Description of steel pipes

The main advantages due to which galvanized steel pipes are preferred for heating:

- resistant to high temperatures and pressure (especially this type - seamless thick-walled);

- mechanically strong, resistant to stress;

- a wide range of applications: even for the transfer of heated steam, the polymer pipe would not withstand;

- allows the ability to carry out any kind of processing: welding, cutting, drill, lathe.

Unfortunately, galvanized steel pipes for heating have negative properties:

- corrosion - although there are methods to reduce the susceptibility to corrosion of steel products, they are one hundred percent unable to protect the heating system;

- inside, foreign substances are deposited on the walls, especially with centralized heating - long-term operation is not possible (only 15-20 years, then the pipes are changed);

Galvanized steel pipes

Features of steel pipes

Classic

Simple pipes made of dark metal have been used in the construction of various buildings and structures for a very long time. Their popularity is due to their ability to withstand increased loads, and not collapse under the influence of negative external factors.

The price also has a great influence on the popularity. High performance carbon steel pipes are fully affordable.

The materials under consideration are simply created for the design of heating networks:

- through them it is possible to transport a coolant heated to a temperature above + 100 degrees Celsius;

- when the liquid freezes in winter (for example, in the event of a boiler failure), it is possible to create heating of pipelines by means of an open flame.

But one cannot fail to mention the significant disadvantages:

- The process of constructing a heating network from steel pipes is quite laborious, requires special skills and the use of complex equipment.

- It is not easy for steel pipes to give the desired geometric shape, especially at a time when it is necessary to bend them in several places at different angles.

- Metal conducts heat well, therefore, when installing a heating network (especially with open areas), it is necessary to whisperly protect steel pipes with heat-insulating shells, glass wool or mineral fiber.

- Iron products are very susceptible to corrosion, therefore, their average life does not exceed 10-15 years.

As already mentioned, it is precisely the latter factor that limits the use of the outlined materials for the construction of pipelines.

There are two ways to cope with the problem:

- Apply polymer parts... There are pipes made of different types of plastic, many of which are successfully used in the design of heating systems for houses and apartments. But they are not able to withstand more internal pressure and a very high temperature of the coolant.

Another disadvantage of plastic pipes is their low strength, especially to impact.

- Cover the steel pipe with a protective zinc layer... In this case, corrosion can be avoided, but only if water is used as a heat transfer fluid. Antifreeze, being chemically active, will reduce all the advantages of zinc plating to zero.

However, a heating system made of galvanized pipes is more reliable, based on this, there is an essence to dwell on the description of these parts in more detail.

Galvanized

Galvanizing the pipe helps to reliably protect it from the appearance of foci of corrosion and to continue its operation for a couple of years.

Note! Not only steel products are coated with a protective zinc layer. It can be cast-iron pipes and other products intended for transporting liquids.

The instructions for the manufacture of galvanized pipes provide for two main methods of applying a protective layer:

- Hot. The finished steel part is immersed in a container filled with liquid zinc at a temperature of + 450 degrees Celsius.

- Diffusion In this case, zinc does more than just create a protective layer. Thanks to a special technology, the atoms of the two materials mutually get into each other, forming a strong coating that resists oxidation.

For diffusion processing, not liquid, but powdery zinc is used. The pipes are placed in special containers, where special reactions take place, which give the pipe not only mechanical, but also electrochemical strength.

Note! The diffusion coating is used only for steel pipe, since other materials cannot cooperate with zinc in this way.

Prevention measures

In connection with all of the above, it is worth moving on to the issue of preventing corrosion, freezing, damage. The technology of creating heating systems has been improved and today we know many ways to reduce the shortcomings of steel pipes and increase the efficiency of the system, and extend its service life.

- To prevent deposits from appearing in the pipes, they are impregnated with an energy carrier fluid. They are also cleaned with chemicals that are delivered inside with the help of water.

- Insulation lining allows you to solve the problem of freezing and heat loss. Heating cable, special materials (polyethylene) - anything can be used. These preventive measures also eliminate corrosion, i.e. reduce the exposure of steel to it.

- It is possible to avoid the appearance of rust with the help of synthetic coatings, processing with metals that are not so susceptible to corrosion - for this they began to apply a layer of zinc. Pipes with such a coating very quickly became in the highest demand due to their low cost. Compared to other anti-rust methods: stainless steel or steel pipes coated with a polyethylene layer. Very quickly, the method spread to other areas of production (in metal profiles, in tiles, zinc began to be used in other alloys, for example, cast iron). In addition, the service life has increased by 10, or even 15 years. Although more expensive methods extend the life of the pipes up to 25 years.

Metal pipes for heating system

Galvanizing technology

Zinc coating is applied to pipes using various methods:

- electrogalvanized galvanizing,

- hot-dip galvanized,

- applying thermal diffusion zinc coating.

Electroplated zinc plating

As a result of the electrolysis process, during which zinc electrodes are placed in a solution of salts capable of conducting electric current, the substance decomposes, and zinc settles on the surface of the pipe. Thus, an even coating is obtained. However, the adhesive properties of such a pipe are insufficient for strong adhesion; the porous surface limits the pipe's service life to a five-year period.

Hot dipped galvanized

The method is expensive, but it achieves the most durable coating, although not even enough, therefore additional mechanical processing is required.

Hot-dip galvanizing is the process of applying zinc to a pipe by placing it in molten zinc mass.

Note! Not all steel grades can be subjected to this treatment: if the carbon content exceeds 0.24%, this method of galvanizing is not suitable.

Thermal diffusion coating

In sealed containers, zinc vapor is applied to the pipe surface. At the same time, the protective layer formed during the thermal diffusion process is very strong and even, regardless of the complexity of the pipe configuration, it is practically impossible to damage it during welding. Galvanized pipe has a service life of up to 15 years, is more expensive and differs in that the surface does not have a characteristic zinc sheen.

Cold galvanized

This method is used for already existing communications and is a conventional painting of pipes with a composition containing zinc, manually or by gas-thermal method. Such a coating is sometimes in no way inferior to hot galvanizing, while it does not require dismantling the pipes being processed, although the resistance to mechanical stress is slightly lower: in the first case, the pipe will last no more than 5-6 years, in the second case, the use time increases to 7-8 years term.

We recommend that you familiarize yourself with: Galvanized steel air ducts, their types and applications

Varieties of metal pipes

The pipe classification was based on several criteria for dividing into types:

- by scope of application;

- by material;

- according to the main characteristics of the model: additional coating and production method (welded, cast, seamless).

Since we are talking about a specific area of application - the heating system of a house, we are more interested in the last classification criterion. Pipes are:

- galvanized;

- seamless or welded (with a longitudinal or spiral seam), or cast;

- water and gas pipelines.

