Today, any building can be built from individual expanded clay blocks. Therefore, it is necessary to know the relevant information about the properties of expanded clay as a source material for expanded clay blocks so that the future construction is of high quality and durable.

A house made of expanded clay concrete is built faster than a brick one, and the finished building is durable and of high quality.

Getting to know the expanded clay concrete blocks

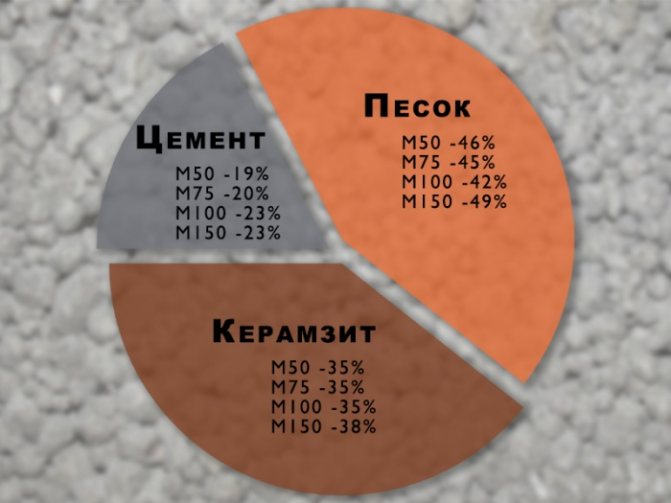

What kind of material is this? If you don't know yet, then expanded clay concrete consists of three main components:

- expanded clay (foamed and burnt clay);

- cement;

- quartz sand.

Based on the components of expanded clay concrete, it can be called an environmentally friendly material, because all the elements are of natural origin, without chemicals in their manufacture. Due to the presence of expanded clay in the composition, the weight of expanded clay blocks is much less than analogues, and its thermal insulation characteristics are at a high level. The cement in the composition makes the product durable and suitable for building houses. What are the advantages of expanded clay concrete blocks for building a house?

- Low hygroscopicity. Despite the fact that the blocks contain cement, the material is quite moisture resistant and is not afraid of liquid.

- High rates of frost resistance. Depending on the type of expanded clay concrete blocks and their purpose, the freezing and defrosting cycle ranges from 15 to 200.

- Excellent strength and density of expanded clay concrete blocks.

- Expanded clay concrete does not burn and does not interact with fire in any way.

- The combination of all the previous advantages gave rise to another one - durability. The construction of a house from expanded clay concrete blocks is done for centuries.

- The material does not rot, does not rust, insects and rodents do not eat it.

- Thanks to its bio-stability, the walls of the house will not be covered with mold and mildew.

- Low coefficient of thermal conductivity, due to which houses made of expanded clay concrete are warm.

- The material, and accordingly the walls of the future house, will "breathe", since the blocks have excellent vapor permeability.

- You can even build a house from blocks yourself, while not spending as much time and effort as on brick buildings.

- A house made of expanded clay concrete will not shrink.

- The material is lightweight.

- Masonry mortar will take half as much as for brick.

- The cost of both the material and the construction of the whole house is small.

Among all these positive points, it is worth mentioning a few disadvantages of expanded clay concrete that you should know:

- despite the low weight, it will not work to save money on the foundation;

- when laying blocks, cold bridges (seams) will form, therefore, the house will have to be insulated from expanded clay concrete blocks;

- there are many low-quality fakes on the market that do not meet the declared characteristics.

If we draw a logical conclusion, then everything speaks in favor of expanded clay concrete blocks. Indeed, judging by the reviews of the homeowners, they are quite satisfied with the quality of the building, despite the years they have lived.

What is expanded clay

Expanded clay concrete blocks

The structure of expanded clay concrete includes three components - cement, quartz sand and expanded clay gravel (fired and foamed clay), from which it follows that the material is environmentally friendly, safe, without harmful impurities.

Lightweight expanded clay granules provide a low weight of products, and many times increase its energy-saving properties. The cement in this building material ensures its strength and stability.

Important! In the process of forming blocks, voids are formed, which affects an additional reduction in the weight of the products.

Today, the construction of houses from expanded clay concrete blocks is a ubiquitous phenomenon.

Previously, at the plants, where expanded clay was produced in the form of granular porous material for use in construction as a bulk insulation, the production of blocks was related to a side activity. The price of the products was not high, since technically sophisticated equipment was not used for their manufacture. Limitations in the use of such products were associated with their narrow range.

Modern producers of expanded clay concrete have not made changes to the manufacturing technology of products, as before, they only contain natural components - concrete and expanded clay filler. Building a house from expanded clay concrete blocks allows you to get housing that is environmentally friendly and optimal microclimatic indicators.

Block making

Important! Depending on the amount of expanded clay filler, the product has certain indicators of density and weight. Thermal conductivity is higher in those blocks that have higher density and weight. The density of products varies from 500 to 1800 kg / m3. The larger the expanded clay granules, the stronger the material, but colder.

