Greenhouse heating options and their comparison in the table

Not every greenhouse needs heating. The system should be installed if it is used throughout the year or if you practice early growing of garden crops.

| Heating method | pros | Minuses |

| Solar heating

| This is a fairly simple and easily feasible option. Of course, you won't build everything for free, but it won't require expensive materials. Heating occurs naturally, heat is released gradually. | This method directly depends on the climate and weather conditions. It will not work to increase or decrease the temperature. |

| The method lies in the fact that biofuel is laid under the fertile layer, which heats up the earth due to natural decomposition processes, heat is given off gradually. Due to it, less feeding and watering is required. | This method also depends on the climate; without additional heating of the air in the winter season, the plants will not survive, and in the summer they can rot. The temperature cannot be adjusted. |

| Air heating

| The system is easy to build, the greenhouse heats up quickly. There is no condensation as there is constant air movement. | When the system is turned off, the temperature drops sharply, so the process needs to be maintained for all the necessary time. |

| Water heating

| The system works reliably and safely. The air does not dry out. The temperature can be changed as needed. | It will be optimal to arrange a separate boiler room or heating water using electricity, so this method cannot be called economical. |

| Steam heating Friends! As part of our portal, we launched a book on how to make a lawn with your own hands. If this topic interests you, then READ MORE >>

| The required temperature is reached very quickly. Fuel is economical. The materials are inexpensive. A large space can be heated. | Heating devices and components get very hot, so they often need to be replaced. |

| Furnace heating

| Inexpensive, easy to build with your own hands, efficient, temperature can be changed, fuel is available. | Such a system must be monitored all the time. |

| Gas heating

| The air heats up quickly and evenly, the system does not require a lot of money and is practical to use. | The operation of the system must be constantly monitored, since the gas is quite dangerous. In addition, it is necessary to coordinate the project with special services at all stages of the construction. |

| Electric heating

| There is no need for control, no need to build a chimney, the process can be automated, there is no danger of ignition, there are no problems with the purchase and storage of fuel. | The air is dry, a power source is required. This is a rather expensive option, as it will consume a lot of electricity. |

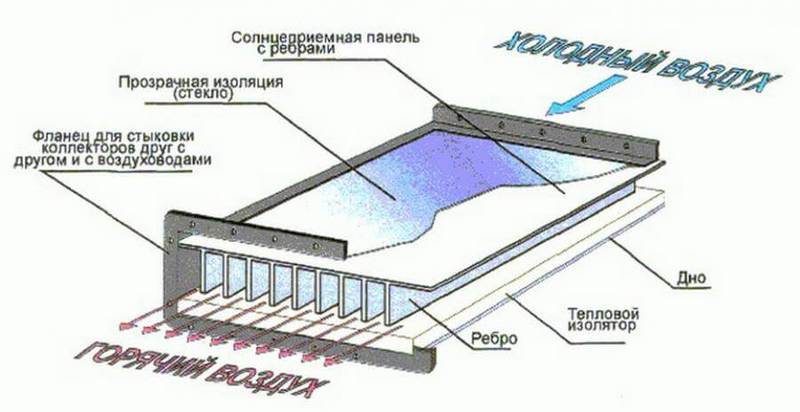

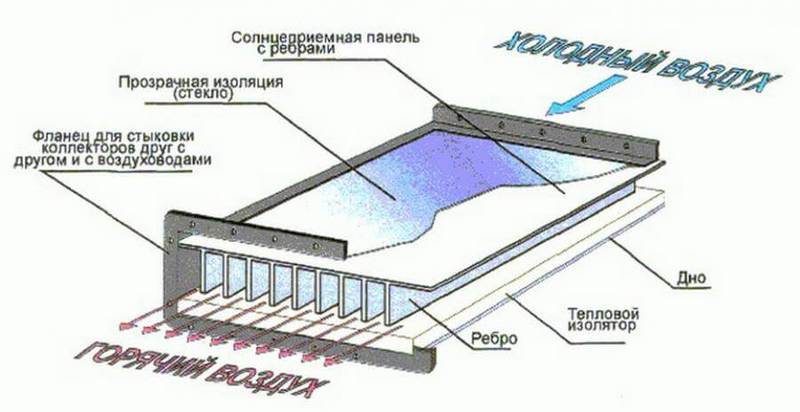

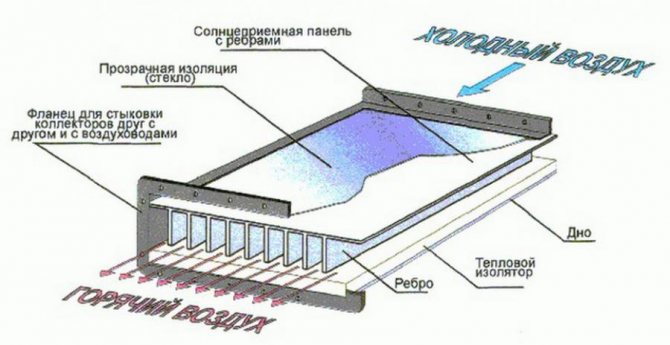

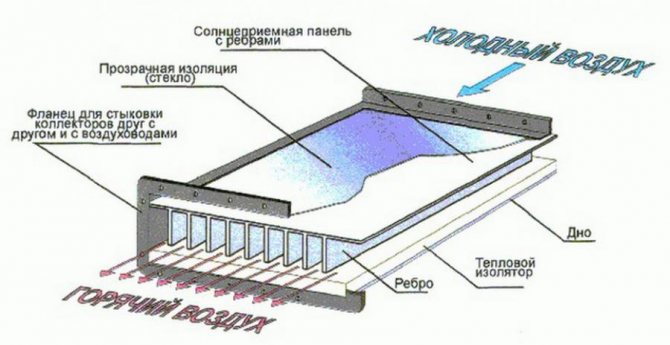

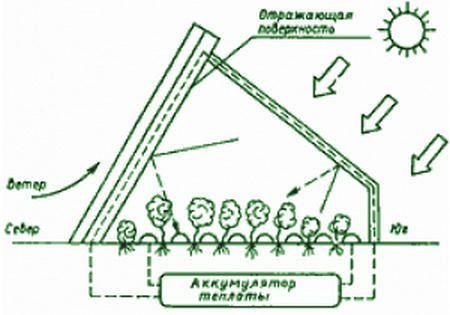

Greenhouse solar heating (solar air collector)

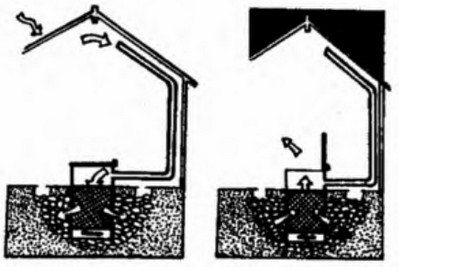

To create such a system, it is necessary to consider the location of the air manifold in order to ensure air circulation. In order for the air masses to move independently, the inlet must be positioned higher than the outlet. Then the warm air will rise and enter the greenhouse, and the cooled air will return back to the collector, there it will warm up and repeat the cycle.

Friends! As part of our portal, we launched a book on how to make a lawn with your own hands. If this topic interests you, then READ MORE >>

If, however, to organize air circulation forcibly, it is necessary to install fans near the inlet. Thus, the soil will warm up more evenly.

To keep the air warm at night, an additional circuit is needed, for which a fan heater can be used.

