.

The length of the product can vary from 50 cm to 1 meter, depending on the goals pursued during the installation of the economizer and the design features of a particular heating system.

The longer the convector is, the larger the area of its contact with the main pipe, which means that the air in the heated space heats up faster.

Short convectors are suitable for use in rooms with low ceilings.

General device

The components of the gas convector are:

- A heat exchanger that heats the air in the room.

- The programmer is a device for maintaining and controlling the air temperature.

- Control panel with indicators.

- Gas valve to control the gas supply.

- Fan - to supply air to the heat exchanger and valve.

- Fan - for forced supply of heated air into the room.

Important! The principle of operation is quite simple. The device is based on the physical phenomenon of convection. The heated air rises upwards, and the cooled air falls downwards. The devices can operate both on the principle of natural and forced convection (in this case, the device is equipped with a special fan).

Advantages and disadvantages

The convector chimney has a number of significant operational advantages:

- Affordable price.

- Easy assembly and installation.

- Low fire hazard.

- Protection against infrared radiation and carbon monoxide.

- High efficiency of the heating system by reducing the volume of fuel and organizing the retention of heat entering the pipe inside the room.

- Regulation of the degree of heating by blocking the convection openings (possible with the selection of the appropriate economizer models).

- The durability of the product, subject to the correct choice of its design and the high quality of the materials used in the production.

Among the disadvantages of using an economizer when organizing heating systems, it should be noted:

- The need to constantly protect the product pipes from contact with flammable objects.

- Complication of the process of cleaning gas disposal systems in the entire structure of the chimney.

- Increase the space occupied by the heating system.

- The need to provide additional circulation of air masses in adjacent heated rooms.

- The finishing of the walls adjacent to the convection system should be carried out in advance, taking into account the maximum recommended distance from the point of view of fire safety from the economizer to the floors. Otherwise, repairs may require complete dismantling and reinstallation of the convector.

Obviously, if it is necessary to regularly heat one or several rooms with a low-efficiency furnace, the advantages of the economizer will fully cover the inconveniences arising during its installation and operation. The low cost of devices of this type will allow them to be used even in heating projects with a low budget.

Convector service life

The service life of a properly selected and installed economizer, while observing all technical requirements, is practically unlimited. Fixtures of this type are made of high-strength materials that are resistant to oxidation, rusting and wear under the influence of high temperatures.

Chimneys-convectors have a simple design and a minimum of working units, therefore, with proper installation and operation in the system, there is simply nothing to break in them.

Nevertheless, manufacturers of convector-type chimneys recommend regular preventive inspection of the flue system in order to prevent possible sealing defects and other technical malfunctions.

Floor convectors manufacturers, prices

There is a fairly wide selection of floor convectors on the Russian market. According to reviews, the following radiator models are especially popular:

Before installing heating pipes in a private house, you need to draw up a project, preferably backing it up with a hydraulic calculation.

You can find the rules for replacing heating pipes in an apartment building here.

The range of prices is quite significant. You can find heat exchangers for 6 thousand rubles. Prices for branded products reach 60 thousand rubles. Naturally, the quality of materials also depends on the cost. The grille can be anodized coating that does not wear off over time. In expensive models, a stiffer trough. This extends the service life and simplifies the installation of floor convectors.

The cost of the heat exchanger should also include additional costs for piping fittings. It is likely that fasteners will also be required - in cheap models, fasteners are not female enough. We wrote here about how to choose fittings for piping a radiator in a water heating system.

Do it yourself or order

An economizer is a device that is simple in design, which can be made independently if you have the necessary materials and tools (welding machine, file or metal scissors).

If it is not possible to make a convector pipe on your own, it can be purchased at a hardware store by choosing a model that is suitable in terms of configuration and cost.

Selection Tips

If you do not have the desire or ability to make an economizer on your own, you can buy it. When choosing the required product, you should pay attention to the following nuances:

- The quality of welding in the docking points should not be in doubt: the welding line should be even and uniform, and the parts should not dangle relative to each other.

- There should be no stains, discoloration or other defects on the surface of the parts, since their presence indicates the low quality of the material used.

Criteria for the selection of the required materials

Since a home-made apparatus is assembled from units that have already been used once, the first step is to assess the condition of the pipes

Particular attention will need to be paid to their walls. Their thickness should be several millimeters.

If the appearance of corrosion is observed, then it is undesirable to use such pipes or it is imperative to eliminate all defects before use. All rust will need to be qualitatively removed from the metal with a brush, and then covered with an anti-corrosion compound so that the problem does not arise during operation in the future.

If the heater is connected to an apartment or garage, then all components must be of absolutely high quality, since such systems are subjected to pressure from a large number of atmospheres. If the wall is damaged, then it will not withstand the load and will eventually burst, which will lead to loss of coolant and breakdown of the entire unit.