Even given the low cost of products, many people prefer to make them with their own hands on a construction site. It is profitable and easy to do it yourself, having a concrete mixer and special forms, where concrete with expanded clay filler is poured.

Positive and negative material properties

Storage of expanded clay concrete

Expanded clay concrete blocks have found application not only in the construction of private houses, but also in monolithic construction as a material filling external and internal openings. This material has a significant effect on reducing the cost of construction.

Building a house from expanded clay concrete blocks will be an excellent solution, due to the many positive qualities of the material:

- Due to the fact that the material has a low thermal conductivity, the thickness of the walls can be small, and the load on the foundation is significantly reduced. This is important if you want to reduce the cost of construction, as well as in conditions of unreliable soils;

- Due to the fact that the material is vapor permeable, favorable microclimatic conditions are created in the premises;

- The material has high sound insulation properties, and also affects the reduction of the noise level in the room;

- For a house built from this material, deformation and shrinkage processes are not characteristic;

- Low material cost;

- It turns out quickly to build a house from expanded clay concrete, due to the fact that the products are larger than brick in size. There is also a solution saving;

- The material is environmentally friendly, fireproof and durable;

- Rodents and insects do not start in it;

- During the installation of internal and external finishing materials, their reliable fixation is ensured.

The dimensions of the products significantly exceed the brick

This material also has disadvantages that you need to know about:

- High-quality waterproofing and wall insulation is required;

- It is necessary to make careful calculations before choosing the type of foundation, since the weight of the blocks is still higher than that of other lightweight concrete;

- The material cannot be used for the foundation;

- Unaesthetic appearance and low moisture resistance require mandatory exterior decoration of the house;

- So that the strength of the walls does not decrease, it is necessary to complete the exterior decoration no later than two seasons after the construction of the house.

