The use of a water gun with solid fuel equipment

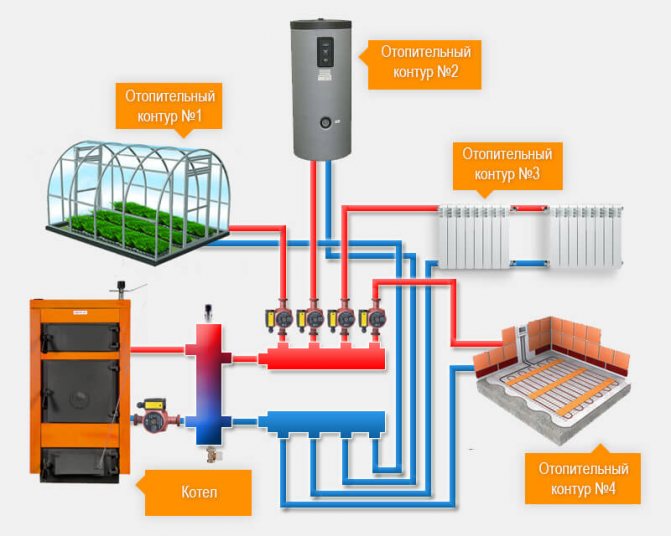

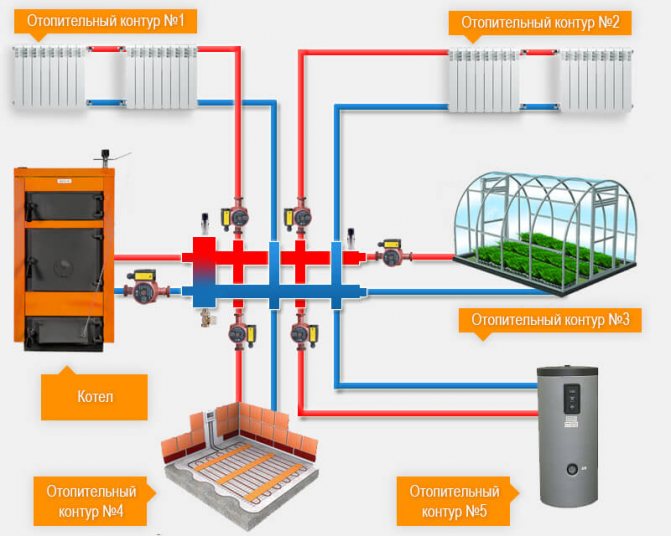

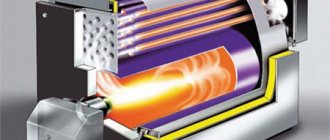

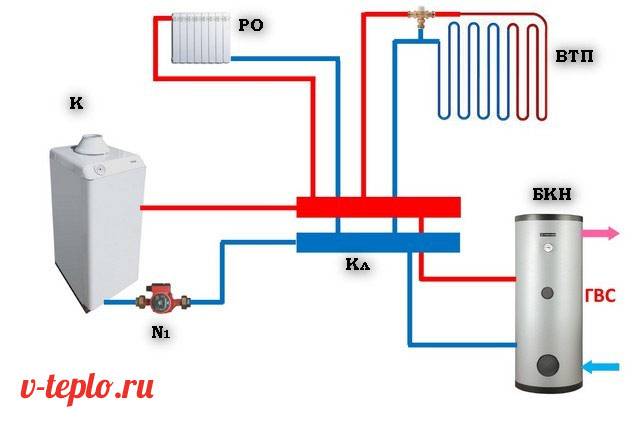

When using a solid fuel unit, the hydraulic separator is connected at the entry - exit point. This option for connecting a different type of heating device ensures the selection of the optimal and individual temperature regime for all components separately.

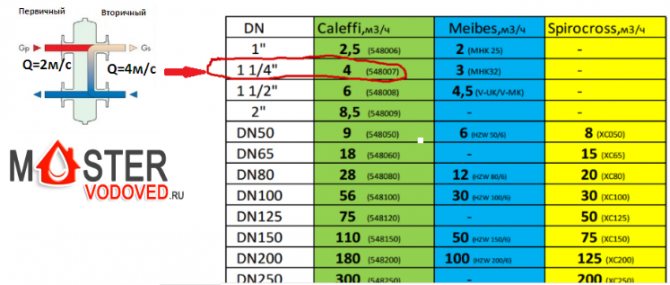

Today, consumers, having figured out how the hydraulic arrow for heating works, prefer ready-made products that are on sale. Choose a hydraulic separator from the catalog, based on the power of the unit and the maximum water flow.

Diy thermal separator

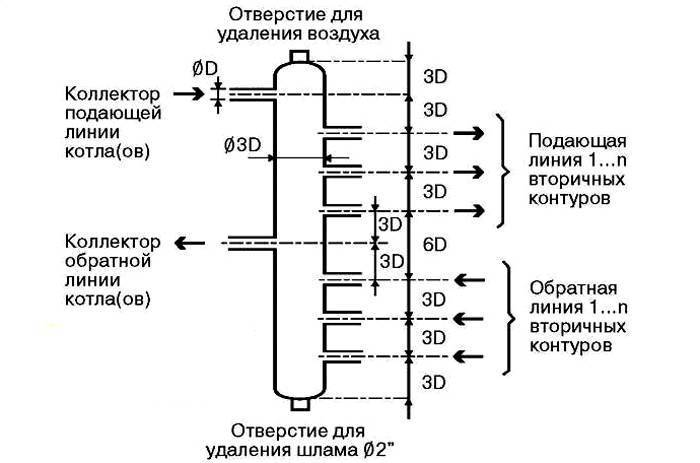

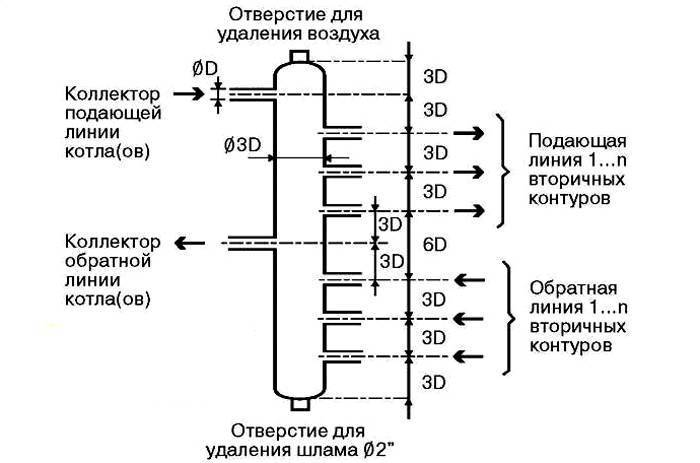

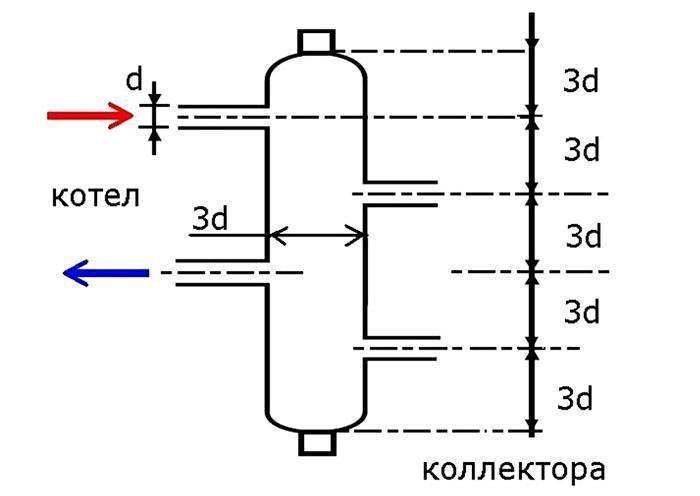

The design of the hydraulic arrow is so simple that it allows the owner of a country house to assemble it on his own without much difficulty. An important manufacturing stage is the correct calculation of the diameters of the branch pipes and the separator. The simple design of the unit is carried out according to the rule of 3 diameters.

It is possible to make a water gun with your own hands.

In this case, the diameter of the nozzle is taken as a basis, which is the same for all inlet and outlet circuits. The total diameter of the hydraulic arrow will be equal to 3 diameters of the branch pipe, and its length should be 4 diameters of the separator. The axes of the inlet and outlet pipelines will be located from the ends of the structure at a distance of one diameter of the thermal separator.