For manufacturing, pipes with a diameter of about 12 cm are usually used. For end caps, sheet metal of an appropriate size is used.

To make bypass channels and fittings, you will need to use pipes of a smaller diameter, which can eventually be connected to the heating system. The threads are pre-cut on the fittings, for this reason, you need the appropriate equipment - a "pin" (for creating an external thread) and a tap (for cutting an internal thread).

A DIY oil cooler can be made portable. In this case, small pipes will be used, and oil is used as a heat carrier. Heating elements are used instead of heating elements. The choice of this component depends on the area of the room to be heated. On such a device, home craftsmen often install an additional thermostat, which periodically turns on and off the heating element.

For good wall anchoring, you will also need strong hooks that can support the weight of the unit. For a more aesthetic look, they can be purchased at the store. But if there is no desire to spend additional funds, then rods of solid reinforcement will do, which will need to be fixed in the wall. It is advisable to pre-paint the hooks in the same color as the heater was painted - so the fittings will become invisible.

Building regulations

The selection and installation of the economizer must be carried out in compliance with the requirements of the current regulations, in particular:

- SNiPa 23-01-99 "Construction climatology".

- SNiPa 41-01-2003 “Heating, ventilation and air conditioning”.

- SNiPa 42-01-2002 "Gas distribution systems".

- SP 42-101-2003 "General provisions for the design and construction of gas distribution systems from metal and polyethylene pipes."

- PPB 01-03 "Fire safety rules in the Russian Federation", as well as other applicable documents regulating the installation and operation of convector-type chimneys in the type of buildings being equipped.

Making and installing a convector with your own hands

The assembly of the economizer is carried out in several stages:

Drawing and diagrams

Before starting work, all the necessary measurements should be made to calculate the required dimensions of the product. The parts necessary for the work must be applied to the corresponding drawings and diagrams in order to simplify and increase the accuracy of the upcoming work.

It should be borne in mind that:

- The inner pipe must be at least 1 mm thick and with an outer diameter that matches the diameter of the stationary chimney. You can weld it from a rectangular sheet of metal.

- The prepared billet will be cut according to the length of the existing chimney.

- If one pipe is supposed to be made, its diameter should provide a distance between its inner part and the outer part of the gas outlet channel of several centimeters.

- The length of the outdoor modules should be slightly shorter than the inner flue pipe. The optimum thickness of steel used for these elements is 0.5 mm.

- If several small-diameter tubes are selected as an external module, it is necessary to calculate their number to completely cover the internal gas outlet during the welding process (the tubes are attached to the body of the internal pipe in a circle, like flower petals).

- If one large-diameter pipe will act as an external pipe, it is necessary to cut out 2 blanks for truncated cones from an additional sheet of steel, and evenly cut convector holes in them. These parts will become the top and bottom of the heat exchanger.

Sizing calculation

The calculation of the dimensions of all of the above elements must be carried out taking into account the design features of a particular heating system, as well as the dimensions of the heated room or premises. To simplify the work, you can use a special table:

| Convector | |||

| d | H | h | n |

| 110 | 570 | 500 | 5 |

| 115 | 570 | 500 | 5 |

| 120 | 570 | 500 | 5 |

| 130 | 570 | 500 | 6 |

| 150 | 570 | 500 | 6 |

| 200 | 570 | 500 | 8 |

Where d is the diameter of the gas outlet pipe, H is the height of the gas outlet pipe, h is the height of the heat exchanger.

Types of convectors

Chimneys-convectors can be used to heat both one room, in which the boiler or stove is located, and adjacent rooms. In accordance with this, two types of equipment can be distinguished:

- chimney-convector-1 - heating device;

- chimney-convector-2 - equipment for heating air in two adjacent rooms.

Homemade - this word means that the product is made by hand, but sometimes it is used with some kind of dismissive connotation. And yet this is far from the case. The most expensive hand-built cars in the world are custom-made. What should you call them? Homemade? Everything that ensures the life of mankind is created by human hands.

The topic of this article is homemade products for home heating, but its purpose is not to teach, but to give an overview of those homemade options that talented people are implementing. Of course, self-production requires certain knowledge, experience, tools and materials for work. Only in this case it is possible to manufacture a high-quality and safe heating device, no worse, and in many cases even better than industrial boilers.

Most often, craftsmen begin to create a heating system by determining the type of boiler, creating drawings and the subsequent construction of the boiler. This work is not easy, therefore, without a good knowledge of the device and the principle of operation of the selected type of boiler, experience, the availability of the necessary tools and materials for its installation, it is difficult to perform it.

