Basic preventive measures

In addition to strict adherence to all established operating rules, it is possible to prevent the occurrence of an accident if a series of preventive actions are carried out in a timely and regular manner. The whole reason is that in the main heating or water supply system, absolutely all processes are closely interconnected. A water hammer, unforeseen by the user, is just the final destructive stage, which may well lead to various negative consequences. All this is happening against the background of the relatively poor technical condition of the pipes used for years.

The pressure drops and vibrations that arise only contribute to the formation of various cracks in the thickness of the metal. Over time, more serious defects appear, which, after the onset of a water hammer, instantly appear in areas of too high internal stress. These can be various bends, mechanical joints, and even welds.

Preventive manipulations include the following steps:

- Timely check of the pressure behind the flexible diaphragm of the exploited expansion vessel. If during this procedure the wizard discovers unsatisfactory results, then it is forbidden to operate the system without a qualitative adjustment.

- Checking the health of the involved security groups. This applies to an air vent, a safety valve, as well as a classic pressure gauge.

- Control of the valve position of the shut-off and control metal fittings involved.

- Periodically check the status of all filters. These elements are responsible for the retention of fine sand, classic scale, rust fragments. If necessary, the master needs to clean and then rinse the filters.

- Testing the system in use for leaks. You also need to check the degree of wear of all elements.

Many experts recommend replacing the classic rigid pipe with a plastic product. It is more flexible to use and expands quickly under pressure. But you need to be careful, since depressurization of the joints is not excluded.

A professional approach to prevention, which is aimed at maintaining the overall optimal condition of the heating and water heating system, necessarily includes elementary types of work. It is not recommended to ignore this stage. This is due to the fact that repairing heating in a private house entails a large waste of finance and free time. All the described protection measures will be effective if the approach to work is comprehensive. Only in such a situation is it possible to neutralize various undesirable consequences and extend the period of the coordinated work of the system.

Installing a high quality wash filter

What are the consequences of a water hammer for the heating system

Quite often, after starting the heating system with the arrival of cold weather, periodic clicks and knocks can be heard in the pipes. Please note that if such phenomena occur too often, this may lead to the need for urgent repairs to the heating system. Such a need may be due to the fact that a water hammer in the pipes sometimes leads to a breakthrough of the coolant, malfunction of heating equipment or damage to the expansion tank.

Since it is rather difficult to independently determine the possible results of the impact of a shock wave on the system, usually specialists are invited for these purposes, whose services are quite expensive. Therefore, we strongly recommend that before the start of the heating season, diagnose the heating circuit and identify all possible deficiencies.

The most common cause of water hammer in the heating circuit is the different cross-section of the pipes used. Since a constant increased friction is created in a section of a pipeline with a smaller diameter, it prevents the coolant from moving freely through the system. Consequently, hum, hiss or clicks are constantly heard in the pipes due to increased pressure.

If your heating system has this problem, it will have to be redone. Otherwise, over time, trouble with her will arise again.

Fluctuations and their causes

Pressure surges indicate system malfunction. The calculation of pressure losses in the heating system is determined by summing the losses at individual intervals, which make up the entire cycle. Early identification of the cause and its elimination can prevent more serious problems that lead to costly repairs.

If the pressure in the heating system drops, this may be due to the following reasons:

- the appearance of a leak;

- failure of the expansion tank settings;

- failure of pumps;

- the appearance of microcracks in the boiler heat exchanger;

- power outage.

How to increase the pressure in the heating system?

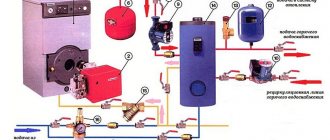

Expansion tank regulates differential pressure

In the event of a leak, all connection points must be checked. If the cause is not visually identified, it is necessary to examine each area separately. For this, the valves of the taps are sequentially closed. The pressure gauges will show the change in pressure after cutting off a particular section. Having found a problematic connection, it must be tightened, previously additionally sealed. If necessary, the assembly or part of the pipe is replaced.

The expansion tank regulates the differences due to heating and cooling of the liquid. A sign of a tank malfunction or insufficient volume is an increase in pressure and a further drop.

Add a clearance of 1.25% to this result. The heated liquid, expanding, will force air out of the tank through the valve in the air compartment. After the water cools down, it will decrease in volume and the pressure in the system will be less than required. If the expansion tank is smaller than required, it must be replaced.

A rise in pressure can be caused by a damaged membrane or an incorrect setting of the heating system pressure regulator. If the diaphragm is damaged, the nipple must be replaced. It's quick and easy. To configure the reservoir, it must be disconnected from the system. Then pump the required amount of atmospheres into the air chamber with a pump and install it back.

You can determine the malfunction of the pump by turning it off. If nothing happens after the shutdown, then the pump is not working. The reason may be a malfunction of its mechanisms or a lack of power. You need to make sure that it is connected to the network.

If there are problems with the heat exchanger, then it must be replaced. During operation, microcracks may appear in the metal structure. This cannot be eliminated, only replacement.

Why is the pressure in the heating system increasing?

The reasons for this phenomenon may be incorrect fluid circulation or its complete stop due to:

- the formation of an air lock;

- clogging of the pipeline or filters;

- operation of the heating pressure regulator;

- continuous feeding;

- shutoff valves overlapping.

How to eliminate drops?

An air lock in the system does not allow fluid to pass through. The air can only be vented. To do this, during installation, it is necessary to provide for the installation of a pressure regulator for the heating system - a spring air vent. It works in automatic mode. The radiators of the new design are equipped with similar elements. They are located at the top of the battery and operate in manual mode.