This size ratio allows you to extinguish the speed of movement of the coolant to the desired results. In the future, you only need to select pipes of suitable sizes and carry out welding work. Such a simple design will work successfully in small heating systems.

The principle of operation of the hydraulic arrow:

How to calculate a hydraulic arrow: the principle of its operation and characteristics

More recently, the heating system has been flawed. The heating did not work when one of the components was poorly regulated, but when it began to be regulated, the balance of the entire system was disturbed. I had to start all over again.

The only dimension when choosing a hydraulic arrow is the diameter of the inlet pipes. The highest recommended speed of water movement through the hydraulic arrow is about 0.2 m / sec.

It was difficult to find pumps for this system, and the boilers had internal thermal fluctuations. Currently, the water gun for heating helps to cope with the problems that arise at the time of starting the heating system.

Hydro arrow characteristics:

- Water supply procedure;

- Location of incoming and outgoing pipes;

- Water drainage method;

- System capacity.

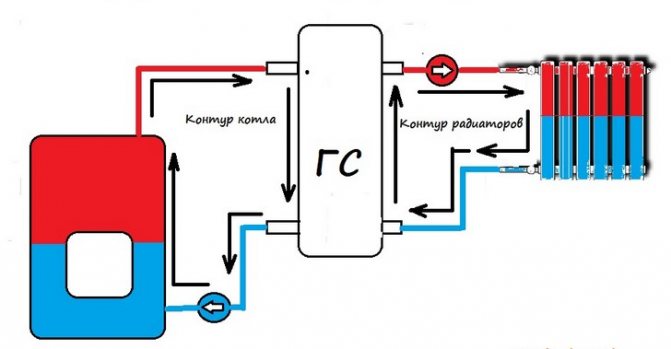

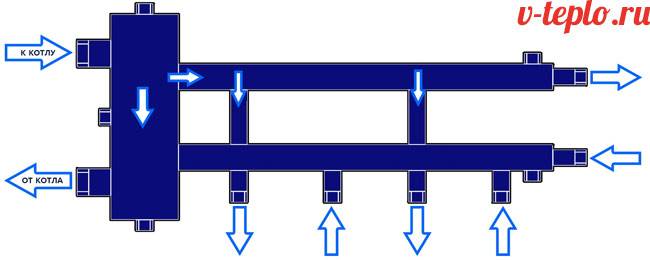

They may look different, but the essence is the same for all of them. It's just a pipe, with pipes welded to it. For a hydraulic arrow, a pipe is suitable not only with a round section, but also with a square one. Delivery and outgoing pipelines are connected to the branch pipes. The heating sequence is divided into circuits. The small circuit is the boiler - the hydraulic switch, the large one is the boiler - the hydraulic switch - the consumer.

What do you need to know?

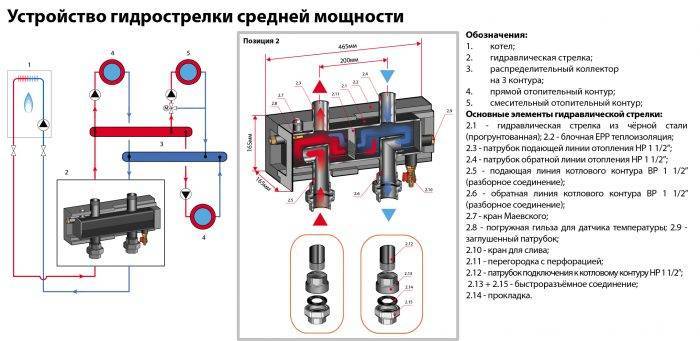

The hydraulic arrow is an additional unit, which is located in a vertical position. It is made in the form of a cylinder, but it can also have a section in the form of a rectangle. Nozzles are cut into this device, which are suitable for the boiler, as well as for the heat exchange circuits. In this device, the division of a small circuit, as well as extended heating circuits, is carried out. Traditional low loss header designs are often used.

Device diagram

Such a device maintains thermal and hydraulic balance. With its help, it is possible to achieve low pressure losses, as well as heat energy and productivity. The design allows to increase the efficiency of the heating system and reduce the resistance in the system.

The important characteristics include indicators of the diameters of the nozzles and the main device. The rest of the parameters can be found from the standard schemes.

Built-in hydraulic catcher

The program has some nuances:

in the calculations, the power of the heating equipment is necessarily used

To determine this indicator, you can also use a special calculation program; an important characteristic is the speed of movement of the coolant in the vertical direction. The lower this indicator, the better the coolant will get rid of gases and sludge.

Also, in this case, a smoother mixing of the cooled and hot streams will occur. The most optimal option is 0.1-0.2 m / s. You can select the required parameter in the program; a special characteristic is the operating mode of the entire structure. This takes into account the temperature levels in the line passing from the heater. All indicators are entered into the calculator.

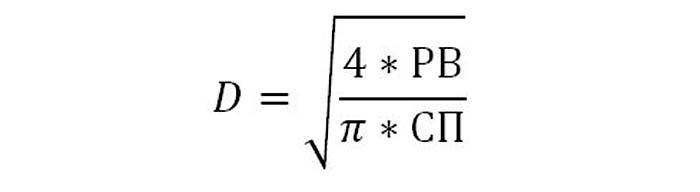

A special calculation formula is provided in the applied calculation algorithm. As a result, a result will be shown, which will show the suitable diameter for the hydraulic arrow, as well as the section of the pipes used. The rest of the parameters of the linear type are even easier to determine.

Before proceeding with the installation of such a device, it is worthwhile to study all the functions of the hydraulic arrow.

Related article:

Save time: select articles by mail every week

Consider how to calculate the hydraulic arrow of the heating system

Hydrostrel is an integral part of the heating system. Thanks to this device, the pressure in the system is regulated and temperature drops in it are excluded.

In order for the boiler of the heating system to work smoothly and more economically, a hydraulic arrow is used. Achieving the hydraulic balance of the system without this element will be a very difficult task.

When choosing a hydraulic arrow, it is necessary to pay attention to such a parameter as maximum power. This indicator can be from 50 kW to 300 kW. You also need to know that these devices are designed to work with a different number of circuits. On average, their number ranges from 3 to 5 circuits. The diameter of the hydraulic arrow is also an important indicator. It increases in direct proportion to the power of the boiler room and the complexity of the heating system.

The body of the hydraulic arrow is usually made of steel. To increase the service life, stainless steel is used. The use of a hydraulic switch has a number of advantages that have been appreciated by those who have installed it in their heating system. The water gun for the heating system, which is used in modern installations, makes it possible to avoid many problems that may arise during operation.

Advantages of a hydraulic arrow:

- Combines heating circuits;

- Ensures good performance of devices;

- Does not allow temperature drops;

- Extends the life of the equipment;

- Prevents the "thermocline" phenomenon.

The most dangerous in the heating system is the "thermocline". This phenomenon happens when there is a sharp jump in temperature when hot and cold water comes into contact. This can greatly damage the boiler. However, this can be avoided by installing a low loss header in the heating system. It is safe to say that the program for ensuring the safety of the heating system with a hydraulic arrow is fully implemented.