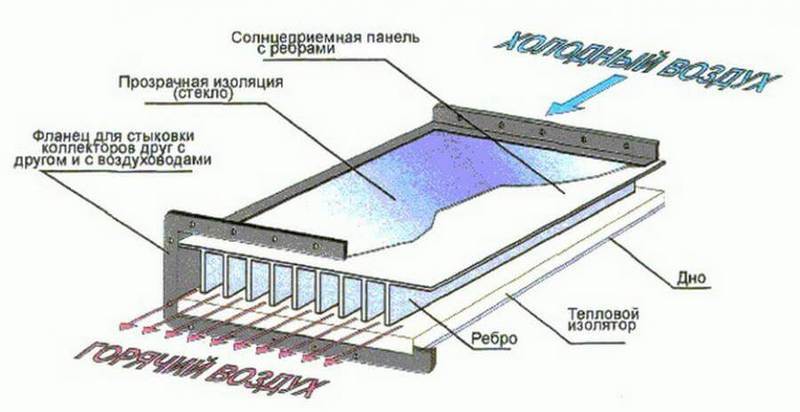

It is not difficult to make a collector. To do this, you need to assemble a box of fiberboard, the height of which should be about 15 cm. You can strengthen it with stiffeners. A layer of mineral wool should be placed on the bottom, which should be covered with an absorber.

All seams must be sealed and the inner surface painted black. The sides must be equipped with pipes through which air will enter and exit. Then the box is closed with tempered glass and the joints are again treated with a sealant.

The box is fixed on the roof, the air ducts are directed into the holes in the walls of the greenhouse. You can supply several similar collectors. The air temperature in them will be about 50 degrees.

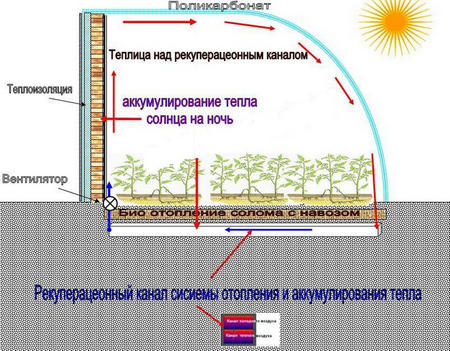

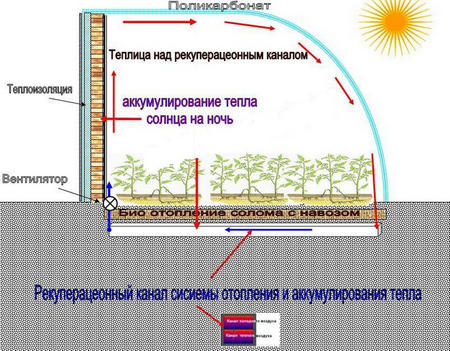

Biological heating of the greenhouse

Such heating is laid when decorating the beds in the greenhouse. 30-60 cm of biofuel is placed under a 20-30 cm layer of earth: manure, peat, straw, and other organic material. It gradually burns inside, giving off heat and supplying plants with nutrients.

Previously, horse manure was used as a biofuel, as the hottest, but at the same time they were afraid not of frost, but of the fact that the plants would rot. It was impossible to ventilate on a very windy day, the heat was immediately blown out. The manure burns all the time, increasing the temperature, it is impossible to adjust it. You can mix it with straw, this will slow down the combustion process, lower the temperature, and the biofuel will last longer.

Another disadvantage is that this is a rather laborious process that involves a lot of earthwork. But if everything is done correctly, the soil will be warm even in cold weather.

The advantage of this fuel is not only warmth for the soil, but also in nutrients for plants. In addition, moisture occurs during evaporation, which will reduce watering.

How it works?

There are four types of solar panels that are used for greenhouses:

1. Solar panels are attached to the greenhouse structure, connected together, connected to inverters and a meter to create a photovoltaic generator. Low weight of panels allows them to be installed on glass, a panel that weighs 12 kg / m² can be installed on a glass greenhouse.

2. There are installations that are integrated directly into the greenhouse frame, they perform two functions: a greenhouse roof and energy production.

3. Thin-film solar panels are also used in greenhouses, they have two advantages:

- The transparency can reach 30%, due to which, part of the light passes through the film, which allows the process of photosynthesis to take place.

- It is very light, unlike a photovoltaic panel.

4. New technology WSPV (Wave Selective Photovoltaic System)

Greenhouse air heating

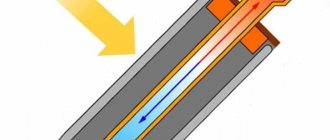

Air has very good thermal insulation properties, so when building a greenhouse, it is worth using polycarbonate or considering double glazing.

In the greenhouse, it is necessary to install air ducts for uniform heating of the soil and air.

Air heating circuit

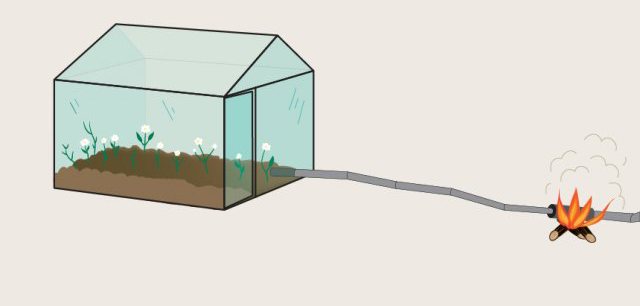

It can be heated with wood, gas or electricity. There are several ways to set up such a system.

- The simplest and most primitive option would be air supply heated from the fire... To do this, a pipe is installed in the center, the diameter of which should be about half a meter, and the length - 2.5 meters. One end extends outside the greenhouse and hot air is fed into it.

- Can be used heat generatorwhich supplies warm air thanks to a polyethylene sleeve. It is fixed to the ceiling and is complemented by perforations. The main disadvantage of this option is the inability to perform high-quality heating of the soil with air.

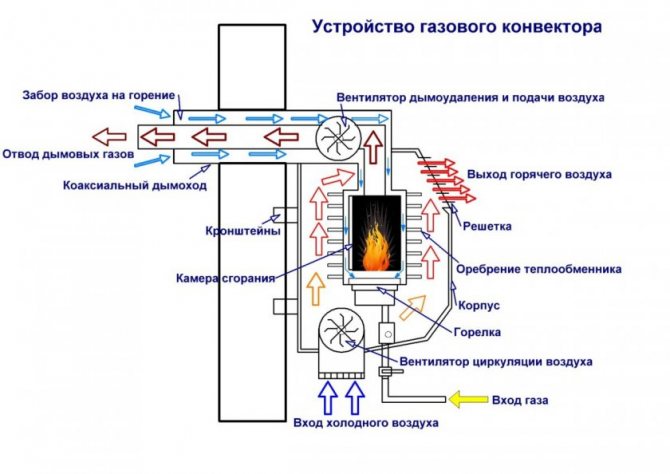

- Another way is to use gas convector... It creates an air stream that circulates around the greenhouse. The disadvantage of this method is that it is necessary to lay out the gas pipes, and place the landings at a sufficient distance from the convector. In addition, this method burns oxygen, so ventilation must be considered.

- You can use heating devices - fan, heat gun... So that the plants do not suffer, the pipe is laid under the beds and is brought out in a certain place, where a heat source is attached to it.