Also, manufacturers began to combine metals to improve properties. This is how:

- massive ribbed cast iron with a zinc layer. Ideal for heating, as a heat exchanger (take heat);

- to increase heat transfer, transverse plates of black steel are applied to the finished pipes;

- stainless steel with thin corrugated walls is capable of bending, strong, resistant to a wide range of temperatures and pressures.

All of them are used in the heating system. For heating residential premises, galvanized steel pipes of different diameters and lengths are more suitable. The main thing is that they comply with GOST: 3262-75; 10704-91; 10705-80. Such a model costs 35 thousand rubles per ton, 58 per kilogram.

Application of galvanized pipes

Thanks to the coating, galvanized pipes are resistant not only to corrosion, but pathogens perish in them, since zinc is a natural antiseptic. Therefore, such pipes are widespread in plumbing systems, for transporting cold water (it is undesirable to use at a carrier temperature above 60 degrees - at high temperatures the zinc layer is quickly destroyed). In addition, they are used in gas pipeline systems for domestic and household needs.

Road signs, advertising structures, supports for partitions in the construction industry, material for greenhouses and greenhouses in agriculture - galvanized products are used everywhere. They can be found in various fields, including medical. They serve for a long time, are hygienic and do not require external finishing, and their advantages become most obvious in the process of use.

The durability of pipelines is extremely important, for example, in utility networks, since communications are buried underground, and repair work is expensive.

How galvanized products are made

There are only two main technologies that allow zinc coating to be applied to steel.

- The steel product is immersed in a zinc solution heated to a temperature of 400-450 C.

- A more expensive way is diffusion coating. It happens at the atomic level. When atoms interact, and for this special conditions are created (placed in a powder container), they penetrate from a substance into another substance, a crystal lattice is formed. This creates a stronger, more durable zinc coating.Protection against chemical and electrical influences is increased.

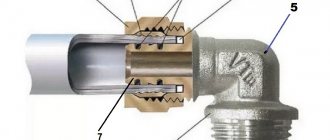

Installation

Experts say that it is possible to lay steel pipes in the heating system with your own hands.

The first feature that the craftsmen draw our attention to is threaded connections. Thermal stresses arising from welding lead to burnout of zinc. Even the sparing regime does not help to solve the problem. Therefore, instead of welding, these joints are used. They are reliable, they are threaded couplings, coals. On the pipe itself, you need to cut the same thread yourself. It is difficult, but possible. However, there is a simpler method - gas welding, it is safe for zinc and gives a high-quality connection of system elements, especially when using thick-walled products (trunk systems). The use of an inverter device will simplify the work.

Heating radiator installation

Is it possible to put galvanized pipes on heating

Metal-plastic.-pipes are very fashionable to install, but judging by the observations, galvanized metal is stronger. What is your opinion? Flimsy metal plastic. But in other places it is very convenient. Of course stronger! and the fashion for metal-plastic has passed! Zadolbali "workers" They put the devil knows what, and after a few years - the owners cry But I have had galvanizing on hot cold water for 46 years, and if only we had money for henna and made heating from this marvelous pipe material ...

Gennady Pankov

Is it possible to weld pipes in a hot water riser butt-to-joint? Sometimes they boil joint to joint, but on top they put a glass from a pipe of a larger diameter It's okay. If the welder is cool, then it will last a long time. I have had it for 12 years and nothing. It would be more correct to finally change the metal pipe to a polypropylene one, and how to weld the pipes is decided by the welder himself, he was taught this. I absolutely agree with Sergei Dmitriev and I will add on my own, do not be afraid not to burst your pipe

Semyon Gorbatykh

Share your experience? Already tomorrow I have to tell the plumbers from which pipes I want to do the wiring in the apartment And so, before setting the problem, you need to know a few rules: 1. Conventional metal pipe DN15 + is available, various installation methods (docking), threaded, flanged, welding,. Service life from 5 to 20 years, depending on the aggressiveness of the water ... Metal - 15 inches We installed the wiring for the toilet and kitchen from metal-plastic.

Artem Spekhin

Is it possible to weld galvanized and black (steel) pipes in a refrigeration system? I will not give you a reference, but if you cook galvanized) zinc coating) and black. met. then at the place of welding (and a little near the joint), the metal will rust, because during welding the metal heats up and zinc (zinc) as a lighter metal “floats” (evaporates ... zinc during welding will smoke so much that the welder can get poisoned if he works in a closed, poorly ventilated room.

Alla Chichagova

Who knows how much it costs to drill a full set, that is, everything related to water, heating, sewage. The cost of a well consists of the cost of drilling (indicated per meter), the cost of equipment, and its installation. Although, if the depth is not great, and you have experience as a plumber and the head of an engineer, then you can ...

Alexander Dryablov

Water pipes Polypropylene will solve all your problems - google the PPR pipe is very reliable - subject to good installation - correct soldering with identical materials pipes, and when the finisher came, he replaced all the pipes with plastic (when installing copper pipes, they did not take into account how the tiles would be laid, I had to pay twice), while everything is in order ...

Antonina Lazareva

Why do fistulas form on completely new heating pipes and break them? Apparently, the pipes were installed simple, but it is necessary - galvanized.

Arthur Bakhmatov

How long will the copper pipe last for heating? budichi walled up in the wall for 2 years. There was an experience. At the beginning of the 2000s, a Colleague cut a heated towel rail and put in a frame like a warm floor. Twelfth crimp copper. He poured and laid the tiles on top. Two years later, leaks started. They opened everything. The pipe was, as it were, bitten ... Do not forget to put on its “fur coat” and then brick it up. According to accepted standards, the service life of copper pipes is 50 years. But in the wall or not, I think there is no difference. They are perhaps the most durable, the only thing is that some believe that they are not very good for a drinking supply, such as drinking without boiling) ...

Anna Spirova

Can fiberglass-reinforced polypropylene pipes be embedded in a wall and placed on central heating? You can definitely hit the wall! And you can also put on heating, BUT! You need to find out the parameters of your central heating. Already better metal-plastic ONLY UNDER THE PRESS OF course, for heating something. It is even necessary, we have been putting it on for many years, I have met more than once about metal-plastic that it tears For myself, it is impossible for myself, there is no operating experience comparable to galvanized pipes in Russia, it will be like with metal-plastic that does not care for the terms originally declared by manufacturers, lay pipes in channels or sleeves for…

Anastasia Mudyugina

Tell me if it is possible to pour antifreeze into an aluminum heating radiator. If yes, from what source is the information I quote: // If galvanized pipes are installed in the heating system, can antifreeze be used? home heating?