Popular manufacturers

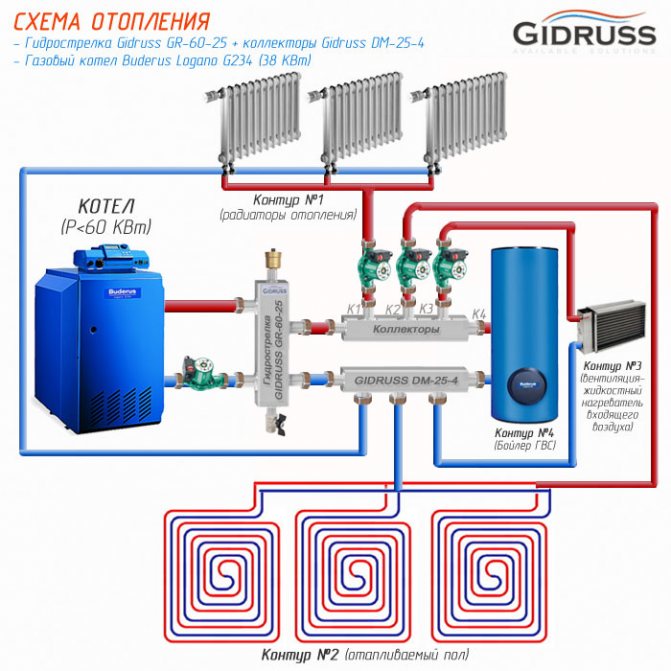

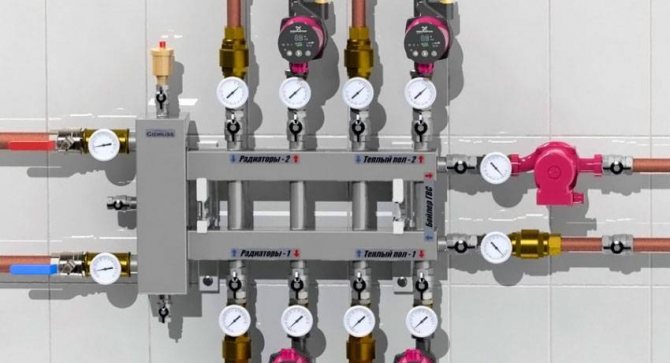

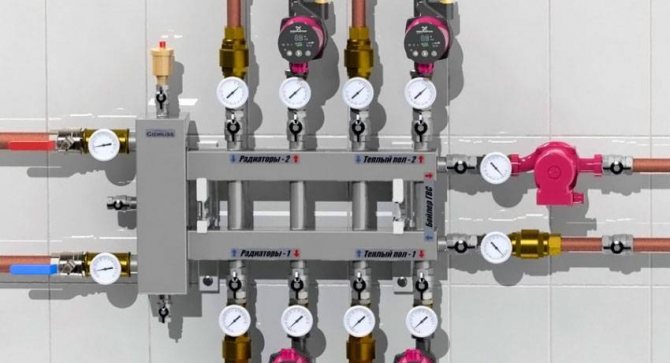

There are not so few companies engaged in the production of hydraulic dividers for heating networks as it might seem at first glance.However, today we will get acquainted with the products of only two companies, GIDRUSS and Atom LLC, as they are considered the most popular.

Table. Characteristics of the low loss header manufactured by GIDRUSS.

| Model, illustration | Main characteristics |

| 1.GR-40-20 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 1 kilowatt; - its maximum power is 40 kilowatts. |

| 2. GR-60-25 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 10 kilowatts; - its maximum power is 60 kilowatts. |

| 3. GR-100-32 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 41 kilowatts; - its maximum power is 100 kilowatts. |

| 4. GR-150-40 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 61 kilowatts; - its maximum power is 150 kilowatts. |

| 5. GR-250-50 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 101 kilowatts; - its maximum power is 250 kilowatts. |

| 6.GR-300-65 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 151 kilowatts; - its maximum power is 300 kilowatts. |

| 7. GR-400-65 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 151 kilowatts; - its maximum power is 400 kilowatts. |

| 8. GR-600-80 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 251 kilowatts; - its maximum capacity is 600 kilowatts. |

| 9.GR-1000-100 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 401 kilowatts; - its maximum capacity is 1000 kilowatts. |

| 10. GR-2000-150 | - the product is made of structural steel; - designed for one consumer; - the minimum power of the heater is 601 kilowatts; - its maximum capacity is 2000 kilowatts. |

| 11. GRSS-40-20 | - the product is made of stainless steel AISI 304; - designed for one consumer; - the minimum power of the heater is 1 kilowatt; - its maximum power is 40 kilowatts. |

| 12. GRSS-60-25 | - the product is made of stainless steel AISI 304; - designed for one consumer; - the minimum power of the heater is 11 kilowatts; - its maximum power is 60 kilowatts. |

| 13. GRSS-100-32 | - the product is made of stainless steel AISI 304; - designed for one consumer; - the minimum power of the heater is 41 kilowatts; - its maximum power is 100 kilowatts. |

Note also that each of those listed above for heating also performs the functions of a kind of sump. The working fluid in these devices is cleaned of all sorts of mechanical impurities, thereby significantly increasing the operational life of all moving components of the heating system.

The role of a hydraulic arrow in modern heating systems

In order to find out what a hydraulic arrow is and what functions it performs, first we will get acquainted with the peculiarities of the operation of individual heating systems.

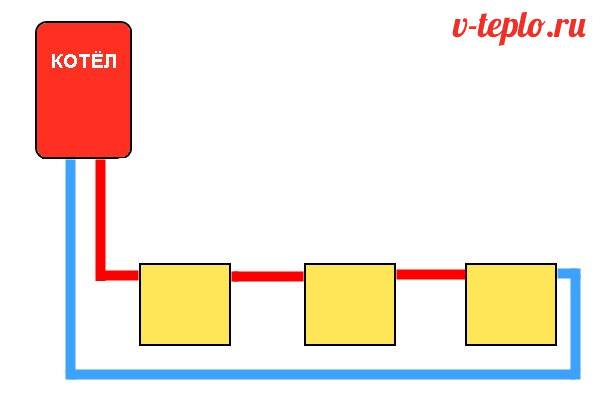

Simple option

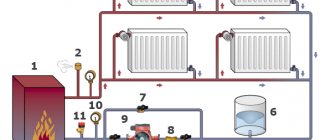

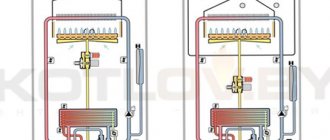

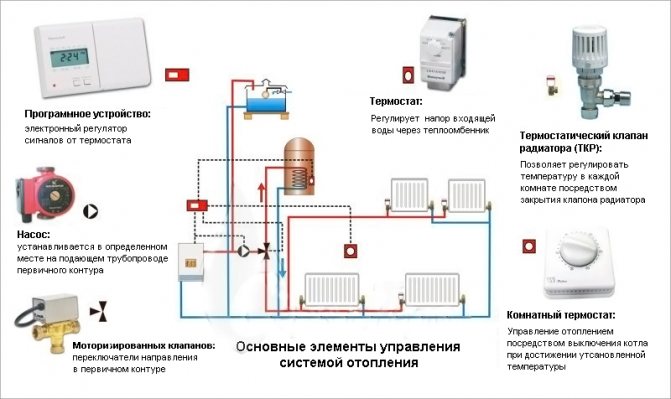

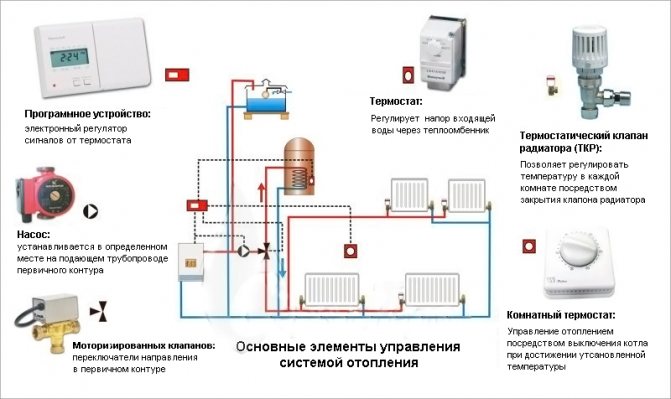

The simplest version of a heating system equipped with a circulation pump will look something like this.

Of course, this diagram has been greatly simplified, since many network elements in it (for example, a security group) are simply not shown in order to "make it easier" to understand the picture. So, in the diagram, you can see, first of all, a heating boiler, thanks to which the working fluid is heated. A circulation pump is also visible, through which the liquid moves along the supply (red) pipeline and the so-called "return".What is characteristic, such a pump can be installed both in the pipeline and directly in the boiler (the latter option is more inherent in wall-mounted devices).

Note! Even in a closed loop, there are heating radiators, thanks to which heat exchange is carried out, that is, the generated heat is transferred to the room. If the pump is correctly selected in terms of pressure and performance, then it alone will be quite enough for a single-circuit system, therefore, there is no need to use other auxiliary devices

If the pump is correctly selected in terms of pressure and performance, then it alone will be quite enough for a single-circuit system, therefore, there is no need to use other auxiliary devices.

