Boiler installation

At this stage, you have to take care of the arrangement of the boiler room and the smoke exhaust system.

Boiler room arrangement

The floor and walls of the boiler room must be made of non-combustible material. The floor can be made of concrete. Pave it with ceramic tiles if desired.

Place the boiler on a strictly level surface. Choose a place so that the distance from the front side of the unit to the nearest wall is at least 100 cm. Choose the distance from the rest of the walls so that in the future it is convenient for you to carry out preventive work, maintenance and repair of the equipment.

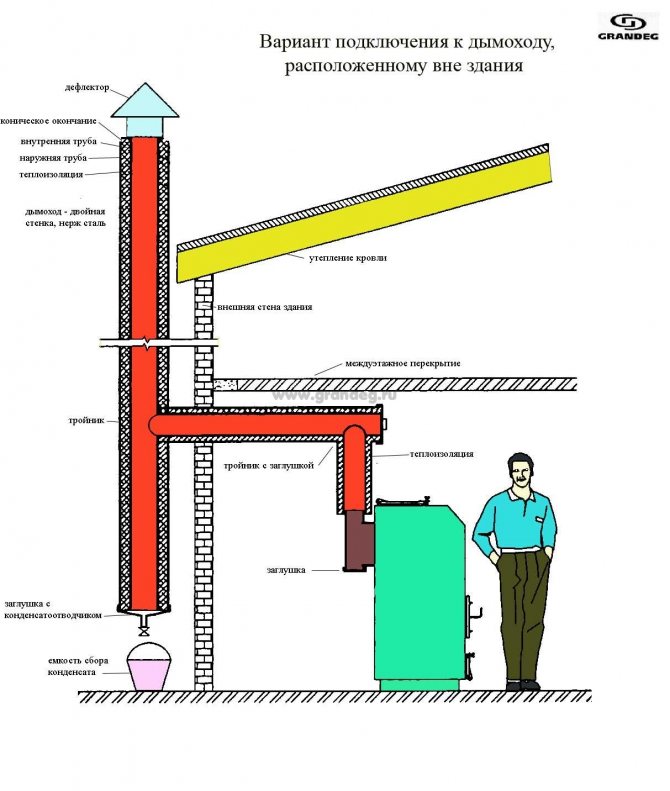

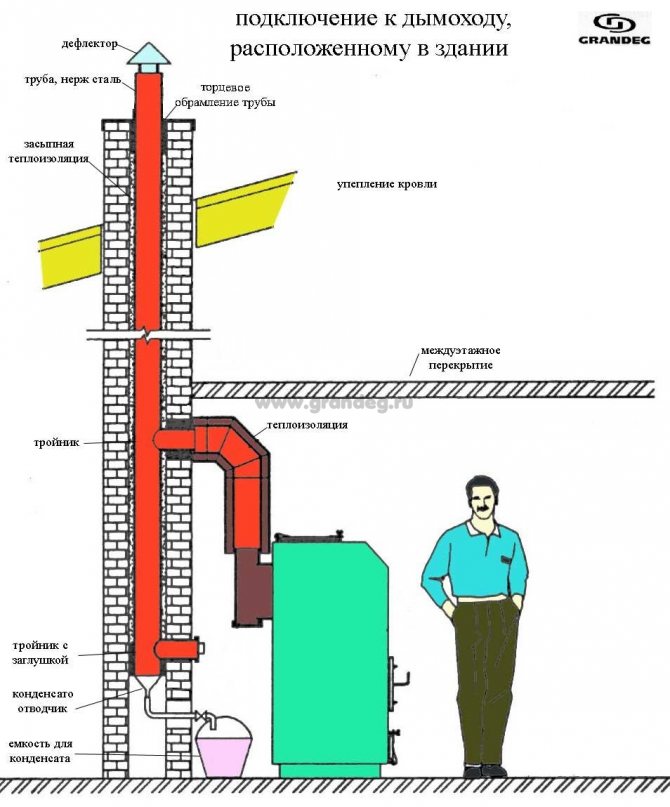

Chimney device

Pay special attention to the issues of arranging the smoke exhaust system. Not only the efficiency of the homemade pellet boiler, but also the safety of the residents of the house directly depends on the correctness and quality of the chimney.

Choose the length of the chimney so that it rises above the roof of the building by at least 50 cm, better - more.

Use a sealed pipe to make a chimney

It is important that the pipe material does not support combustion and withstands high temperatures.

The chimney must be insulated. Install a protective cone on the pipe to protect it from atmospheric precipitation.

Make a hole at the bottom of the chimney to drain the condensate. For more convenience, you can connect a tap to the hole. Also prepare a hole to clean the soot from the pipe.

Pellet installation: 6 installation rules

In the absence of heating in a private house, you can use a pellet installation

While multi-storey buildings are already equipped with such a blessing of civilization as heating, this issue remains a problem for a private house or a country house, but many solutions can be found that will save the situation. An influencing factor in the choice of the method of heating the room is the savings of the future heating system. At the moment, the cheapest and most profitable option is main gas, but only it is practically not supplied to country and private houses. Therefore, their owners have to look for other options, these include the Pellet plant.

Installing a pellet boiler: step by step instructions

Before you start installing a pellet boiler yourself, it is very important to prepare a separate room, floor and walls, in which they should be made of material that does not burn. The floor is best done with concrete or ceramic tiles. Make sure that the distance between the unit and the walls is sufficient for its maintenance, and the surface on which it stands is perfectly level. As for the space between the front side of the unit and the wall opposite it, it must be at least one meter. The acceptable temperature in the room where the boiler is located is not lower than +10 degrees.

Another important condition in the installation is the correct arrangement of the boiler room, namely exhaust and ventilation, because the boiler furnace absorbs a large amount of air during combustion, and all the results of combustion are distributed outside.

