Photo from the site: utepleniedoma.com

As soon as our ancestors got out of the caves and built their own dwellings, it became necessary to organize decent lighting in them, for which the windows were invented. Long before the invention of such a material as glass, the frames on such windows were already made of wood, and even now a third of all window structures in our country are made of wood, although metal-plastic windows, which are more durable, easy to use and reliable, are gaining more and more popularity. A house with wooden window frames is a dwelling with a unique microclimate, since this natural material does not have the ability to retard the circulation of air masses.

However, it should be understood that wood structures have one very significant drawback, which, of course, cannot be overlooked. Compared to newfangled plastic, they simply do not hold up in terms of thermal insulation qualities, and this is extremely important. However, you should not be upset, since modern technologies and materials make it easy and simple to deal with the problem. It is about how to insulate wooden windows in a wooden house, and in any other, and will be discussed in our article, especially since there is nothing super complicated here, and even a person with absolutely no experience can cope.

Preparatory stage: finding problem areas

Depending on how and from what types of wood the frames were made, how the glasses were inserted into them, how long and intensive the operation was, the following main problems of wooden windows are distinguished:

- cracks and gaps between frames and jambs or a window sill. They arise as a result of skewing of frames, drying out of wood, shrinkage of the house. Serve as a source of drafts and dampness;

- gaps between jambs (frame) and walls;

- loose closing of frames or inability to completely close. The reason is also skewed frames and / or jambs, window sill. Leads to a complete lack of protection of the premises from heat losses;

- cracks, holes and cracks in frames, voids in wood;

- loose adhesion of glasses to the frame. Causes drafts, cold feeling from the window. Significantly increases the heat loss of the room;

- insufficient glass thickness or the presence of only one glass. With very thin (1.5 ... 2 mm) glass, high thermal conductivity (0.75 W / m * degree) reduces the resistance to heat loss by 30 ... 50% compared to the normal thickness of window glass (3 ... 4 mm). Single glass glazing is permissible only for non-residential premises.

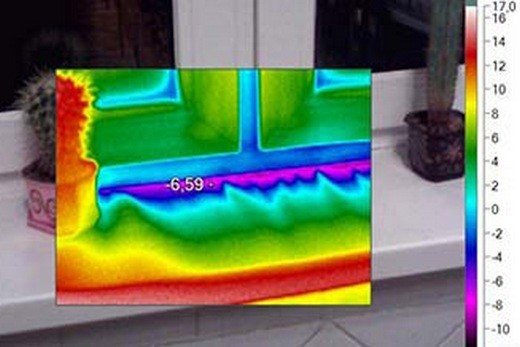

Thermal imaging will help in identifying the sources of drafts and cold.

Once the underlying problem - or set of problems - has been identified, solutions can be sought.

Thermal insulation technology for wooden windows

All methods of insulating old wooden windows can be conditionally divided into two groups: seasonal (without repair of structures) and capital (with the repair of frames, window sills, replacement or new sealing of glass and other measures).

Seasonal insulation

There are three main options in this group.

Protection of glass and frame joints.

It is produced only from the inside, using sealant or narrow strips of paper, cloth or tape, as well as masking tape. If the method with the adhesive tape - paper or woven - is chosen, then such a tape is glued to the glass-frame joint so that it goes on the glass and wooden structure by 2 ... 5 mm. For paper and fabric strips, paste or soap solution is used, scotch tape or masking tape is attached using its own adhesive layer.The use of scotch tape is undesirable, as it leaves stubborn glue residues on glass and wood.

Sealing the joint between the glass and the frame with a sealant is carried out either with silicone-based materials or with window putty. A clear sealant gives the best results and is less visible.

Protection of the joints of the glazing frame with jambs and window sill.

It is also performed from the inside, for this they apply:

- paper - in the form of special paper tapes with an adhesive layer or cut strips of newspapers or writing sheets. When using ordinary paper, gluing is carried out on a soapy solution or paste;

- fabric - strips of fabric are glued with a soap solution, if a bandage is used, gluing is in several layers;

- technical or ordinary cotton wool, rags - the material is tightly hammered into the gap between the frame and the jamb (window sill);

- recycled paper. It is not difficult to insulate wooden windows in an apartment using such a "putty", paper pieces soaked in a solution of glue or paste are tamped tightly into all cracks. It is important to remember that printed newsprint can stain light frames;

- foam rubber - strips of material are pushed into the gap between the flaps and the frame using a narrow blunt object (screwdriver, table knife, ruler);

- a special seal in the form of a tubular strip of rubber or foam rubber, usually with an adhesive layer. The seal is glued to the part of the frame adjacent to the jambs when the window is open. Once closed, the tube deforms and tightly blocks the outside air flow.