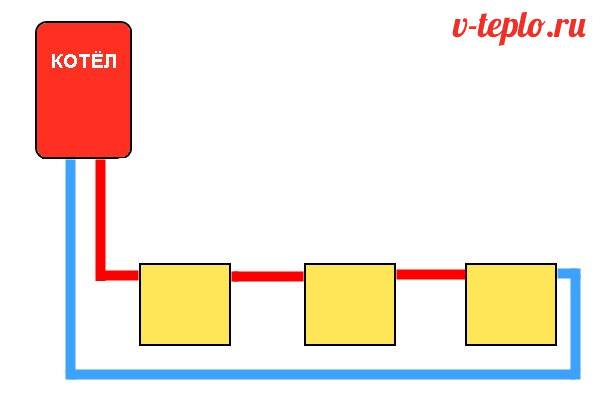

More complex option

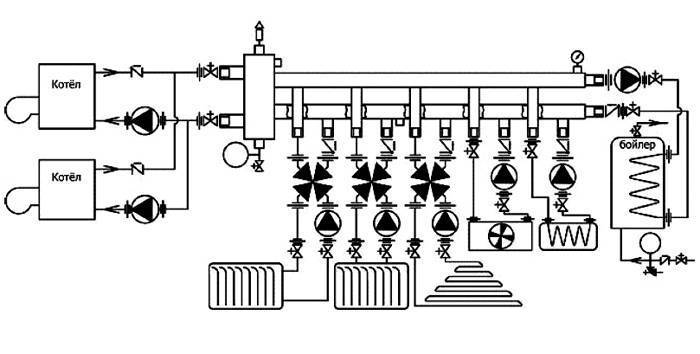

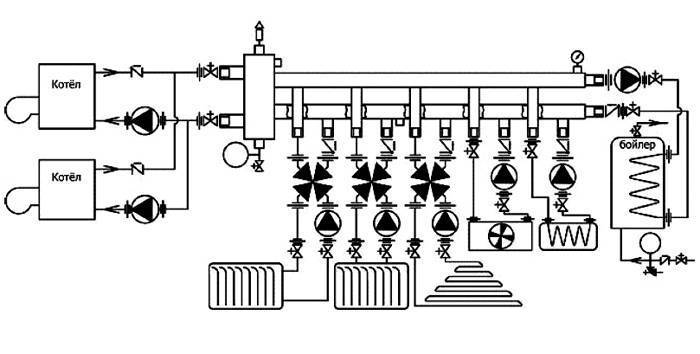

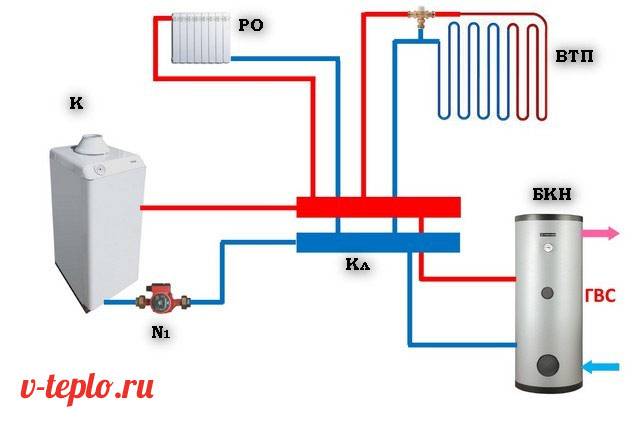

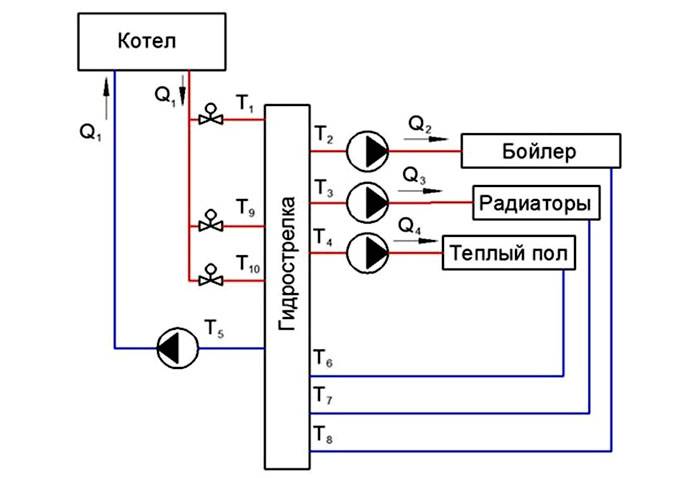

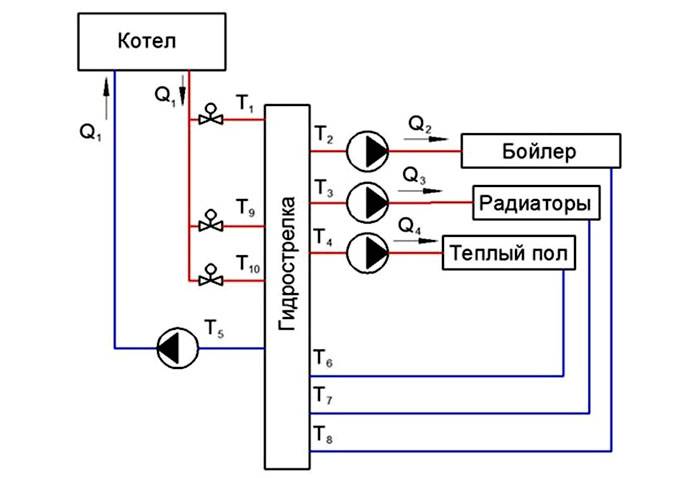

If the area of the house is large enough, then the scheme presented above will not be enough for it. In such cases, several heating circuits are used at once, so the diagram will look somewhat different.

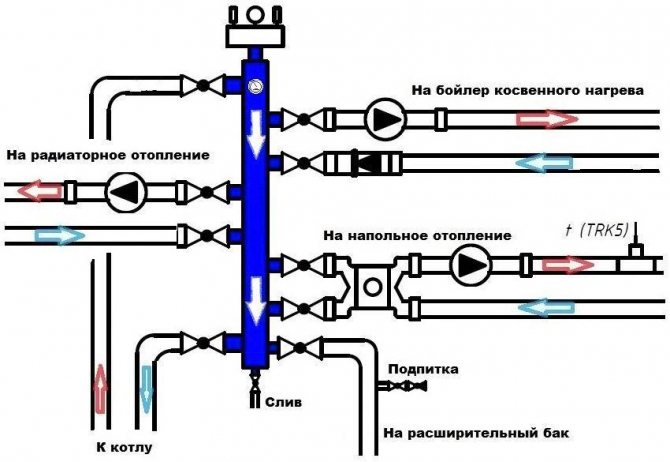

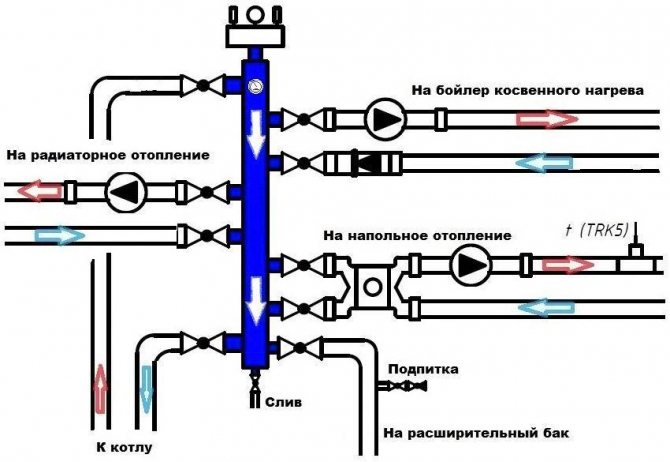

Here we see that, through the pump, the working fluid enters the collector, and from there it is already transferred to several heating circuits. The latter include the following elements.

- High temperature circuit (or several), in which there are collectors or conventional batteries.

- DHW systems equipped with an indirect boiler. The requirements for the movement of the working fluid are special here, since the temperature of heating the water in most cases is regulated by changing the flow rate of the fluid passing through the boiler.

- Warm floor. Yes, the temperature of the working fluid for them should be an order of magnitude lower, which is why special thermostatic devices are used. Moreover, the contours of the underfloor heating have a length that significantly exceeds the standard wiring.

It is quite obvious that one circulation pump cannot cope with such loads. Of course, today high-performance models of increased power are being sold, capable of creating a sufficiently high pressure, but it is worth thinking about the heating device itself - its capabilities, alas, are not limitless. The fact is that the elements of the boiler are initially intended for certain indicators of pressure and productivity. And these indicators should not be exceeded, since this is fraught with breakdown of an expensive heating system.

In addition, the circulation pump itself, operating at the limit of its own capabilities in order to provide all the circuits of the network with liquid, will not be able to serve for a long time. What can we say about the strong noise and consumption of electrical energy. But let's get back to the topic of our article - to the water gun for heating.

What are the impurities in the water?