Sizes and main types of expanded clay blocks

External cladding made of bricks

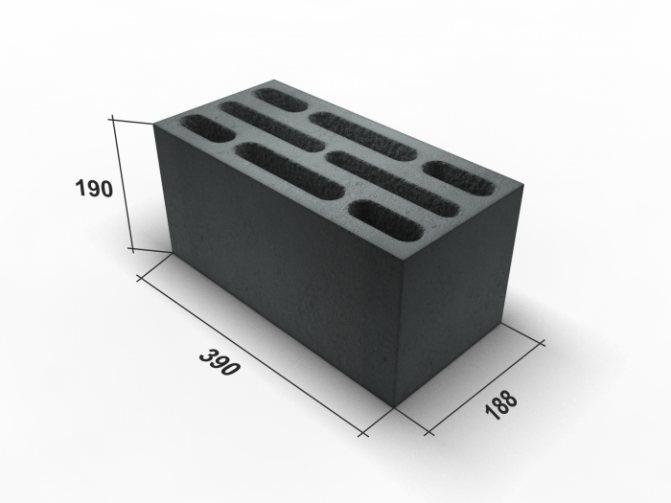

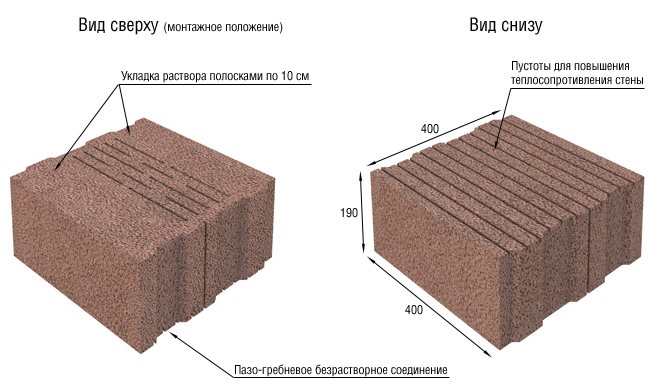

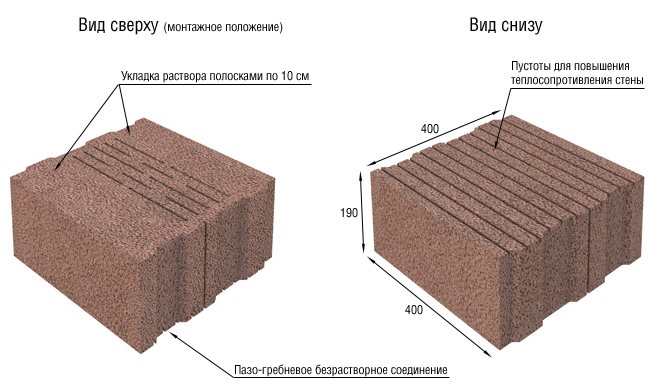

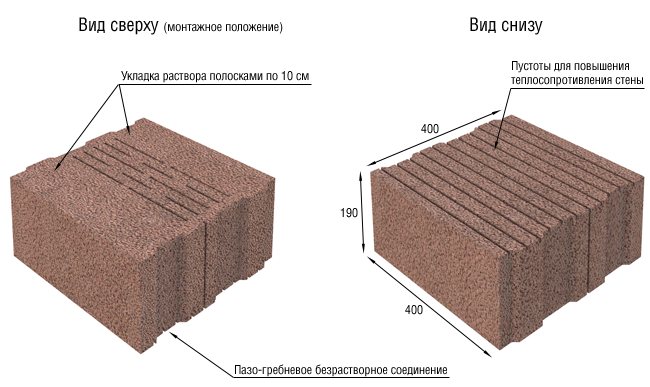

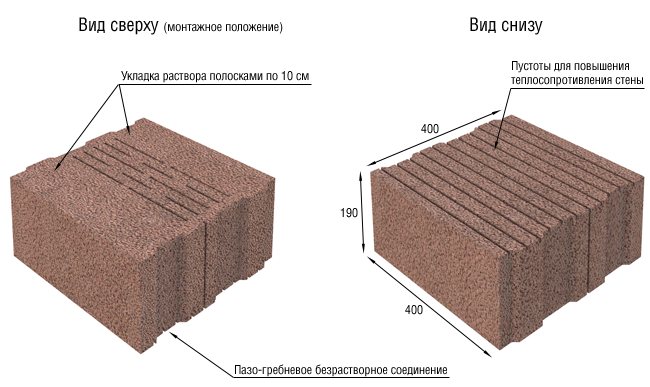

Expanded clay concrete blocks during manufacture can have different sizes, but the most common in construction are products with a length of 40 cm, a width and a height of 20 cm.

Such blocks are larger than bricks, but less foam and gas blocks due to the fact that their weight is greater.It is products of this weight that can be used without the involvement of special machinery and equipment on the construction site.

Front brick finish

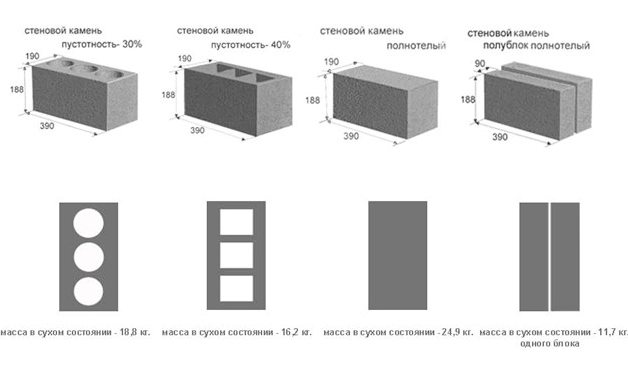

Building expanded clay blocks can be hollow and solid. Due to their great strength, with the help of the latter, sufficiently reliable load-bearing walls and structures are erected.

Internal partitions are erected using hollow products. They are also used when it is necessary to create an additional thermal insulation layer. The width of such products is smaller than that of standard blocks.

The process of one-time construction, insulation and front finishing

You can reduce the amount of mortar and increase the speed of construction using tongue-and-groove building blocks. When using such products, the probability of the formation of cold bridges is practically reduced to zero, due to the tight fit of the elements to each other and a thin layer of solution between them.

Loose expanded clay as insulation

Also, products from expanded clay concrete are divided into front and ordinary. Facial products do not need subsequent finishing, since they initially have a decorative front layer. Walls erected from ordinary elements are subsequently subject to final finishing.