A combined version of protection is also used, in which the gaps are filled with cotton or sealant, a sealant, and then sealed on top with paper or fabric tape.

Thermal glass protection.

A thin transparent film is glued to the water on the entire surface of the glass, going over the frame. Due to the ability to reflect infrared (thermal) radiation, the film prevents heat loss, keeping the heat in the room.

It is mounted with the metallized side outward.

Do-it-yourself capital insulation of wooden windows

For a better and more durable result, it will be necessary to partially dismantle the window. It is better to do this during major or at least cosmetic repairs.

- The frames are removed from the hinges.

- The hinges are checked, their fastening strength and performance, position accuracy. Parts are replaced or reattached if necessary.

- The condition of the frames is checked, the presence of cracks, holes and cracks in them. This may require the removal of the decorative coating - varnish or paint.

- Seal gaps in wooden windows with wood putty, alabaster, paraffin or sealant. If you plan to paint or varnish wooden frames in the future, it is better to choose a putty or alabaster, since varnish-and-paint coatings do not fit well on a sealant or paraffin.

- Check the condition of the jambs and the window sill, the presence of gaps between them and the wall. Seal the found voids in the wall with foam or cement-sand mortar, gypsum, alabaster or other repair material. The sealed fragments are hidden by the trims.

- Insulate the slopes from the inside using any modern heat-insulating material and drywall. At the same time, this will help give the inside of the window a more attractive look and simplify the decorative trim of the slopes.

- Put the frames in place and remove the glass beads by removing the wooden glazing beads. If there is no need to replace the glass, its contact (in contact with the frame) surfaces are cleaned like seats in the frame. After that, the place of installation of the glass along the contour is treated with a sealant, after which the glass is put in place and fixed with a new glazing bead. As a rule, additional thermal insulation of the glass and frame joints is not needed.

Important: glass change and re-sealing is performed with the frame in place and closed! If you change the glass with the frame exposed or simply open, there is a risk of it skewing and damage to the glass during installation.

In case of insufficient thickness / thermal insulation of the wall above / below / next to the window, internal or external thermal insulation of the entire wall may be required.

Additional methods of insulation - gluing joints, installing a seal on the frame, installing a heat-saving film on glass - only increase the efficiency of the main repair work, but do not replace them.

Cold bridges and ways to eliminate them

Insulation technology includes a preliminary examination of the entire window structure to identify the places of cold penetration and their further isolation. The most likely culprits for heat loss are the joints of dissimilar materials, installation defects or cracks in the structural elements of the building, formed due to long-term use (in old houses).

One of the most common places for heat leakage is in lintels over windows. They can be insulated with their own hands, pasting on the outside with facade foam. Then the surface is reinforced with a special mixture, plastered and a decorative coating is applied.

Window slopes can also contribute to heat loss. To eliminate this, the lateral planes are first primed, pre-sanded. Then, special PVC elements are installed, filling the internal voids with polyurethane foam or natural tow. Insulating the gaps between the slopes and frames with your own hands, they can be insulated with a sealant, covered with a cement-sand mixture and putty.

If the window sill was incorrectly foamed, under it in an inclined position, you can attach a piece of plastic panel with the same filler as for the slopes. When revealing through gaps in the brickwork, they are blocked from the outside with foam plastic, doing this not before winter, but long before it.

Such a seemingly harmless thing like cracks in old frames can also be cold bridges. To eliminate them, the standard technology recommends filling the grooves with wood putty and sanding after drying. A sealant is also used, the cracks are poured with molten paraffin, they are filled with a solution of sand (1 part) and flour (3 parts). After the putty is over, the frames are covered with enamel or varnish.

Glasses also need to be prepared for winter. To increase the heat reflectance of the glass surface, the windows are washed clean for the winter and polished dry with wrinkled newspaper. The next step is gluing a transparent self-adhesive film with a high reflectivity of infrared rays. Home craftsmen sometimes mount a special plastic wrap, covering not only the glass, but also the frames. Attach the material with double-sided tape or a stapler to the frame.

How to insulate old wooden windows using Swedish technology

The listed methods of thermal insulation of a room by sealing windows are mainly applicable to dilapidated, not too high quality wooden frames. However, for houses of the "old fund" with windows made of high-quality and expensive wood for a long time, you can apply a more modern and effective "Swedish" or "groove" sealing technology.