Water is both a universal solvent and a cheap heat carrier; nevertheless, it can also cause damage to a steam or hot water boiler. First of all, the risks are associated with the presence of various impurities in the water. It is possible to prevent and solve problems associated with the operation of boiler equipment only with a clear understanding of the causes of their occurrence. There are three main groups of impurities in water:

- insoluble mechanical

- corrosive

- dissolved sediment-forming

Any type of impurities can cause malfunction of the heating plant equipment, as well as reduce the efficiency and stability of the boiler. The use of water in thermal systems that has not passed mechanical pre-filtration leads to more serious breakdowns - the failure of circulation pumps, damage to pipelines, a decrease in the cross-section, control and shut-off valves.

Typically, mechanical impurities are clay and sand, which are present in almost any water, as well as corrosion products of heat transfer surfaces, pipelines and other metal parts of the system that are in constant contact with aggressive water.

Impurities dissolved in water are the cause of serious malfunctions in the operation of power equipment:

- the formation of sticky deposits;

- boiler system corrosion;

- foaming of boiler water and removal of salts with steam.

Dissolved impurities require special attention, since their presence in water is not as noticeable as the presence of mechanical impurities, and the consequences of their exposure can be very unpleasant - from reducing the energy efficiency of the system to its partial or complete destruction.

Carbonate deposits caused by sedimentary deposits of hard water (scale formation). The process of scale formation, which occurs even in low-temperature heat-exchange equipment, is far from the only one. So, when the water temperature rises above 130 ° C, the solubility of calcium sulfate decreases, and an especially dense gypsum scale is formed.

The resulting scale deposits lead to an increase in heat loss and a decrease in heat transfer from heat exchange surfaces, which provokes heating of the boiler walls, and, as a consequence, a decrease in its service life.

Deterioration of the heat transfer process leads to an increase in energy costs and an increase in operating costs. Sedimentary layers on heating surfaces of even a small thickness (0.1–0.2 mm) lead to overheating of the metal and the appearance of fistulas, deflections and, in some cases, even pipe rupture. Scale build-up indicates the use of poor quality water in the boiler system. In this case, there is a high probability of the development of corrosion of metal surfaces, the accumulation of metal oxidation products and scale deposits.

In boiler systems, there are two types of corrosion processes:

- chemical corrosion;

- electrochemical corrosion (formation of a large amount of microgalvanic vapors on metal surfaces).

Electrochemical corrosion often occurs due to the incomplete removal of impurities such as manganese and iron from water. In most cases, corrosion occurs in the leaks of metal seams and flared ends of heat transfer tubes, resulting in ring cracks. Dissolved carbon dioxide and oxygen are the main stimulators of corrosion formation.

Special attention should be paid to the behavior of gases in boiler systems. An increase in temperature leads to a decrease in the solubility of gases in water - they are desorbed from the boiler water. This process is responsible for the highly corrosive activity of carbon dioxide and oxygen. When water is heated and evaporated, bicarbonates begin to decompose into carbon dioxide and carbonates, which are carried away with the steam, as a result of which a low pH and high corrosiveness of the condensate are provided. When choosing schemes for intra-boiler treatment and chemical water purification, one should take into account the methods of neutralizing carbon dioxide and oxygen.

Another type of chemical corrosion is chloride corrosion. Chlorides, due to their high solubility, are present in almost all available water sources. Chlorides cause destruction of the passivating film on the metal surface, thereby provoking the formation of secondary corrosion processes. The maximum permissible concentration of chlorides in boiler water is 150-200 mg / l.

The use of low quality water in the boiler system (unstable, chemically aggressive) results in corrosive and scale-forming processes. The operation of boiler systems using such water is dangerous from the point of view of man-made risks and is economically inexpedient. The boiler equipment manufacturers' warranty does not apply to cases related to the use of untreated and improperly prepared water in boilers.

What is a hydrostatic gun for: principle of operation, purpose and calculations

Many heating systems in private households are unbalanced. The hydraulic arrow allows you to separate the heating unit circuit and the secondary heating system circuit. This improves the quality and reliability of the system.

Features of the device

When choosing a water gun, you need to carefully study the principle of operation, purpose and calculations, as well as find out the advantages of the device:

- a separator is required to ensure that technical specifications are met;

- the device maintains temperature and hydraulic balance;

- parallel connection ensures minimal losses of heat energy, productivity and pressure;

- protects the boiler from thermal shock, and also evens out the circulation in the circuits;

- allows you to save fuel and electricity;

- a constant volume of water is maintained;

- reduces hydraulic resistance.

Function of the device with a four-way mixer

The peculiarities of the operation of the hydraulic arrow allow to normalize the hydrodynamic processes in the system.

Helpful information! Timely elimination of impurities allows you to extend the service life of meters, heating devices and valves.

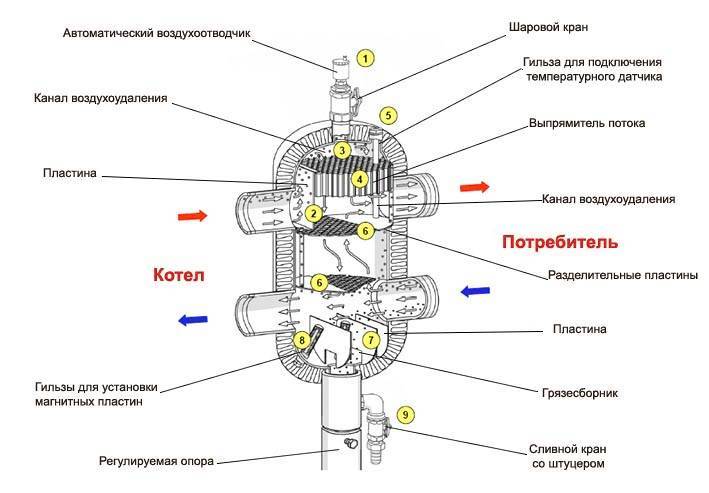

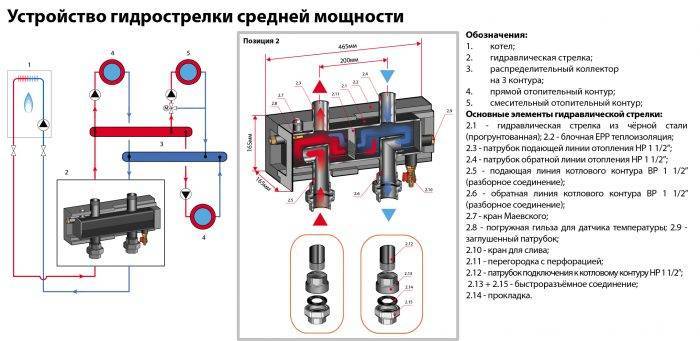

Heating water arrow device

Before buying a water gun for heating, you need to understand the structure of the structure.

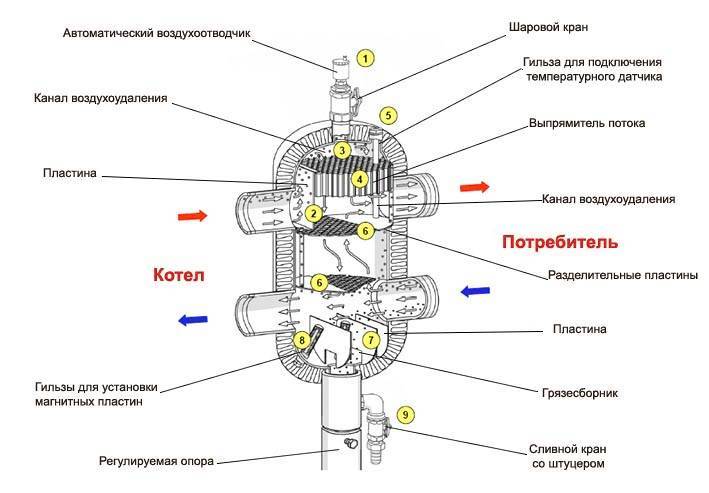

Internal structure of modern equipment

The hydraulic separator is a vertical vessel made of large-diameter pipes with special plugs at the ends. The dimensions of the structure depend on the length and volume of the circuits, as well as on the power. In this case, the metal case is installed on support posts, and small products are attached to brackets.

The connection to the heating pipe is made with threads and flanges. Stainless steel, copper or polypropylene are used as the material for the hydraulic arrow. In this case, the body is treated with an anti-corrosion agent.

Note! Polymer products are used in a system with a 14-35 kW boiler. Making such a device with your own hands requires professional skills.

Additional equipment functions

The principle of operation, purpose and calculations of the hydraulic arrow can be found out and performed independently. The new models have the functions of a separator, separator and temperature controller. The thermostatic expansion valve provides a temperature gradient for the secondary circuits. The elimination of oxygen from the coolant reduces the risk of erosion of the internal surfaces of the equipment. Removing excess particles increases impeller life.

