The organization of individual gas supply gives a lot of advantages to the owner of a private house, removing his dependence on central communications. In addition, many regions of the country to this day do not have full coverage with main gasification. In this case, it remains to think over the methods and means of storing explosive and therefore demanding fuel. The most rational and financially advantageous solution is a gas tank. What it is? It is a capacious reservoir that can store an impressive supply of gas, sufficient for long-term maintenance of the house.

Appointment of equipment

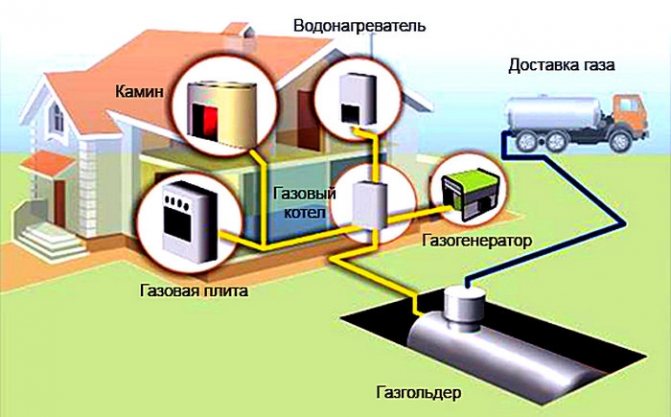

The gasholder is used as a source of gaseous substances. On the one hand, it acts as a storage facility, and on the other, as a container from which fuel is provided to supply target equipment. The most common installations for heating systems. It is for these purposes that gas boilers and boiler tanks, as well as kitchen stoves, are more often used. Delivery means are pipelines and related communications with plumbing fixtures. At the same time, the gas for the gasholder can be different, but it is for domestic purposes that butane and propane are more often used.

What to look for when choosing

When choosing a gas tank for installation in the country, you need to be aware of two things.

First, the gas tank must be designed for use in Russia. Otherwise, there is a great risk that the gas supply will stop just at the moment when it is most needed - in cold weather.

Secondly, how much you have to pay for its maintenance directly depends on the quality of the gas tank. Maintenance of cheap gas tanks that are poorly protected from corrosion costs tens of thousands of rubles a year. Maintenance of a high-quality gas tank is many times cheaper.

Equipment device

The traditional design is a one-piece container, the upper part of which provides only one technological opening - the neck. The higher it is, the more effective the protection of the main body from climatic influences. Through the neck, the fuel mixture is filled and taken from the container. The features of the device include the materials used for the gasholder. What is it from a technical point of view? The construction of household models is made mainly of steel with rare inclusions of rubberized materials, which provide a sufficient degree of tightness. Domestic gas tanks are mainly based on low-alloy steel alloys 17G1S and 09G2S. The outer sides are necessarily treated with anti-corrosion compounds made of polyurethane substances, bitumen and epoxy mixtures.

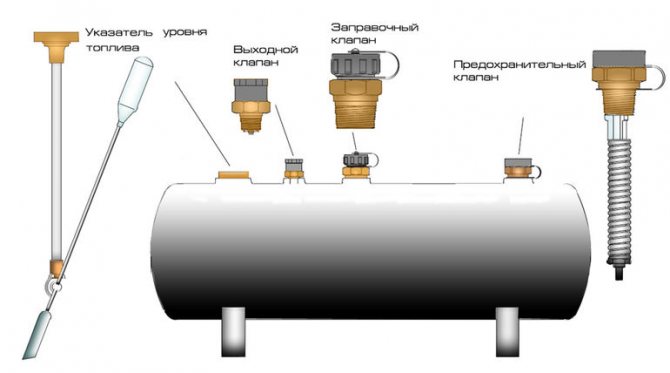

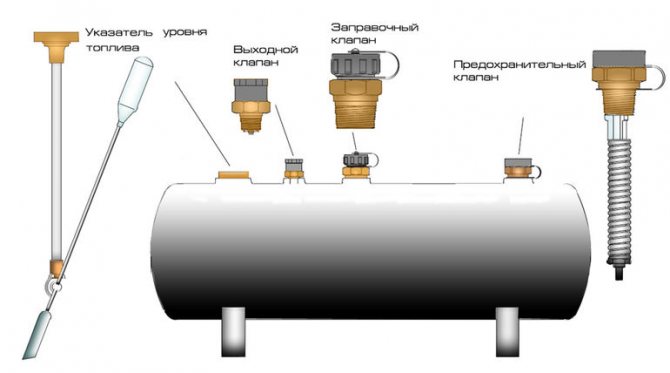

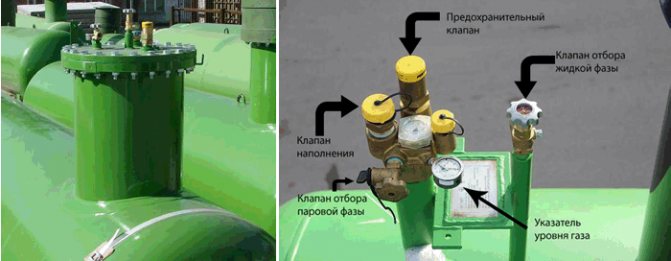

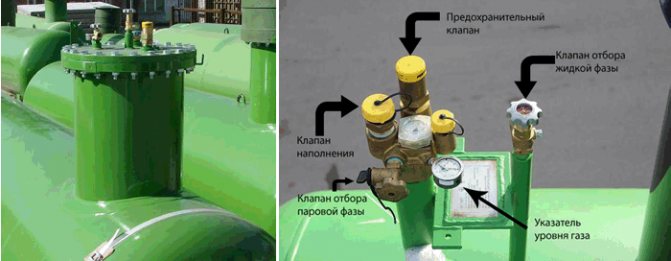

Work processes and equipment control are carried out through shut-off and control valves. Its composition may vary, but even the simplest gas tank for a home will include safety and filling valves, fill level sensors, a regulating reducer, etc. Expensive models provide for the presence of automation with high-precision pressure gauges and programmed control.