There are 6 rules to follow during installation and design:

- The diameter of the smoke outlet connector must be less than that of the chimney section, it is calculated based on what power the boiler has;

- The chimney pipe must be at least half a meter above the roof;

- The chimney must be made exclusively of material that does not burn and does not allow gas to pass through;

- Make sure that the gas outlet is located at the bottom of the chimney;

- Be sure to protect the chimney from possible precipitation, carry out additional thermal insulation;

- In the chimney there should be a canvas that will close the hole and provide access in order to clean it inside in time.

If the system for the combustion products is not made correctly, then this can entail not only poor efficiency of the work process, but also a threat to human health.

Pellet boiler piping: basic requirements

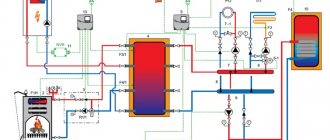

Basically, the installation of boilers for heating corresponds to one standard scheme. It includes a number of stages.

Namely:

- Installation of spreading combs;

- Installation of the required contours;

- Installation of fuses;

- Expansion tank installation;

- Installation of valves;

- Connection of the unit to the supply and return type circuits;

- Equipping the circuits with coolants;

- Checking the functionality of the installation.

It must be said right away that very impressive requirements are put forward for the strapping of the pellet plant. This is due to the fact that the moisture content of the fuel must be low, and since it heats up to a very high temperature, high-quality operation may be impaired and the installation will stop working.

Taking into account fire safety standards, it is better to use non-combustible pipelines for piping a pellet boiler. It is better to refuse polypropylene materials. As practice has shown, such use is dangerous and unprofitable, because the outlet temperature is sometimes much higher than the material can withstand.

The pellet installation is quite complicated, therefore, experts do not recommend doing amateur activities and entrusting the installation and strapping to those who work in this area.

But if you know the main stages of strapping and certain nuances of this case, then you can control the quality of the work of the specialists you have called.

High-quality strapping includes the following steps:

- Boiler installation;

- Installation of a suitable burner;

- Installation of a pellet hopper;

- Fuel auger connection;

- Remote control connection;

After all the steps above have been completed, you can proceed to the next, which are the main ones.

They include:

- Installation of a pressure gauge, automatic air vent and relief valve;

- Installation of a sensor for a thermal valve;

- Chimney installation;

- Installation of devices that control and maintain reverse flow;

- Installation of a circulation pump and thermal head.

The connection diagram is not complicated, all actions are combined. The master can easily install and configure any boiler. It is categorically impossible to use a pellet installation if the coolant has a low temperature. The temperature equal to 55 degrees is called the "dew point", with this indicator a large amount of condensate is formed, as a result, the amount of soot in the heat exchanger increases, and the equipment will reduce its capacity.

Pellet boiler chimney: the importance of correct installation

Thanks to the good draft, the efficiency of the pellet plant is increased. If the chimney is made, it is true, then it will be able to provide the required draft, despite the weather conditions. What a homemade chimney looks like can be found in the photo.

It is very important to remember that the diameter of the chimney pipe must match the outlet.

In this chimney, a device is installed that will drain condensate.The correct approach to the installation of the hood will guarantee protection against aerodynamic pressure or pipe blocking.

Most often, metal pipes are chosen for the chimney, which are equipped with hatches for cleaning and insulation. Speaking about the gap between the outer surface and the roof, it should be no more than 13 cm. It will not be superfluous to say that both a small draft and too large draft are dangerous for a pellet boiler. To avoid this, additional installation of a gate damper and stabilizer will be required.

Setting up a pellet boiler: common mistakes

Those who have not yet gained sufficient experience in the installation of pellet boilers very often make a number of mistakes.

Here are the most common ones:

- Neglect to install a device for controlling the level of the return water temperature, this is the reason for increased condensation and the appearance of tar and soot;

- Poor sealing of the boiler, chimney or bunker, which entails a leak of pyrolysis gas and a decrease in efficiency;

- The lack of thermal insulation during the installation of the base will lead to the fact that during the winter period the boiler will begin to emit harmful condensate;

- Installation of a bowl that is not intended for this type of work;

- Small dimensions of the room, which will not allow you to take out the auger with pellets and clean the bunker;

If you are sure that the installation was carried out, correctly, and the boiler still smokes, goes out or there are unburned pellets, then after the boiler was started it was not configured correctly or no adjustment was made at all. Do not rely on factory settings, they need to be adjusted taking into account fuel and boiler power.

Pellet plant connection (video)

Installation and adjustment of a pellet plant is a very serious matter. You should not undertake this if you do not have certain skills and knowledge. It is better to familiarize yourself with the theory and control the actions that the specialists will perform. Entrust this business to professionals. The correct approach to installation is the key to proper operation and long service life of the boiler.

homeli.ru

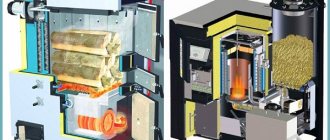

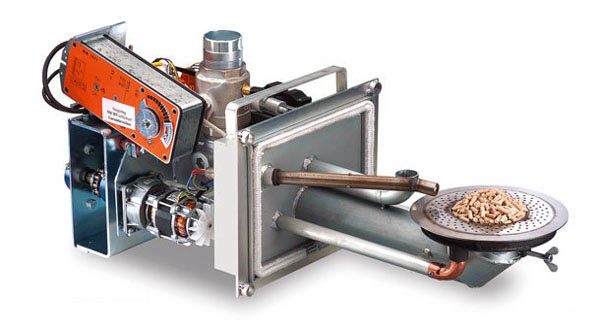

Device

Any burner has one goal - to create a powerful flame to heat the air or water jacket of the boiler. In this case, the very power of combustion can be adjusted independently.