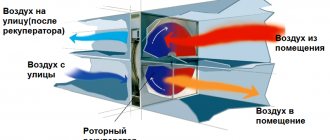

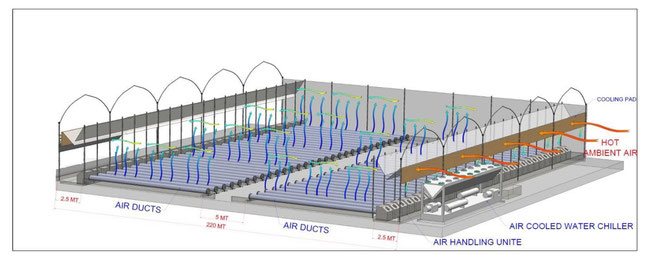

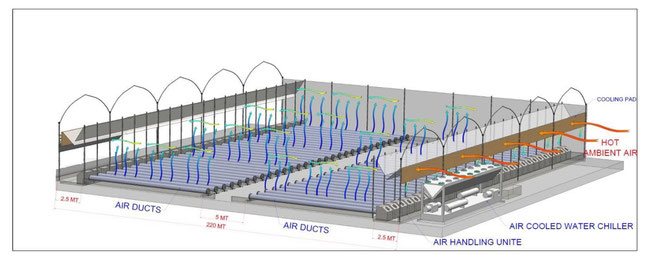

Do-it-yourself heating in a 5th generation greenhouse

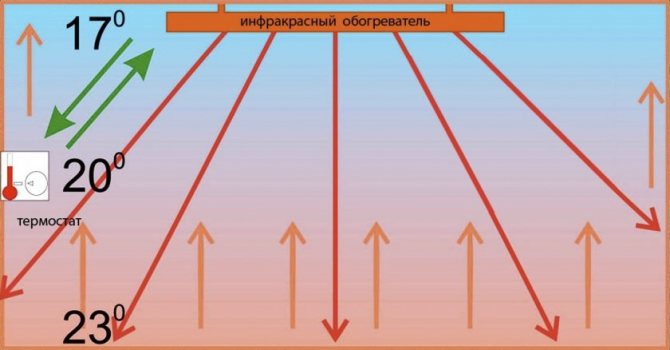

The innovative technology in the 5th generation greenhouses provides for the distribution of air flows through the air hoses, ensuring precise climate control. The concentration of CO2 is uniform throughout the greenhouse, temperature deviations in both the horizontal and vertical planes are 1-2 ° C, which in itself is a serious technological achievement.

Distribution of air flows in the 5th generation greenhouse

This technology reduces heating costs by 25%.

Benefits of using solar panels for greenhouses

- A modular system that can be integrated into any greenhouse.

- High mechanical resistance, withstands hail, falling stones, wind, snow.

- Resistant to moisture and condensation if glass modules are used.

- Low maintenance costs for solar cells.

- Energy savings (long term).

- Reducing the amount of greenhouse gas.

- Uninterrupted power supply.

- Regulation of the degree of heating in the room (in the case of using solar collectors).

- Storing solar energy and using it on unfavorable days.

- The ability to build a greenhouse anywhere.

We suggest that you familiarize yourself with How much mash should be poured into the moonshine still

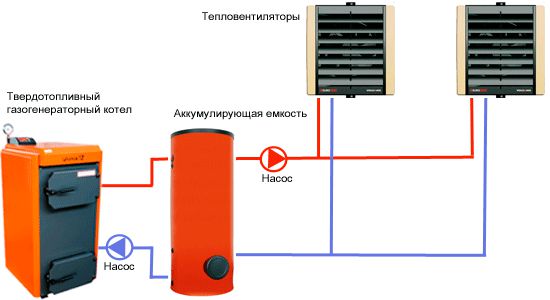

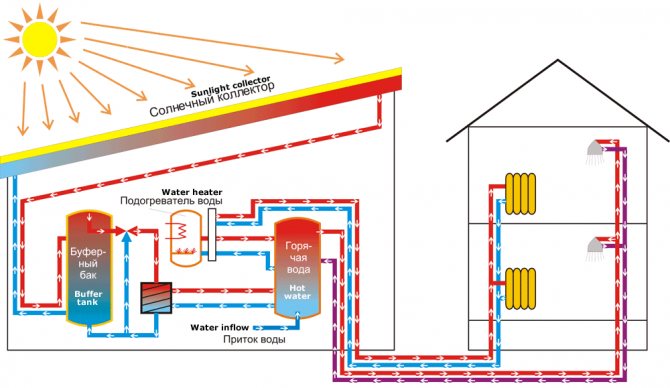

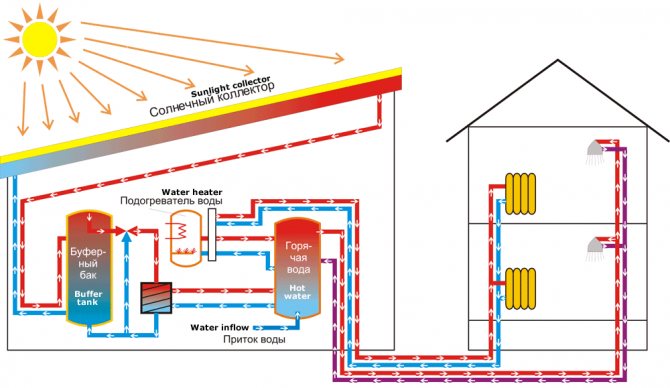

Greenhouse water heating

There are two methods you can use. If the house is heated according to the same principle, the greenhouse is connected to the house system.

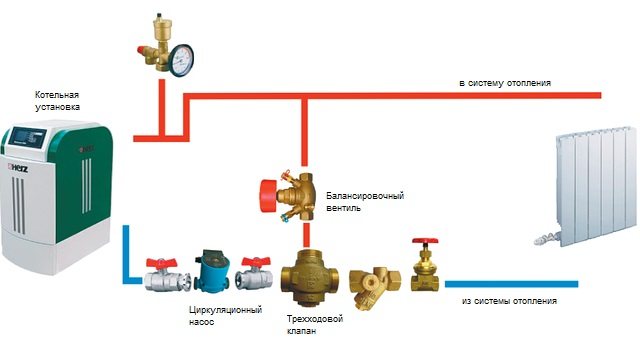

Scheme of water heating of a greenhouse with connection to a common system (for example, using a solar collector)

The possibility of shutting off and draining water is necessarily provided.

Another option is to install a separate boiler.

If a separate system is installed for heating the greenhouse, then it is necessary to install a boiler that can run on gas, electricity or solid fuel.

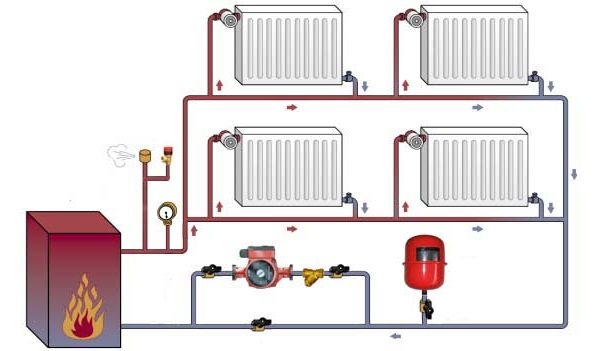

Greenhouse heating scheme using water heating

The cheapest to operate is a gas boiler. You can configure automatic maintenance of the desired mode. In order for the combustion products to be removed from the greenhouse in a timely manner, it is necessary to install a chimney.

The fuel for a solid fuel boiler can be coal or wood. This design requires constant monitoring.

An electric boiler has only one drawback - electricity is expensive.

If the site is gasified, then it is better to stop at a gas boiler. If this is not possible, then you have to make a choice between the other options. It should be noted that it is better to heat a large greenhouse with a solid fuel boiler, but if the area is small, then a small electric boiler can do it.

To determine how many radiators you need to install, you must first calculate the area of the greenhouse by multiplying its length by its width.

Then the calculated thermal power is calculated, for which it is necessary to multiply the area of the greenhouse in square meters by 120.

After that, the thermal power of the greenhouse must be divided by the thermal power of one section of the radiator (this parameter can be found in the product data sheet).The result will be the number of sections that need to be evenly spaced inside the greenhouse.