Choosing a gas tank without mistakes, nuances, expert recommendations

Do not use used, homemade and other containers that do not meet standards.

To ensure a high level of safety, only high-quality factory-made gas equipment should be used.When buying, you need to make sure that there are certificates, official warranty obligations. Also noteworthy are the following facts:

- Strong enough walls are made of steel with a thickness of 6-10 mm.

- Built-in stiffeners increase resistance to mechanical stress.

- The most inexpensive anti-corrosion layer, bitumen mastic, is less durable.

- Epoxy resin performs its functions for a long time. But such a coating can be damaged by shocks, temperature drops.

- You will have to pay more for the polymer layer. But such a coating retains its tightness for many years, so in the end it will be possible to save money.

- Additional protection is provided using active and passive electrochemical technologies.

- It is better if all safety and shut-off valves are standard. In this case, these components are covered by the general manufacturer's warranties.

- In the underground version of the installation of a horizontal gas tank for a country house, additional heating can be excluded.

If necessary, install a specialized evaporator

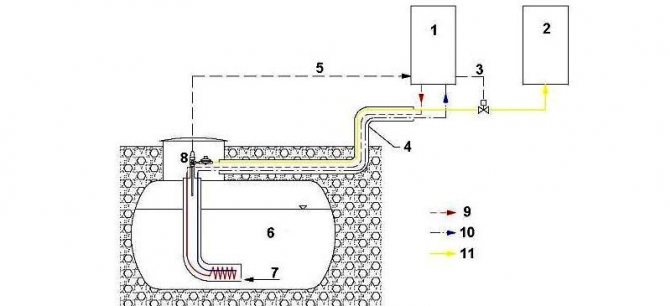

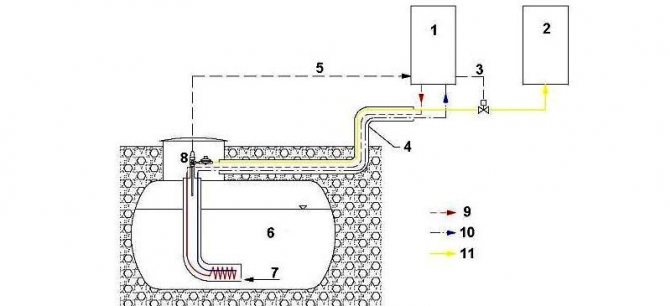

The diagram shows the components of the corresponding tank equipment (6). To control gassing, a sensor (8) installed in the throat is used. The signal from it (5) goes to the heating boiler (1). The liquid mixture of propane and butane (7) is heated by a coil, which is connected to the supply (9) and return (10) pipes.

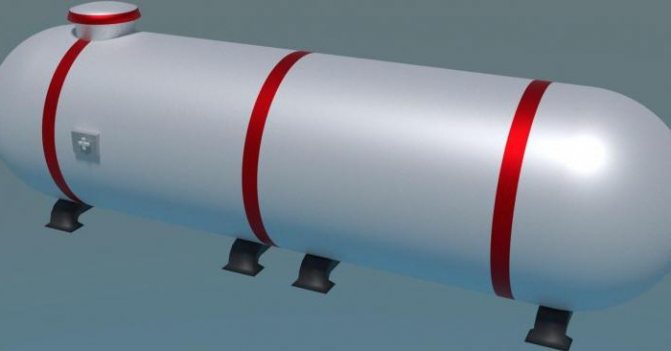

A hatch of sufficient width is useful for technological inspection

Periodic removal of paraffins and other contaminants is stipulated by standard operating rules. It is also necessary to visually check the condition of the seams. These routine operations are performed at least once every 10 years.

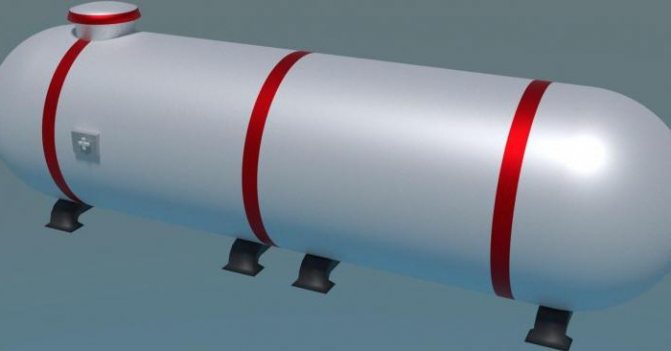

These supports provide a secure fit. When buying, you need to make sure that you have such "paws" so as not to use dubious devices for fixing a heavy container