The pellet burner serves a similar purpose. The device is a wind tunnel into which solid fuel is supplied and air is injected for combustion. The fuel is fed into the pipe using a special screw-type conveyor. The fuel itself is stored in the feed hopper before combustion. The bunker can have a different volume, while it depends on the volume how long the burner can burn on its own without human intervention (adding fuel).

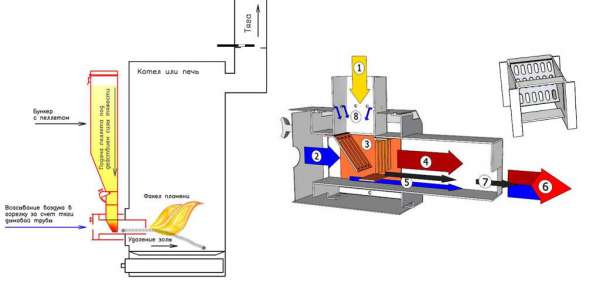

Pellet burner device: 1 - Pellet enters the burner by gravity; 2 - Air enters the burner due to the vacuum created by the chimney draft; 3 - Pellet combustion takes place in a combustion chamber called a "basket"; 4 - Due to the high temperature, thermal decomposition of wood occurs in the basket, which forms a flow of combustible gases; 5 - Secondary air flow under the basket; 6 - In the nozzle of the burner, the flow of combustible gases and secondary air is mixed, forming a torch; 7 - Solid combustion products are ejected from the burner into the ash pan of the boiler or furnace by the secondary air flow; 8 - Ventilation of the feed duct prevents hot gases from diffusing up the duct and destroying the pellets, ensuring a stable pellet feed.

Air is supplied to the combustion zone by means of forced delivery by means of a fan.

The chamber for combustion of fuel in the burner can be of a round or rectangular type. Round burners are the most common due to their ease of manufacture.Outside, a pipe branch is attached to the combustion chamber, through which fuel is supplied from the conveyor.

The design also provides an ash pan in which combustion waste accumulates. In the process of burning pellets, a little ash is formed, therefore, the ash pan should be cleaned no more often than once a week with active use of the burner.

There are several types of pellet burners, each of which has its own advantages and disadvantages.

Flare type

Initially, the device was used to generate heat by burning grain, later it was re-equipped for burning solid pressed fuel.

Flare burner side view

- Small overall dimensions;

- Can be used in conjunction with boilers in which the combustion chamber is small;

- Simplified operation;

- Increased reliability;

- Poor quality pellets can be burned.

- Low power compared to other burners;

- The flame is directed horizontally, which causes it to heat up the boiler locally.

Volumetric type

Unlike the previous model, they have increased power and high efficiency. The disadvantages of the device include a complicated design, large overall dimensions, dependence on the quality of the used pellets.

General view of the volumetric combustion burner Pellet combustion in a fireplace burner

Such structures are mainly used in domestic conditions, installed in fireplaces and boilers. The principle of operation of the device is as follows: pellets fall into a special bowl, where they are burned under the action of the air supplied from below.

The disadvantages of the model include the size of the device and the need for spot adjustment for proper combustion.

Principle of operation

The principle of operation of a pellet boiler (click to enlarge)

However, alternative heat sources form serious competition for it, among which a pellet boiler for heating a house is the most profitable solution. At first glance, there are no fundamental differences. The heat exchanger, which is built into the combustion chamber, heats up the water, which heats the house.

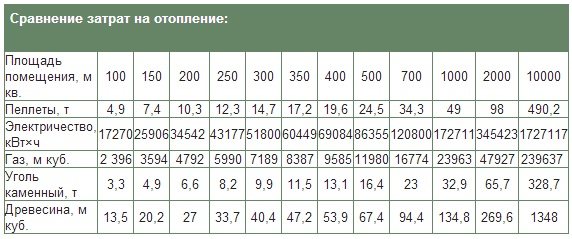

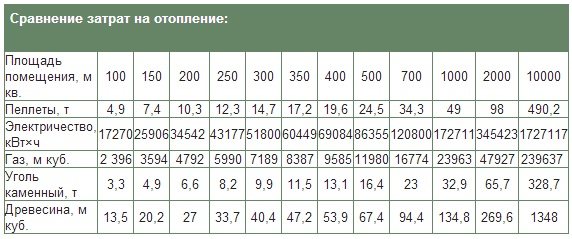

Why are the most productive gas boilers made using innovative technologies economically inferior to self-made counterparts working on pellets? The answer is simple, the cost of 1 kW of energy during gas combustion will be higher than the same amount of heat when using alternative fuels.

The raw material for pellets is woodworking waste, the cost of which is minimal, since the issue of their disposal is very acute and the production of fuel pellets is one of the ways to get rid of unwanted products of the main activity. Pellets can be made with your own hands, but this will require special equipment.

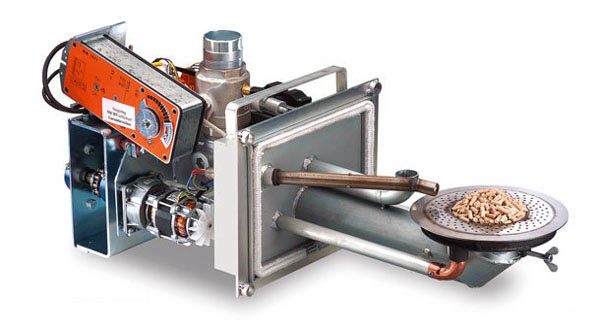

About pellet burner

A pellet burner is a special heating device that generates heat by burning pellets or fuel pellets in a boiler. In some cases, these burners use unnecessary dry grain.