Why does the pressure in the heating system increase when dirt and scale accumulates in the filters and on the pipe walls? Because the flow of fluid is obstructed. The water filter can be cleaned by removing the filter element. It is more difficult to get rid of scale and blockages in pipes. In some cases, flushing with special means helps. Sometimes the problem can only be resolved by replacing the pipe section.

The heating pressure regulator, in the event of an increase in temperature, closes the valves through which the liquid enters the system. If this is unreasonable from a technical point of view, then the problem can be rectified by adjusting. If this procedure is not possible, the assembly should be replaced. If the electronic make-up control system breaks down, it should be adjusted or replaced.

The notorious human factor has not yet been canceled. Therefore, in practice, the shut-off valves overlap, which leads to the appearance of increased pressure in the heating system. To normalize this figure, you just need to open the valves.

What should be present in the heating system of a private house to avoid water hammer

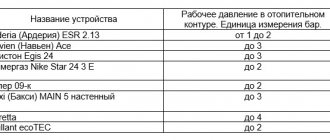

The heating system must be protected from water hammer, therefore, even at the design stage, the necessary elements are provided. All of them are used in combination. It is worth noting that below will be a list of devices that are selected based on the characteristics of the heating system: type of pump, apartment or private house, diameters and length of pipelines. Only a professional who has studied the features of your home can fully select the entire set of devices and fixtures.

- special shut-off valves with smooth closing - when purchasing elements of the heating system, you should give preference to taps with smooth closing. This will save the system from a sharp jump in pressure and the coolant will have a softer effect on the pipeline and fittings when the taps are closed, which will save from a strong water hammer;

- an automatic system that regulates the flow of the coolant - the pump with such a modernization smoothly starts up the liquid, thereby more gently affects the heating system as a whole. Working in an automatic mode, such a device independently regulates the flow of fluid without human intervention;

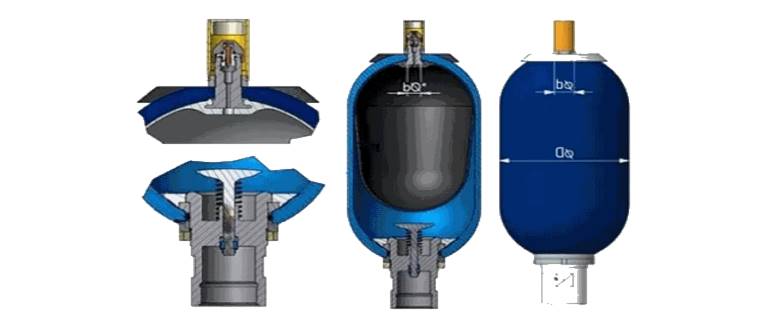

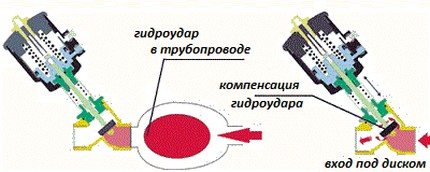

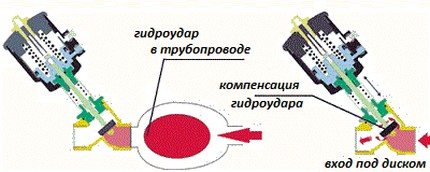

- hydroaccumulator (expansion tank) - this device must be present in the heating system of a private house. After all, it compensates for pressure drops, reducing the load. Its principle of operation is as follows: during a water hammer inside the tank, the rubber membrane is squeezed out by a water column. This compensates for the pressure inside the heating system;

- a thermostat with a spring mechanism - the principle of its operation is identical to a hydraulic accumulator with the only difference that the pressure compensator is not a rubber membrane, but a spring mechanism;

- membrane hydraulic shock absorber - this device is installed on hot and cold water in order to extinguish pressure drops when opening and closing taps. The principle of operation is identical to the two previous devices.

Using these devices, it is possible to exclude the occurrence of water hammer in heating a private house if they are used during the installation of a new system. There are also ways to prevent this phenomenon from occurring in an already functioning system.

Possible consequences of a water hammer and its danger

The signs of the phenomenon can be recognized by extraneous sounds in the system: clicks, knocks, collapses.Visual signs will also help: leaking taps, mixers, compression fittings-connectors with rubber gaskets.

When the water supply system is exposed to frequent water hammer, even with a weak force, the gaskets, seals are squeezed out first. Violation of the tightness of the system can lead to the appearance of centers of deformation and rupture of pipes.

As a result of the pressure increase, the water supply is interrupted. But this is not the only nuisance. If a water hammer has led to a complete rupture of a pipe, for example, in an apartment building, the entire structure is left without water. The flow of liquid spoils the property of the apartment owners, the neighbors of the lower floors are flooded. As a result - work on the repair and restoration of several housing objects.

A water hammer in the hot water supply system, in addition to the final damage to property, threatens with burns. The danger threatens when the heating system is depressurized, where the carrier maintains a temperature of + 70C and is constantly under pressure. A break in a battery or pipeline during the winter heating season will damage the system. Frost will finish the destructive business - the pipeline will have to be changed.

Avoiding water hammer - basic rules

People who are faced with water hammer and who know firsthand about their destructive effect are interested in: is it possible to avoid all this? There are several options at once, let's get acquainted with each of them.

- Above all, act gently and gently. Do not abruptly close the ball valve, otherwise an impact will occur. To avoid its appearance, close the fittings smoothly, there is no need to rush. Take the time to spend a few extra seconds - not much compared to the upcoming plumbing renovation.