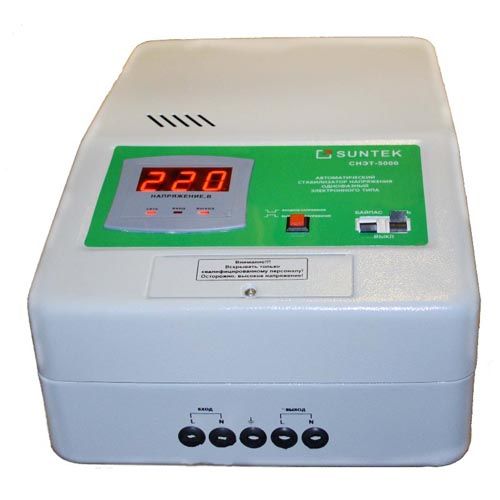

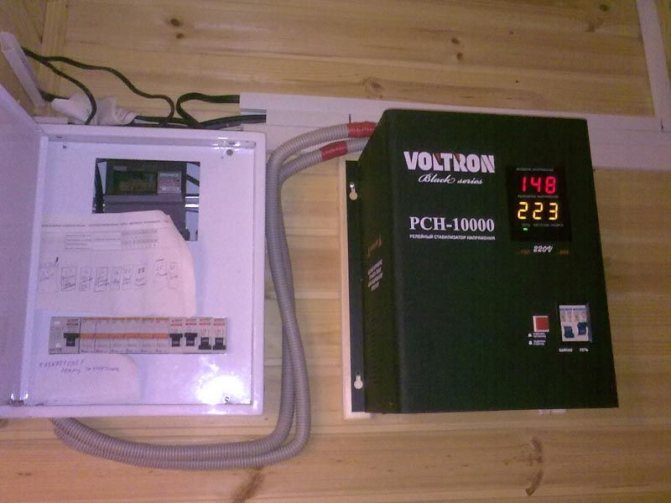

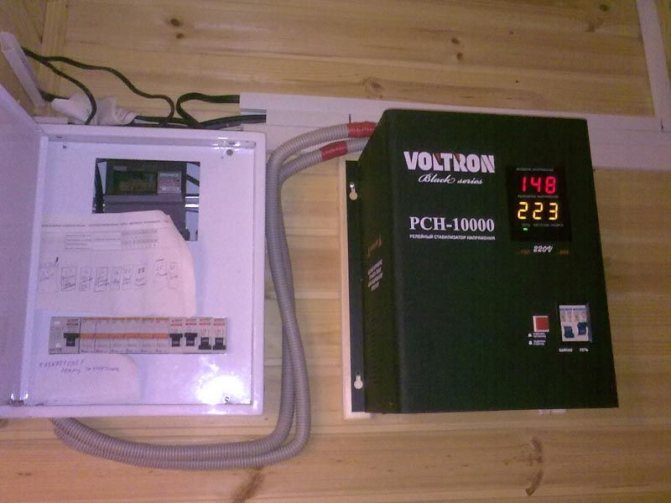

In order to understand which voltage stabilizer to choose for a private house, you need to answer the following questions for yourself:

- What is the total power of the equipment that will be connected to it or what is the nominal value of the machine installed at the input;

- How many phases are planned to be connected to the stabilizer;

- What is the required input voltage range;

- Output voltage accuracy.

Other issues, such as speed and price category are not so important anymore and everyone will have to solve them, based on their wishes and capabilities.

On some devices, there are two electronic displays at once - input and output voltage

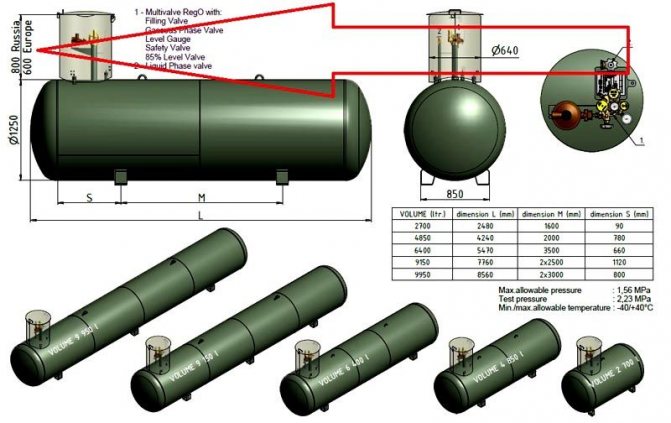

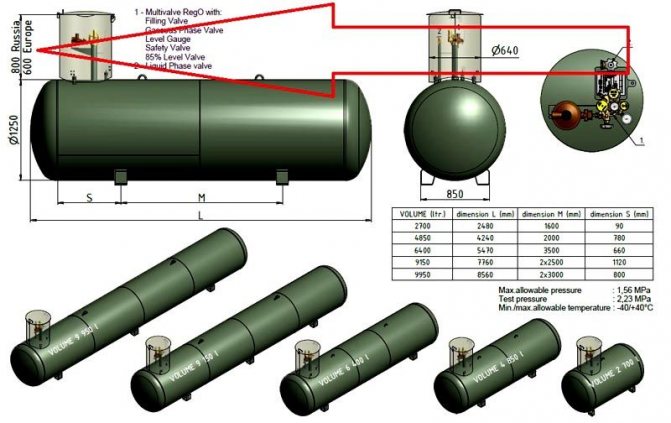

Tank characteristics

The main technical and operational characteristics include wall thickness, operating temperature, maintained pressure and volume. Usually, sheet steel with a thickness of 7-10 mm is used in the manufacture. It should be borne in mind that models of the European standard may have lower indicators - about 5-6 mm. But thin walls are not designed to store domestic gas mixtures. For a gas tank in Russian regions, it is more likely that liquefied propane-butane will be used without special processing, therefore, the requirements for the reliability of the structure are increasing. The temperature range also depends on the region of use. As a rule, manufacturers provide enclosures with frost-resistant coatings rated for –40 ° C.

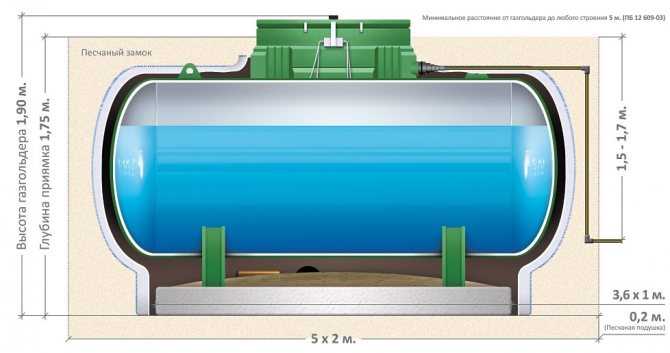

With regard to volume and pressure, these indicators are interrelated. For home use, it is recommended to purchase a reservoir with the ability to correct pressure up to 16 atm. The volume of the gasholder will be 2,000-5,000 liters. There are also household models with a capacity of more than 10,000 liters, but due to their size, such gas storage facilities are rarely used.

Main characteristics and features of gas tanks for a private house

On the modern gas equipment market, there are various types of Russian and foreign types of gas tanks, differing in the following criteria:

- design features: horizontal;

- vertical.

applied pressure:

- low pressure;

high pressure.

- 1000;

- without a neck;

Until recently, manufacturers focused mainly on the creation and sale of horizontal gas tanks, which were initially (and still) used in industry, but gradually began to be used in the domestic sphere.

Only in staged photos, chopping wood seems to be a simple and easy task.