There are manual and automatic burners, in automatic burners the fuel is fed into the combustion hopper using a special screw, and the whole process is controlled by sensors, due to which the device needs minimal control by the user. Pellet burners have found their application not only in everyday life, but also in industry. They are used for space heating, water heating and a number of other needs.

Pellets, or fuel pellets, are a special solid fuel that is obtained from wood waste or agricultural waste by pressing and granulating under the influence of high temperatures.

Pellets are an environmentally friendly type of fuel, since when they are burned, the same amount of carbon dioxide is emitted into the atmosphere as is formed during the natural decomposition of wood.

In countries in which agriculture and woodworking industry occupy leading positions, the cost of pellet fuel is much lower than that of coal. The only exceptions are those regions in the immediate vicinity of which coal mining enterprises are located.

When burning pellets, no hazardous vapors are emitted, as is the case with burning liquid fuels.

Making a pellet burner

Pellet installations are often ignored by buyers due to their high cost compared to gas and electrical equipment, while the problem is solved by making the device at home.

General scheme for self-production of a pellet burner

The combustion chamber can be equipped with a square or round pipe. Give preference to better heat-resistant steel that can withstand elevated temperatures, the wall thickness should be at least 4 mm.

The self-made installation is fastened to the boiler with a flange plate made of heat-resistant steel with a thickness of 3 mm or more.

A container for supplying fuel to the combustion chamber can be purchased or made by hand. The best option is to immediately make an installation in which fuel will be supplied automatically. To do this, we place the auger in the purchased pipe of the required diameter. The rotation of the device will be carried out at the expense of a bearing, a gearbox and a motor operating at low speeds.

Additionally, a fan is purchased in the store, which will blow air. The fan is fixed on a plate, which is made depending on the size and design of the door of the boiler used in your home.

It is also important to worry about adjusting the amount of incoming fuel and the amount of air blown by the fan, otherwise the homemade device will be unstable. In home devices, the air supply and the amount of pellets are adjusted manually

This method is inconvenient due to the fact that it requires constant supervision of the burner.

For automation, an electric filament element and a photosensor are purchased. The first device ignites the flame in case the pellets are extinguished, and also regulates the switching on of the device. A photo sensor monitors the appearance of a flame: if the flame is stable, the sensor sends a signal to the glow plug to stop ignition.

A fill sensor is also purchased to automate the system. It will notify the electronic filling of the device about the degree of filling the combustion chamber with pellets.

Pellet burners are modern equipment for boilers that can improve the environmental friendliness of the process and reduce fuel costs. At the same time, the equipment itself in the store has a high cost. For basic household needs, it is better to give preference to home-made devices, the work of which can be automated if necessary.

Minimizing housing maintenance costs is one of the most important tasks today. The search for ways to optimize costs is ongoing. Heating a house, with regularly increasing tariffs, is an essential item in the family budget.

There are several ways to reduce it. With the help of energy-saving technologies in the construction of a house and the use of efficient heating systems. A pellet boiler is more economically profitable than analogs working on gas, not to mention electricity and other energy sources. The reason lies in the low cost of consumable raw materials and high energy efficiency of the device.

We make ourselves

Having decided to do everything yourself, you should first develop a project. Guided by the drawings, you should purchase everything you need, as well as prepare the tool.

What is required?

It is better to purchase the most complex elements already assembled.So, a factory-assembled pellet burner is always preferable to one assembled with your own hands. The same applies to sensors and programmers, a fan, an electric motor for the auger, a grate, two oven doors, if they are not planned to be manufactured independently. You will also need:

- steel sheet with a thickness of 3mm and 6mm;

- steel square and round pipes (wall thickness 4 mm);

- sheet asbestos and in the form of a sealing cord;

- fireclay brick for the combustion chamber;

- round bar (20 mm);

- electrodes.

To perform the work, you need to prepare a grinder, a welding machine, a ruler, a drill.

Pellet feeding unit

We cook the pellet hopper. We connect it to the auger shaft. The latter can be in the form of a pipe. If a dispenser is provided for supplying fuel, we install it at the entrance to the auger shaft and connect it to the electric motor.

Heat exchanger

Square pipes are used as frontal pipes, round - connecting pipes. In the frontal ones, round holes are cut for supplying and removing the coolant.

The spatial arrangement of the connecting pipes at the time of their welding is carefully controlled. After completing the welding work, check the tightness of the seams by filling the heat exchanger with water.

Case fabrication and assembly

The body is welded from sheet steel 6 mm thick. We provide two doors for subsequent maintenance of the equipment, located in the front and rear. We lay fireclay brick inside the chamber.

We place the heat exchanger inside the case, providing a small gap between the outer surface of the first and the inner second. We install the fan at the top of the case.

In many regions, the problem of heating private houses is still relevant. Of course, on the modern market there is a huge range of equipment that uses a wide variety of materials as fuel, be it gas, wood, electricity or oil, etc. However, access to gas pipelines and stable power grids is far from everywhere, so solid fuel heating remains the most preferable in many regions.

One of the best options for a solid fuel heating unit is a pellet boiler that you can assemble yourself.