- To reduce this effect, you can slightly improve the system. As already noted, for this, accumulators are installed (they are also called dampers), which accumulate water in the event of an increase in pressure in the circuit.

- If shocks occur due to the stoppage of the pump, then you can install a special valve for protection. Such devices operate exclusively on impact and reduce the increasing pressure in the line. This valve is extremely reliable. It is installed next to the pump.

- Automation is another possible solution to the problem. Thanks to special control units, activation and shutdown of the system will be extremely smooth. The pump will increase or decrease the pressure as necessary, due to which the risk of water hammer is practically reduced to zero.

- Finally, if water hammer occurs due to improper planning of the entire system, then the only way out is to completely redo it.

Note! If the problems are not eliminated immediately after the appearance of the blows, then the system in any case, sooner or later, will still have to be redone. After all, if the situation repeats itself all the time, then all elements - including pipes - will soon fail. After that, repairs will cost a lot more.

Causes of water hammer

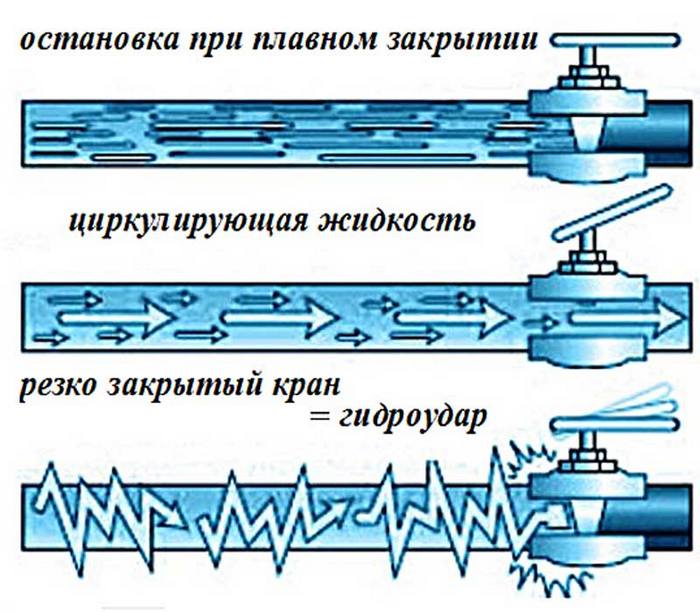

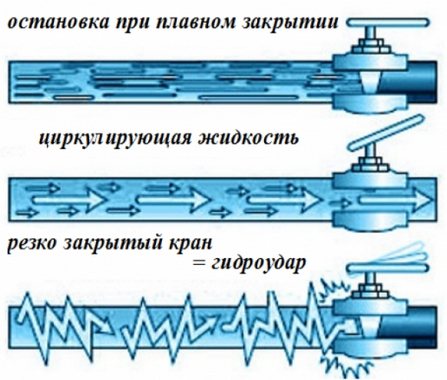

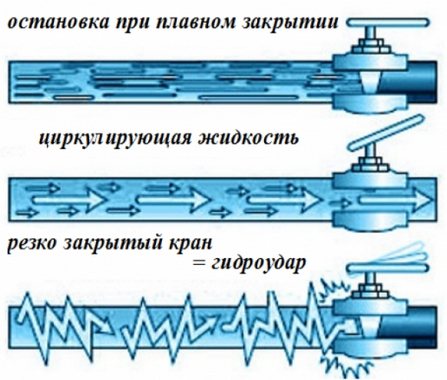

The most important reason is the abrupt closure of the shut-off valves. If the water flows in a thin stream, the risk is minimal, but with sudden openings / closings of the tap, the danger is maximized.

Why else does a water hammer occur in the water supply system:

- With sudden switching on of powerful pumps. It occurs when the power supply of objects equipped with powerful pumping stations is unstable.

- In the presence of air plugs in the water supply system, heating. Therefore, before putting into operation closed systems with a liquid carrier, it is necessary to first evacuate the air.

Today, water hammers are considered the most common factors in the failure of water supply systems. This is due to the emergence of a new shut-off valve that does not require long turns of the valve (tap) to open / close the water.

How to prevent water hammer

In order to avoid or reduce pressure surges in the system, there are a number of specific measures to help protect the pipeline network as a whole, or in a specific area.

Smooth closing of valves

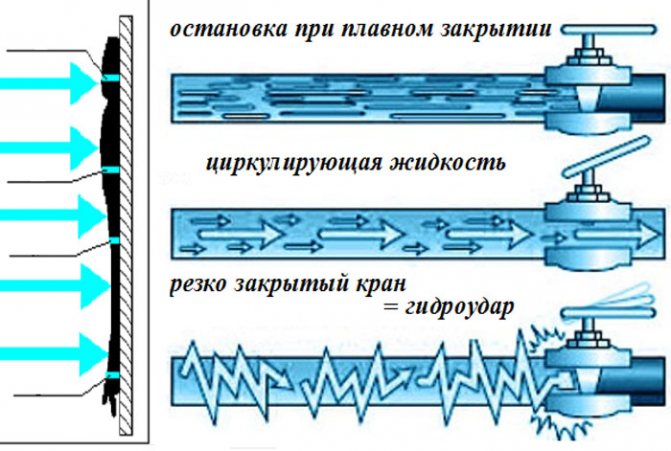

One of the main reasons for the occurrence of water hammer is a sharp shutdown of valves.