Andrey Grigoriev

The stove in the bathhouse was purchased with an iron one. Question about pipes. Why are galvanized pipes not good? I have not seen galvanizing on chimneys recently, unless on the outer shell of a sandwich pipe, if a sandwich is expensive for you, then look for a thick-walled steel with a diameter of 100 mm or more. it will not work out of galvanized (thin-walled) pipes, Directly, put steel D120-150 (you will less often clean the chimney with a heater - any metal.

Galina Menshikova

How to create a warm floor Lay a carpet) First you need to learn how to write not “Create”, but “To do”. We all want coziness and comfort in our home. Surely you like to walk barefoot at home, which means that your floor should not only be clean, pleasant and comfortable, but also warm. It happens that because of cold weather, or heating shutdown, the floor ... Buy a warm floor!

Albert Taborsky

How to heat such a house? underfloor heating, a boiler on electricity or diesel fuel, a lot of things there is a boiler, finally, a long-burning stove, electric wall-mounted convectors (the house is wooden - therefore there are fewer problems than in a stone one. only one floor.Two cars of firewood are enough for the winter (the chocks are expensive, I buy a croaker The money comes out about the same as heating with electricity. Only ...

Zhanna Rybnikova

Good day! Has anyone changed the heating battery? Connected like. Only not metal-plastic On heating in any case! If you don't want to weld, use polypropylene. It must be reinforced for heating. Guys, well, you give! What kind of flexible hoses for heating? The water temperature is high there! Pressure! There are hydraulic shocks! Any water with chemical additives! Your hoses will burst and drown everything around! The battery can be connected: 1) Ordinary ...

Irina Mikhina

Chimney. Gas heating. The question is inside There is such a document SNiP 2.04.08-87 * Gas supply. So clause 6.36.Indicates: “The arrangement of chimneys must comply with the requirements of SNiP 2.04.05-91 * as for heating stoves. When deciding on the possibility ... Unas, all this was done by firemen. And on top they made such a round visor. A circle was cut out of a tin, a quarter was cut out of a circle, and whether it was smaller than all of this connected, such a cone was obtained. It must be larger than the pipe diameter. And the distance from the pipe ...

Vladimir Sumarokov

Is it possible to put a black pipe on the heating riser and not galvanized? Better stainless steel! Yes, of course, since it is the black pipe that is intended for heating risers and Stanislav is not galvanized in any way. Take some advice here, look for https://www.mastercity.ru/vforum/ If the pipe wall is thin, then it is better not to install it (it will stand for 1 or two years A thick-walled one can be black, but better metapol-) Normally, the service life is up to 20 years ...

Nadezhda Shapina

The return line on the iron heating system is rotten. What to replace? Put a galvanized water pipe and do not invent it. And it's scary to look at plastic in emergency situations. Place the Metapol Reinforced polypropylene. Service life - 50 years. Polypropyleg is cheaper and easier to replace; everything is cooked on the spot.

Vitaly Demulin

Why is it impossible to put galvanized pipes on the central heating Who told you that? When using pipes with a zinc metal coating, you need to know: when working on networks, zinc coatings, in addition to barrier-insulating functions, also carry out electrochemical protection of the pipe metal if present in the coating ... Use is not prohibited. Apply only this unnecessary rise in price. The zinc coating adheres to the metal inside the pipe only in cold water. At t> 70 C, there will no longer be a protective pore on the pipe. You will get heating from a black pipe at the price of galvanized ...

Zhanna Valneva

We install a gas boiler for heating in a log house. The question arises: how and with what to equip the walls (+) First of all, you do not go to gas workers and firefighters, but to VDPO (All-Russian Voluntary Fire Society The wall on which the heating device is hung must be sheathed with non-combustible asbestos-cement material (we are to parents ... Basalt mat (holds over 1000C) - galvanized top can be simply plastered

Daria Vashutkina

What pipes to install in the country for heating in the house? Would you even indicate whether you need a chimney or will you make wiring around the house - water heating for heating? if for the stove do not put metal-heated-cooled-damp, soot stuck-fell-clogged the pipe. or at least insulate, fortieth pipe Galvanized

Installing the radiator

Consider the features of installing galvanized pipes when assembling a radiator at home.

- Prepare the tool: an electric carving tool is welcome (in its absence, use either a grinder for steel or a hacksaw for metal); file; die; vice; gas wrench # 1 (for assembling connections) and 2 (for threads and for radiator plugs).

- Buy materials: galvanized pipes, steel DU 20 and fittings of the required amount for inserting the device. For example, modern ball valves, not screw-type - this is the last century. They will be installed on the piping to the radiator, on the jumper. Do not forget about the sealant - traditional plumbing flax. Buy for him and impregnation - paint, drying oil or silicone.

- We cut the threads at the riser and the liner, taking into account the length of the nozzles with a margin. It recedes from the floor, walls 8-10 cm. This should be enough to freely cut.

Carving instruction:

- Remove the burrs from the end, from the outside, be sure to make an approach at an angle, into which the die will fit. Use a file or other suitable tool. You can squeeze the end with a gas wrench for lack of a better one.

It will be enough 5 threads for a pipe and a corner, and for driving into a radiator - 7-8.

- We carry out the assembly of threaded connections. The threads of both elements must match.If we press with force, a new one can form, and we do not need this, since it will lead to damage to the connection. Also, do not "drive" the valve all the way. Even if the handle remains in an uncomfortable position for you, further efforts will lead to a crack in the body. It is better to stop before reaching the end of one revolution. And in general, be extremely careful, as you are dealing with fragile brass.

Drive the locknut to 5 mm between the coupling until you feel resistance. Wind the winding along the thread, into the gap. After assembling the threads, paint. Since during the work we have broken the zinc layer, and some joints require additional protection (cast iron is stronger than brass).

- Connect the device from below. It will not need to be rinsed. And the brass elements will not break if you suddenly fall on them. You will have to put a tap in the upper plugs.

Despite the disadvantages known to everyone, galvanized pipes for heating will be used for many decades to come. And even if they only seem more reliable than modern plastic ones, their use in centralized systems is more justified if preventive measures are taken. Firstly, the heating schedule always gets lost, the pressure in the pipes constantly jumps, like the temperature. It is unlikely that in such conditions plastic will show itself as strong as steel. Secondly, it makes no sense to connect powerful radiators to such pipes.

However, arranging an autonomous system, you can calculate the "ceiling" of pressure and temperatures, display your own schedule and adjust all structural elements to your calculations. If you do not need a powerful radiator, your house is already warm, especially in summer - the only season that you spend in the country, then there is no point in spending money on galvanized pipes. You can give preference to reinforced polypropylene or metal-plastic with fittings. By the way, they are well suited for the installation of an autonomous system with controlled parameters in a year-round living environment. In this case, the installation of pipes will be easier than in the case of steel products.

Installation features

So, we are going to mount the radiator on galvanized pipes with our own hands. What is useful to know before getting started?