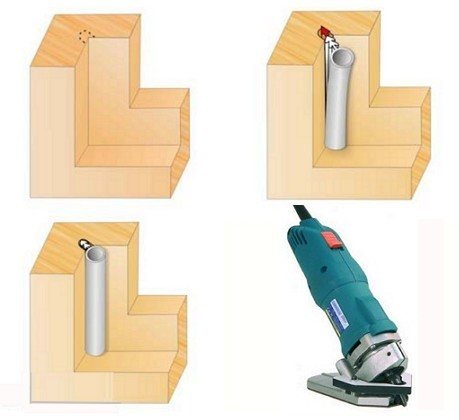

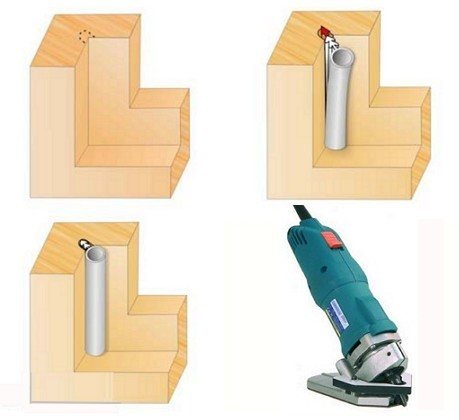

The essence of the technology lies in the installation of a special insulation that is fastened in a groove around the perimeter of the sash and frame. The groove for the insulation is selected using a cutter, the sashes, if necessary, are adjusted so that a tight, but not difficult, closing of the window is ensured.

Depending on the frame design, not one, but two or three seal contours can be installed.

The type of seal (profile) depends on the size of the gap between the frame and the window sash. This gap is determined along the entire perimeter, since in different places it can differ 2 ... 4 times (for example, between the top and bottom of the window). This can be done with a piece of plasticine wrapped in plastic.It is clamped between the frame and the sash, the size of the gap is estimated by the height of the ridge.

EuroStrip profile marking for gaps of size:

- 2 ... 3.5 mm, E - tubular;

- 3 ... 5 mm, P - tubular with a round or figured section;

- 3 ... 12 mm, D - shaped tubular.

This type of insulation is optimal if a high-quality wooden window as a whole blows and only needs to be compacted around the perimeter. The sealing process is shown in more detail in the video.

The advantage of the method is the possibility of free opening of the sashes at any time of the year (as opposed to windows sealed or sealed with foam rubber, cotton wool, sealants), as well as the preservation of the natural microclimate.

Using Swedish technology, you can insulate wooden windows with your own hands, thereby reducing the cost of installation work and allocating large funds for the purchase of a high-quality insulating profile and new window fittings.

Sealing self-expanding tape

PSUL is made of polyurethane, impregnated with a special solution that makes the tape elastic and expandable. The material is fixed with the adhesive side to wooden doors, seams, doorways. PSUL protects windows from precipitation, wind, helps to remove moisture from the room.

The tape is resistant to low and high temperatures, does not burn, is not susceptible to fungal attack, does not deteriorate under the influence of ultraviolet rays, and can even be used on uneven structures. Before fixing the tape, the sash surface must be cleaned, dust and dirt removed, the material expands within 48 hours after gluing.

[ads-pc-2]

Conditions for proper insulation of wooden windows

Most of the insulation work is carried out in the first autumn months, before the indoor temperature drops below 15 degrees Celsius. It is very problematic to insulate housing well in cold weather. On very cold frames, the soapy water, paste or adhesive layer of the finished materials will not adhere.

Extreme situations

As an emergency measure, you can use the sealing of cracks with cotton wool, foam rubber or homemade sealant (papier-mâché mass based on newsprint or writing paper with paste), installation of a heat-saving film on glass. In extreme cases, it is permissible to install a dense polyethylene film (one- or two-layer) over the entire window area, including frames, with an approach to the slopes from the inside. Such a film is attached using ordinary or double-sided tape. The disadvantage of this method is a strong decrease in illumination, but when the heating is turned off, record frosts or a crack on the glass (broken glass), this method may be the only rational one.

With a sharp drop in room temperature and the impossibility of carrying out normal thermal insulation of windows, it is worth remembering also about the old protective device - very dense, heavy curtains. They will reduce the flow of cold from the glass and help, at least partially, get rid of drafts. Roller shutters can serve the same purpose.