In reality, this is hard work, associated with increased injuries, calluses on the palms, and other troubles. Firewood must be stored in special conditions. It is impossible to automate the supply of such raw materials in everyday life. Similar disadvantages can be found when analyzing the characteristics of other energy resources:

- The loading of wood pellets (pellets) requires a complex loading system.

- Coal is dirt and dust.

- The use of electricity for high-grade heating at the current level of technology development is economically inexpedient.

- Diesel is too expensive.

With a comprehensive assessment of the significant factors, it is not difficult to draw a conclusion about the advantages of gas. But for this option, you need a nearby highway, or the organization of regular delivery of fuel in a liquefied state. Instead of relatively small cylinders (up to 50 liters - maximum), you can purchase and install a large container. Its volume is selected taking into account real needs.

Autonomous gasification of the summer cottage will help to solve the problem quickly, without excessive costs

The following list describes the principle of operation of the equipment and shows the purpose of the individual components:

- A propane-butane mixture in a liquid state is filled into a gas holder.

- The container is installed below the level of soil freezing. At positive temperatures, gas is formed.

- It enters the house through a pipeline through a special device in which condensate is discharged.

- Control functions in modern systems are performed by a specialized telemetry unit.

- For reliable fixation, preventing extrusion by heaving forces, the container is fixed on a concrete slab.

- To prevent the appearance and development of corrosion processes, the metal parts of the structure are protected with special coatings. Electroplating techniques are also used.

Gas tank design

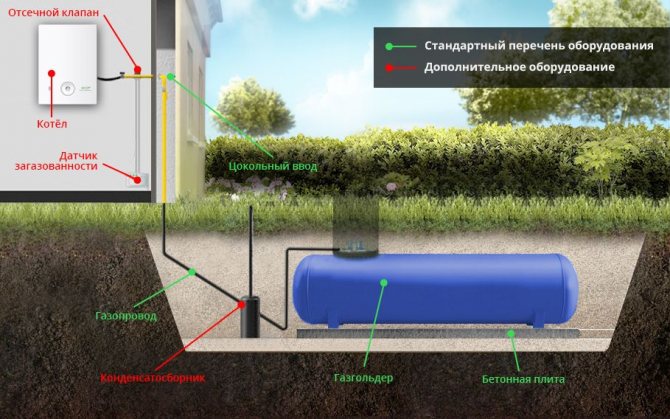

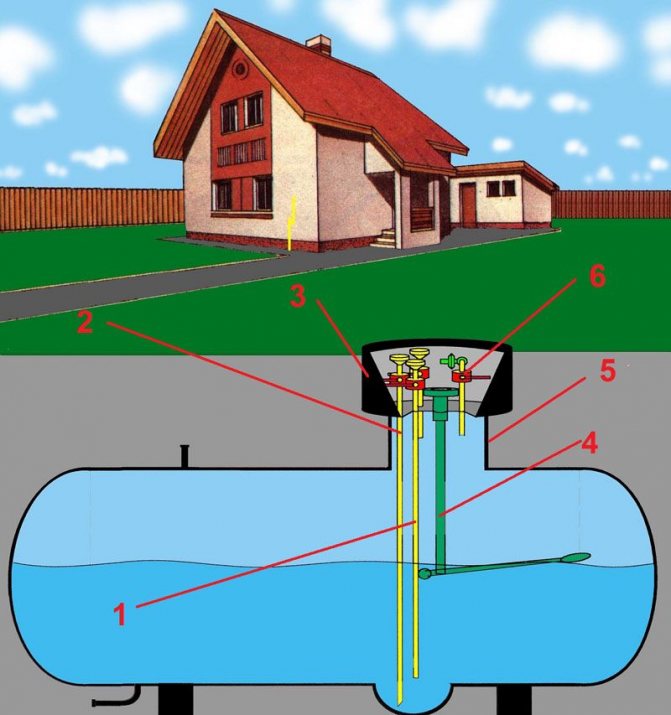

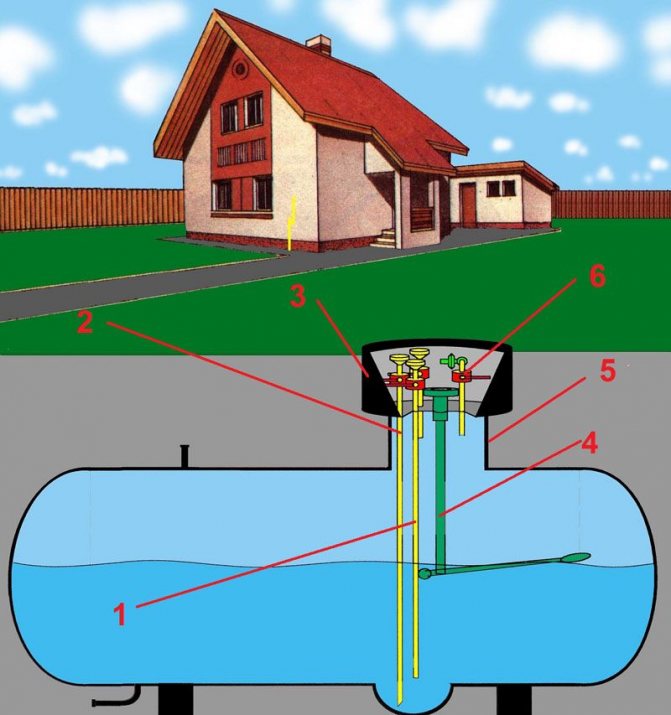

The illustration shows the details of the standard equipment:

- Pipes that are used to extract the liquid phase (1) and condensate (2).

- Float device (4) for level measurement.

- Two-stage reducer branch pipe (6). This device maintains a constant head in the user's gas supply system.

- Well (3), which houses the technological equipment.

- High neck (5).

Gas tanks for a country house do not need to be registered with government agencies. It is quite enough that the servicing filling company has the necessary permits to carry out its activities.