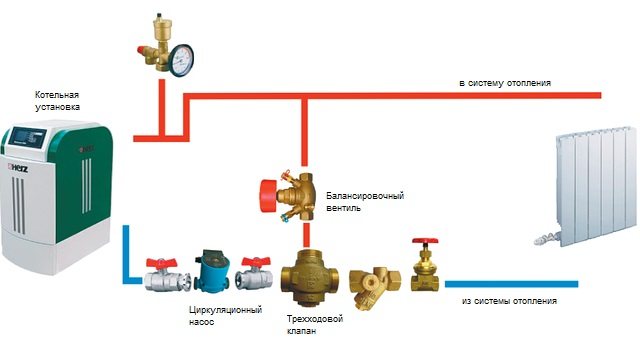

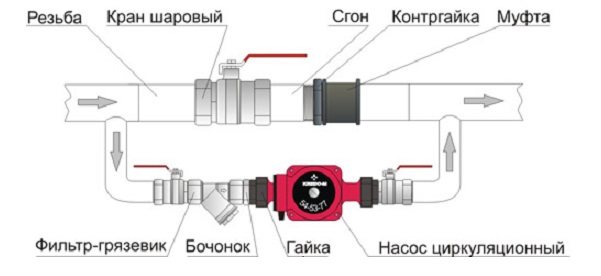

Water heating is always assembled according to a specific scheme. The system includes the following components:

- boiler;

- circulation pump;

- coarse filter;

- balancing valve;

- pipes and radiators;

- expansion tank;

- collector unit (needed if there are several circuits in the system); heat accumulator (for solid fuel boilers).

Boiler connection diagram

Do-it-yourself water heating of the greenhouse: step-by-step instructions

Let's consider connecting the system in stages.

Boiler installation

Boiler installation

This will require either a separate boiler room or a small vestibule. If the boiler runs on gas or electricity, it can be installed directly in the greenhouse.

Two options are possible here - strengthening the boiler on the wall, which must be permanent, or installing it on the floor. This requires an even base. The foundation is ideal.

Chimney connection

This step is necessary if the boiler runs on solid fuel or gas.

The chimney for solid fuel boilers is made of stainless steel and is brought out.

Connecting the chimney to the boiler

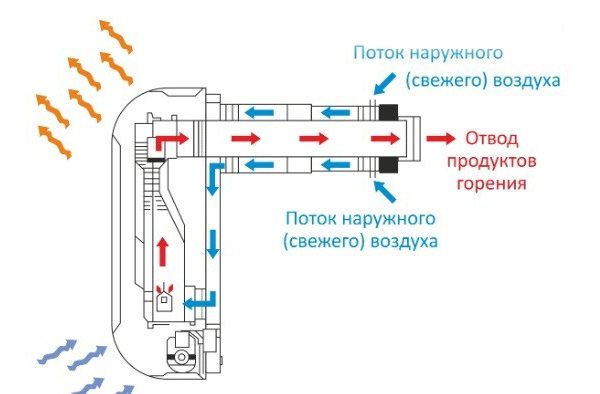

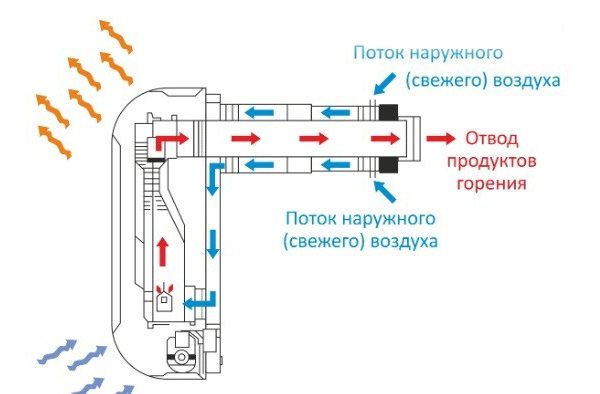

If you plan to use a gas boiler, then the chimney must be coaxial. The outlet to the outside is mounted directly next to the boiler.

Connecting a gas boiler to a chimney

Connecting radiators

They are mounted on walls at approximately equal distances for even heating. Each radiator must be equipped with a Mayevsky tap and an individual valve to shut off the water. The section of the pipe should be 20-25 mm.

Radiator connection diagram

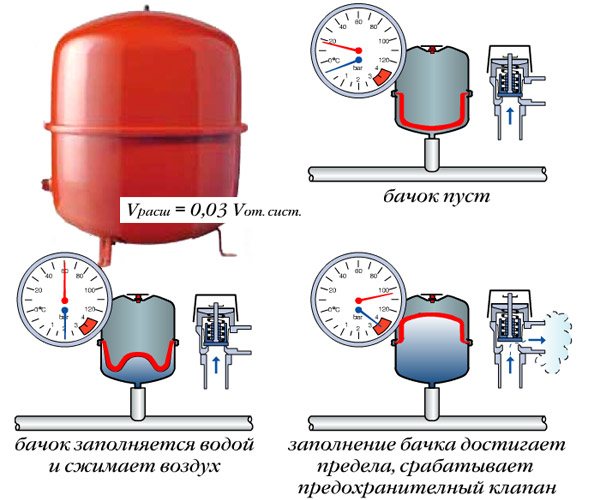

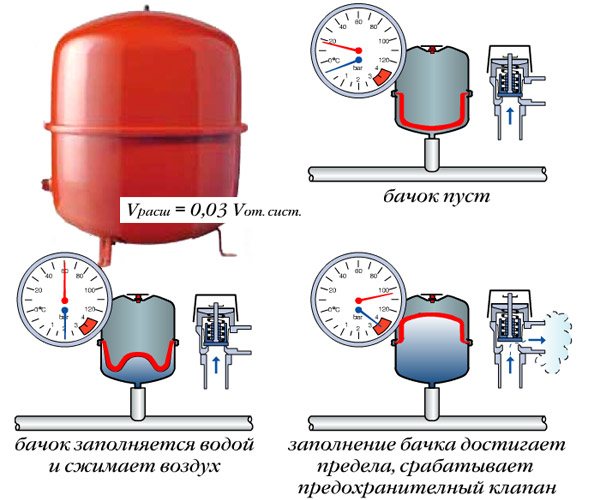

Expansion tank installation

If forced circulation of water is planned, then a closed membrane expansion tank is required. It is needed to maintain constant water pressure in the system, which is achieved by compressing air using a membrane inside the tank.

The tank can be installed anywhere, and it is connected from below by means of a valve.

Expansion tank connection

Installation of the safety group

It includes a pressure gauge that controls pressure, a safety valve and an air vent. All this is placed on a special metal manifold, which is connected to the system with the help of a clutch. This structure should be located immediately after the boiler in the place where the temperature and pressure reach the highest values.

Security group

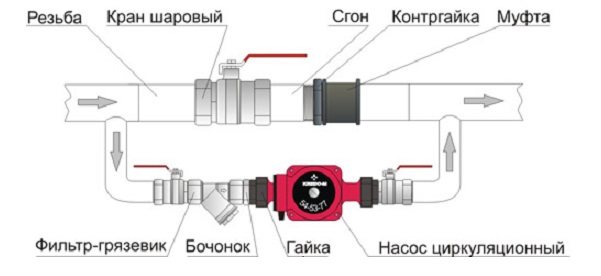

Circulation pump installation

It is necessary for the pressure in the system to be stable and correct. The pump is mounted on the return pipe before it is introduced into the boiler. In order for the pump to last longer, a coarse filter must be placed in front of it.

Circulation pump installation diagram

Air pressure testing

This is a test that is designed to detect errors and defects in the assembly. After the system is assembled, a compressor is connected to it and pressure is applied. Before doing this, all valves and valves must be shut off. The pressure must be brought up to those indicators that are indicated in the technical data sheet for the equipment. After the pressure has stabilized, all joints and assemblies must be checked for tightness. This can be done with regular soap suds that are applied to where the joints are. If bubbles appear, this place is leaky.