Instruments

You will need:

- Grinder with a cutting wheel for steel. In its absence, you can do with an ordinary hacksaw for metal, but then cutting pipes will be quite tedious.

- Rough file. When threading, you will need to chamfer the outside of the pipe.

- Die with holder. Of course, if you have an electric threading tool at your disposal, even better; but purchasing it for the sake of installing one heating system is clearly unprofitable.

- Vise or clamp. Do not cut the threads on the branch pipe by weight.

- Gas keys. At least - # 1 and # 2. If you have to tear off the stuck plugs in cast-iron heating radiators, even a huge number 4 may not be superfluous.

The photo shows gas keys of the three most useful sizes. The first number is needed for assembling the connections, the second and third for threading and unscrewing the radiator plugs.

Materials (edit)

Fittings - corners, tees, valves - it makes no sense to enumerate: their number is selected depending on the project and is calculated when sketching a sketch of the future insert of the heating device.

Nuance: use only modern ball valves. It is better to completely forget about the existence of their screw predecessors. They are much less fault-tolerant and have much higher hydraulic resistance.

To replace the heating riser, in the vast majority of cases, a galvanized steel pipe DN 20, or 3/4 inch, is used. It can also be used for liner and jumper.

Tip: put the valves not only on the piping to the heater, but also on the jumper.With the jumper closed, all the coolant will flow through the radiator; when open, you can regulate the temperature of the battery without making your neighbors freeze.

Plumbing flax is traditionally used to seal the threads. So that it does not burn out and does not rot, it can be impregnated with paint, drying oil or silicone sealant, smearing a little on the thread and on a strand of winding. When assembling the threaded joint, the flax will be impregnated fairly evenly.

Cutting

There are few subtleties here.

- When measuring the length of the pipes you need, do not forget to take into account the length of the thread that will go into the fitting.

- When choosing a place for cutting a riser or liner, keep in mind that you have to cut a thread on it. The distance from the floor and walls should be at least 8-10 centimeters.

The distance from the floor and walls must be sufficient to cut the threads.

Threading

Manual threading instructions are simple:

- Prepare the pipe end. Remove the burrs and make a run for the die - chamfer from the outside at a gentle angle. This can be done with a file, grinder, emery; in extreme cases, you can even squeeze the edge of the pipe with a gas wrench.

- Clamp the pipe in a vise or clamp. If we are talking about a riser, fix it with a gas wrench so as to compensate for the torque from the die. Otherwise, there are great chances to completely tear off the riser from the radiator of the neighbors above or below.

- Apply some oil to the pipe. Anyone - from spindle to grease. In this case, the die will go easier and will not leave scuffs on the steel.

- Slide the holder with the long side onto the pipe and press it against the end with the maximum possible force. Twist the holder clockwise at the same time. Do not rush to stop the pressure: until the first thread is completely cut, the die can come off it.

To assemble a pipe with an angle or tee, five threads are enough. In the case of a squeegee that goes into the radiator plug, cut about 7-8 centimeters.

Assembly

When assembling threaded connections, there are only two serious mistakes:

- If you do not accurately align the male and female axes and try to reassemble the joint, you will, with sufficient force, cut a new thread in the brass or cast iron fitting with the steel pipe. However, nothing good will come of this - after two or three turns, the thread will stall tightly and will be damaged.

- An attempt to turn the valve another five degrees so that its handle takes a comfortable position almost always ends in a crack in the body. Better to re-disassemble the connection and rewind a little more reel, and then reassemble, stopping one turn earlier.

When assembling threaded connections, do not overdo it. Brass is a rather fragile metal.

The locknut is wound like this:

- It is driven to a distance between it and the coupling (radiator plug, fitting) of about five millimeters.

- Then a reel is wound into the gap. Of course, as usual - along the thread.

- The locknut is clamped until the moment when resistance to rotation of the wrench becomes noticeable. Excessive efforts are not needed here either.

- Remember to paint the threads after assembly and crimping. Let's remind: the protective zinc layer on them is broken.

- Cast iron corners and tees are much stronger than brass ones. If the riser and piping are tightly assembled, there is a real chance of damaging the brass fitting simply by leaning on the pipe.

- The best connection for the heater is at the bottom. In this case, it will not need flushing. In one of the upper plugs, however, you will have to put a Mayevsky crane.

Useful little things

The bottom connection allows the radiator to work for decades without flushing.

Is it possible to use galvanized pipes for heating systems and hot water supply.

Very often you can hear a question from a customer, is it possible to use galvanized pipes for heating systems and hot water supply? Sometimes this question is even pronounced with a reproach, why are you putting "rusty" pipes to us? Save on us! And really why? Why put a "rusty" pipe or plastic that melts from high temperatures, because everyone has long known galvanized pipes that do not rot and serve for more than 50 years.

The answer here is simple and unambiguous, galvanized pipes for heating and hot water supply systems with temperatures above 55 degrees cannot be installed, and that's why. When the coolant in the heating or hot water supply system is heated above 55 degrees, and especially strongly at 70 ° C, a chemical reaction occurs in the coolant with active flaking of zinc, while filters and thin sections of pipes are clogged first, then fistulas will appear on the pipes and the heating system naturally leaks ... If you use water as a heat carrier, and we use it in 99 percent of the heating systems of garden and country houses and 100% of apartment buildings, in the water over 70 degrees, and especially after 82 degrees, oxygen is actively released. As you know, oxygen is an active catalyst that accelerates any chemical processes. Consequently, the corrosion process will go even faster.

The situation is not the best with cold water supply, if your water runs on schedule, or it very often does not exist. The alternating contact of galvanized pipes with water, and then with air, is very bad for their integrity, galvanized containers and pipes in such conditions give a leak after two to three years. And only galvanized pipes that work without temperature extremes and interruptions in water serve thirty years or more. By the way, too, provided that they are isolated from moisture and outside.

Views

There are many different types of galvanized pipes. They differ only in the substance from which they are made.

Heating pipes made of massive pieces of cast iron (canopy) are usually called cast iron. They are also used, by the way, like heat exchangers, and not only as heating devices. As a condenser, cast iron pipes take in excess heat.

Black steel. In such things, everything has been done to increase heat transfer. For this, transverse plates were pressed onto a finished workpiece.

Galvanized Carbon Steel Pipe

Stainless steel. Corrugated pipes are made of this steel. One such pipe is very flexible, since the walls are very small. But remember that stainless steel is durable. Therefore, a stainless steel pipe will be able to withstand a greater pressure range in heating and temperature differences.

The next type is used only to protect the metal from external aggressors (only polymer and metal-polymer), since it does not have a high density, and therefore strength. These are plastic pipes for the heating system.

Is there an alternative to galvanized pipes.