There are perforated partitions inside the device that divide the internal volume in half. This does not create additional resistance.

The diagram shows the device in section

Helpful information! Sophisticated equipment requires a temperature gauge, pressure gauge, and power line for the system.

The principle of operation of a hydraulic arrow in heating systems

The choice of a hydraulic arrow depends on the speed of the coolant. In this case, the buffer zone separates the heating circuit and the heating boiler.

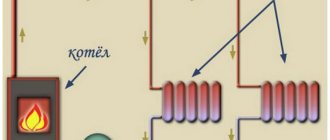

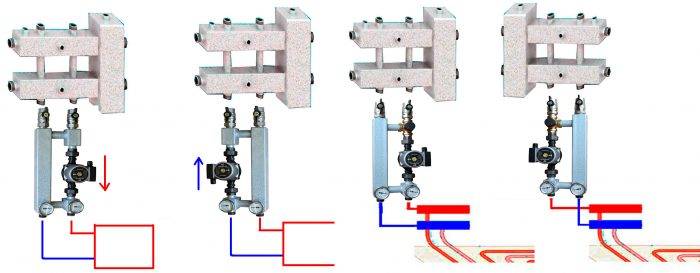

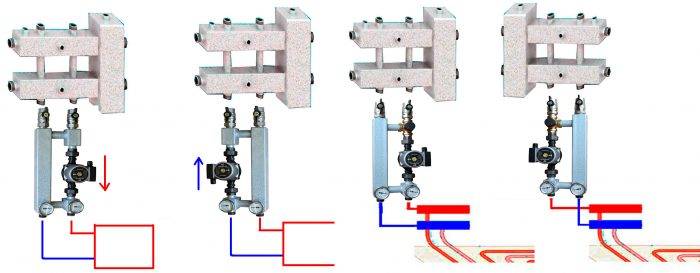

There are the following schemes for connecting a hydraulic arrow:

neutral scheme of work, in which all parameters correspond to the calculated values. At the same time, the structure has a sufficient total power;

Using the underfloor heating contour

a certain scheme is applied if the boiler does not have sufficient power. If there is a lack of flow, an admixture of the cooled heat carrier is required. When there is a temperature difference, temperature sensors are triggered;

Heating system diagram

the volume of flow in the primary circuit is greater than the consumption of the coolant in the secondary circuit. At the same time, the heating unit operates optimally. When the pumps in the second circuit are turned off, the coolant moves through the hydraulic arrow along the first circuit.

Use of a water arrow

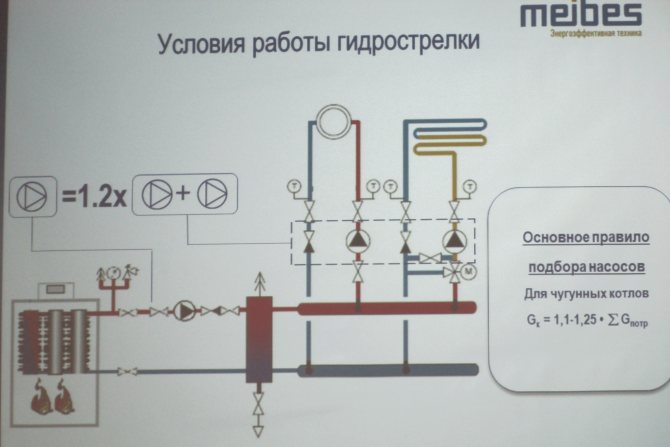

The capacity of the circulation pump must be 10% more than the head of the pumps in the second circuit.

Features of the system

This table shows some of the models and their prices.

Calculation method

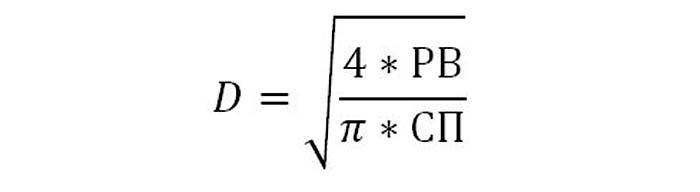

To make a hydrostatic gun for heating with your own hands, you need preliminary calculations. This figure shows the principle by which the dimensions of the device can be calculated quickly, with a sufficiently high accuracy.

Principle "3d"

These proportions were obtained taking into account the results of experiments, the efficiency of the device in different modes. The value of D, which consists of three d's, can be calculated using the following formula:

- РВ - water consumption in cubic meters;

- SP is the water flow rate in m / s.

In order to fulfill the above-mentioned optimal conditions, the value of SP = 0.1 is inserted into the formula. The flow rate in this device is calculated from the difference Q1-Q2. Without measurements, these values can be found out using data from the technical data sheets of the circulation pumps of each circuit.

Calculator for calculating the parameters of the hydraulic arrow based on the performance of the pumps

How to calculate

Hydro arrows are distinguished by certain parameters:

- the order of supplying water to the system;

- the order of water drainage;

- the location of the incoming or outgoing pipes;

- by capacity.

In order to calculate the diameter of the hydraulic arrow (or the branch pipe that is supplied), you need to know some of the values indicated below. The mechanism is matched considering the largest water flow that can be driven through the system and the lowest water velocity in the gun and nozzles.

And also when calculating, you also need to know the following values:

- diameter of the hydraulic boom in mm (D);

- diameter of the underwater branch pipe in mm (d);

- maximum water flow in the direction of the arrow in m3 hour (G);

- maximum water speed in ms (w);

- heat capacity (i.e. heat output) (c);

- boiler productivity in kVA (P);

- temperature difference between supply and return in degrees (∆Т).

And when all of the above data has been collected, we proceed to the calculations themselves.

So, using the calculator, we calculate:

- how much the diameter of the hydraulic arrow depends on the watercourse: D = 3 * d = 1000 * √ ((4 * G) / (P * 3600 * w)) Or: D = 3 * d = 18.8 * √ (G / W)

- dependence of the diameter of the hydraulic arrow on the highest boiler power: D = 3 * d = 18.8 * √ (G / W) = 18.8 * √ (7.6 / 0.2 = 11.6).

Manufacturers and prices

It will be easier to buy a water gun for heating after reading the data from the following table. Current price offers can be clarified immediately before purchasing the goods. But this information is useful for comparative analysis, taking into account different characteristics of products.

Table 1. Characteristics and average cost of hydraulic shooters

| Picture | Equipment model | Heating system power in kW (maximum) | Price in rub. | Notes (edit) |

| GR-40-20, Gidruss (Russia) | 40 | 3 600 — 3 800 | The cube body is made of carbon steel with anti-corrosion coating, the simplest model. | |

| GRSS-60-25, Gidruss (Russia) | 60 | 9 800 — 10 600 | Stainless steel body, six nozzles, integrated separation mesh and a set of mounting brackets as standard. | |

| TGR-60-25х5, Gidruss (Russia) | 60 | 10 300 — 11 800 | Low-alloy steel body, the ability to connect up to 4 external circuits + heating. | |

| GRSS-150-40, Gidruss (Russia) | 150 | 15 100 — 16 400 | Stainless steel, 6 spigots. | |

| MH50, Meibes (Germany) | 135 | 54 600 — 56 200 | Sophisticated design with integrated sludge and air removal devices. |

Modern hydraulic arrow

It is clear from the table that, in addition to general technical parameters, the following factors affect the cost:

- body material;

- the ability to connect additional circuits;

- the complexity of the design;

- availability of additional equipment;

- manufacturer's name.