Contents of step-by-step instructions:

Advantages and disadvantages

The equipment has a number of advantages:

- Pellets are a safe fuel compared to gas and electricity;

- It allows you to significantly reduce the cost of heating the premises in comparison with the use of electric boilers. At the same time, pellet installations are more expensive than gas equipment, but do not forget that it is not always possible to supply gas and purchase gas cylinders;

- Self-made installations guarantee high efficiency - 95%. Some in-store installations have over 97%;

- They are used not only for heating the room, but also for obtaining hot water;

- There are no rules for transporting and storing fuel. Being near a person, pellets do not cause allergic reactions, and there are no toxic fumes during combustion;

- Fuel is available for purchase. The owners of the equipment complained about the lack of fuel and the need to prepare a supply of pellets from the winter when the devices appeared, now there is no need to store a large volume of pellets at home, you can buy them everywhere if necessary;

- The price for pellets is on average at the same level, in contrast to gas and electricity, the tariffs for which periodically experience seasonal fluctuations;

- Installation of the device does not require special skills, and there is no need to coordinate the installation with the authorized bodies;

- After the combustion of pellets, natural mineral ash is formed, which does not require special rules for disposal.

Along with the advantages of similar equipment, a number of disadvantages are also distinguished:

- The high cost of finished store equipment.Despite the popularization of devices in recent years and a slight decrease in prices, pellet boilers are still more expensive than gas or electric equipment of similar power;

- The equipment needs constant maintenance (especially outdated models). The user will have to clean the ash pan and heat exchanger from the accumulated ash once a week. In modern models, cleaning is provided at an automatic level;

- In the absence of automatic fuel supply, the user has to load pellets into the hopper in manual mode;

- It is necessary to ensure the conditions of minimum humidity in the rooms in which the pellets will be stored pending use;

- Imported equipment is practically not designed for the conditions of the harsh domestic winter, as a result of which breakdowns and malfunctions often occur;

- In remote areas, fuel for the winter still has to be stored due to the instability of supplies.

Setting up a pellet boiler: common mistakes

Those who have not yet gained sufficient experience in the installation of pellet boilers very often make a number of mistakes.

In order for the pellet boiler to work correctly, it must be properly adjusted.

Here are the most common ones:

- Neglect to install a device for controlling the level of the return water temperature, this is the reason for increased condensation and the appearance of tar and soot;

- Poor sealing of the boiler, chimney or bunker, which entails a leak of pyrolysis gas and a decrease in efficiency;

- The lack of thermal insulation during the installation of the base will lead to the fact that during the winter period the boiler will begin to emit harmful condensate;

- Installation of a bowl that is not intended for this type of work;

- Small dimensions of the room, which will not allow you to take out the auger with pellets and clean the bunker;

If you are sure that the installation was carried out, correctly, and the boiler still smokes, goes out or there are unburned pellets, then after the boiler was started it was not configured correctly or no adjustment was made at all. Do not rely on factory settings, they need to be adjusted taking into account fuel and boiler power.

Boiler start-up and maintenance

Comparison of heating costs

The equipment can be started only after installing the pellet boiler and connecting the corresponding pipes of the heating system to it. After the above tasks have been completed, turn on the cold water supply to the heating system.

Observe the boiler operation. If you have any abnormal symptoms, turn off the equipment and do not use it until troubleshooting.

Observe the boiler operation

Homemade pellet boilers, like any other heating units, need proper care.

Clean all waste from the ash pan every 2-3 weeks. Clean the flue gas duct every 2-4 weeks. This will not take you long, but ignoring such simple maintenance will lead to a significant decrease in boiler efficiency and make the equipment potentially unsafe.

If desired, additional automation equipment can be connected to the pellet boiler. This will make the operation of the equipment more convenient - you can simply forget about the need to reload fuel and other related activities for a while.

Modern automation tools even make it possible to establish remote control of the heating unit, which is also very convenient.

And these are not the only possible additions. How do you, for example, self-cleaning systems for boilers? Be sure to check the available modifications and, if you wish, buy such add-ons for your boiler.

Boiler with pellet hopper

You can assemble a simple pellet boiler with your own hands, following the instructions received earlier.

Video - The principle of operation of a pellet boiler

The unique smell of natural wood, a clean and decorated room in a modern style - this is how a boiler room in a house can look if you choose the right equipment. An innovative heat-generating equipment that will allow you to create the described conditions in a room is a pellet boiler or an automatic pellet burner, working on special fuel pellets that are created from agricultural or woodworking waste.

If a few years ago, pellet installations were used only in 20% of houses in Europe, at the moment the figure has increased to 70%. The use of pellet boilers and burners is the most profitable option for heating a living space from an environmental and economic point of view. Today we will talk about the principles of operation of the equipment, its advantages and disadvantages, and also consider the scheme for making a pellet burner with our own hands.

How relevant is a pellet boiler in the 21st century?

This is a fairly new heating product and has won high popularity only in European countries. Most people use electric heating or gas, so a pellet boiler for a home is often installed during the construction of new living quarters, since it is a little difficult to make a replacement. But if you pay attention to the list of advantages of the boiler, then its popularity becomes justified. Many experts believe that with the rise in gas and electricity prices, the use of solid fuels will take a leading position. If you need a device that will economically consume energy resources and at the same time heat the room with maximum efficiency, then installing a pellet boiler is just for you.

Pellet boiler installation instructions

Of course, you can install the unit on your own if you have special knowledge, but it is still better to seek qualified help from a specialized organization that has a building license.

The main and important stage in the installation is a professionally executed design. It is followed by the following stages for the installation of heating equipment:

- Preparatory stage. Includes preparation of the boiler room, erection of a hill for the boiler, installation of a chimney, ventilation;

- Installation of a heating unit on a hill;

- Connection of heating system pipes and hot water supply to the boiler;

- Flue gas duct connection;

- Commissioning and start-up of the heater.

Preparatory work

The boiler room should be prepared - the base should be leveled and strengthened, which should withstand a weight of up to 200 kg. According to the requirements, the boiler is installed vertically, therefore there should be no slope. The base must have a fireproof surface.

Wiring is needed to automate the heater and to illuminate the boiler room, which will provide convenience during operation. Construction of a sandwich-type chimney with a height of at least 5 meters. A chimney and ventilation are also installed.