Glass fiber reinforced pipe

So what alternative to galvanized pipes exists, do we really have to drink water flowing through rusty pipes. Of course not. For many years, low and high pressure polyethylene has been produced and is used everywhere for water, and for hot water the so-called PPRS pipes (polypropylene reinforced pipes) or as they say now everywhere in advertising - this is "kalde". Such pipes can withstand temperatures up to 90 degrees Celsius, although their service life at such a temperature is no more than 6 months, but how many days a year does this temperature occur in our heating plants? But the owners of private houses using polypropylene pipes in their heating systems should not forget about this. The temperature in an improperly designed or installed heating system can be kept at the temperature limit of using polypropylene pipes for a very long time, as a result of which they can become covered with deflectors and collapse.

This defect is typical for heating systems with automatic regulators on heating devices. When the boiler is 85 degrees constantly, and the heat is controlled by radiator regulators.This is as bad as the temperature in the heating system is below 55 degrees, when condensation forms on the pipes, and especially on the outer surfaces of the boiler and its chimney. They say that the boiler is crying, and naturally its surfaces, especially the chimney, even if it is made of stainless steel, are actively corroded.

the answer to the question - is it possible to use galvanized pipes for heating systems and hot water supply and what is better to use a "rusty" pipe or PPRS pipes received.

If anyone else has questions or you need heating system project for a private house and competent professionals for its implementation are welcome to contact us. The company has been operating in this service market since 1985, has self-regulatory organizations and certified specialists. Designs and builds roof and conventional boiler houses, conducts installation of heating systems for residential apartment buildings and private houses. Examples of our work, address and phone numbers on the next page.

Galvanized pipe: what is it for and which one is better?

Zinc plating - technology of zinc coating of the surface of metal pipes. In the main technological processes of galvanizing pipes, a high temperature is required.

If products are galvanized in an oxygen-free atmosphere, then a metallic-colored surface is obtained without streaks and patterns, since zinc oxidizes when interacting with oxygen.

Due to this property, a method has been developed for the manufacture of products with various patterns. This method has proven itself well in Europe, which is one step ahead in galvanizing technology. But, we are not interested in patterns. We are interested in galvanized pipe and its properties.

What is a galvanized pipe

Let's try to figure out why the galvanized pipe? Despite the fact that today, when carrying out heating and water supply systems, plastic pipes of various modifications are increasingly used, the galvanized pipe has firmly occupied its niche, and is in no hurry to give up this place in the field of metal rolling.

The reason for the high demand for galvanized pipes is their quality properties and performance characteristics, which are not inferior to pipe products made of other materials. Plus a relatively low cost.

Performance characteristics:

- increased resistance to corrosion;

- ability to withstand high pressure;

- resistant to sudden temperature changes;

- less susceptible to external factors;

- high strength;

- safety;

- durability.

What is a galvanized pipe for?

Based on the characteristics, the galvanized pipe has found its application in various directions, both in everyday life and in many areas of construction and industry.

Galvanized pipe is widely used for installation:

- heating systems;

- gas pipeline systems;

- hot and drinking water supply pipelines;

- ventilation systems;

- lighting sections;

- when carrying out various types of construction work.

When choosing a galvanized pipe, it is necessary to take into account that GOST galvanized pipes with a different registration number and year of adoption of the standard are used for different works. So, for example, a galvanized pipe GOST 3262 75 is used when laying water and gas supply systems.

Galvanized pipes are classified by category

- water and gas pipes

- electrowelded pipes

- shaped pipes

Having decided on the choice of the category of galvanized pipes, the outer and inner pipe diameters should be taken into account. When installing pipelines in residential premises, as a rule, pipes with a small diameter are used for systems with final water supply devices.

For interfloor plumbing, medium-diameter galvanized pipes are used. If you are installing galvanized pipe in a pressurized system, you must choose reinforced pipes.

Galvanized pipe withstands temperature changes well and withstands the most severe climatic conditions.Galvanized pipes are made using a seamless or electro-welded method. The most common material for the manufacture of galvanized pipes is stainless steel, less often copper.

What material, and by what manufacturing technologies, are galvanized pipes better in operation?

Based on their performance characteristics, galvanized pipes made of copper are considered the most practical in their application. They can withstand both high temperature drops and high pressures, and also have the property of oxygen impermeability.

Galvanized pipe installation technology

Traditionally, welded joints and fittings are used to connect galvanized pipes. Most often, installation of galvanized pipes with fittings is carried out, which are divided into:

- threaded;

- flanged.

When installing the pipeline, you should pay attention to the fact that the zinc coating of the pipe may be damaged during the welding connection. This leads to the formation of rust at the joints.

This means that after welding, the joints must be treated with anti-corrosion materials. Also, experts do not recommend using cast iron fittings during installation. They "stick" to the pipe and in the future, dismantling becomes impossible

Good luck with the selection and application of galvanized pipes.

How to choose galvanized pipes for heating and water supply

Despite the saturation of the market with many varieties of high-tech polymer pipes, metal for the installation of heating systems, hot and cold water supply is widely used today. Metal pipes for these purposes are mainly made from steel and copper, less often from aluminum. Each type of such pipes, depending on the material of manufacture, has a set of individual characteristics that provide the consumer with enough room for maneuver when choosing.

One of the most common types of pipes is zinc-coated steel products - a material that has many positive characteristics, but is specific in application. Consider what kind of material it is, and how to properly use galvanized pipes for heating.

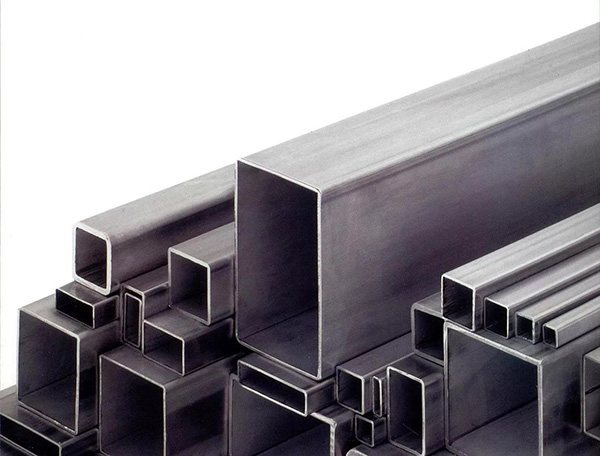

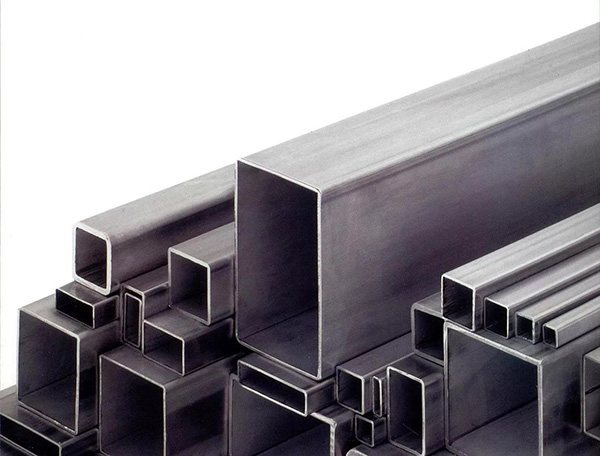

Profile galvanized pipes

The galvanized profile pipe differs from others in its cross-sectional shape. The shape of such a pipe is usually square or rectangular. This type of pipe differs not only in shape, but also in the size of the section side.