Compressor for pressure testing

If the pressure test was successful, then the entire system is filled with water and a test run of the boiler is carried out. At this time, it is necessary to bleed all the air from the system using Mayevsky taps and balance the pressure using balancing taps.

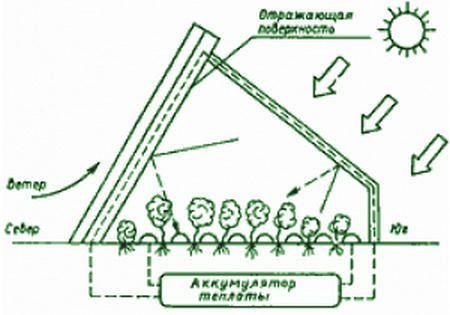

Solar heating methods

The simplest and most inexpensive option for heating a greenhouse is to use solar energy.To use it, you need to install the greenhouse in a place where there is most of the sunlight throughout the day. The material from which the structure is made is also important. Polycarbonate materials are used for the solar heating of the greenhouse. It helps to get an excellent greenhouse effect, as it has a cellular structure.

Solar air collector circuit

Each of its cells contains air, which functions according to the insulator method. Another good material from which it is better to create a greenhouse if you want to warm up with the sun's rays is glass. 95% of the sunlight passes through it. To collect as much heat as possible, build an arched greenhouse. Moreover, it should be located along the east-west line if you want to make a winter version of the design. Additionally, a solar battery can be installed around it. To do this, you need to dig a hole 40 cm deep and 30 cm wide. After that, put insulation on the bottom, cover with coarse sand, and cover the top with plastic wrap and earth.

It is best to use extruded polystyrene foam as a thermal insulation material. It is not afraid of moisture, it does not deform, it has a high degree of strength and perfectly retains heat. This design retains the heat that has accumulated in the greenhouse during the day at night. The downside of this method is that it can only be used during the solar activity season, and in winter it will not give the desired result.

Solar heating for greenhouses with a collector is in great demand today. The profitability of this process depends on the following factors:

- climate conditions (only sunny days are needed);

- arrangement of the greenhouse (it must be well insulated from the environment);

- monetary opportunities.

Solar heating

Solar energy is not worth anything at all, because it acts on its own. But you cannot rely only on the sun, because it does not always shine. The cost of an industrial-type solar collector varies from 20 thousand to 40 thousand rubles. This cost is affordable. But it is also necessary to provide for the option of supplying heat to the room.

We recommend: What are the types of solar water heaters for home heating?

Greenhouse steam heating

The main advantage of this method is the uniform heating of the greenhouse, which has a beneficial effect on the plants. The air is heated by steam, which appears after the water in the boiler boils.

Hot air enters the radiators connected by pipes.

Steam heating system composition:

- boiler for heating water;

- Exhaust valve;

- radiators;

- pump;

- pipes;

- firebox.

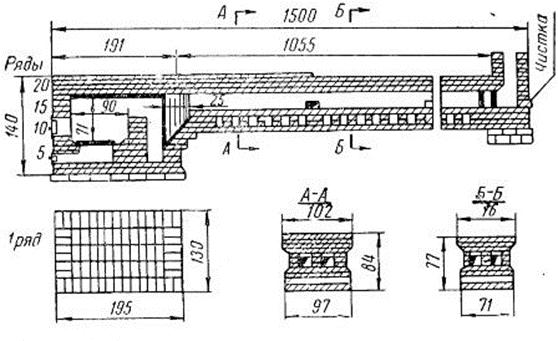

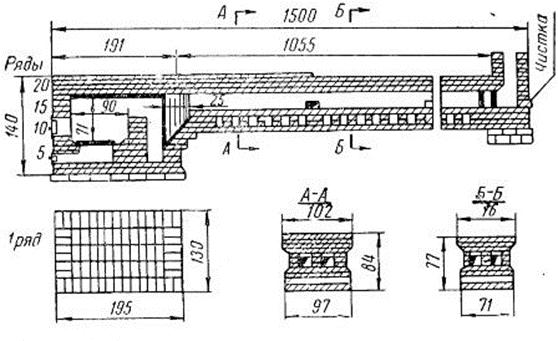

Connecting the furnace to the greenhouse foundation through cutting

The system can be of two types - closed and open. In the first version, the condensate is returned to the boiler using a special pump. If the second option is used, the pipes are made with a slight slope and the condensate enters the boiler on its own.

The system can be high pressure (from 170 to 600 kg / m2), low pressure (from 100 to 170 kg / m2) or vacuum-steam. This parameter is influenced by the length of the pipes and some other characteristics of the system.

Pipe routing can be single-pipe, when both steam and condensate are in the same pipe, or double-pipe, when steam and condensate are separated, but both pipes form a closed loop. The second option is preferable, because it is possible to regulate the temperature by turning the valve.

Such a heating system can run on wood, coal, fuel oil, diesel fuel or natural gas. The boilers also differ. They can be gas-tube, with low power, or water-tube, which are safer.

Water tube boilers can be vertical (drums are located at different heights) or horizontal (drums are equipped with collectors).The boiler consists of a burner, a furnace, an ash pan and a drum.

What to look for during installation

- It is necessary to install only metal pipes, since plastic pipes will not cope with a heavy load.

- Particular attention must be paid to reliability. All components must be manufactured in a verified factory.

- It is necessary to correctly calculate the boiler output.

Greenhouse stove heating

The main source of heat in this case is a solid fuel boiler that runs on wood or coal (recently, Buleryan-type stoves have been popular).

Greenhouse oven

The easiest way is to install a boiler and a pipe that will remove smoke and combustion products. You can add pipes and radiators, then the quality of heating will increase significantly. It must be remembered that the chimney must be cleaned of ash and soot in a timely manner.

One of the disadvantages of this option is excessive air drying. To maintain the required humidity level, you can simply place a large container filled with water in the greenhouse.

Furnace heating

An important plus of such a system is the ease of installation, which even an inexperienced master can handle. In addition, stove heating is much cheaper than electric heating.

Furnace heating of the greenhouse: step-by-step instruction number 1

Greenhouse ovens

First stage... In the vestibule of the greenhouse, it is necessary to build a foundation, on which then lay out a brick firebox.

Brick oven with hog

Second phase... A chimney is laid out along the entire length.

The hog base and blower chamber with side air intakes

Firebox and chimneys

Stage three... From the opposite side of the greenhouse, a pipe for exhausting smoke is brought out. Thanks to this design, all combustion products will be removed, and heat will remain in the room.