However, already at the stage of project preparation, the legal requirements of the current standards for the installation of containers (household category) for gas storage should be taken into account:

- It is necessary to make a convenient passage for filling equipment. This path should not pass over the reservoir, other parts of the gasification system.

- The minimum distance from the gas tank to the country house is 5m. With an increase in volume, it is increased (10 cubic meters - 10 cubic meters; 20 cubic meters - 20 cubic meters).

- You should study the entire list of restrictions. It indicates the permissible distances to warehouses, schools, highways, and other facilities.It is these standards that are studied by the responsible employees of the Ministry of Emergency Situations (fire supervision) during inspections.

- If the base is made of reinforced concrete at the installation site, you should take a break for at least a month after pouring to gain sufficient strength. For this reason, it is preferable to use a prefabricated board of the correct size.

You must first perform a geodetic survey. Specialists will make a conclusion about the possibility of installing a gas storage facility in a given area. They will check the groundwater level, the presence of stray currents, seismic indicators. In some situations, only ground installation is possible.

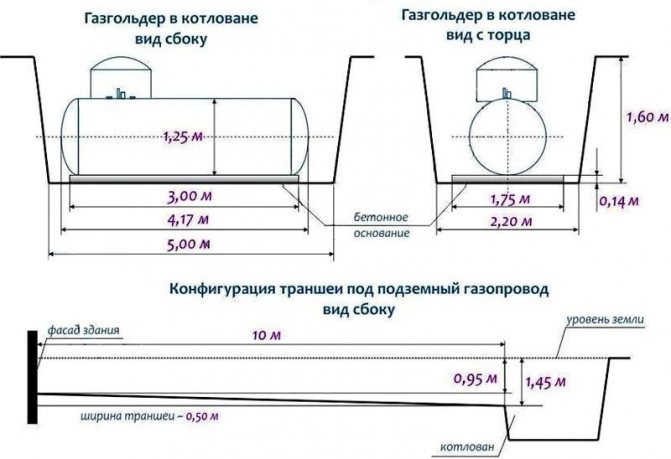

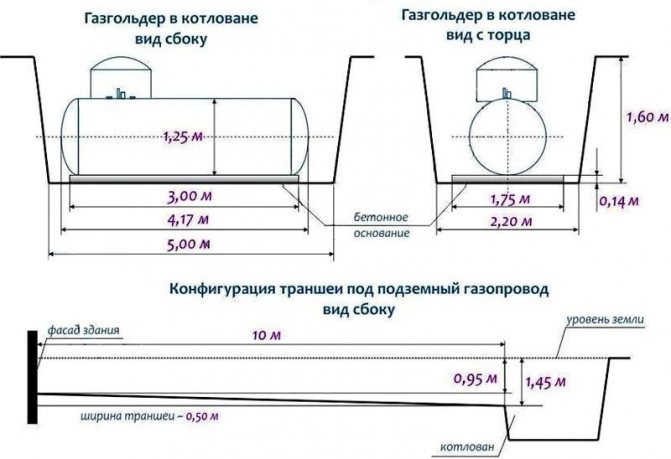

Responsible manufacturers provide earthworks schemes, fittings connections. Here is a drawing for the installation of a VPS gas tank with a capacity of 4800 l

Not all models of horizontal and vertical gas tanks can be found on the Internet. For an objective assessment, use the information set forth in this article in a complex. Study the issues of corrosion protection separately. Apply reliable waterproofing.

If the consumption is incorrectly calculated, as well as for other reasons, condensate accumulates in the tank. To remove it, you can use the services of specialized specialists. It simplifies the performance of such operations by including a special tank for collecting condensate in the equipment.

If you have any additional questions, use the comments to this article. Here you can also publish your own reviews about the tanks, share your experience of real operation.

POSSIBLY

Varieties of designs

The tanks can be installed horizontally or vertically. The location method determines the features of the housing design. The difference is that the vertical models take up less space but have higher safety requirements. If a high level of groundwater is observed at the site of placement, then it is better to use a horizontal structure of a gas holder. Reviews note that in this case, a deep excavation is not required and the risk of equipment flooding will be minimized. But on the other hand, a large storage area will have to be cleared.

Distinguish between structures and the type of occurrence. This classification also applies to horizontal models that can be completely submerged in the ground or installed on the surface. Moreover, differences in approaches affect both the ergonomics of control and the nuances of maintenance - it is enough to note the specifics of technical support for an underground gas tank. What is it in practice? This is equipment that once a year or several years will need to be dug up and checked for a wide range of technical and physical parameters - from tightness to the quality of protective coatings. And in this respect, ground-based models are much more attractive in terms of maintenance costs and ease of management.

Installation location and operational safety

The first thing to do when installing an autonomous heating system is to install a gas holder. Its location is determined depending on its type. Usually buried in the ground at a distance from living quarters. The volume of the device is calculated based on the parameters of the house or room. The location is chosen in such a way that the gas carrier or other machine has free access to the installation.

Gas is delivered with the help of supplier companies, in bulk gas carriers. The installation depth also depends on the characteristics of the gas tank. The installation of the whole system should be entrusted to specialists who will carefully calculate all the parameters for installation. When choosing parts for the system, special attention should be paid to the service life (can reach 20 years) and to the neck of the container. It should be tall and wide.

When operating the system, it should be remembered that the cylinder must contain no more than 85% of the gas from the total volume of the container. You should also have instruments that can detect leaks and control gas flow rates.

It is necessary to acquire thermal shut-off valves that shut off the gas supply in the event of a fire, and gas level alarms with solenoid valves. The gas analyzer activates the isolation valves, which prevent leaks and provide greater safety.

With all the nuances, a system equipped with a gas holder is today the most convenient and environmentally friendly solution to the problem of individual gas supply.

Installing a gas tank

Regardless of the placement method, the structure will require a supporting platform. This will be a kind of foundation that can be made as a screed or use reinforced concrete tiles with a thickness of 15-20 cm. On this platform, with the support of special equipment, the tank is mounted by welding on metal racks. Alternatively, the installation of the gasholder can be carried out without holding devices on an insulated composite pad, which is specially selected for the size of a particular container. This solution is advantageous in that it does not require cutting off the metal racks during dismantling. Then plumbing operations are carried out in the form of laying a pipeline and installing a condensate trap. At the final stage, a control valve is installed in part of the neck.