Torn stone face elements

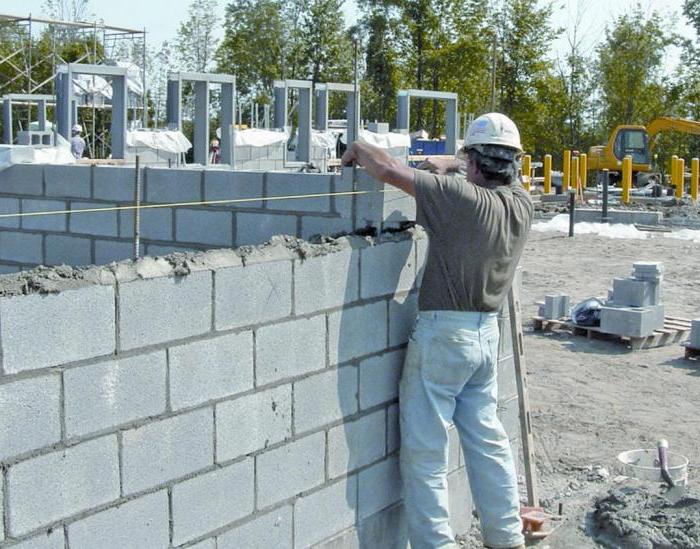

Specifications

Corpulent elements

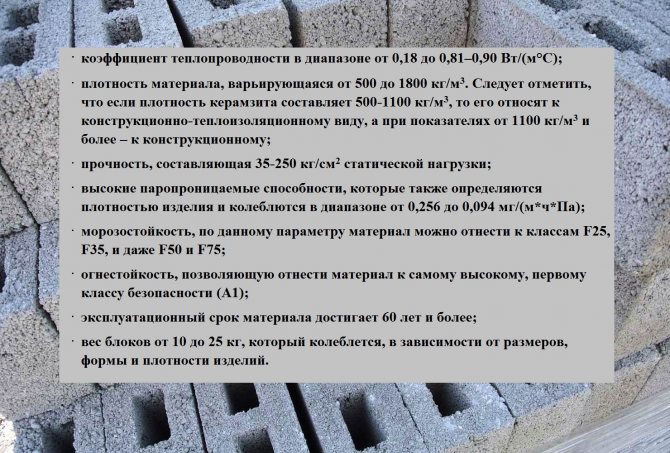

Expanded clay concrete has many positive properties, the main of which is the ability to select a material with the required thermal conductivity. Depending on the density, the products are structural and structural and heat-insulating. The photo below describes the main properties of the material.

Properties of expanded clay concrete

When calculating the thickness of the walls and the required amount of material, they use special markings that provide comprehensive information about the material:

- "TO" - this letter can be found on all products made of expanded clay concrete and means that it is an artificial building stone;

- "FROM" - wall, "L" - facial, "R" - privates, "P" - partition elements. This is a classification according to the purpose of products;

- "UG" - element for corner connection, "PZ" - an element for dressing seams, "PS" - hollow and other designations indicating the specificity of products;

- Then the length of the product and technical indicators are indicated - strength, frost resistance, density.

Example: KBSL-50-M25-F35-D600 GOST - expanded clay concrete wall facing block 50 cm long, compressive strength M25, frost resistance F35, average density D600. How to build a house from expanded clay concrete blocks will be described below.

Nuances you need to know during construction

In order for your lightweight aggregate house to stand for a long time, be warm and reliable, it is important to familiarize yourself with the intricacies of construction technology from lightweight aggregate concrete blocks.

The first moment is to choose the type of material for work. For example, if you plan to build a low-rise house, then the best option for work will be structural and heat-insulating expanded clay concrete blocks, whose density is in the range of 700–1200 kg / m3. Less light and dense materials are suitable for insulation, but multi-storey buildings are erected from heavy (structural) blocks.

Important! The lower the density of the material, the better its thermal insulation properties, and vice versa.

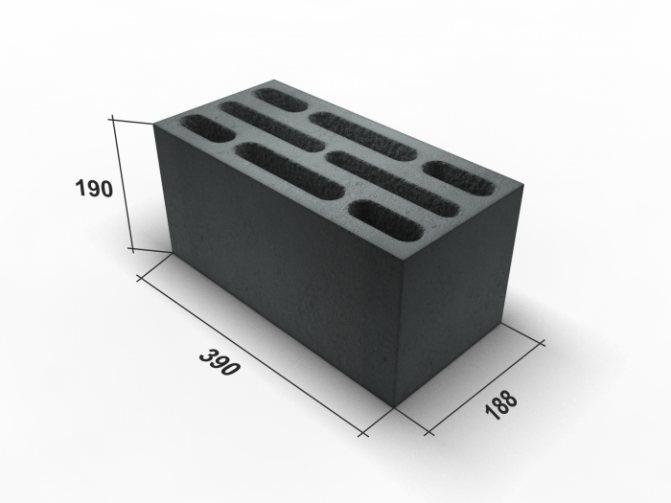

The second point is that it is important to choose the right size of the products. If you want to make your home warm while reducing energy costs, then the walls of the house should be at least 40 cm thick. One of the popular block sizes in the construction of load-bearing walls is 190 × 188 × 390. Walls made of blocks, the thickness of which is from 90 to 120 mm, are used as self-supporting partitions of the house.

The third point - the foundation for a house made of expanded clay blocks must be made strong and in-depth.The depth of the foundation is selected taking into account the type of soil, the freezing point and the location of groundwater, however, it is not less than 1 m.Make sure to make a sand cushion with a layer of 20 cm, and also fill in an armored belt of concrete of 20 cm.In this case, the frame consists of 5 or 6 rods of reinforcement Ø18 mm. If the soil settles, then the walls and foundation of the house made of expanded clay concrete will not crack.

The fourth point is that it is better to do the insulation and decoration of the building at the same time - this is beneficial in order to save money. That is why you need to choose the facing material and insulation in advance. You can sheathe the walls of the house with siding, blockhouse, facing brick or facade plaster. And as a heater, mineral wool or foam is suitable.