Continuation of the furnace and overlapping the hog Connection of the furnace with the greenhouse foundation through cutting

Water tank mounted above the firebox

A bed located directly on the stove

Ready oven in the greenhouse

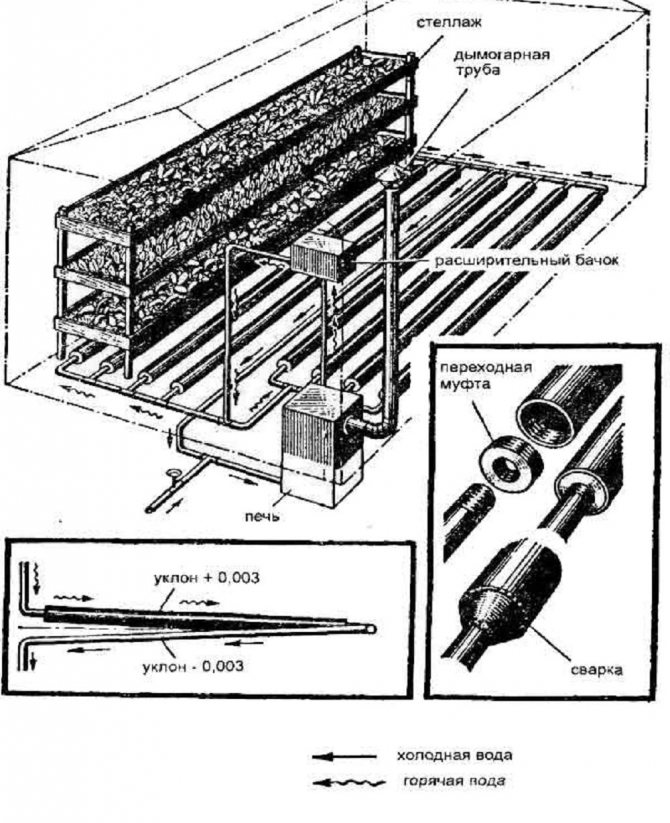

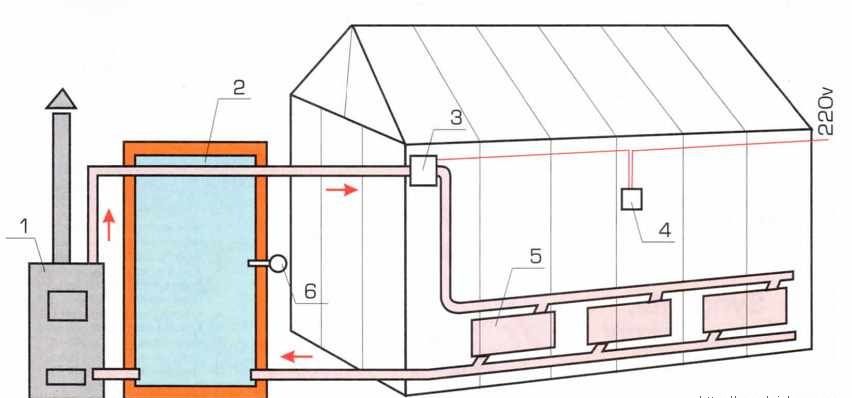

Furnace heating of the greenhouse: step-by-step instruction number 2

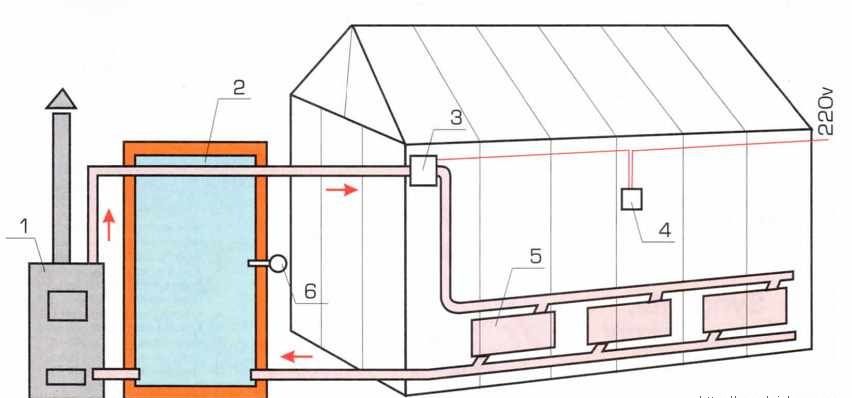

Heating system diagram:

- 1 - heating boiler;

- 2 - thermos tank;

- 3 - circulation pump;

- 4 - relay-regulator;

- 5 - registers;

- 6 - thermocouple.

First stage... You will need a large metal barrel. Its inner surface must be protected against corrosion. To do this, it must be painted, preferably in two layers.

Second phase... Several holes are punched in the body. One of them will be needed to connect the chimney, the others for the tap and the expansion tank.

Stage three... It is necessary to weld the stove itself, for which sheet metal is used. Then it is inserted into the barrel.

Fourth stage... A piece of pipe is welded to the hole in the barrel intended for the chimney. The total length of the smoke outlet structure must be at least 5 meters.

Fifth stage... An expansion tank is mounted on the barrel. The optimal capacity is 20-30 liters.

Sixth stage... Pipes are installed throughout the room. They can be laid out directly on the ground, keeping a step of 1.2 meters.

Seventh stage - a pump is installed to ensure the movement of water in the system.

Solid fuel boiler in a greenhouse

After the entire system is assembled, you need to turn on the water and check the tightness of all joints. If there are leaks, they must be repaired immediately. After that, you can check the operation of the oven.

Thermal energy for your home: how to make a collector with your own hands?

For the manufacture of the device, polycarbonate sheets, copper or polypropylene pipes can be used.

The most versatile design is the development of the Bulgarian engineer Stanislav Stanilov. The main principle of this collector is the use of the greenhouse effect. The storage device is a tubular radiator placed in a heat-insulated wooden box, welded from steel pipes.Use 1 ”or” water pipes to supply and drain water.

It is also possible to make a camping flashlight from solar panels. Read more about this here:

The box is insulated from all sides with foam, expanded polystyrene, mineral or ecowool. The bottom is especially carefully insulated, where a sheet of galvanized roofing iron is placed on top of the insulation, on which the radiator itself is placed. It is fixed in the box with steel clamps. The metal sheet and the radiator are painted with black matte paint, and the box is covered with white paint on all sides, except for the glass lid. The cover glass, through which sunlight will pass to the radiator, is well sealed. A metal barrel placed in a plank or plywood box can serve as a heat accumulator, in the cavity of which it is filled with ecowool, dry sawdust, expanded clay, sand.

Required tools and materials

The main principle of operation of such a collector is the use of the greenhouse effect.

- glass (for example, 1700/750 mm);

- glass frame;

- hardboard for the bottom;

- board with a section of 120/25 mm;

- steel strip with a section of 20 / 2.5 mm, length 3 m;

- overlay corner;

- wooden block with a cross section of 50/30 mm;

- coupling;

- radiator pipe;

- intake pipe of the radiator;

- clamps for fastening;

- galvanized iron as a reflector;

- heat insulator;

- tank for 200-300 liters.

Manufacturing: step by step

The design of the solar collector is simple

- A box is hammered out of the boards, the bottom of which is reinforced with a bar.

- Thermal insulation (polystyrene, expanded polystyrene, mineral wool) is placed on the bottom, on top of which a sheet of iron or tin is placed.

- A radiator is placed on top and secured with steel strip clamps.

- All joints are sealed, joints and cracks are covered.

- Radiator pipes and sheet metal are painted black.

- The box and the water tank are painted silver. The water tank is placed in a heat-insulated box or barrel (heat-insulating material is poured between the tank and the box walls).

- To create a constant low pressure, an aquacamera with a float valve is purchased, like in a toilet barrel. It can be purchased at a plumbing store.

- In the attic of the house, under the roof there is an aquacamera and a water accumulator (tank). The aquacamera is placed at least 0.8 m above the tank.

- The collector is placed on the roof of the south side of the house at an angle of 450 to the horizon.

- Next comes the connection of the entire system with pipes: half-inch pipes are used to mount the high-pressure part of the system from the aquacamera to the water supply. Low-pressure parts are mounted with inch pipes. The minimum number of pipes is 12 pieces, but, depending on the distance between the parts of the collector, 18-15 pipes will be needed, but not less than 12.

- To avoid air pockets, the system is filled with water from the bottom of the radiator. As soon as the entire system is filled with water, water will flow from the drainage tube of the aquacamera.

- We open the valve in the pipe to fill the tank.

- The water starts to heat up immediately. Warm water rises up, displacing cold water, and it automatically enters the radiator.