Most often, the following types of boilers are independently made:

Gas boilers are difficult to manufacture on their own, since this equipment is of increased danger and special technical requirements are imposed on it. Attempts to make a homemade one are limited by the need to obtain a quality certificate and permits from supervisory authorities. Passing all the required checks for compliance with quality parameters is problematic. But do-it-yourself repair of the convector is permissible. Most often, the central pipe of the coaxial output burns out and it can and should be replaced.

Electric boilers

Boilers of this type are characterized by extreme simplicity and low safety requirements during installation. An electric boiler can be compared to ordinary electrical appliances that are used in the house. The only drawback is the high and constantly increasing electricity price. But for a garage or a summer cottage, if it turns on sometimes, it is quite suitable.

Oil fired boilers

Liquid fuel boilers are also easy to manufacture. The high price of the injectors can be an obstacle for manufacturing.

Solid fuel boilers

This class of boilers, and they are divided into wood, pyrolysis and pellet, is the most popular for self-production. Do-it-yourself wood-fired heating boiler is one of the simplest and cheapest, but its efficiency is rather low.There are many drawings and practical advice on the Internet for making this type of boiler. A wood-fired boiler can operate on any type of solid fuel.

Pyrolysis boilers

Two-chamber pyrolysis boilers are quite expensive to manufacture on their own. They have two combustion chambers. One burns fuel with minimal oxygen access. That is, there is a process of pyrolysis or dry distillation of wood. The gas released from the wood is burned in the second chamber, releasing a large amount of energy. The pyrolysis boiler can operate on wood, coal and peat.

Craftsmen have learned how to make a pyrolysis boiler from a gas cylinder with their own hands, economical and perfectly working. The easiest way to make a boiler is from a gas cylinder with a capacity of 50 liters.

Installation features

The economizer is installed directly into the bottom of the chimney. The structure leaves the chimney body, and then re-enters it, remaining an intermediate part of the flue system.

The length of the convector is selected based on the height of the room, as well as the required distance of the structure from the wall. The less the economizer is from the wall partition, the greater the heat of the air discharged through it. Most of the factory-made convector pipes are equipped with additional modules to extend their actual length. In the absence of such a part, you can use a corrugated stainless steel pipe.

The lower part of the convector is mounted directly above the floor. During the installation process, it is recommended to strengthen this area with a gasket, and only then process the seams with a specialized sealant.

It is important to tightly dock both ends of the product with the stationary chimney, preventing further ingress of gases from the inner pipe into the room.

After finishing work on the manufacture of a chimney-convector with your own hands, it is recommended to paint it with heat-resistant paint in black: this will ensure an increase in the thermal conductivity of the product.

If you want to heat absolutely any room without creating complex communications in it, then the installation of an electric convector is what you need! Silent, safe, if desired, completely invisible or, on the contrary, striking with its original stylish look, a modern electric convector will warm not only your home, but also your soul!

Content

- What is an electric convector and how it works

- Electric convectors heating: types

- Are electric convectors so good: reviews

- Installation of an electric convector video

What is an electric convector and how it works

An electric convector is a variant of modern heating. The design and principle of operation of the electric convector are as follows:

A decorative metal case (it is thanks to him that the electric convectors got their second name - a decorative heating panel) with openings for the intake of cold air in the lower part and the exit of warm, warmed air in the upper part. The housing is made of metals with high heat dissipation (for example, aluminum), in order to minimize energy consumption and increase safety, because such a panel will not heat up above 45 ° C (the likelihood of burns is minimal) and by itself will be a heating element.

A heating element (TEN) in the lower part of the case, consisting of a conductive component protected by ceramics and hermetically sealed in a steel tube with a radiator, the average temperature of the TEN in various models of electric convectors is about 100 ° C.

Mounting frame - is a frame with attachment points. The possibility of installing the convector on any surface of any room is practically unlimited.

As an additional option, the following can be built into the electric convector:

- a fan that promotes faster and more uniform heating of the room by increasing the speed of air circulation, both in the electric convector itself and in the heated room.

-the thermostat (electronic or electromechanical), which is both a safety sensor: it cuts off the power of the heating panel when it overheats or drops in voltage in the network, and a thermostat (electronic thermostat) programmed to deliver air of a certain temperature or maintain the required temperature in the room for a certain, a given period of time, which allows to reduce electrical costs: to reduce them by more than 50%.

Considering the power of the electric convector declared by the manufacturers, ranging from 0.5-3.0 kW in increments of 250 W, such energy-saving functions of the thermostat will be very useful. In addition to everything, the electronic thermostat makes the operation of the electric convector not only more convenient, but also even more economical (up to 4% energy savings in comparison with electromechanical analogs). All these new possibilities make it possible to use electric convectors as both main and additional heating in apartments and houses.

Electric convectors heating: types

Depending on the principle of operation, all electric convectors can be divided into:

- appliances with natural heat exchange (electric convectors or wall panels);

- devices with heat exchange based on forced airflow (electric fans and heat guns).