GOST, which is used in the manufacture of the pipe - 13663-86.

The range of profile structures includes:

- Pipe in accordance with GOST 8639-62 - square;

- According to GOST 8645-68, rectangular.

Depending on the wall thickness, the profile pipes are:

- Thin-walled;

- Thick-walled.

The characteristics of such pipes are:

- The strength of the product;

- Using it for a long time;

- Low weight;

- Corrosion resistant.

Production methods and varieties of galvanized pipes

The main enemy of steel pipes is corrosion. One of the ways to protect against it is to apply a protective zinc layer to the surface of the steel pipe, after which the material is classified as a separate subgroup - galvanized pipe for water supply and heating systems.

The method is moderately costly, so the cost of a steel pipe after galvanizing remains affordable - an approximate price ratio can be found according to the table:

| GWP pipe size (gas pipeline) | Price (rub / m) | |

| black steel | galvanized | |

| 15x2.8 st1-3sp / ps | 33 | 50 |

| 20x2.8 st1-3sp / ps | 42 | 66 |

| 25x2.8 st1-3sp / ps | 59 | 95 |

| 32x2.8 st1-3sp / ps | 81 | 127 |

| 40x2.8 st1-3sp / ps | 90 | 155 |

| 50x2.8 st1-3sp / ps | 117 | 194 |

There is no independent standard for galvanized products. Zinc-protected steel pipes are manufactured in accordance with regulatory documents for electric-welded products with a straight seam (GOST 10704) and material for gas pipelines (GOST 3262-75).

Zinc coating methods

Zinc coating, depending on the operating conditions of the pipe, can be performed both on its outer surface and on its inner surface.

There are 4 methods of galvanizing pipes, each of which is used depending on the size of the products and the requirements for the thickness and strength of the zinc coating:

- hot - the prepared part is immersed in molten zinc, which ensures high quality and durability of the coating, but the energy consumption of the process is high;

- cold - products are painted by one of the painting methods with substances containing zinc, which does not provide high strength of the zinc layer (used to protect already mounted structures against corrosion);

- electro-galvanic - the coating is carried out by the method of electrolysis, that is, the deposition of zinc dissolved in the electrolyte (cathode) on the part (anode), when an electric current passes;

- thermal gas - a device for a protective coating by gas-flame spraying on the surface of a zinc powder part, a disadvantage is porosity and low strength of the layer;

- thermal diffusion - parts are covered with a layer of zinc, which is after heating to 2500 degrees. in a vapor state, it is used for processing small parts in large quantities - screws, bolts, nuts, washers, requiring high adhesion of zinc to metal.

Diameter and length of galvanized pipes

Galvanized pipes are made in different sizes depending on the application.

For example, water and gas pipes are made in accordance with GOST 3262-75. They have different diameters - from 6 to 150 mm. Also, pipes can have different lengths - from 4 to 12 meters. And these pipes can be made according to the customer's project and have a different length.

Galvanized pipes can be electrowelded. They are manufactured in accordance with GOST 10704-91. The diameter of such pipes varies from 10 to 1420 mm. The length can be different: the larger it is, the larger the pipe diameter.

When designing pipelines, pipes are selected in accordance with the requirements of the project.

Parameters of zinc coated steel pipes

The main technical parameters of zinc coated steel pipes are:

- outer diameter (10.2 - 165 mm);

- weight of 1 m of pipe (0.4 - 22 kg);

- nominal bore (6 - 150 mm);

- wall thickness (1.8 - 5.5 m);

- length (4 - 12 m).

As with ordinary pipes, the walls of galvanized products can be light, reinforced or standard, the accuracy of execution is assigned ordinary or increased.

Important! Protective zinc coating should be applied to the entire surface of the product and have a thickness of 30 microns or more. Peeling of the protective layer, peeling and swelling on it are not allowed ("Steel water and gas pipes", Technical conditions, GOST 3262-75, rev. No. 4.6).

Types and sizes of galvanized pipes

There is no GOST in which all types of galvanized pipes would be described at once. There are quite a few standards, and depending on them, products can be divided into the following categories.

Water and gas pipes

Used for utility communications, including indoors. They are easy to weld and serve for more than 25 years with proper installation (for galvanized pipes, threaded connections are mainly used).

Products with the same diameter are available in different wall thicknesses. The entire assortment is clearly defined by the standard. According to GOST 3262-75 for water and gas supply steel pipes, they can have an outer diameter from 10.2 to 165 mm, and a wall thickness from 1.8 to 5.5 mm (because of its volume, it is better to look at the table in the text of GOST). At the same time, pipes of a light series, designed for thread rolling, at the request of the consumer, can be manufactured according to other parameters, also described in the document.

Electrowelded pipes

They differ in that when they are formed from rolled metal, seam welding is used. The finished seam is then checked with a special scanner.They are used for laying communications and transporting gas and water with a pressure of no more than 16 MPa, for the construction of structures for hangars and sheds.

Pipes with a spiral seam are also produced, the presence of which makes it possible to withstand a higher pressure. In accordance with GOST 8696-74, spiral-seam pipes have a diameter of 159 to 2520 mm and a wall thickness of 3.5 to 25 mm. It is better to familiarize yourself with the assortment for electric-welded longitudinal welded pipes in the text of GOST 10704-91, since the table with dimensions is large volume. Briefly, we will clarify that for products with an outer diameter of 10-1420 mm, a wall thickness of 1 to 32 mm is prescribed.

Seamless pipes

They are free of seams and are required where maximum tightness is important. They perfectly show themselves as a part of oil pipelines, they can transport highly toxic liquids. They are also used in the nuclear and aviation industries, in mines and on drilling rigs.

Depending on the method by which they were made, seamless pipes are divided into hot-worked (or hot-rolled) and cold-worked (cold-rolled), for these subspecies there are different standards.

The outer diameter of hot rolled products, according to GOST 8732-78, can range from 25 to 550 mm, and the maximum wall thickness is 75 mm. Measured length limitation: from 4 to 12.5 m.

At the same time, the range of cold-rolled pipes is determined by GOST 8734-75. Their outer diameter is from 5 to 250 mm. And the wall thickness is in the range from 0.3 to 24 mm.