This is due to the fact that the valve shut-off period is very short. As a result, a sharp pressure drop in this place is inevitable. In order to avoid the problem at this stage, it is necessary to increase the duration of the shut-off of the liquid flow. Thanks to this action, the increase in pressure in this place will occur smoothly without a sharp jump.

That is why, at the stage of installation, it is recommended to install shut-off valves (taps, valves) with a longer shut-off time for the plumbing system.

Using automatic means in the system

Automatic devices built into the network are designed to smoothly "extinguish" the increasing pressure. Among such means, it is possible to note pumping equipment capable of changing the number of revolutions in automatic mode, or designs equipped with frequency converters.

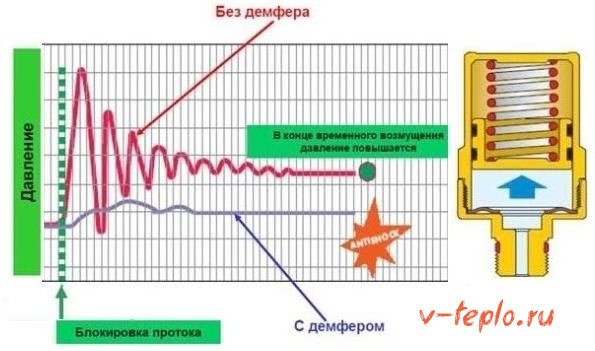

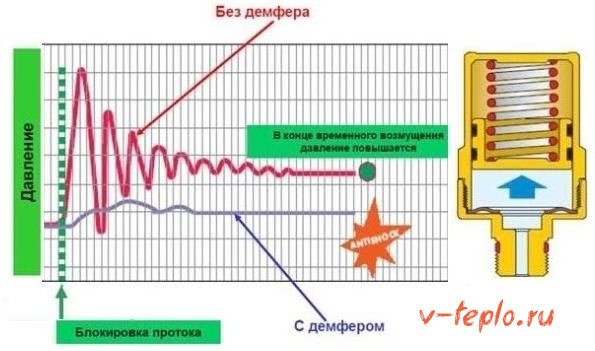

Introduction of shock absorbers

Hydroaccumulators and dampers implemented today are capable of simultaneously performing several important functions. They not only collect liquid, but also eliminate excess water from the system, and also help prevent various undesirable manifestations. Hydraulic accumulators perform all the functions of compensating units. They are installed only in the direction of the main flow of water in those sections of the heating circuit, where the probability of a sudden decrease or increase in the level of the measured pressure is especially high.

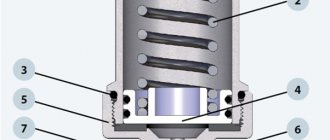

A kind of extinguisher, as well as a hydraulic accumulator, in practice, is a capacious flask made of steel, which can easily fit up to 35 liters of liquid. They include two sections separated by a durable rubber or rubber partition at once. In the event of an increase in pressure, all water hammer is redirected to the reservoir. Due to the bending of the involved membrane at the moment of a sharp increase in the indicators, specialists manage to achieve the effect of forced expansion of the contour.

Pipes made of heat-resistant reinforced rubber or elastic plastic act as shock-absorbing elements. To achieve the desired effect, it is quite enough to use a product with a length of 35 centimeters. If the pipeline is long, then the section of the shock absorber must be increased by at least 12 cm.

High-quality water hammer damper

Methods for complex modernization of the system

Comprehensive modernization of the system involves the installation of equipment aimed at neutralizing the effect of excess pressure.

Method # 1. The use of expansion joints and shock absorbers

Dampers and accumulators simultaneously perform three functions: they collect liquid, while eliminating its excess volume from the system, and also help to prevent an undesirable phenomenon.

A compensating device, the role of which is played by a hydraulic accumulator, is installed in the direction of water movement at those intervals of the heating circuit where there is a high probability of pressure fluctuations in the system.

The hydraulic accumulator or damper is a steel flask with a volume of up to 30 liters, including two sections separated by a rubber or rubber membrane.

When an overpressure occurs in the system, the water column of the first section begins to press on the separating membrane, due to which it bends in the direction of the air chamber

When the pressure rises, hydraulic shocks are "thrown off" into the reservoir.Due to the bending of the rubber membrane towards the air chamber at the moment the water column rises, the effect of artificially increasing the volume of the circuit is achieved.

Pipes made of heat-resistant reinforced rubber or elastic plastic are used as shock-absorbing devices.

The elastic material of the shock-absorbing devices spontaneously dampens the water hammer energy at the point where the pressure reaches a critical value

To achieve the desired effect, it is enough to use a product with a length of 20-30 cm.If the pipeline has a long length, the section of the shock absorber is increased by another 10 cm.

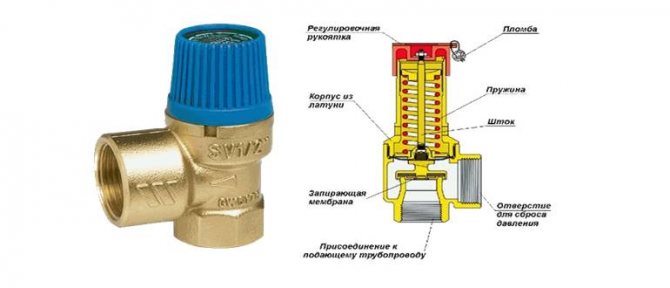

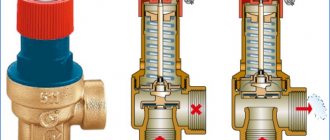

Method # 2. Installing a Diaphragm Type Safety Valve

A diaphragm-type safety valve is placed on the branch pipe next to the pump in order to release a predetermined amount of water in case of excess pressure.