Let us consider the first option in more detail.

Based on the size, all electric convectors are divided into two groups:

High (40-45 cm high and short) - wall-mounted electric convectors (wall panels).

Skirting boards (no more than 20 cm high and up to 2.5 m long).

Are electric convectors so good: reviews

Despite the many advantages of using electric convectors in houses and apartments, such as:

-compactness and aesthetics,

-safety,

-possibility of use in damp rooms,

- environmental friendliness: practically do not change the humidity of the air in the room, do not dry it out, the dust deposited on the heating element does not burn, and therefore there is no specific unpleasant smell.

All electric convection heaters have common disadvantages common to all convection systems:

- convection air flows are formed, as a result, uneven heating of the room, especially along its height, which is very important for low-rise buildings with an unheated basement, but, practically not noticeable in a standard apartment,

- the resulting convection currents, circulating around the room, carry away dust, which increases the risk of unwanted allergic reactions.

Also, when choosing electric convectors, it is necessary to pay close attention to the manufacturing quality of the heating element, the use of stainless steel and aluminum alloys.

With a declared warranty period of 2 years, often the service life of such electric convectors is about 15-20 years.

At the moment, the most demanded, due to their high quality and extended warranty period, up to 5 years, in some models, are electric convectors nobo, evub, ballu, noirot.

Installation of an electric convector

Installation of an electric convector can be very simple and consists only in installing a mounting frame on a wall, in a given position, hanging an electric convector on it and connecting it to the network.

But, for this you need to think over the power of the electric convector in advance, select the appropriate section of the wiring cable.

Author: Sergey and Svetlana Khudentsov

10

Frequent errors and problems during installation

The convector chimney is easy to install and operate, so its installation does not require much effort.However, problems may arise due to the wrong choice of the diameter or length of the product.

The main mistakes during the installation of the economizer can be associated with the incorrect height of the location of its nozzles relative to the floor covering (too high or low), as well as with poorly performed sealing of the joints of the product with a stationary pipe.

Difficulties in installing the economizer are caused by the need to build it up with a corrugated pipe, followed by verticalization of the structure relative to the wall ceilings. In this case, you should additionally use a sealant to strengthen the joints, as well as level the structures using a building level.

Selection of convectors

Installing an underfloor convector can seem like a rather complicated process. Therefore, we will describe everything step by step, starting with the choice of equipment. In front of panoramic windows or in front of the entrance area, we can install electric or water heaters - it all depends on the type of main heating in the building.

Electric floor convectors operate on a 220 Volt network and are designed to heat households that are not connected to gas mains. In their design, most often, fans of one design or another (axial or tangential) are already provided. The disadvantage of electrical appliances is their high energy consumption, but in some situations they are irreplaceable. But only wires are needed to connect them.

Electric convectors can also be used in gasified buildings, where it is difficult to lay water heating to the place of their installation.

Installation of a water convector installed in the floor.

Water convectors have a similar design - there are heat exchangers that are connected to the heating system. For this, metal or plastic tubes are used, which require a certain skill for their laying. In this regard, electric floor convectors benefit - for their installation and connection, only wires of a suitable cross section are needed.

When planning the installation of a floor convector, pay attention to the choice of a model with forced convection. These devices have the following advantages:

- Higher heating rate;

- Increased efficiency of work in rooms with a ceiling height of 3 meters;

- Effective removal of moisture from the entire glazing surface.

By choosing floor convectors with low-noise fans, you can increase heating efficiency and prevent a source of noise.

Maintenance and cleaning

For the full functioning of the economizer, it is necessary to regularly carry out preventive inspection and repair of all its parts. As a rule, this task boils down to renewing the sealant layer if necessary, as well as cleaning the internal gas outlet pipe.

Cleaning the pipe should be carried out simultaneously with the stationary chimney, if necessary, completely or partially dismantling the convector system, using a mechanical (using special brushes) or chemical (using specialized compounds for cleaning a stainless steel chimney) method.

Expert advice

Specialists in chimneys for heating systems at suburban-type facilities recommend purchasing high-quality economizers from trusted manufacturers - i.e. do not save on the device. According to them, the optimal solution for complementing the stationary gas outlet system with a convector would be the implementation of the professional implementation of the installation, as well as the subsequent maintenance of the device.

A convector chimney is a safe and inexpensive device that can increase the efficiency of a heating system without increasing the financial costs of its operation.Devices of this type are distinguished by their durability and simplicity of design, which allows them to be assembled and installed on their own and for a decade to forget about replacing or major repairs of the gas discharge system.

Now you know how to get your oven to work 100% without a major investment. Subscribe to our articles and share useful information with your friends. Until next time!

(

1 estimates, average: 5,00 out of 5)