Profile pipes

The main difference is the sectional shape, and hence the breadth of application. In the manufacture, GOST 13663-86 is used, and the range of profile structures includes pipes:

- square section according to GOST 8639-62 (section size - from 10/10 to 180/180 mm; wall thickness - from 0.8 to 14 mm);

- rectangular section according to GOST 8645-68 (section size - from 15/10 to 180/150 mm, wall thickness - from 0.8 to 12 mm);

- oval section according to GOST 8642 (section size - from 6/3 to 72/22 mm, wall thickness - from 0.5 to 2.5 mm).

Advantages and disadvantages

Most of the characteristics of galvanized VGP pipes, both positive and negative, coincide with the parameters of products made of black steel, but there are also individual qualities.

Dignity

- Strength (especially tensile strength).

- Fire resistance.

- Low coefficient of thermal elongation.

- Absolute tightness.

- Shock resistance.

- Durability.

- Can be used as a heat exchanger.

- The possibility of installation, including maintenance, do it yourself.

- Two assembly methods (welding, threaded connection).

- Ease of disposal.

In favor of steel GWP pipes is the fact that the external laying of the gas pipeline from the main to consumers is allowed only from steel material.

disadvantages

- Significant share.

- Electrical conductivity.

- High thermal conductivity (the need to insulate pipes in heating and hot water systems).

- Corrosion susceptibility when zinc protection is damaged.

Installation and assembly methods

Galvanized pipes that form a heating or hot water system are mounted in three ways:

- welding;

- flange connection;

- threaded connection;

- soldering.

Each of these methods has its pros and cons. Consider these installation methods and the nuances associated with them.

Welding galvanized pipes

Zinc-coated water and gas pipes can be connected by electric or gas welding - both types of installation are convenient because they take little time. But there is one negative factor, the effect of which must be minimized, since it will not be possible to completely eliminate it.

The fact is that the temperature of the weld reaches 1200 degrees, and zinc boils at 906 degrees and begins to evaporate from heating during the welding process. In this case, the following happens:

- the harmful effects of zinc vapors on the welder, up to the onset of suffocation, since they are poisonous;

- Evaporating zinc exposes steel and makes it vulnerable to corrosion;

- zinc vapors contribute to the formation of pores and cracks in the weld, which reduce the strength of the joint.

For the maximum localization of these processes, before starting welding, not counting the mandatory device for efficient ventilation of the room, it is necessary to perform the following actions.

- prepare the edges of the joint, that is, make an external chamfer on them and remove the zinc coating by 25-30 mm on both sides of the joint;

- to weld the joint, followed by cleaning the weld seam from slag and coating the bare pipe section with zinc-containing paint (zinc dust content - 94%, binder - 6%) - cold galvanizing.

To prevent the zinc layer from boiling, you can treat the junction with hydrochloric acid 5 cm in both directions, but in this case, acid fumes will form during welding.

Important! According to clause 4.6 of the joint venture (Building Regulations) 73.13330.2012, the device of welded joints on galvanized steel pipelines is not allowed, since zinc is not removed from the inner surface of the pipe before welding, and zinc vapors, the formation of which cannot be avoided, cause the formation in the seam pores and shells. But this document is voluntary, and if there is no reference to the mandatory use of this item in the project, then the installation of galvanized pipes by welding is permissible.

- perform welding at a low speed, but avoiding pipe burn-through, and with an increased current strength;

- use rutile coated electrodes (the electrode contains titanium oxide).

Electric welding of zinc-coated pipes requires certain skills from the welder. In addition to the composition of the outer coating of the electrode, the quality of the weld is affected by the thickness of its rod, which determines the power of the arc - an excessively thick electrode will burn through the wall, and a thin one will not provide the necessary strength of the welded joint. For welding galvanized pipes with a wall thickness of 1.5 - 5 mm, electrodes with a diameter of 2-3 mm are used.

Flange connection for galvanized pipes

This method is based on bolting together fragments of pipes, at the ends of which flanges are welded - steel rings with an inner diameter equal to the outer diameter of the pipe, and holes along the perimeter for mounting bolts. Two flanges of different fragments are applied to each other using an intermediate gasket and tightened with bolt-nuts or studs.

In this method of installation, the same negative factor is present as in the welded joint - in the process of welding the flanges to the pipes, zinc boils and the protective layer is destroyed in the area of the weld. Therefore, it is also necessary to take measures to localize the temperature effect on the zinc layer, and after the end of welding, clean the seam and apply an anti-corrosion zinc-containing coating on it (cold galvanizing).

The flange connection is not compact, therefore it is used in most cases when laying the pipeline in utility rooms or outside. On the abutting side of the flange, there is an annular area called a mirror. A paronite gasket with a hole, the diameter of which must coincide with the inner diameter of the pipe, is installed between the two mirrors of the abutting flanges before they are pulled together. The outer diameter of the gasket is made equal to the distance between the opposing fastening bolts.

Threaded connection

This installation method eliminates the need for thermal connection methods and is performed using fittings of various types, designed to connect individual fragments of the pipeline after threading them.

Threaded assembly also has its drawbacks:

- the threading process is laborious and time-consuming;

- a cutting tool (die) removes a layer of steel of a certain thickness along with a protective zinc coating when cutting a thread.

- the tightness of the threaded connection is ensured by winding the thread with FUM tape, sealing paste or tow with paint, which eventually lose their properties and require replacement.

Soldering galvanized pipes

To mount a heating system or hot water supply from galvanized pipes without damaging the zinc layer, brazing is used, which is performed in the following sequence:

- the pipe ends to be connected are butted and, if the wall thickness is more than 3 mm, chamfer is performed on the outer edges;

- the joints are degreased by heating, after which the flux (composition HLS-B) heated to plasticity is also applied in a thick layer to the surface adjacent to the planned joint;

- the ends are positioned with a gap of 2-3 m;

- the burner flame is exposed to excess oxygen.

The size of the burner is selected depending on the diameter and wall thickness of the galvanized pipe:

For high-quality brazing of a galvanized pipe, it is necessary to adhere to the rule: the size of the burner should be one unit smaller than when welding a pipe of the same dimensions without a zinc coating. During the brazing process, the flame should be concentrated on the edges to be joined and the joint gap in order to exclude heating and evaporation of zinc from under the flux layer.

Joint seams of high-quality brazing of galvanized pipes do not need additional anti-corrosion protection, but applying on zinc-containing paint as a safety operation will not be superfluous.

Independent design of the heating system

In the manufacture of a climatic network from galvanized steel pipes, two types of connections can be used:

- electric or gas-welded;

- using threaded fittings.

It should be noted that both the first and second methods require the master to have certain building skills. If you doubt your abilities, it is better to entrust the installation procedure to experienced plumbers.