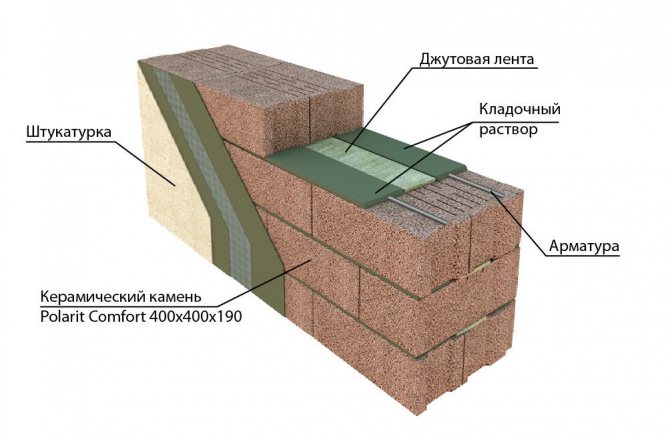

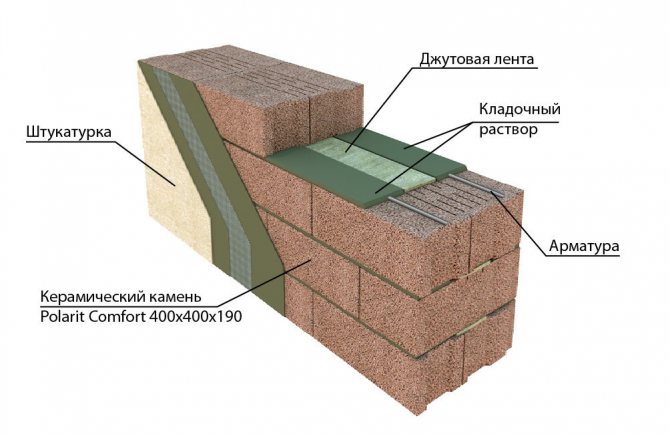

Advice! In order to prevent the formation of cold bridges through the seams, jute tape is used when laying the house. It fits in the middle of the masonry, not allowing the cold to pass through the solution.

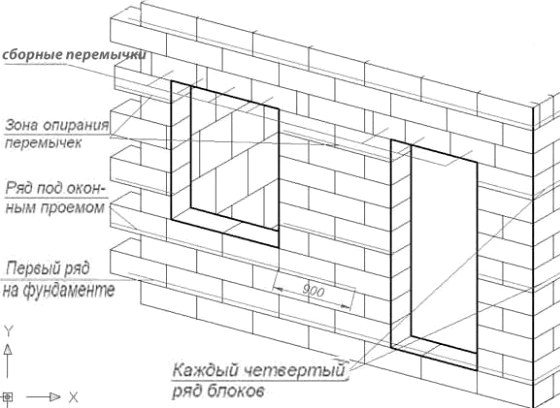

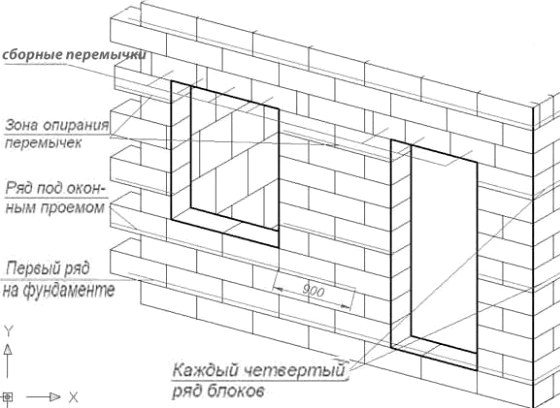

The fifth point is that the laying of blocks of expanded clay concrete must be reinforced. This is done every 3 or 4 rows using reinforcement rods, Ø12 or 14 mm. In the blocks, grooves or grooves are made, where the rods are laid. Then everything is sealed with cement mortar.

Advice! Armopoyas must be done before the installation of floor slabs, if the claydite-concrete house is two-story, as well as in front of the roof.

Warming

To insulate houses from expanded clay concrete blocks, different materials are used outside: mineral wool with a foil layer (aluminum foil provides vapor barrier to this material), glass wool, polystyrene, foam.

Important! To increase the service life of the thermal insulation layer, it is necessary to equip a vapor barrier on top of it.

The most effective and affordable material is considered to be mineral wool with a foil layer (produced in the form of dense and durable slabs), it is perfectly suited for such a "breathing" material as expanded clay concrete.

The technology for laying the thermal insulation layer is quite simple:

- we clean the outer walls from dust and treat with a primer for outdoor work; knead the glue according to the instructions on the package; apply glue around the entire perimeter of the mineral wool sheet and additionally in the middle; glue the plates to the wall in a checkerboard pattern, starting from the bottom from one of the corners; after 1 day the glued mineral slabs are fixed with plastic dowels ("umbrellas"); we install the reinforcing layer (special facade fiberglass mesh): press it into the layer of applied plaster glue with a wide spatula; put another layer of special glue on the dried reinforcing layer and cover with some or facade decorative plaster; after final drying, we paint.