Boiler installation and piping

Installation and piping occurs in the following sequence:

- The brought boiler is mounted on a podium;

- The fuel compartment and the auger feeding the pellets are mounted;

- The distributor comb is connected;

- An expansion tank and shut-off valves are being installed;

- The boiler is connected to the heating medium supply and return circuits.

Chimney connection, start-up and commissioning

After the system has been filled with a heating medium (water, ethylene glycol or propylene glycol), it must be connected to the chimney. Moreover, the diameter of the chimney must correspond to the diameter of the outlet pipe. And the height of the chimney - to the technical requirements.

The correct diameter will provide good traction regardless of wind strength and air temperature.Good draft is the key to efficient operation of pellet equipment. But this type of boiler is afraid of strong draft, but too small will not work. Therefore, to solve this problem, a traction stabilizer or a gate damper is used.

Most often, the chimney is made from a metal pipe, in which hatches are built for further cleaning. Also, the chimney should be equipped with a condensate drainage device and insulated. An important step is pressure testing, if it is done poorly, pyrolysis gases will leak, which will lead to a decrease in efficiency.

After that, a test start-up and adjustment are carried out. An unsettled device will entail such problems: the boiler will smoke, smoke, extinguish, and the pellets will not completely burn out.

Pellet boiler chimney

Pellet boilers are high-tech heating equipment with excellent technical and operational characteristics. But its efficiency depends not only on the parameters declared by the manufacturer, but also on the chimney, this is the most important engineering system that affects both the efficiency of the unit and fuel consumption, and most importantly, safety. An incorrectly selected or assembled chimney with flaws will not only worsen the operation of the boiler, but can also cause a fire.

Design features of chimneys for pellet boilers

There are two main requirements for chimneys:

- ensuring sufficient traction;

- removal of carbon monoxide gases into the open air in any combustion mode.

Since a fan is usually installed in pellet boilers, for a more complete afterburning of pellets, the diameter of the chimney pipe can be slightly reduced. But even with this tolerance, it cannot be less than the size of the outlet pipe, in this case - 159 mm, or better, a little more, the shape of the pipe is a cylinder. The exact section and height of the chimney is calculated taking into account the air vacuum (-24 Pa), the minimum is six meters, but excluding the horizontal, tee and deflector. The angle to the ridge and eaves must be 10⁰. Too high a pipe is also not the best option, there may be a decrease in the efficiency of the equipment, and no one canceled the wind load. If, due to the design features of the boiler room, it is impossible to directly lead the boiler chimney into the chimney, an adapter is used, but not longer than 1 meter. It is unacceptable to connect several units to one chimney.

In modern houses, brick pipes are practically not found, and there is no special need for them, since the temperature of the outlet gases from pellet equipment is much lower than that of other solid fuel. The best option, "sandwich" - is a two-layer modular stainless steel chimney with a stone wool core. This type of chimney is not only the safest, but also the most convenient in terms of installation, especially when it comes to an already built house. Thanks to the insulating layer, the risk of ignition of floors or enclosing structures through which the pipe is discharged is eliminated, and less condensation will form. Nevertheless, in the lower part of the pipe, a branch pipe must be installed to drain condensate and combustion products (creosote). This detail cannot be neglected, since even with correct installation, several liters per week can accumulate, and with deviations, up to ten liters at all. If you install a single one instead of a two-layer chimney, even more condensate will form. In addition to the branch pipe, the chimney must have at least one inspection hatch for inspection and periodic cleaning (once a year), it must be hermetically closed so as not to affect the pressure in the pipe.

As for the characteristics of steel, special grades with increased corrosion resistance are preferable - Aisi 304 (08X18H10), Aisi 310 (20X23H18) or Aisi 316 (10X17H13M2). These are acid-resistant grades designed for heavy condensation.

Requirements for boiler rooms

In addition to the requirements for the chimney, there are certain requirements for the boiler room, not only in terms of the minimum cubic capacity, there must also be natural or forced ventilation. The size of the ventilation opening when organizing natural ventilation is calculated based on the power of the equipment and the characteristics of the room. If there is no ventilation, a pellet boiler of even small capacity will quickly take oxygen from the room. This is fraught not only with equipment problems, but also with the possibility of an explosion - as soon as the oxygen content drops to a critical level, the pellets will begin to produce flammable gases.

Only if there is a chimney system that meets the standards, the pellet boiler can be put into operation and accepted under the guarantee by the service organization. At your own peril and risk, you can independently start the system with errors, but then no one can guarantee that the boiler will consume a minimum of fuel and give out maximum heat, rather, just the opposite. And this is at best, there can be dire consequences of such violations.

dozatech.ru

Boiler assembly manual

Pellet boilers have a rather complex design. Instructions for assembling them will also be difficult and multi-stage. For greater convenience, the assembly process for each main unit is considered separately. Buy or manufacture the items you need, and then simply assemble them into a single system.

This element of the pellet boiler is highly recommended to buy ready-made. It is on the burner that you will spend the most money.

Self-fabrication of the burner is almost impossible for the reason that this part of the boiler is not just a container for igniting the loaded pellets, but a complex control and regulation mechanism.

Pellet burners are equipped with special sensors and have several pre-installed programs that allow you to achieve the most rational fuel consumption and ensure the most efficient heating of the house.

Housing and heat exchanger

You can handle the assembly of the case and the manufacture of the heat exchanger yourself. It is best to make the boiler body horizontal - with this arrangement of the unit, the maximum heating efficiency is achieved.

For the manufacture of the case, it is recommended to use fireclay bricks. You simply assemble a kind of box without a top cover and place a heat exchanger with pipes and other elements connected in it. Brick is recommended for the reason that it accumulates heat much more efficiently than cast iron, steel sheets and other popular materials.