The safety valve, equipped with a rigid seal, which acts as a quick release of pressure, is a reliable safety device for an autonomous system

Depending on the manufacturer and model type, the safety valve is driven by an electrical command from the controller or by a quick-acting pilot device.

The device is triggered when the pressure exceeds a safe level, protecting the pumping station if the equipment stops suddenly. At the moment of a dangerous surge in pressure, it opens completely, and when it drops to a normal level, the regulator slowly closes.

Method # 3. Equipping the thermostatic valve with a shunt

The shunt is a narrow tube with a lumen of 0.2-0.4 mm, which is installed in the direction of the coolant circulation. The main task of the element is to gradually reduce the pressure when overloads appear.

A narrow tube, the cross-sectional range of which does not exceed 0.2-0.4 mm, is placed on the side from where the liquid enters the thermostat

The shunting method is used when arranging autonomous systems, the pipeline of which is made only of new pipes. This is due to the fact that the presence of rust and sediment in old pipes can reduce the effectiveness of shunting to "no". For this reason, when using a shunt at the heating circuit inlet, it is recommended to install efficient water filters.

Method # 4. Using a super protection thermostat

This is a kind of safety device that monitors the pressure in the system and does not allow it to work after the indicator reaches a critical level. The device is equipped with a spring mechanism located between the thermal head and the valve. The spring mechanism is triggered by overpressure, preventing the valve from closing completely.

Such thermostats are installed strictly in the direction indicated on the body.

What is water hammer in a water supply system

A water hammer is a short-term powerful increase in the pressure of a liquid that circulates in pipes. The pressure increases due to the change in the flow rate.

The pressure change sign affects the type of water hammer:

- positive - at which the pressure rises due to the sharp closing of the valve or the inclusion of the pump unit;

- negative - at which the pressure increases due to the stopping of the pump.

According to the laws of physics, even when the tap is suddenly closed, the water continues to move. Only the flow closest to the valve stops, the remaining layers continue to flow. The collision of the stopped and the moving layers also causes an increase in pressure. If we imagine that the entrance was abruptly closed in front of a moving crowd, then the first rows have already stopped - the next ones stumble upon them, continuing to walk, it turns out to be a crush. Water also acts, which causes a water hammer.

The pressure rises instantly, the level rises by several tens of atmospheres. The consequences cannot be avoided.

Water hammer theory

The occurrence of the phenomenon is possible only due to the lack of compensation for pressure drops. A jump in one place causes the force to propagate along the entire length of the pipeline. If there is a weak point in the system, the material can be deformed or destroyed completely, a hole is formed in the system.

The effect was first discovered at the end of the 19th century by the Russian scientist N.E. Zhukovsky. He also derived a formula by which to calculate the period of time required to close the tap in order to avoid unpleasant consequences. The formula looks like this: Dp = p (u0-u1), where:

- Dp is the pressure increase in N / m2;

- p is the density of the liquid in kg / m3;

- u0, u1 - average indicators of water velocity in the pipeline before and after closing the taps.

To know how to prove water hammer in a water supply system, you need to know the diameter and material of the pipe, as well as the degree of compressibility of the water. All calculations are carried out after establishing the water density parameter. It differs in the amount of dissolved salts. Determination of the speed of propagation of a water hammer is made according to the formula c = 2L / T, where:

- c - designation of the shock wave velocity;

- L is the length of the pipeline;

- T is time.

The simplicity of the formula allows you to quickly identify the speed of propagation of a shock, which, in fact, is a wave with oscillations of a given frequency. And now how to find out the fluctuations per unit of time.

For this, the formula M = 2L / a is useful, where:

- M is the duration of the oscillation cycle;

- L is the length of the pipeline;

- a - wave speed in m / s.

To simplify all calculations, knowledge of the shock wave velocity at impact for pipes made of the most popular materials will allow:

- steel = 900-1300 m / s;

- cast iron = 1000-1200 m / s;

- plastic = 300-500 m / s.

Now you need to substitute the values in the formula and calculate the frequency of oscillations of the water hammer in the water supply section of a given length. The theory of water hammer will help to quickly prove the occurrence of the phenomenon and prevent possible risks when planning the construction of a house or replacing the plumbing, heating system.

The nature of the water hammer

It is not difficult to characterize or describe a water hammer in a water supply system, a working imagination and a minimum knowledge of physics will help with this. Imagine how water flows through a pipeline, it moves at a certain speed and exerts a pressure of 2-3 atmospheres on the pipe walls.

But suddenly an obstacle arises in the path of the water flow, it can be:

- Airiness is an airlock resulting from improper operation of the water supply system, its illiterate design, etc. (everyone knows that you need to open valves in plumbing systems in order to release air before supplying water, usually we are talking about heating systems).

- Shut-off valves are a valve element or ball valve that closes the pipe in order to stop the water and prevent its further flow through the water supply system. Each heating system and other water supply systems are equipped with such taps in certain areas.

Facing such an obstacle, the water flow cannot instantly reduce its speed, which means that at the same speed in a certain area there is an attempt to increase the volume of liquid, that is, a sharp jump in pressure. In such a situation, the pipe is tested for strength by a colossal rise in atmospheres and may not withstand.

It follows from this that a water hammer in a pipeline is a frequent cause of its destruction, and the longer the water supply system lasts, the more vulnerable it becomes, especially in the case of metal pipes that are prone to corrosion.