Choosing blocks for building a house from expanded clay concrete

Just before you start building your dream home, you need to prepare the material. The basis of construction is blocks of expanded clay concrete. Above, we mentioned a little about their varieties, but we want to dwell in more detail on the choice of products. According to the purpose, blocks of expanded clay concrete are:

- Heat-insulating type (500-700kg / m3)

- Construction type (1200-1800 kg / m3).

- Structural and heat-insulating type (700-1200 kg / m3)

Which one is suitable for building a house? If you want to build a cottage, then choose structural expanded clay concrete blocks. And when your goal is a small warm house, then choose structural and thermal insulation blocks. They are quite durable and have excellent thermal insulation performance. Now that you have decided on the type of expanded clay concrete blocks, let's look at how the construction work begins.

Advantages and disadvantages of expanded clay blocks

Before discussing the advantages and disadvantages of a lightweight aggregate concrete block, I would like to say that such material is widely used not only in the construction of low-rise buildings, but also in the construction of private houses and other utility structures. The product is also popular in the construction of monolithic structures, where it acts as a wall material to fill openings, both internal and external.

Expanded clay concrete for building a house

If we consider the price category, it becomes obvious that the use of expanded clay concrete blocks can be a good way to reduce financial investments in the construction of a multi-storey monolithic-frame structure.

In addition, expanded clay concrete blocks have the following advantages:

- have a low coefficient of heat conductivity (this helps to build a wall of small thickness and reduce the load on the foundation of the building);

- the blocks are distinguished by a vapor-permeable feature, which creates the most favorable environment for a person in the room;

- a high level of sound and noise insulation (it is also worth noting that the product is capable of reducing the amount of noise);

- high level of strength avoids shrinkage and deformation of the structure;

- affordable cost;

- the material allows you to shorten the time for the construction of a building due to the large dimensions of the blocks, as well as save good money on such masonry, which brick decoration cannot boast;

- the product is environmentally friendly, resistant to high temperatures and has a long service life;

- on the market, blocks are presented in a huge variety, which makes the embodiment of any architectural or design idea available.

The disadvantages include the following features:

- blocks are capable of forming bridges of cold (but this problem can be easily solved by subsequent cladding or heat-insulating material);

- the material does not have sufficient moisture resistance, therefore, the finish will require additional processing with protective agents;

- the weight of the blocks is slightly more than other counterparts made of aerated concrete, so you need to take care of a solid foundation;

- blocks cannot be used when constructing a foundation.

I would like to immediately note that the arrangement of external surfaces with expanded clay concrete blocks should not stay for a long time without subsequent registration, because this will significantly reduce the service life of the building.

The first necessity is designing a house

Whatever one may say, everything starts with this step. For the project you need to pay a lot to a specialist, however, without him, both expanded clay concrete and any other house cannot be built. This is the same as going from Russia to Africa without a map. And you will not be given a building permit without documents. Therefore, the first thing you should do is order a construction project from a specialized company.

Together with you, the architect will create not only the exact dimensions of the house, its structure, and other details, but will also be able to draw up an estimate. It indicates the amount of material, its type and the cost of all work. Only after that you can start building a house from expanded clay concrete blocks with your own hands.

Advantages of expanded clay concrete houses

Walls made of expanded clay blocks have many advantages:

Low thermal conductivity. The source of this parameter is the porosity of the filler.

Thanks to it, the building retains heat well. Low weight. This parameter becomes possible due to the lightness of expanded clay. In addition, in addition to solid analogs, manufacturers also produce hollow blocks.

This further reduces the weight of the material. Thanks to this, the walls from it do not put pressure on the foundation. Expanded clay concrete is durable and strong. Walls made of it can easily withstand the loads from lintels, girders and floor slabs. The cost of the material is low.

This makes it possible to carry out low-cost construction. Expanded clay concrete walls shrink little.Thanks to this, cracking does not occur on them. The material is environmentally friendly. Therefore, it does not emit any harmful substances. Porous concrete has excellent sound insulation properties.

As a result, the house will be well protected from external sounds. Plastering walls from expanded clay concrete blocks is very convenient. Cement-sand mortar adheres well to them. Thanks to this, finishing work can be carried out at a lower cost.

How to make finishing the foundation with panels with your own hands, read this article. Due to their not very large dimensions and lightness, blocks of expanded clay concrete are relatively easy to lay. Therefore, you can build a house from them on your own.