The heat exchanger of a pellet boiler is a system of pipes interconnected and connected to the heating pipes of a private house.

First step. Assemble a rectangular heat exchanger from square pipes. To do this, cut the pipes into pieces of the desired length and weld them into a single structure.

Second step. Make holes in the profile serving as a vertical post for connecting round pipes.

Step three. Prepare holes in the remaining front pipes for the water outlet and connection pipes. Hot water will be discharged through the top hole, cold water supplied from the bottom.

Use metal pipes with a length of 150 mm or more. Further, it will be possible to use polypropylene pipes. Be sure to install ball valves in the places where pipes are connected to the boiler. Additionally, you can install filters if necessary.

Fourth step. Weld the rear of the unit to the front and weld the side pipes.

At the same stage, choose a convenient place for connecting a chimney with a diameter of 10 cm. At the bottom of the heating unit, provide a small chamber for collecting ash. Also, the design of the pellet boiler necessarily includes a firebox. About him further.

In the firebox, as already noted, pellets are stored and from here they are fed to the burner.

First step. Prepare the necessary materials and fixtures. You will need an auger with a diameter of 7.5 or 10 cm, an electric motor and a metal casing. Connect the engine to the pellet burner control unit.

Any container of suitable volume with sufficiently thick walls can perform the function of a metal casing.

Second step. Install the inlet of your auger into the outlet of the casing. Connect a corrugated plastic pipe to the other part of the auger to supply granular fuel to the burner.

In the end, you just have to collect all the listed elements into a single structure. Do this and proceed to installing the boiler.

Strapping a pellet heating boiler: rules for proper installation

How to heat a house that is not connected to the gas main? Of course, with pellets! A pellet boiler is much more convenient to use than other solid fuel heating equipment. And since the cost of fuel is not high, heating costs can be significantly reduced. Automatic control allows the system to be serviced no more than once a month. However, the uninterrupted and efficient operation of expensive equipment largely depends on how correctly the piping of the pellet boiler was performed.

Features of work and installation of pellet boilers

Although pellet boilers are classified as solid fuel equipment, they are an order of magnitude better than traditional units that burn wood or coal, because:

- dry pellets burn, giving off much more heat, which significantly increases the efficiency of the unit;

- in the process of operation, a minimum amount of fuel combustion products is produced;

- the loading of pellets into the hopper is carried out much less frequently than when using firewood or coal.

This effect is achieved due to the special design of the equipment, as well as through the use of highly efficient pyrolysis combustion processes. An important point in the operation of a pellet boiler is the moisture content of the fuel, which should be less than 20%. If this requirement is not met, then the power of the equipment will decrease and condensed moisture will enter the system. And this can very soon lead to serious equipment damage.

There are combined pellet boilers in which there are two furnaces: one for burning pellets, the other for conventional solid fuel. The efficiency of such units is slightly lower than that of boilers that operate only on pellets, and the requirements for installation and piping remain quite high.

During the installation of the pellet boiler, it is necessary to install a hopper, burner and auger mechanism for feeding pellets. Often, experts also recommend using a special buffer tank, the volume of which can be 50 liters for each kW of power of the pellet boiler. All this significantly increases the size of the boiler room, in which the equipment will be installed and piped.

How is the strapping of such equipment carried out?

The general scheme for installing heating boilers consists of the following series of stages:

- installation of distribution manifolds;

- installation of appropriate pumping circuits for each consumer;

- installation of safety equipment;

- installation of an expansion tank;

- installation of valves;

- connection of the boiler to the supply and return circuits;

- filling the circuits with a coolant;

- pressure testing of equipment and checking of its operation.

In practice, everything depends on the power of the equipment, the number of consumers, the design features of the boiler, etc. It should be noted that rather high requirements are imposed on the piping of pellet boilers. Firstly, because the moisture content of the fuel must remain acceptably low, and secondly, since both the fuel and the coolant are heated to very high temperatures.Poor piping can lead to the fact that the operating conditions of the equipment will be violated, and the boiler will quickly fail.

In accordance with fire safety standards, it is recommended to use non-combustible metal pipelines for piping pellet boilers. The use of polypropylene structures in practice is not only dangerous, but also not profitable, since the temperature of the coolant at the outlet of the boiler often exceeds the performance of polymeric materials. As a result, the pipelines will have to be replaced in a couple of years.

A pellet boiler is a rather complicated device. Experts strongly discourage inexperienced beginners from installing and strapping such devices. However, knowledge of the main stages of strapping and some of the nuances of this process will allow you to effectively control the work of the invited team of installers.

The diagram shows one of the options for piping a pellet heating boiler: 1 - MK pump; 2 - mixing valve MK; 3 - pump TK1; 4 - mixing valve TK1; 5 - water recirculation in TK1; 6 - pump TK2; 7 - mixing valve TK2; 8 - water recirculation in TK2; 9 - hot water pump; 10 - DHW heat exchanger; 11 - supply of running water to hot water supply

To strap a pellet boiler, you must:

- install the boiler;

- connect the appropriate burner (if a combined boiler model is used);

- install a pellet hopper;

- connect the auger for fuel supply;

- connect the boiler automatic control panel.

After that, you should run:

- Installation of a safety group for the boiler supply, which includes a pressure gauge, an automatic air vent and a relief valve.

- Installation of a thermal valve sensor, if this is provided for by the design of the model;

- Installation of a chimney, the diameter and height of which meet the technical requirements.

- Installation of a system of devices to maintain a reverse flow: two pressure gauges for supply and return, a circulation pump and a thermal head.

- If there is a high likelihood of sudden power outages, it is recommended to complement the system with a suitable UPS model.