Gas tank for "turnkey" summer cottages: the advantage of professional performance

You need to order a gas tank for a turnkey private house only in a specialized company that has the necessary license. It is impossible to install a gas tank with your own hands - it is illegal.

Various volumes of vertical and horizontal gas tanks

To properly install the gas tank, you first need to carry out preparatory work. All dimensions of the pit and its location relative to the building must comply with the norms and requirements for the installation of gas tanks.

- The pit should be 0.5 m larger than the size of the tank on all sides.

- A concrete slab with attachments for the tank legs is laid at the bottom of the pit.

- The trench for the highway should not interfere with or intertwine with other communications.

- The depth of the pipeline trench must be at least 1.70 m, and the slope towards the house must be at least 5 °.

- The distance to the residential building from the gas tank is at least 10 m.

Delivery of the gas tank to the site for installation

Work order

After the completion of the preparatory work, the storage facility is brought to the facility, carefully removed from the transport, and installed on a concrete cushion. In this case, it is very important not to damage the tank coating in order to subsequently avoid the appearance of rust. Having carefully installed the storage in the prepared place, it is necessary to securely fix it by screwing the paws with bolts. This will avoid possible movement of the tank during soil shrinkage. Installation is required strictly in a horizontal position.

Installation of three small underground gas tanks at once

After the installation of the gas tank, work is carried out on the construction of the gas pipeline. The gas supply line consists of steel pipes with an anti-corrosion coating or of plastic pipes, the material of which is low-pressure polyethylene. The pipes are joined together by welding and laid on the sand bed of the trench.

The pit and trenches are first covered with sand, which is well compacted. A warning tape is laid along the entire length of the gas pipeline trench, which will prevent damage to the pipes during further excavation work. Then a soft soil is used, in which there are no stones and other solid particles. The top layer can be covered with fertile soil, on which flowers can be subsequently grown.

Regardless of the type, the gas tank can fully satisfy the gas needs of a private house.And if it is not possible to connect to centralized heating, the gas tank will be a good solution. In addition, despite all the costs of installing and buying the tank itself, it is more profitable than using electric heating.

Read later

We will send the material by mail

If you decide to buy a mini gasholder for giving a stationary installation, then you need to remember about the need for periodic refueling. That is, it must be installed in the correct location. The location of the gas tank on the land plot relative to other objects is regulated by the SNIP and SanPIN norms. According to them, the installation of a gas tank in the country should be:

- from the construction site - at a distance of at least 8 meters;

- from the perimeter of the site - at least 2-3 meters;

- from the foundation of the house - at least 10 meters;

- from communications (pipelines, septic tank) - at least 4 m;

- from the source of water intake - at least 5 meters.

When choosing a place where a mini-gas holder will be installed for a summer residence, it is also worth remembering that the length of the refueling hose, as a rule, does not exceed 24 meters. The laying of gas communications can only be carried out in the underground version, and on top of this section, accordingly marked with tapes "Caution, gas!" placement of any structures or elements of landscape design is not allowed.

A gas tank for a turnkey summer cottage can be installed independently, but in this case there can be no question of any operational safety. Autonomous gasification of the country house, fully carried out by our qualified employees for little money within one or two days, will provide you with guaranteed peace of mind and comfort in using the gas supply system of the country house.

Read more: Distance from the gas tank to the residential building type of location on the site

You can get qualified answers to any questions you may have regarding the gasification of a country house or other objects from our managers.

Often, low-power devices of this type do not require a special connection - just plug the stabilizer wire into the outlet. But more powerful equipment does not provide for such installation. It is impossible to give specific advice here, because each model has its own nuances. Connection diagrams for these devices are always contained in the technical documentation.

The main thing in the installation is care and accuracy.

If you need a general idea of how to connect a voltage stabilizer, the video instruction will help you with this.

We hope that the information presented today was useful to you. If the dear reader still has questions, we will be happy to answer them in the discussions for this article. And now one more video that can help you when choosing a 220 V voltage stabilizer for your home.

In accordance with the SNiP requirements, the turnkey installation of the gas tank should be carried out after the approval of the autonomous gasification project.

An autonomous gas supply system with a gas holder must go through all the stages: installation, insulation of installed equipment, check of work performed, setup and test run of the system.

Underground installation:

Initially, a corresponding pit is prepared for the placement of the tank. At its bottom, a sand and gravel "airbag" is created, which becomes the basis for the installation of a concrete slab. It is also allowed to pour a concrete screed directly on site. The container is attached using pins or steel cables and specially designed metal talers. The basement entrance to the house and the foundation pit itself are connected by a small trench designed for laying communications. A condensate collector is mounted on the gasholder body, which is necessary for the disposal of residual oil from gas compressors and residual liquefied gas mixture, and other additional units.At the final stage, the compressor is used to test the performance of the entire system.

Gas tank filling

Our company carries out the delivery of liquefied gas and filling with a mixture of gas holders for guaranteed non-stop operation of an autonomous gas supply system for country houses.

As a rule, the change in prices for liquefied gas occurs seasonally throughout the year. The minimum prices for gas tank filling services are established during the period from March to September. With the onset of October and throughout the winter, the price of the gas mixture increases. If the volume of the tank is determined correctly, then it is optimal to fill it once a year, choosing the most favorable time for this.

| Region | Price for 1 liter of gas, rub. (depending on the distance from the Moscow Ring Road) | |

| up to 90 km from MKAD | over 90 km from MKAD | |

| Moscow and Moscow region | RUB 18.00 * | check with managers |

* The cost is indicated including delivery

Refueling is performed quickly (30–60 minutes), the speed is influenced by the volume of the gas tank and the pump performance of the tanker truck. We provide these services with a high quality guarantee for all residents of Moscow, the Moscow region and in other areas that border the Moscow region.