The use of a hydraulic arrow together with a manifold and the solution of other tasks

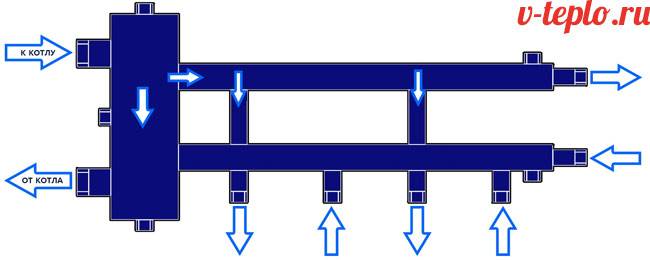

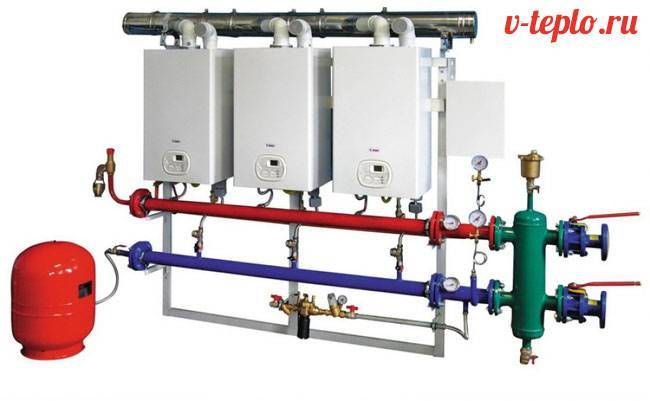

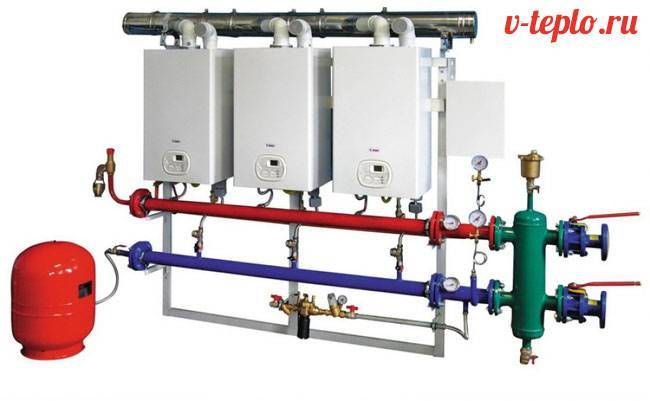

Installation of a hydraulic arrow in a connection diagram with several heating interconnections is carried out using a special switchgear. The manifold consists of two separate parts with nozzles.Shut-off valves, measuring and other devices are connected to them.

Hydrostrel in a single block with a manifold

To connect solid fuel boilers, it is recommended to increase the volume of the hydraulic expansion joint. This will create a protective barrier to prevent a sudden rise in temperature in the system. Such jumps in parameters are typical for aging equipment.

In the presence of a shift in the outlet nozzles along the height, the movement of the liquid slows down somewhat, and the path increases. Such a modernization in the upper part improves the separation of gas bubbles, and in the lower part it is useful for collecting debris.

Connection of several different consumers

This connection of several circuits provides different temperature levels. But one must understand that it is impossible to obtain the exact values of the distribution of heat in dynamics. For example, the approximate equality of the consumption values Q1 and Q2 will lead to the fact that the temperature difference in the circuits of radiators and underfloor heating will be insignificant.

What is a hydraulic arrow and where is it installed

The correct name for this device is hydraulic pointer or hydraulic separator. It is a piece of round or square pipe with welded pipes. There is usually nothing inside. In some cases, there may be two nets. One (above) for better "discharge" of air bubbles, the second (below) for filtering out impurities.

In the heating system, a hydraulic arrow is placed between the boiler and consumers - heating circuits. It can be located both horizontally and vertically. They are often placed vertically. With this arrangement, an automatic air vent is placed in the upper part, and a shut-off valve at the bottom. Some of the water with accumulated dirt is periodically drained through the tap.

That is, it turns out that a vertically placed hydraulic separator, simultaneously with its main functions, removes air and makes it possible to remove sludge.

Conclusions and recommendations

To make a hydrostatic arrow from polypropylene with your own hands, you will need a special soldering iron. Working with metals will require welding equipment and related skills. Despite the large number of instructions on the Internet, it will be difficult to make quality products. Taking into account all the costs and difficulties, it is more profitable to purchase a ready-made device in a store.

With the help of knowledge about hydraulic arrows, principles of operation, purpose and calculations, a specific model is selected. The features of boilers and heat consumers are taken into account.

To create complex systems, you can turn to specialized specialists for help.

Save time: select articles by mail every week

What is a water gun for heating

In complex branched heating systems, even oversized pumps will not be able to meet different parameters and operating conditions of the system. This will negatively affect the functioning of the boiler and the service life of expensive equipment. In addition, each of the connected circuits has its own head and capacity. This leads to the fact that at the same time the entire system cannot work smoothly.

Even if each circuit is equipped with its own circulation pump, which will meet the parameters of a given line, the problem will only worsen. The whole system will become unbalanced because the parameters of each circuit will differ significantly.

To solve the problem, the boiler must deliver the required volume of coolant, and each circuit must take from the collector exactly as much as needed. In this case, the manifold acts as a hydraulic separator. It is in order to isolate the "small boiler" flow from the general circuit that a hydraulic separator is needed. Its second name is a hydraulic arrow (HS) or a hydraulic arrow.

The device received this name because, like a railway switch, it can separate the coolant flows and direct them to the desired circuit. This is a rectangular or round tank with end caps. It connects to the boiler and manifold and has several cut-in pipes.

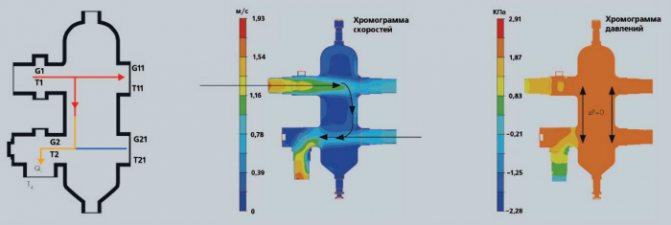

The principle of operation of the low loss header

The coolant flow passes the hydraulic separator for heating at a speed of 0.1-0.2 meters per second, and the boiler pump accelerates the water to 0.7-0.9 meters. The speed of the water flow is damped by changing the direction of movement and the volume of the passing liquid. In this case, the heat loss in the system will be minimal.

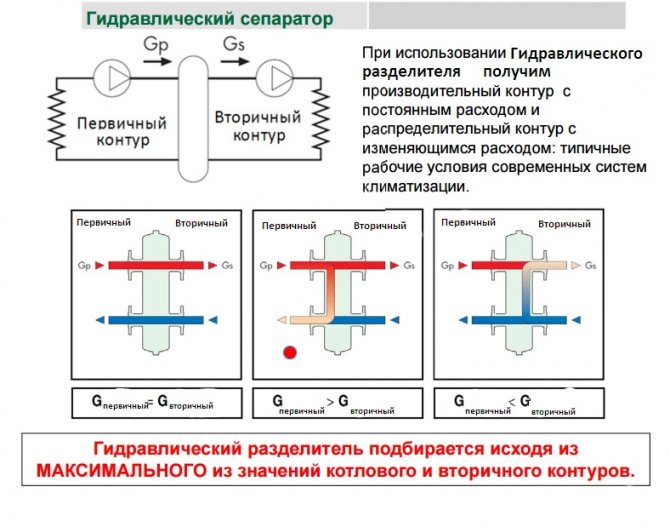

The principle of operation of the hydraulic switch is that the laminar movement of the water flow practically does not cause hydraulic resistance inside the body. This helps to maintain the flow rate and reduce heat loss. This buffer zone separates the consumer chain and the boiler. This contributes to the autonomous operation of each pump without disturbing the hydraulic balance.