Backflow support allows you to control the heating level of the coolant before it enters the system. Until the return temperature reaches the required level (usually 60 degrees and above), the coolant will remain within the small circulation circle. Only when the coolant is heated to the required level will the thermal head open and cold coolant begins to flow through it, and the hot one will begin to circulate in the main circle.

In no case should a pellet boiler with a low coolant temperature be used. A temperature of 55 degrees is the so-called "dew point", upon reaching which a significant amount of condensation occurs. As a result, the volume of soot in the chimney as well as on the heat exchanger can increase significantly. The equipment will require additional maintenance efforts, and its power will be noticeably reduced.

This is how the combustion chamber of a pellet heating boiler looks like after exposure to an excess amount of condensate, which appears due to errors in the installation of the recirculation system

In detail, the process of tying a combined pellet boiler is presented in the video:

Many manufacturers of pellet boilers recommend supplementing the design with a special storage tank, which allows you to accumulate heat. In this case, fuel savings can reach 20-30%. In addition, the use of a storage tank avoids overheating of the boiler and achieves the highest possible efficiency.

A few words about the chimney

Good draft largely determines the efficiency of a pellet boiler. If the chimney is designed correctly, it will provide sufficient draft in any wind and air temperature. First of all, it should be remembered that the diameter of the chimney must be the same as the dimensions of the outlet.In such a chimney, a condensate drainage device must be installed. A properly installed hood will not create an aerodynamic support or block the pipe section.

The photo shows two options for installing a chimney for a pellet heating boiler. The wrong version is shown on the left, the chimney is installed correctly on the right

Usually, metal pipes are used for chimneys, which should be equipped with hatches for cleaning, as well as carefully insulated. The clearance between the outer surface of the chimney and elements of floors and roofs must be at least 130 mm. It should be remembered that too much draft and too little draft is dangerous for pellet boilers. To eliminate this problem, you will need a gate damper or a traction stabilizer.

Common errors and how to fix them

Inexperienced installers often make a number of dangerous mistakes during the installation of pellet boilers. Here are the most common ones:

- The master neglects the installation of a control system for the level of heating of the return water, which causes an increase in the amount of condensate, soot and tar.

- The sealing of the boiler, hopper or chimney is broken, which leads to leakage of pyrolysis gases and significantly reduces the efficiency of the equipment.

- Thermal insulation work was not carried out during the installation of the base. On a thin floor in winter, such a boiler "freezes", as a result, harmful condensation forms.

- The pellet burner bowl is not installed correctly. Most often, a bowl is installed instead of it, designed for other types of fuel.

- The dimensions of the boiler room do not allow you to freely remove the long pellet feed auger for cleaning the hopper.

Not but if you seem to have done everything correctly, but the boiler smokes, fumes, suddenly goes out, and pellets not completely burnt out are found in the ash pan, then after the start-up the boiler was not configured correctly, or was not adjusted at all.

On the left is a handicraft version of the piping of a pellet heating boiler, made with errors. The correct strapping is shown on the right, corrected by an experienced craftsman (click to enlarge)

Do not rely on the factory settings of the pellet boiler. It must be adjusted during the first start, taking into account the actual state of the fuel, the set power and the draft of the chimney.

aqua-rmnt.com

Principle of operation

All pellet installations that can be purchased in the store are equipped with additional units:

- Auger - supplies fuel from the bunker to the combustion chamber;

- Controllers for automating the work process;

- Bunker - the place where the fuel is located before being fed to the combustion chamber;

- Lambda probe is a special sensor that monitors the oxygen content in smoke chambers and independently controls the fuel combustion process, depending on the conditions.

The pellet burner must be protected with a plastic corrugated pipe. It acts as a safety device in the event of reverse thrust. If the fire starts to move towards the bunker, the pipe burns out, preventing the spread of the flame.

Additionally, a fan is used, which enhances the combustion of pellets by forcing air, as well as a thermoelectric heater, which allows you to ignite the fuel without human intervention.

In automated devices, pellets are fed into the combustion chamber in an automatic mode; a person is only required to monitor the amount of fuel in the bunker. The need to supply fuel to the combustion chamber is determined using thermal sensors (they can monitor the air temperature in the room, the water temperature, or any other ambient indicators, depending on the operating mode of the equipment).

The required temperature of the heat carrier is set by the user; all further increases and decreases are controlled by automated equipment.As soon as the temperature reaches the set level, the burner starts to work in standby mode (the pellets do not go out, they start to smolder). If, on the contrary, the temperature has dropped, the controller activates the built-in fan. Under the influence of air, the pellets ignite, the burner goes into operation. If the pellets go out for any reason during the downtime, the heating element is activated, which re-ignites.

Pros and cons of pellet heating

Boilers operating on pellets, in terms of technical and economic indicators, are close to gas counterparts.

Advantages of pellet heating boilers:

- high efficiency - 70–96%;

- long service life. For devices of the "premium" class, it is at least 20 years;

- automatic operation. Fuel in granules is fed by a screw conveyor from the operational hopper to the burner without operator participation. The period of autonomous operation of the boiler varies

I am from 2 to 15 days. It depends on the capacity of the bunker;

- automatic maintenance of the set temperature regime;

- the ability to control a pellet heating boiler using SMS messages. Communication is carried out via a built-in modem (GSM). It is set to the phone number of the owner of the cottage, can accept

b and send SMS messages. He does the latter in case of any equipment breakdown, as well as if the fuel has run out;

- rare maintenance. For example, ash removal from a grate is done automatically. It is collected in an ash pan, from where it is disposed of once every few days.

The system has one drawback: the high cost of the boiler. Nevertheless, the equipment pays for itself and successfully competes with gas counterparts.