- As soon as some of the water is used up, the float valve in the aquacamera will be activated and cold water will flow back to the bottom of the system. There is no mixing of water.

At night, it is advisable to block the access of water to the tank so that heat loss does not occur.

Video: the device of an air solar collector for home heating

Video: using solar energy to heat the pool

Video: manufacturing and installation of a greenhouse heating manifold

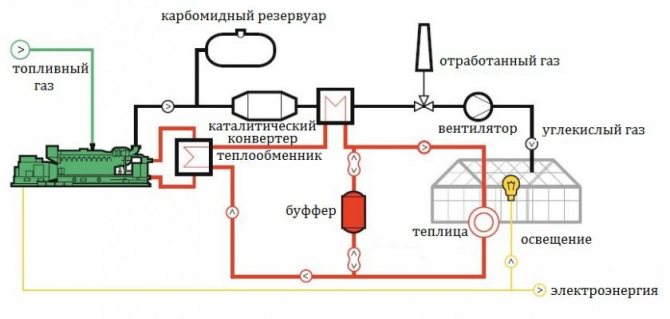

Greenhouse gas heating

Systems providing this type of heating can be divided into three types:

- Infrared.

- Catalytic.

- Convection.

Gas-air and gas-water systems can also be distinguished.Heaters with open burners, convectors and systems with infrared burners are ideal for greenhouses.

Heaters with open burners

The structure includes a thermostat, main and pilot burners. The system is connected to a gas cylinder. The disadvantage of this method is that oxygen is burned, so ventilation is required.

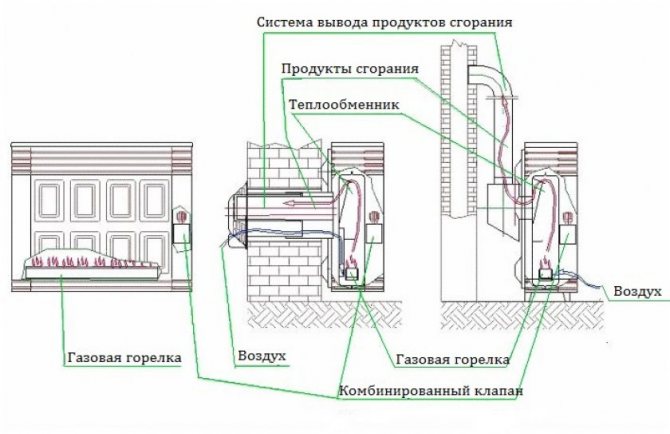

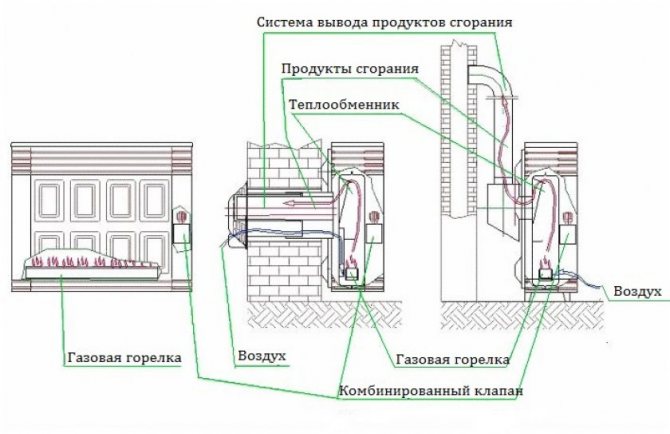

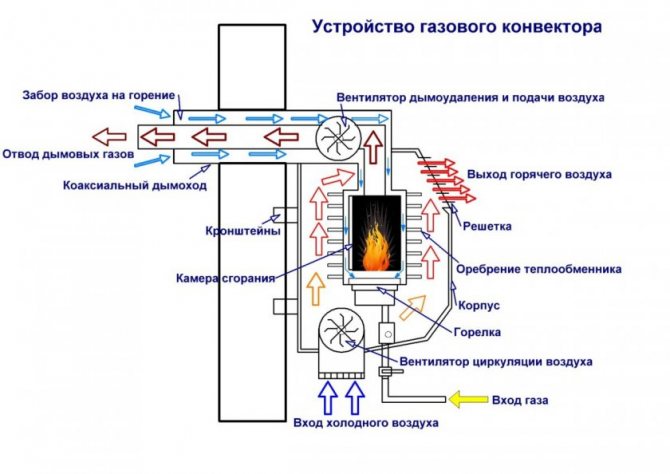

Gas convectors

Such equipment consists of the following parts:

- Fireproof housing. It must be heat resistant.

- A heat exchanger that heats the air.

- Gas burner inside the heat exchanger.

- Combined valve that regulates pressure.

- System that removes combustion products.

- A thermostat that controls the microclimate.

- Automation that controls the operation of the system.

Combustion products can be discharged using two different systems.

The chimney system includes a vertical chimney, which is used to remove combustion products outside.

Parapet system - combustion products enter the coaxial pipe, which is laid through the outer wall.

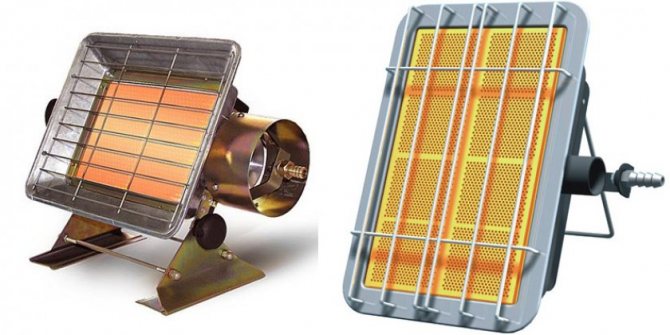

Gas heaters with infrared burners

This design is ideal for heating a large room. When choosing equipment, it is necessary to focus on those heaters that are intended for the street.

Such an apparatus consists of the following parts: a body in the form of a cylinder, into which a gas cylinder is built; stand and hose for connecting the cylinder and the burner; a grid with a large section and a cylindrical handicap, a control panel is attached to it; gas burner umbrella.

The device is powered by propane. Just 11.5 kg will provide 15 hours of uptime.

An important difference between heaters of this type is that it is not the air that heats up, but objects that are at a certain distance.

How to conduct gas into the greenhouse with your own hands

It is important to remember that the connection to the main gas pipeline should be carried out only with the involvement of the appropriate services. Any independent actions are prohibited here.

To mount gas heating in a greenhouse with your own hands, it would be optimal to dwell on the option with infrared burners. First you need to think about where the device will be mounted - on the floor, walls, parapet.

Then ventilation is mounted, which can be assembled from PVC pipes.

After that, the equipment is installed. It is important to follow a few rules:

- There should be a distance of 1 m from the soil to the device.

- A similar distance is maintained from the plants to the device.

- Several infrared devices are located no closer than half a meter from each other.

After that, a hose is connected to the reducer on the cylinder, the other end of which is fixed to the device. The joints are reinforced with clamps.

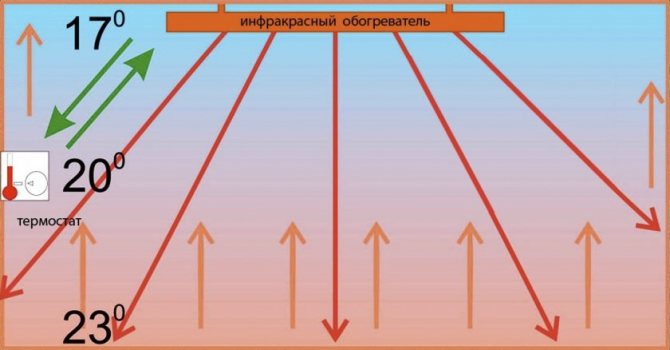

Infrared heaters: how to heat a greenhouse in winter

These heaters operate on the principle of solar heating - they heat the soil and everything around, and this all around then heats up the air. Such heaters for a greenhouse are easy to install, they also do not occupy a useful area, because they are mounted on the ceiling of the greenhouse.