Today many companies, when buyers of a vertical gas tank contact them, offer to install it on a turnkey basis.

This means that in addition to the actual delivery of the gasholder-capacity, the supplier offers a whole range of additional services, including the following points specified in the Agreement:

- an engineer of the company leaves for inspection and measurements of the site;

- a container for gas, refueling equipment and elements related to the safety system for the use of this equipment are delivered;

- earthwork is being carried out - a pit / pit is being pulled out, a concrete or sand base is being installed;

- conduct a gas pipeline (also underground) - from the gas tank to the house;

- a pressure regulator and other measuring instruments are installed;

- fastening-installation of the entire system is carried out;

- a contract for warranty service is drawn up (at the request of the client).

Thus, taking into account the above, it should be noted that the acquisition of a horizontal or vertical type gas tank and its installation is a rather serious step towards comfortable living conditions in a private house. Therefore, before purchasing it, it is recommended:

- study consumer reviews on the Internet;

- seek advice from specialists who will tell you, based on the characteristics of your home (number of square meters, degree of insulation, number of residents, etc.), the required volume, model and manufacturer of the gas holder;

- when choosing a selling company, be guided by the presence of a federal license for the provision of services for the installation of gas tanks and the installation of autonomous gasification systems.

How is the gas tank refueling carried out?

Fuel reserves are replenished, on average, once every 2-3 years. Moreover, this service should be ordered when the residual gas level in the tank is about 20-25%. Refueling is performed directly by special machines provided with hoses 30-40 m long.The whole process consists of the following stages:

- Clearing the area around the equipment and preparing the neck.

- Checking the data of the measuring equipment showing the exact filling level.

- Connecting the tank nozzles to the hose of the special equipment.

- Resetting the counters of the measuring automation.

- Fuel supply and gas tank filling with the support of pumps or a compressor unit.

- Removal of gas residues by blowing out the channels with compressed air.

- Dismantling the connected equipment.

The whole procedure takes on average 30 to 60 minutes. It depends on the fuel injection technology and the gasholder capacity. Feedback from equipment owners note that it is cheaper to order large volumes in a single order. For example, filling 30% will cost about 20-22 rubles.per 1 liter, and 70% - respectively, 15-17 rubles.

Principle of operation

The principle of operation of the gas tank is quite simple: gas is pumped into the tank, and due to the fact that the tank is not completely filled, an air-gas mixture (propane-butane) is formed in the empty space of the storage facility. In order for the process of natural evaporation to be effective, several rules should be followed:

Do not fill the container with liquefied gas more than 85%.

When installing the tank, it is necessary to strictly take into account that it should not be cooled below 0 °, therefore, if a surface gas tank is installed, it will need to be insulated.

If it is assumed that the evaporation area will be small (for example, in vertical containers), then it is necessary to consider an additional evaporator system.

The gas mixture enters the house through a pipeline, as well as through a conventional pipeline. The filling of the gas tank is carried out by specialists working on a machine with a filling tank. The procedure itself resembles refueling a car at a gas station.

This might be interesting!

In the article at the following link, read about how to insulate a house from a bar from the inside.

For more information about the gas tank and its installation, see the video:

To control and adjust the process, the system provides for special automation, if you need to shut off the flow, you just need to turn a special tap. Excess pressure is removed using a special valve. The account of the remaining gas is carried out thanks to the notification system, which will warn the owner about the need to fill the tank.

Manufacturers and prices

On the engineering equipment market, gas tanks are presented in different segments, including the budget class, the middle group and the premium category. The most notable manufacturers are Spetsgaz, Real Invest, Chemet, Calor, VPS and Kadatec. The first two companies represent domestic enterprises, while the rest represent Poland and the Czech Republic. As already noted, Russian products are preferable due to their adaptation to the target region of use, but European firms manufacture models according to stricter quality standards. The price question can help to solve the problem of choice - how much does a gas tank cost? Russian models for 2,000-2,500 liters are estimated at 130-150 thousand rubles. Imported products of a similar level are available for 170-200 thous.

Calculation of model parameters

Before making the final decision on the purchase of a gas tank, you should decide on the specific characteristics. For this, first of all, the average gas consumption is estimated. If cylinders were previously used, then the average monthly indicator of their volume is multiplied by 12. Further, the area of a cottage or house is divided by 10 (approximate boiler power in kW). If the area is 120 m2, then the target boiler plant is 12 kW. Accordingly, you need to choose a gas tank for a house with a volume capable of servicing a heating unit of a specified capacity, while maintaining a stock for several months or years in advance (for example, with a consumption of 500 liters per year). Here, the optimal frequency of filling the tank is also calculated from the point of view of financial savings and technical feasibility.

Which voltage stabilizer for the home is better: owner reviews and model ratings

Today, on the domestic market, you can buy containers for liquefied gas from various countries - Italy, Poland, Bulgaria, Russia.

Two foreign companies can be noted among the main manufacturers of vertical gas tanks:

- Italian firm Antonio Merloni;

- Bulgarian company CITI GAS.

With generally accepted, but slightly different volumes, their products differ in the color of the container and the brand name on it.

So, for example, Italian gas tanks are green, and the blue gas tanks of the Bulgarian company indicate the letter name of the company - city gas and the volume (2700, 4800 and 6400 liters - the main line of vertical gas tanks).

Products of various brands are presented in the corresponding market segment. There are vertical and horizontal, large and mini gas tanks for a country house. When comparing such proposals, in addition to the criteria noted above, one should pay attention to other important details:

- As a rule, imported containers are created using thin steel sheets. But at the same time, an improved anti-corrosion coating is used.

- Domestic counterparts are somewhat stronger. But they have to be additionally protected by anode-cathode circuits.

- Other standards of European fittings (filling stations) can create difficulties during operation. It is necessary to make sure that the selected service organization can fill a gas tank of a certain model with a mixture.

- In European countries, winters are milder than in Russia. Accordingly, there is less requirement for extremely low temperatures. It is necessary to check the passport data taking into account this factor.

- Products in this category of any manufacturer must be certified according to the current legislation.