Basic methods of protection

To protect materials, equipment and communications from water hammer, the following methods are used:

- Installation of thermostats with built-in shunt;

- Plastic inserts;

- Installation of membrane devices;

- Control of pump operation modes according to the data of the pressure sensor in the system;

- General preventive measures.

Thermoregulators with a built-in shunt are installed as shut-off valves. A shunt is a small-diameter tube that allows excess coolant to pass through when the pressure rises.

Steel elements are most often susceptible to destruction from water hammer due to the rigidity of the structure, the absence of a shock-absorbing effect. To create a shock absorber, small sections of polymer pipes are often cut in, which have good flexibility. In the event of a water hammer, they compensate for the shock force by bending, without being damaged.

Hydraulic accumulators and expansion tanks also do a good job of increasing pressure, taking on the excess. The membrane, made of rubber or polymer, bends, compresses the air in the air chamber. Water from heating enters the vacant space, the total pressure in the system decreases.

Circulation pumps are equipped with a pressure control system. The sensor monitors the water pressure in the network. When the value is increased, it issues a command to decrease the pump speed. This system is applicable for pumps with frequency control of the impeller rotation speed.

General preventive measures to prevent water hammer and their consequences:

- Perform smooth control of shut-off valves;

- Switch on the pumps at low speed;

- Check the performance of air vents and safety valves;

- Timely, regularly bleed air from the equipment;

- Regularly carry out a visual inspection for the integrity of the structural elements of the heating;

- Monitor the integrity of the expansomate membrane.

Water hammer is a frequent and dangerous phenomenon in heating networks. Their timely prevention will save heating communications and equipment from damage, preserve their integrity and performance.

Owners of private apartments and houses often hear sharp, distinct blows in the equipped heating pipeline. Many do not pay due attention to this phenomenon, but the outcome of the situation can be very different. Specialists often have to correct the results of the destruction of important parts.

In some cases, injury to residents is possible. Water hammer in the equipped heating system is the main cause of most breakdowns and destruction of heating equipment. A high-quality and timely solution of this issue is of great importance for the stable and trouble-free operation of the system.

Classic consequences of an emergency

Protection of heating systems against water hammer

Water hammer is a phenomenon that occurs in a pipeline when the fluid velocity changes rapidly. Water hammer is characterized by instantaneous increases and decreases in pressure, which can lead to pipeline rupture. The likelihood of water hammering increases with an increase in the power of heat sources, an increase in the diameters and length of heating networks, and when the network is equipped with regulators, valves and valves.

The causes of water hammer are: sudden shutdown of pumps at a heat source or pumping station when the power supply is cut off; sudden switching on of pumps; boiling of the coolant in the boiler in the event of a decrease in the flow rate of the coolant and subsequent condensation; quick closing of control valves and gate valves at the heat source, pumping stations and heating network.

Protection against water hammer can be carried out through the use of a number of special devices.

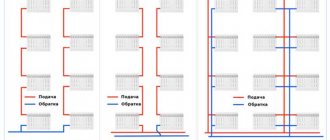

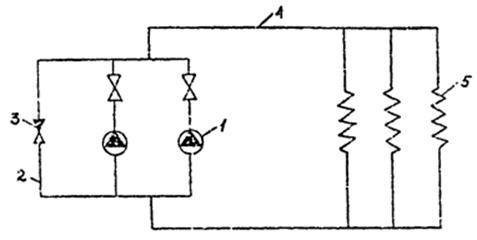

At pumping stations, it can be recommended to install a shockproof bulkhead between the return and supply pipelines with a check valve installed on it (Fig. 1). In case of a sudden stop of the pumps, when the pressure in the return pipeline exceeds the pressure in the supply, the check valve on the shock-proof bulkhead opens, which leads to equalization of the pressures in the pipelines and attenuation of the shock wave.

In boiler rooms, to prevent water hammer, water locks are used that are connected to the return manifold. The water lock is a vertically installed "pipe in a pipe" with a height of about 3 m higher than the head in the return collector. The inner pipe of the hydraulic seal is cut into the return collector of the heating network, the external one serves to receive the release of the coolant when the hydraulic seal is triggered and is connected either to the receiving tank or to the sewage system.

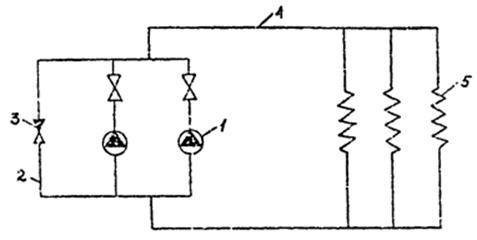

Fig. 1. Diagram of the shockproof jumper device:

1 - pump; 2 - shockproof jumper; 3 - check valve; 4 - heating network; 5 - heat consumers

The system for ensuring reliability and protection also includes safety and control valves (ZRK) RK-1 with regulators of the RD-3a type of three-bellows assembly and pulse valves IK-25 for emergency shutdown of the boiler house from the system. In addition, the air defense systems are equipped with RD-3a regulators of single-bellows assembly, which makes it possible to regulate the pressure of the supply water in the supply and return lines (Fig. 2). The system uses hydraulic automation, the operation of which does not depend on the availability of electricity. In the event of a power outage and a sudden stop of the pumps, the pressure in front of the pump rises, which leads to the operation of the IK pulse valve, as a result, the RK-1 regulators close, cutting off the boiler room equipment. The water hammer is extinguished as a result of the actuation of the water seal. The combination of protection "Hydrozatvor-ZRK" provides protection of boiler equipment, heating network and heating systems.