The basis of the foundations is the foundation of a house made of expanded clay concrete

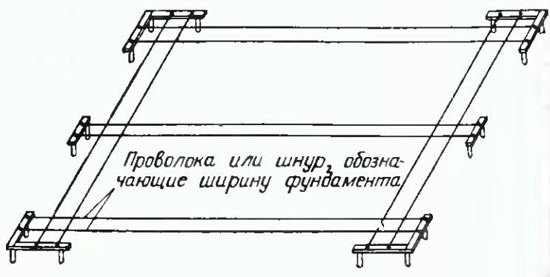

When you have the required amount of materials, a detailed plan, a finished site and communications carried out, you can get to work. The foundation for the building is everything! It depends on him how durable a house made of expanded clay concrete will be and how long it will stand. It is not surprising that almost half of all funds are spent on the foundation, if not more. So what is your task? Let's walk through the process step by step. The basis will be a strip monolithic foundation, ideal for the construction of such a house. The device instruction is as follows:

- To begin with, the site is cleared of all unnecessary: garbage, vegetation, unnecessary trash.

- Further, the markup is done according to the project. The twine stretched between the rods plays the role of a landmark, which indicates the place of digging a trench. It exactly follows the contours of the foundation.

- Based on the markings, you will have to dig a trench. The depth and width thereof are selected in advance at the design stage. The walls of the trench should be flat, everything is controlled by a plumb line and level.

- At the bottom, a sand cushion and an armored belt are arranged, according to the data given above.

- Removable formwork is made from boards, OSB sheets or plywood. It is strengthened and covered with a film from the inside.

- Inside the trench, you need to make a frame of reinforcement so that the concrete becomes reinforced after pouring. So, it will not crack and become much stronger.

- At the end, it remains to fill everything with concrete. As it is poured, the composition becomes denser. It is best to do everything in one day, without leaving the concrete to dry out.

- The surface is leveled and left to dry completely.

The strip foundation for a house made of expanded clay concrete blocks will dry for about a month. For this time it is better to protect him. After 10 days, the formwork can be removed.

Advice! If the weather is hot, it can be moistened periodically to prevent cracking of the concrete.

Foundation

Professionals say that a strip foundation is most suitable for building a house from expanded clay concrete blocks (by the way, as well as for a monolithic house). The technology of its arrangement is simple, so you can easily make the foundation necessary for your house from expanded clay concrete blocks by yourself. We carry out the following works:

- we dig a trench under the foundation (the width exceeds the width of the wall by 10-15 cm, and the depth is 50 cm); on the bottom we put a pillow of sand (height - 15 cm); abundantly moisten the sand with water and ram; pour a layer of rubble (15 cm high) ; tamp crushed stone; equip a waterproofing layer (for example, roofing material); we mount the formwork, which we must waterproof; inside the formwork we make a reinforcing frame; pour concrete; after 5 days we make stripping, the upper and side surfaces of the foundation are waterproofed with mastic and roofing material; cavities between the foundation and the trench fill with sand; take a break for 1-3 months so that the foundation has settled; we begin laying the walls.

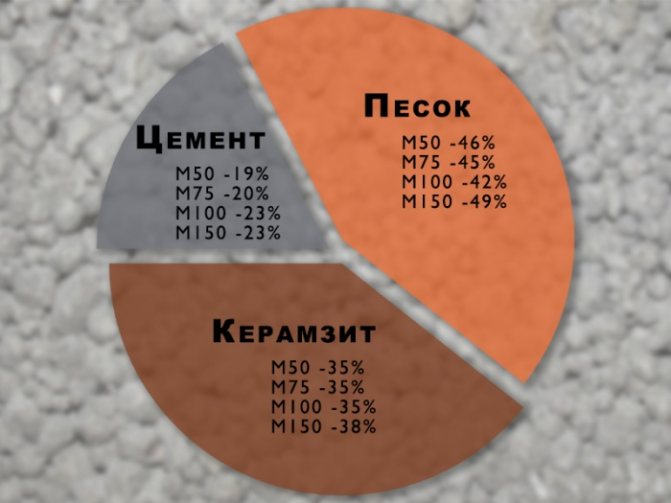

We build walls from expanded clay concrete blocks

When the foundation of the house is dry, it can be waterproofed using mastic. Everything is now ready to start building the building box. What is the construction technology? Everything is quite simple, here are the instructions step by step:

- Since the foundation has shrunk in 30 days, its surface may not always be flat. To eliminate this phenomenon, you can level the surface with mortar. Quality and evenness should be checked by level

- When the mortar hardens, lay on top of 2-3 layers of waterproofing material (roofing felt). Lubricate the layers with mastic.