Read more: Height of sockets from the floor according to European standard - PMSR

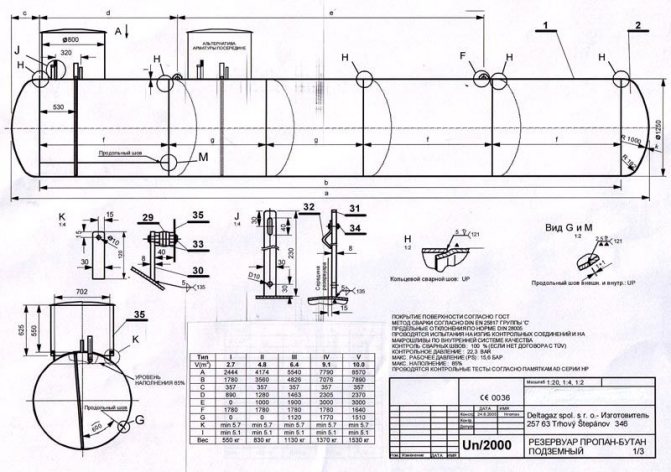

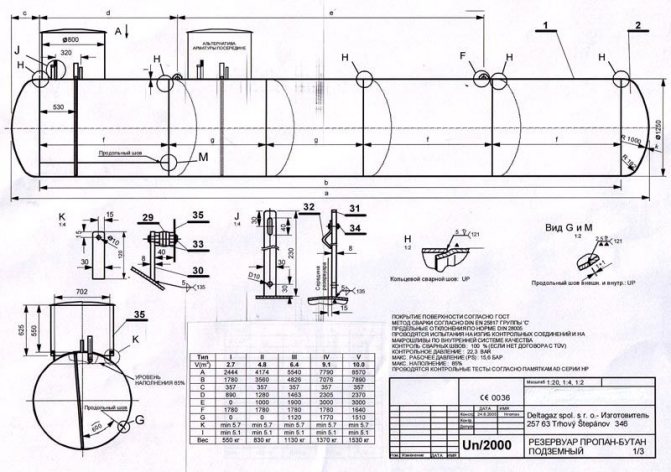

Deltagaz

Gas tanks of this brand are created in the Czech Republic. However, this enterprise is a structural division of the German company G.A.M. Holding. For this reason, some sellers list both countries in their product descriptions. According to statistical data, Deltagaz (Deltagaz) occupies a leading position in Europe. Our own design office allows you to quickly develop and implement models, taking into account the current market requirements.

Drawing of a standard gas tank for a Deltagaz country house

High pressure tests of 22.3 bar are used to check welded joints. Limit deviations of technical parameters are regulated by DIN 28005.

Kadatec

These gas tanks are produced in the Czech Republic. The Kadatec catalog contains containers with standard and enlarged necks. It is not difficult to select a product for installation at great depths to ensure efficient gas formation.

To increase the strength of the structure, the bottom is made of steel sheet with a thickness of 5.7 mm. The well is closed with a low temperature resistant polymer cover. For protection, the outer side of the container is sandblasted. Next, a layer (at least 1 mm) of epoxy resin is applied. Its integrity is checked using non-destructive testing techniques.

Gas tank Kadatec

This capacity is simple and cost effective. However, in this option, it is impossible to perform mandatory routine procedures with the removal of contaminants. It should be noted that in the current brand catalog there are products with a neck.

This manufacturer produces containers with good corrosion protection, made of steel grades resistant to external influences. With proper installation and operation, the service life of VPS gas tanks (Czech Republic) will exceed 50 years. Reliable German fittings (GOK) are used as standard. In the appropriate design (with a high neck), the containers can be immersed in the ground to a depth of 0.8 m. Such insulation ensures productive gas formation in winter.

VPS standard product parameters

Pay attention to the different modifications for Europe and Russia (marked with an arrow). In the second version, the neck is increased to 80 cm. With an appropriate installation depth, safe operation is permissible up to an air temperature of -40 ° C.

Chemet

These gas tanks for a country house are produced by a Polish manufacturer. To protect the steel hull, Chemet specialists use epoxy resin. It is applied using "hot" technologies to ensure a uniform structure, the formation of a uniform layer thickness in all areas of the surface.

The current product range includes horizontal gas tanks with a capacity from 4850 to 9200 liters.

City-Gas

For the Russian market, this Bulgarian manufacturer offers series created according to different standards.

The composite resin / epoxy coating provides good corrosion protection. The City-Gas catalog contains gas tanks for a country house with a volume of 2700 to 10000 liters and weighing from 580 to 1790 kg.

Domestic products

At a democratic cost, Russian-made gas tanks for a country house have good consumer characteristics:

- The walls are made of steel with a thickness of 8 mm or more.

- Neck height - at least 80 cm.

- The total thickness of bitumen insulation is from 6 mm.

- The factory warranty for perforating corrosion is 20 years.

All 220 V voltage stabilizers can be divided into 3 main subgroups - these are devices up to 5 kW, 5-10 kW and 10-15 kW. For these subgroups, we will make our today's small rating. It would not hurt to familiarize yourself with some of the reviews of the owners of such equipment about one of the review models.

Let's imagine several models with a power of 5 kW. There are also 2 kW voltage stabilizers, but today we will not talk about them.

| Photo | Make and model | Input voltage range, V | Efficiency,% | Weight, kg | Average cost, rub. |

| SUNTEK SK1.2_RL5000 | 120-285 | 95 | 12 | 7500 |

| Caliber ASN- 5000/1 00000060752 | 140-265 | 90 | 13.8 | 8000 |

| RUCELF SDW.II-6000-L 00-00000470 | 110-275 | 98 | 15.5 | 12300 |

| Stavr SN-5000 | 140-260 | 98 | 10.7 | 5000 |

Such equipment is most often used as a voltage stabilizer for a gas boiler, but you can also connect a small country house to it if it does not have equipment with high power consumption.

"Stavr SN-5000" is a pretty good voltage stabilizer

And yet I would like to say separately about another model, which is an outsider, if we rely on reviews from the network.