Thermal film is a heater of the same type. In operation, it is not as convenient as a ceiling heater, but it will evenly warm the ground in the greenhouse and reduce energy losses. So there is plenty to choose from.

Infrared heaters can be used to heat the greenhouse.

We also recommend reading:

Do-it-yourself winter greenhouse: 4 types of heating and video Gas heater for a greenhouse: advantages and installation features How to heat a greenhouse in freeze: 4 ways High-quality heating tape for a greenhouse: a guarantee of an excellent harvest

You can also heat the greenhouse using the electric heating method. This is an underground device, because the expectation is that it will not take up space either. This method helps the air and soil to warm up evenly.With such heating, you can regulate the temperature, use the automatic temperature control, and this has a good effect on the harvest. This is a fairly economical heating method and you will be pleasantly surprised by the equipment costs.

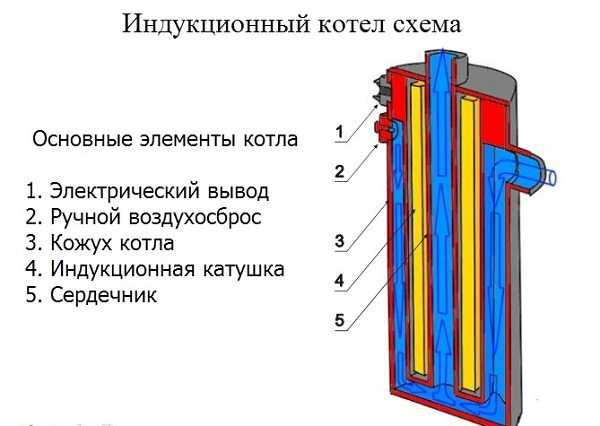

Greenhouse electric heating

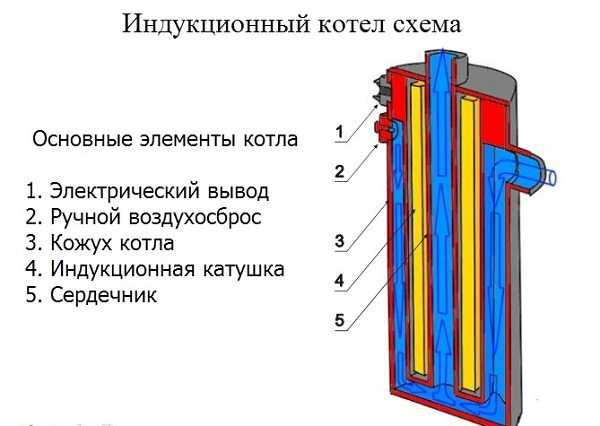

There are several options:

- Air: heat guns, fan heaters or oil coolers.

- Water: boilers with heating elements, working on electrodes or on the principle of induction.

- Electric infrared heaters (differ in that they do not heat the air, but directly objects, reducing electricity costs by 30%);

- Heating cables that are laid directly in the soil.

We already talked about the first three options earlier in the article, now he will consider the last method of heating the greenhouse - using a heating cable.

Heating cables can be of various types:

First type - resistive cables. They are quite inexpensive, but can lead to either overheating of the soil or insufficient heating.

Resistive cable

Second type - self-regulating cable. It consists of two carbon fibers separated by a semiconductor. It saves energy and doses the heating of the soil.

Self-regulating cable

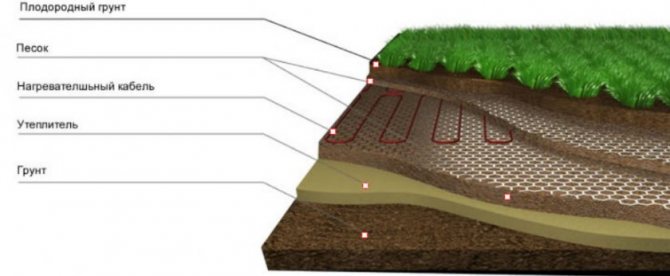

Installation of the cable system

The better the cable is laid, the more efficient the system will work. Its arrangement includes the following stages:

- It is necessary to remove a layer of soil about half a meter.

- Add some fine sand. The thickness of the pillow should be about 5 cm.

- Install thermal insulation, for example, penoplex.

- Lay waterproofing - polyethylene.

- Pour another 5 cm of sand on top.

- Install fine-mesh metal mesh.

- Then the cable is laid in the form of a snake. It is important to keep a step of about 20 cm.

- The cable can be secured with plastic clamps.

- After that, 5 cm of sand is poured again.

- The structure is closed with a protective mesh made of plastic or stainless steel.

- Now 40 cm of soil can be laid.

- The sensor, with the help of which the temperature will be controlled, is mounted about a meter above the soil surface.

Criteria for choosing a heating system

What needs to be considered before installing a greenhouse heating system?

- Finance. We must be aware that a winter greenhouse will require certain expenses.

- Plants. It is necessary to take into account which crops will grow in the greenhouse, what level of heat is needed for them.

- Fuel availability.

- Features of the climate.

- Arrangement of the greenhouse and its purpose.

- The size of the heated room.

- Location of the greenhouse.

- The ability to carry out constant monitoring.

Solar panel performance

Many people doubt the efficient operation of these installations, because the weather in our country is not always sunny. And in winter, cloudy days are almost constant, and severe frosts contribute to the rapid waste of accumulated energy.

Today's solar power plants are very powerful (from 200 W - for one module). They generate energy all day long, and capture light even in thick clouds or precipitation. True, in bad weather, their power is almost halved. Their advantage is that they are able to accumulate energy for future use. and with a lack of sunlight, they will give back the already accumulated one.

In winter, the plants operate at full capacity, but their productivity is reduced due to the short daylight hours. The generation of batteries made from amorphous silicon doesn't even need to be pointed at the sun. they work great in moderately cloudy conditions. The disadvantages of this type of modules include the fact that they require a large area for placement.

The effectiveness of their work also depends on the region. For example, in St. Petersburg or Moscow, productivity will be slightly lower than in the southern regions. But this does not mean that their use in the northern regions is not advisable.Moreover, they have been used there for a long time all year round and quite effectively.

Internal thermal insulation

To make heating more efficient and cheaper, you need to pay attention to thermal insulation.

The plinth can be sheathed with a suitable material - foam or foam. Then polycarbonate is mounted on top, which is pasted over with foil insulation or just foil.

Wall decoration in a greenhouse with foil

The frame part can be thermally insulated with double glazing. Polycarbonate will be used optimally. The inner part can be additionally covered with bubble wrap.

Friends! As part of our portal, we launched a book on how to make a lawn with your own hands. If this topic interests you, then READ MORE >>

Friends! As part of our portal, we launched a book on how to make a lawn with your own hands. If this topic interests you, then READ MORE >>

Sizing calculation

Calculation of dimensions in order to make a solar collector for heating with your own hands, first of all, is aimed at determining the load of the heat supply system, the coverage of which is assumed by this device. It goes without saying that this implies the use of several energy sources in the complex, and not just the energy of the sun. In this matter, it is important to arrange the system in such a way that it interacts with others - then this will give the maximum effect.

To determine the area of the collector, you need to know for what purposes it will be used: heating, heating water, or both. After analyzing the water meter data, heating needs and insolation data of the area in which the installation is planned, the collector area can be calculated. In addition, it is necessary to take into account the needs for hot water of all consumers that are planned to be connected to the network: washing machine, dishwasher, etc.