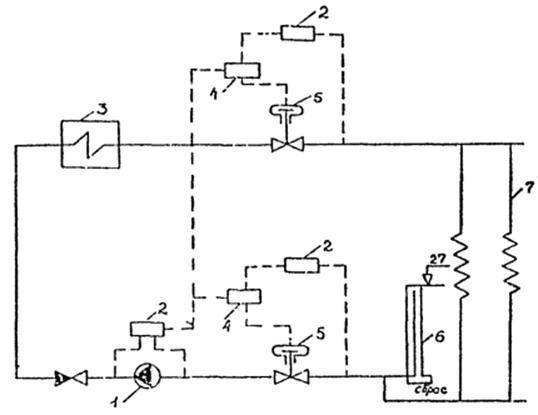

Fig. 2. Installation diagram of protective devices:

1 - pump; 2 - regulator RD-3a; 3 - boiler; 4 - pulse valve IK-25; 5 - valve RK-1; 6 - water seal; 7 - heat consumers

The following can be used as high-speed relief devices for heat supply systems: a hydraulic lock, a relief valve of the SKV VTI design, bursting convex membranes, bursting flat discs, a relief valve of the Soyuztekhenergo design.

With a pressure in the return line in the range of 0.1-0.25 MPa, it is most advisable to install a water seal. If the pressure in the return line is more than 0.25 MPa, it is possible to install a relief valve in network pumps with an electric motor having a swing moment of more than 150 kg x m2 (for example, pumps of the SE2500-180, 20D-6 type, etc.). When the pressure in the return line is more than 0.25 MPa, for network pumps with electric motors having a swing moment of less than 150 kg x m2, it is most advisable to install membrane safety devices with a response time of about 0.05 s.

Retrofitting of a thermostatic valve

This accessory is a compact tube. The final clearance can vary from 0.2 to 0.6 millimeters. The shunt is mounted in the direction of the circulated fluid. The main task of the part is to gradually reduce the pressure when overloads are detected. When designing autonomous systems, the shunting method is necessarily used, since only in this case it is possible to protect the new pipeline from breakage.

This effect is due to the presence of rust and other debris in worn-out pipes, which is a serious obstacle to achieving the desired result. It is for this reason that during the use of the shunt at the very outlet to the equipped heating circuit, it is advisable to install high-quality water filters.

The reasons

What could cause this trouble? Consider the causes of water hammer in the heating system:

- Abrupt opening or closing of shut-off valves.

- Airing the system.

- Rapid change in pump operation mode - start or stop.

- Narrowing or bending of the pipe.

Abrupt actions with shut-off elements (opening or closing) cause a rapid change in pressure at the location of the equipment. When closing, the pressure on the valve and its connecting elements increases. Often the seals of threaded connections, gaskets between flanges, and at increased pressure also deteriorate elements of shut-off equipment.

When an abrupt opening occurs, the water quickly, picking up speed, moves to the zone of reduced pressure, which is available behind the valve. In this situation, the sections that are located after the reinforcement are damaged. In particular, places with the highest liquid resistance are susceptible to water hammer - pipe bends, heating devices (batteries, convectors, etc.).

Causes of a water hammer

Air in the system can be the result of misconfiguration and installation oversights. As a result of an incorrect installation, the required slope of communications is absent, "bags" and "dead zones" appear. Air congestion often occurs in such areas.

The water stops in front of the air plug and the pressure starts to build up. The coolant slowly begins to compress the air volume and, upon reaching a certain pressure level, breaks through the barrier. Then it circulates to the low pressure area, damaging system elements and components.

When the pipe has sharp contractions, this also affects the fact that the coolant picks up speed. Limescale and other deposits can cause the bore to decrease. The narrowing of the pipe should be smooth and extend along its entire length.

The circulation pump mode also affects the possible occurrence of water hammer in the heating system. Shocks often occur when the pump is started (especially at high speed). With all this, the water picks up speed and circulates through the communications that had previously had hydrostatic pressure. During start-up, the fluid pressure becomes dynamic, which makes its speed higher.

When stopped, the circulation pump is a natural obstacle in the path of the coolant. The pressure in front of it increases, there is a flow of water through the impeller.

Water hammer is considered a common occurrence in steam heating systems. The reasons for their appearance are various states of vapor and liquid. Therefore, the communications of steam systems are made of metal, from durable materials.

Short description

A very common water hammer in a well-equipped high-quality heating system is a kind of phenomenon that is based on the norms of the dynamics of various substances. The manifestation itself differs in that with a periodic change in the speed of movement of the flow of the working fluid, an increase in pressure is observed. Water acts as the main heat carrier, the main indicator of which is incompressibility. During the period of circulation of the charged coolant through pipelines and heating elements, various hydraulic obstacles may arise in its path. In most cases, these are turns, sharp changes in the diameter of pipelines, as well as valves of the shut-off and control type.

In the unfavorable conditions created, the coolant can damage those elements that present a strong hydraulic resistance to the flow. These can be convectors, pipe bends, various devices, radiators and even boiler heat exchangers.

An accident may well arise as a result of gradual wear of the operating structure and its elements, or as a result of the sudden impact of a strong jump in performance. In all situations, the consequences of a water hammer entail material waste to eliminate the leak. In order not to find yourself in such a situation, one should understand the basic reasons for the formation of a water hammer.The consequences of an accident are always unpredictable, ranging from the most common breakdown of the circulation pump to large-scale flooding of the entire house. It all depends on the quality and power of the system.