Welding

The process of manufacturing heating using the welding method consists of the following stages:

- Vertical main risers (supply and return) are mounted, and then horizontal wiring is made from them to each central heating radiator.

Advice! If you are modernizing an old heating system, it is advisable to install pipes according to the old scheme, performing their successive replacement. Such engineering networks are very carefully designed and tested, so there is no need to make major changes unnecessarily.

Welding is a responsible and complex process

- Gas welding is carried out using a special solder with a thickness of 0.8 to 1.2 mm. If electric welding is used, it is necessary to use electrodes with calcium fluoride or rutile coating with a diameter of up to 3 mm. Otherwise, it will not be possible to achieve a tight connection.

- Galvanized pipes, unlike conventional steel pipes, are overlapped welded. To do this, one of the parts is flared a little.

When welding pipes with a protective coating, special attention should be paid to the quality of the seam. The joint should not have sagging, chips, cracks and other defects.

With the same care, it is necessary to make holes for pipes and fittings. You can use a drill, a milling machine, or punch out the hole with a press.

You need to carefully monitor the quality of the seams.

If you have initial skills in working with a welding machine and decide to mount galvanized pipes yourself, you must adhere to the following tips during operations:

- the seam must be started from the central part of the part, starting from the floor and gradually moving up;

- the electrode should be placed strictly perpendicular to the surface of the product (otherwise it will be impossible to make a high-quality joint);

- if welding is carried out on a vertical surface, the electrode must be positioned at an angle, directing it from top to bottom;

- spot welding technology can be used to achieve the best quality.

Note! Welding of galvanized pipes is practically not used.Under the influence of high temperature, the protective layer completely evaporates, as a result of which the joints will corrode, and you will lose all the benefits of using expensive galvanizing. It is better to dwell on the connection technology involving the use of threaded fittings.

The welding arc evaporates the protective zinc layer from the pipe surface

Fitting connections

To install the heating system using the twisting method, you need to stock up on the required amount of fittings: elbows, adapters, valves and so on.

Galvanized Threaded Pipe Fittings

Tools of various diameters are also required for threading. You can use dies, but it is better to purchase a die cutter: this device allows you to cut more efficiently, avoiding distortions.

In addition, you will need:

- grinder for cutting steel pipes into pieces of the required length;

- a file with which the end chamfer is removed;

- a vice that will help to securely hold the workpieces while working with them;

- gas wrenches for twisting fittings and pipes (preferably torque wrenches - they will not damage the fitting thread by dosing force).

The cutting process usually does not cause difficulties even for a novice master, but here you need to take into account several features:

- when measuring pipes, do not forget to take into account the distance at which the pipe will enter the fitting when twisting;

It is better to use special equipment for cutting galvanized pipes.

- during installation, pay attention to the fact that placing the pipe too close to the wall will not make it possible to cut threads (this requires at least 8-10 cm of free space).

Assembly is not particularly laborious.

Here, novice masters make only two common mistakes:

- Misalignment of products along the longitudinal axis. If the pipe and fittings are inaccurately aligned, the threads can be broken. Because of this, it will be impossible to achieve the desired tightness, and the damaged parts will have to be replaced with new ones.

- Tightening fitting or shut-off valve too tight. It often happens when screwing on taps, when the master wants to tighten the nut a little more so that the crane handle moves more freely. Most often this leads to breakdown.

Complete disassembly and rewinding of additional layers of polymer tape or tow will help to cope with the situation.

Docking with radiators

Another crucial stage of installation is the connection of pipes with heating radiators. For this, a special type of fittings is used - bends.

The operation is performed according to the following scheme:

- the squeegee is screwed onto the pipe until the distance between its cut and the inlet of the battery reaches 5 mm;

- tow is wound on the inlet pipe of the radiator (along the thread);

Flanges for connecting pipes to radiators

- the squeeze is screwed onto the thread until the force becomes noticeable, but not excessive;

- joints can be painted to avoid corrosion.

Specificity of using galvanized pipes in heating and hot water systems

Zinc coated pipes in heating systems and water supply systems are used taking into account the operating conditions.

If the temperature of the coolant does not exceed 65 degrees, then the zinc coating successfully performs its functions. In the northern regions, where this parameter is much higher, the inner zinc layer reacts with water under the influence of high temperature:

Zn + H2O = ZnO + H2.

Both substances resulting from this interaction are negative factors:

- ZnO is flakes that precipitate and clog the lumen of small-diameter pipelines;

- H2 is hydrogen, which, when mixed with air in a certain proportion, is explosive or, at least, forms blockages in the system.

Therefore, in hot water and heating systems with a coolant temperature above 60 degrees, it is allowed to use pipes that have only an outer protective zinc coating, which will protect the pipeline from corrosion during periods of inactivity. However, when water gets on the surface of the hot pipe, the zinc sheath begins to peel off from the base, therefore, to avoid this, it is necessary to paint such pipelines on top of the zinc, which will lead to an even greater rise in the cost of the system.

Output: the use of pipes galvanized from the outside in hot water and heating systems with a coolant temperature above 60 degrees is unreasonably expensive, and galvanized pipes from the inside are harmful and dangerous.

Advantages and Disadvantages of Galvanized Pipes

Metal pipes are a classic when laying communications. The most common metal from which they are made is steel. This metal has excellent performance, except that its cost is low. The production of steel pipes is well paid off by manufacturers and pleases consumers.

The advantage of steel as the main material from which pipes are made:

- Steel perfectly transfers heat;

- Can withstand high temperatures;

- Thick and durable material;

- It can serve for a long time;

- Low cost of metal;

A significant disadvantage of steel is its instability to corrosive processes and the inability to withstand all environmental factors. The manufacturer needed a solution that could tackle the problem of corrosion. And this solution was found. It was the galvanizing of steel pipes.

Galvanized pipes are ordinary steel hollow inside products, the surface of which is coated with a layer of zinc. It is this layer that provides significant protection against corrosion.

The advantages of galvanized products are:

- High percentage of metal strength.

- They are not affected by environmental factors and processes, including corrosion.

- They do not need to be protected from mechanical damage.

- Such pipes, however, like other metal ones, in comparison with plastic ones, are stable in size, do not undergo changes under the influence of high temperatures.

- The product can withstand any operating temperature range.

- Withstands high working pressure inside.

- Thanks to zinc, pipes are resistant to the emergence and development of painful microorganisms.

Among the disadvantages of galvanized pipes, one can single out a not entirely presentable appearance from the outside of the product. Some experts in the field of construction argue that when mechanical impact on such products, they become unusable. At least the normal appearance of this product cannot be betrayed.

In addition, the price of galvanized steel products has become more expensive than conventional steel pipes, so their installation requires large financial costs.