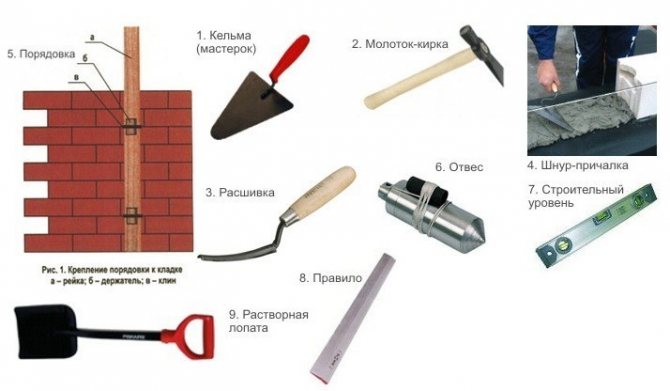

- Now you can start laying the material. The technology is practically no different from brick laying. You need blocks, mothers, mortar and thread with nails. It all starts with placing corner blocks. If the wall is more than 10 m, then the block is also placed in the middle. Your task is to ideally align the expanded clay concrete blocks and pull a thread between them for orientation. The evenness of the entire structure will depend on this.

- The thread being pulled should indicate the position of the block. Based on it, you should expose the first row of expanded clay concrete blocks around the perimeter using mortar. Check if you are doing everything smoothly using a level and a plumb line. You can adjust the blocks by tapping a rubber mallet.

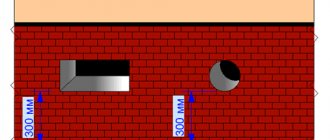

- When the first row of sides is ready, proceed to the second. Everything is done identically, only with blocking. The recommended wall thickness of expanded clay concrete blocks is from 40 cm. Do not forget to make doorways and windows.

- After 3 or 4 rows, reinforce the masonry around the perimeter, complementing the row of blocks with reinforcement rods in the grooves.

- The work is carried out until you reach the desired level. The last row is necessarily reinforced, since it will be the main load of the roof of the house made of expanded clay concrete blocks.

That's all, the box of the house made of expanded clay concrete sides is ready. It remains to make the roof. If before that everything was done according to technology, then you will not have any problems.

Calculation of expanded clay concrete blocks at home. Calculation example

Before purchasing blocks, you will need to calculate the required number of blocks. As an example, we will give the calculation of the required material for a building measuring 10 × 10 m. Let it be a two-storey building with a ceiling height of 3 m and a total area of 200 m².

First, the length of the outer walls along the perimeter is calculated: 10 + 10 + 10 + 10 = 40 m.

Then it is necessary to determine their area, for this purpose the perimeter of the house is multiplied by the total height of the two-story house: 40 ∙ (3 + 3) = 240 m².

After that, you need to determine the required number of blocks.

To do this, multiply the area of the walls by the number of blocks in 1 m². If this is an ordinary material, the dimensions of which, taking into account the seams, are equal to 40 × 20 × 20 cm, then it is contained in one square meter of 12.5 pieces. So, on the walls of the building you need: 240 × 12.5 = 3000 blocks.

In the given example, the openings of doors and windows were not taken into account. When making calculations, subtract their dimensions from the area of the walls to get the exact amount of material required.

Description and characteristics of blocks

The production of expanded clay blocks is a simple process. First, concrete is mixed from sand, cement and water, and then expanded clay is added to the mixture. It is a lightweight, rather porous and at the same time durable material made from clay. Ready-made expanded clay blocks are lightweight and have low thermal conductivity.

The sizes of expanded clay concrete blocks can be different, but most often the following parameters are observed - length - 40, width and height - 20 cm.Products are produced in 2 types:

One type of such material that can be found on sale is hollow.

- hollow;

- full-bodied.

The latter are more durable, therefore, the load-bearing walls of houses, cottages and other structures are built from them. But they prefer to build partitions from hollow ones or use them for additional thermal insulation. From expanded clay blocks, you can build a one-story, two-story and even a three-story house. However, it is important to correctly calculate the load, since structures made of this lightweight material are not as strong as, for example, sand-lime bricks.

Counting the number of blocks

In order to accurately determine the volume of the purchase, you need to make a preliminary calculation of expanded clay concrete blocks at home. For this, the length of all external walls is summed up and the length of the internal partitions of the building is calculated separately.

The results obtained are multiplied by the height and thickness of the walls and partitions. Then the total volume of the masonry is divided by the volume of one standard block - 0.014 m3. This is how the amount of material is obtained in pieces. As a working margin, 20% is added to the final figure, or, when calculating, the volumes of window and door openings are simply not subtracted from it.

Correct material calculation

Diagram of the structure of the expanded clay concrete block.

In any construction, it is necessary to calculate the amount of consumables. In order to carry out this procedure, there must be a ready-made plan for the future construction on hand. The length of all walls is added up, and the length of all partitions is added to the result obtained. The resulting figure will indicate the total length of the house. After that, you need to multiply by the planned height of the ceilings.

At this stage, you should think about two points: firstly, what size will be used claydite-concrete blocks, and secondly, what will be the thickness of the walls, in one, two or more rows.

The previously calculated amount must be multiplied by the estimated thickness. This calculates the total volume.

But experts recommend purchasing building materials with a margin, since damage to blocks often occurs during construction.