The most common consequences of water hammer exposure

Effects

With repeated exposure to high pressure, which occurs as a result of water hammer, even very reliable systems can lose their tightness. A pipeline rupture can also occur from a single, but strong water hammer.

As a result of this impact, the water supply to the facilities to which the water pipe is connected is completely stopped. Unfortunately, the consequences of this phenomenon are not limited only to the lack of water in the tap.

If a pipe rupture occurs in an apartment building, then after the pipe ruptures and liquid enters the dwelling, the property of the apartment owners, as well as the neighbors on the floor below, will be damaged.

If the main water pipe breaks, through which the whole area of the city is supplied with water, then the accident can already be regarded as an emergency.

As a result of such an incident, residents of dozens of apartment buildings will be left not only without drinking water, but also without sewerage, since all toilet bowls are powered from a cold water supply pipe. Using a shower, even with an intact hot water pipe, is also unlikely to work.

If a hot water pipe is damaged as a result of a water hammer, this incident, in addition to material damage, can lead to serious burns. Depressurization of the heating system can be especially dangerous, in which the coolant is always under significant pressure, and the temperature of the liquid is more than +70 degrees.

Watch the video

The consequences of water hammering in large-diameter pipelines within the city can also be very dire. In addition to possible injuries that pedestrians who are near the accident site can receive, a significant leakage of liquid very often leads to paralysis of the road section, especially when passengers are transported on this section by vehicles powered by electric traction.

The consequences of the occurrence of a water hammer can lead to significant damage, therefore it is so important to learn how to prevent the appearance of a sharp increase in pressure in the pipelines.

Gradual system overlap

This is one of the most important requirements when starting and then shutting down a heating installation. All optimal parameters are described in detail in the basic accompanying documents. The whole reason is that the accumulated energy of the water hammer, due to the increased strength of the pipe walls, may not act with all of its power.

This feature is achieved through lightning-fast bending in the desired direction. With an equal final impact force, the indicator of the power of influence on a certain section of the system will significantly decrease. Thanks to smooth switching on, specialists can significantly extend the rate of pressure rise in time, minimizing the likelihood of damage to the heating system of a cottage or apartment building.

How to avoid the problem?

To reduce the intensity and neutralize the effect of excess pressure, competent protection of the water supply system will help.

Protective mechanisms for autonomous systems against water hammer in most cases are aimed at smoothing the force of the water mass flow

To prevent the creation of one-time and permanent overpressure, both in a separate section of the circuit and in the entire system as a whole, a number of basic measures are used.

Option 1. Smooth system overlap

This is one of the main requirements when starting up and shutting down pipeline systems, which is clearly spelled out in the regulatory documents.

The fact is that the energy of a water hammer, due to the elasticity of the pipe walls, does not act simultaneously with all of its force. Due to the compensation of elastic deformations, it is divided into several time intervals.

Therefore, with the same total impact force, the impact power at a certain moment will significantly decrease. By means of a soft start, the pressure build-up process can be extended over time, minimizing significant damage to the system.

When choosing shut-off valves, preference should be given to products that have a relatively large gap of water shut-off

Cranes, the design of which provides for a large gap until the water closes, are installed at the stage of equipment installation.

Option # 2. Application of automatic devices

The automatics must be set to smoothly correct the static pressure in the system. The installation of pumps with automatic change in the number of revolutions or electronically controlled units, which are equipped with built-in frequency converters, helps to achieve the desired effect.

The use of automatic systems will allow you to control the flow of liquid, as well as read the readings of its pressure in the pipeline

Pumps equipped with automatic control of the speed of the electric motor are able to smoothly increase / decrease the pressure in the system. In this case, the software simultaneously performs two tasks: monitors the change in pressure in the water supply system and automatically regulates the pressure.

Image gallery

Photo from

Hydraulic accumulator against water hammer

Diaphragm tank action

Diaphragm tank for closed heating

Additional pumping station

Batteries gurgle

The next reason for noise in metal heating pipes is air. If something is constantly bubbling and bubbling in the battery, like in the stomach of a sick cow - he, darling. Sound insulation of heating pipes, even if it was carried out, would not give anything - the sound will be heard through the walls of the radiator.

Are you on the top floor of a house with a bottom outlet (when both the heating supply and return pipes are located in the basement)? Then look for a Mayevsky faucet on the radiator or a jumper between adjacent rooms - a device that helps to release air.

In all other cases, it is worth looking for a counter-slope (of course, if the heating system is working normally in all other respects, except for noise). A radiator hanging with a skew or a section of supply to it, which is lower at the riser than near the battery itself - this is what you have to fix, and most likely in the summer - to stop the heating system in winter for a long time, especially in the harsh climate of Siberia or the Far East, hardly would be a good idea.

Ways to prevent water hammer

Immediately after installation or overhaul of the heating system, care should be taken to prevent water hammer. This can be achieved with the help of the correct configuration of the contour operation. If done correctly, you will minimize the consequences of installation or layout errors for the entire system.

If you are planning to update and improve heating in the house, for these purposes it is worth choosing durable and wear-resistant components and consumables. In this case, you need to pay attention to the performance characteristics of the parts.

In order to prevent a sharp increase in pressure in the pipes, the heating circuit should be supplemented with compensating devices - hydraulic accumulators. They absorb excess water, preventing blockages and water hammer formation.

In addition, an electric pump is a convenient device for controlling the pressure level inside the system. It allows water to be fed into the pipeline gradually, adjusting the pressure in case of the slightest pressure fluctuations.

So, we talked about the main causes and consequences of water hammer in pipelines. We hope that this information will help you avoid possible problems and material costs.