Modes of operation

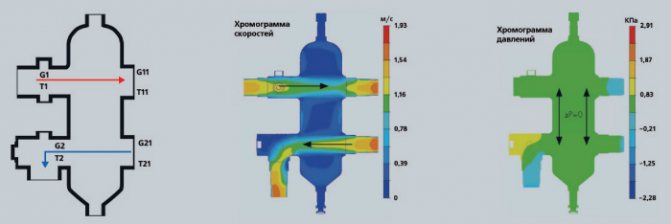

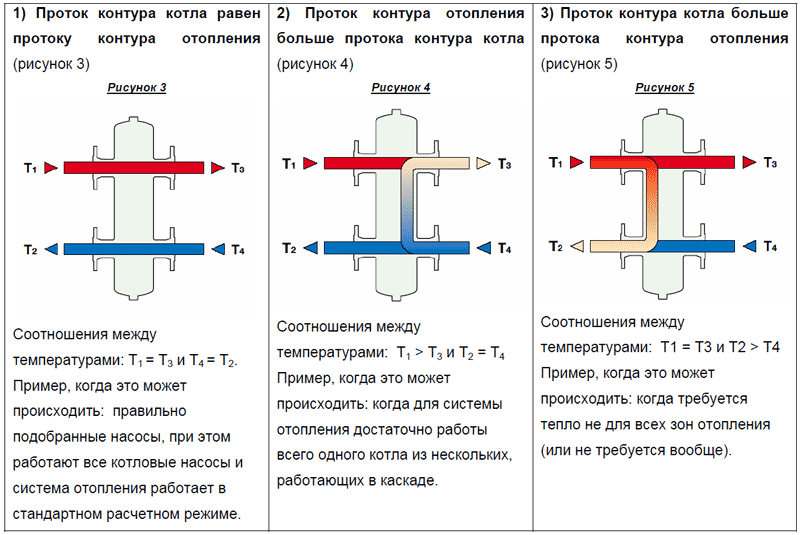

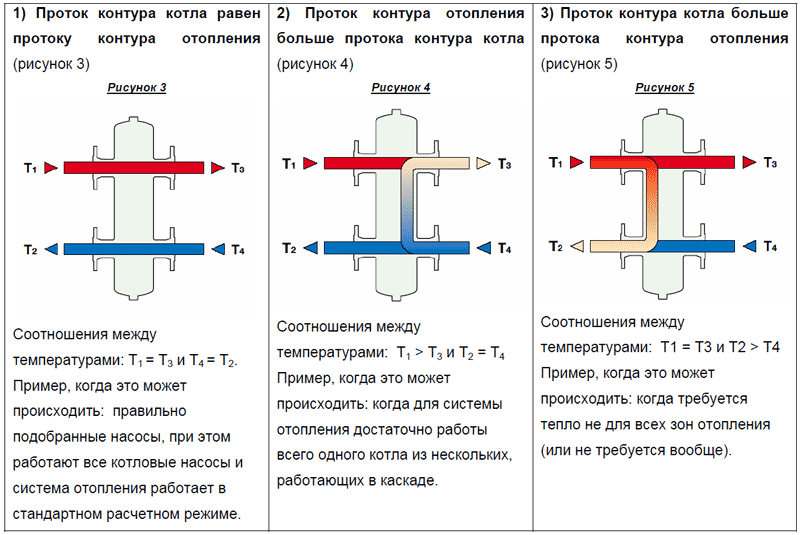

The hydraulic arrow for heating systems has 3 operating modes:

- In the first mode, a hydraulic separator in the heating system creates equilibrium conditions. That is, the flow rate of the boiler circuit does not differ from the total flow rate of all circuits that are connected to the hydraulic switch and the collector. In this case, the coolant does not linger in the device and moves horizontally through it. The temperature of the heat carrier at the supply and discharge nozzles is the same. This is a rather rare mode of operation in which the hydraulic arrow does not affect the operation of the system.

- Sometimes there is a situation when the flow rate on all circuits exceeds the boiler capacity. This happens at the maximum flow rate of all circuits at once. That is, the demand for the heat carrier has exceeded the capabilities of the boiler circuit. This will not lead to a stop or imbalance of the system, because a vertical upward flow will form in the hydraulic gun, which will provide a mixture of hot coolant from a small circuit.

- In the third mode, the heating arrow works most often. In this case, the flow rate of the heated liquid in the small circuit is higher than the total flow rate at the manifold. That is, demand in all circuits is lower than supply. This also will not lead to an imbalance in the system, because a vertical downward flow is formed in the device, which will ensure that the excess volume of liquid is discharged into the return.

Additional features of the hydraulic arrow

The principle of operation of the low loss header in the heating system described above allows the device to realize other possibilities:

After entering the body of the separator, the flow rate decreases, this leads to the settling of insoluble impurities contained in the coolant. To drain the accumulated sediment, a valve is installed in the lower part of the hydraulic arrow. By reducing the speed of the ceiling, gas bubbles are released from the liquid, which are discharged from the device through an automatic air vent installed in the upper part. In fact, it acts as an additional separator in the system

It is especially important to remove gas at the outlet of the boiler, because when the liquid is heated to high temperatures, gas formation increases. The hydraulic separator is very important in cast iron boiler systems. If such a boiler is connected directly to the collector, then the ingress of cold water into the heat exchanger will lead to the formation of cracks and equipment failure.

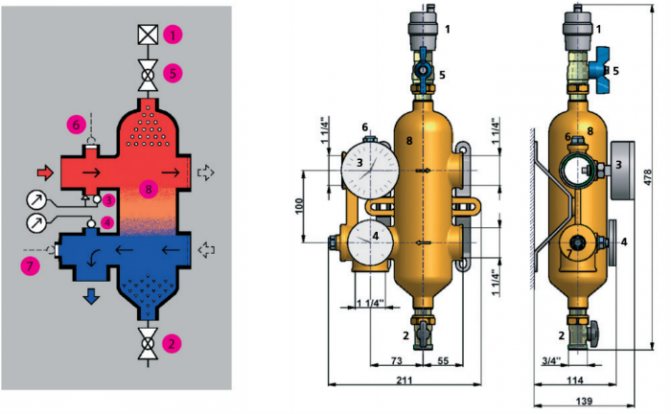

Construction and equipment

Due to a sharp decrease in the flow rate in the hydraulic gun, its design and spatial arrangement (true for vertical hydraulic separators), this element is an ideal point of the system for removing air and sludge from the coolant. (Note, however, that not all hardware manufacturers implement these features.)

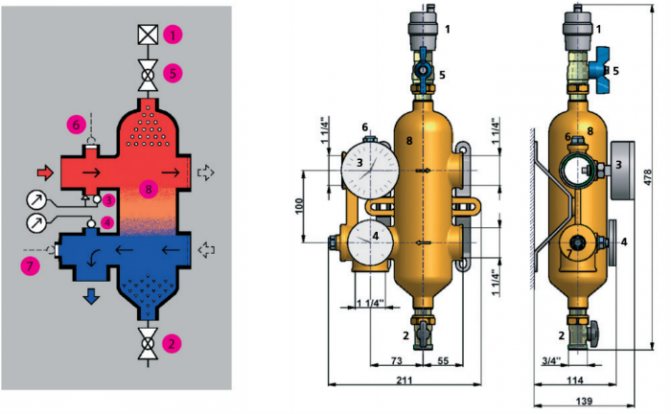

On the fig. 6

... shows the hydraulic pointer VT.VAR.00 (diagram, design and dimensions) supplied by VALTEC as one of the modules of the VARIMIX fast assembly system. To remove air accumulating in the upper part of the flask, the separator is equipped with an automatic air vent

1

, for draining sediment and draining the coolant, a drain ball valve is provided

2

... The shutdown of the air vent during repair or maintenance is carried out with a ball valve

5

... A thermomanometer is provided to control the temperature and pressure in the supply line of the primary circuit.

3

, temperature in the return pipe - thermometer

4

... There are also sockets for temperature sensors on the supply and return pipes

6

,

7

(plugged with plugs). The body of the hydraulic separator is made of OTS 60Pb2 bronze. The technical characteristics of the module are given in

tab. one

.

Fig. 6. Scheme and structure of the hydraulic arrow VT.VAR.00

Table 1. Technical characteristics of the VT.VAR.00 hydraulic arrow

| Characteristic | Value |

| Working pressure, MPa | 1,0 |

| Test pressure, MPa | 1,5 |

| Maximum temperature of the working environment, ° С | 120 |

| Permissible ambient temperature, ° С | 0 to +60 |

| Permissible relative humidity of the environment,% | 80 |

| Maximum flow rate of the heating agent, kg / h | 4500 |

| Maximum connected heating power (at ΔT = 20 ° C), kW | 104 |

| Kit weight, g | 4500 |

| Collector connection | Fitting VT.0 606 1 1/4 |

| Average full service life, years | 50 |

In 2020 VALTEC announced the release of the VT.VAR05.SS stainless steel low loss header. The choice of body material allowed to reduce the cost of the product, providing it with high strength and resistance to corrosion. At the same time, the developers have also improved the design of the hydraulic arrow (fig. 7

), supplementing it with a perforated partition to reduce heat loss due to convection of the coolant - from about 7 to 2–3%, as well as a spiral perforated separator - for more intensive removal of air from the working medium.

Fig. 7. Construction of hydraulic arrow VT.VAR05.SS: 1 - pressure gauge, 2 - drain valve, 3 - automatic air vent, 4 - shut-off valve, 5 - additional threaded connections, 6 - threaded plugs for additional connections, 7 - spiral perforated separator, 8 - perforated partition

The hydraulic arrow from stainless steel is completed with an automatic air vent with a shut-off valve, drain valve, pressure gauge. Additionally, the body has connections for a thermometer, temperature sensor, magnetic sludge trap. The separator is designed for heating systems with operating pressures up to 10 bar and temperatures up to 110 ° C. Maximum heat output at ΔT

= 20 ° С - 120 and 200 kW for models with nominal diameter 1 and 1 1/4 ″, respectively.