Rules for crimping SNiP

The norms for crimping the heating system are described in documents such as SNiP 41-01-2003, and also 05.03.01-85.

Air conditioning, ventilation and heating - SNiP 41-01-2003

It is possible to carry out hydraulic checks of water heating systems only at positive temperatures in the premises of the house. In addition, they must withstand a water pressure of at least 0.6 MPa without damage to the tightness and destruction.

During the test, the pressure value should not be higher than the limit for the heating devices, pipelines and fittings installed in the system.

Internal sanitary systems - 3.05.01–85

According to this SNiP rule, it is necessary to check the water heat supply and heating systems with disconnected expansion vessels and boilers by hydrostatic pressureequal to 1.5 working, but not less than 0.2 MPa in the lower part of the system.

The heating network is considered to have passed the test if it holds for 5 minutes under test pressure and does not fall by more than 0.02 MPa. In addition, there should be no leaks in heating equipment, welds, fittings, threaded connections and pipes.

Signs of air congestion

The first sign of air in the system is poor heating of the batteries. The battery heats up unevenly, it is not enough, and if any sounds appear in it, then the answer is unambiguous - the air in the heating batteries prevents the circuit from working properly. If the radiators have a bottom connection, and its upper part is cold, then air has accumulated in such a radiator and the release of air from the heating radiator will restore normal operation.

Removing air from heating circuits

What needs to be done and how to remove air from the heating battery, a lot has been written on the network. For open heating systems with an expansion tank, this problem is not relevant. In such systems, the air escapes independently through the tank located at the highest point of the circuit. Problems with some radiators may arise, especially if the slope is incorrect. Such air bubbles are removed using Mayevsky taps or automatic air vents.

For closed systems with forced circulation, the problem of how to get rid of air in the heating system is also quite solvable. The air from the batteries is removed manually by tearing off the Mayevsky crane. If a hiss is heard when it is opened, then the actions are correct, there is air in the system. It is necessary to release the air before the Mayevsky water appears at the outlet of the tap.

The most dangerous air locks at pipe bends and bends.

Such accumulations of air can completely stop the circulation of water in the system. If the installation of problem areas of the circuit, for some reason, cannot be changed, then in such problem areas a bleed valve of the heating system is installed to bleed it off.

Features of aluminum radiators

An unpleasant phenomenon is sometimes observed in aluminum radiators. The radiator material reacts with water. As a result, gases are constantly formed and they must be constantly removed from the radiator, and how to remove air from the heating battery is described above. To avoid the above problem, it is enough to buy and install aluminum radiators with an internal anti-corrosion coating. The correct solution would be to replace the aluminum radiator with a bimetallic one.

Conditions for performing crimping

Test work is correctly performed if all the necessary requirements are met.For example, it is impossible to carry out third-party work on the tested object, and testing must be supervised by the shift supervisor.

Pressure testing is carried out only according to the program approved by the chief engineer of the company. It defines:

the order of actions of employees and the technological sequence of verification... They also outline safety measures for ongoing and ongoing work performed at adjacent facilities.

There should be no unauthorized people during pressure testing of the heating system, switching on or off the testing devices, only employees who take part in the test remain in place.

When work is carried out in adjacent areas, it is imperative to provide for reliable fencing and disconnection of test equipment.

Inspection of heaters and pipes may only be carried out at operating pressures. When the heating system is pressurized, the certificates are filled out to confirm the tightness.

Air removal sequence in high-rise buildings

For multi-storey buildings, the problem of when and how to properly bleed air from the heating system is solved as follows. Air usually rises and collects in the batteries and pipes of the upper floors. But before the heating season, checking and removing air must be carried out sequentially, starting from the lower floors.

If an automatic air vent for heating radiators is installed on the heating radiator and in problem areas, it will provide air release. Of course, you can check the system manually; contamination or sticking of the valve is possible, which will exclude the automatic discharge of air from the heating system and disrupt the operation of the circuit.

Crimping procedure

This method of checking the heating system involves the implementation of hydraulic tests:

- Heat exchangers;

- Boilers;

- Pipes.

Thus, it is possible to identify leaks, which indicate a depressurization of the network.

Before testing the heating system with plugs, isolate the heating system from the water supply, visually assess the reliability of all connections, and also check the functionality and condition of the shut-off valves.

After that, the expansion tank and the boiler are turned off for flushing radiators, pipelines from various deposits, debris and dust.

During the hydraulic test, the heating system is filled with water, but when performing air tests, this is not done, but simply the compressor is connected to the drain valve. Then the pressure is increased to the required value, and its indicators are monitored with a pressure gauge. If there are no changes, the tightness is good, therefore, the system can be put into operation.

When the pressure begins to decrease beyond the allowable value, means there are defects... It is not difficult to find leaks in a filled system. But in order to identify damage during the air test, a soap solution should be applied to all joints and joints.

An air pressure test takes at least 20 hours, and a hydraulic test takes 1 hour.

Having corrected the identified defects, the procedure is repeated again, and this has to be done until there is good tightness achieved... After carrying out these works, the certificates of pressure testing of heating systems are filled out.

Checking the heating network with air, as a rule, is carried out if it is impossible to fill it with water, or when working at low temperatures, because the liquid can simply freeze.

Equipment and frequency of tests

The pressure testing of centralized systems is carried out by personnel using standard means, therefore it is hardly worth talking about it. But about what private heating and water supply is tested, not everyone probably knows. These are special pumps.There are two types of them - manual and electric (automatic). Manual crimping pumps are autonomous, pressure is injected using a lever, and the generated pressure is controlled using a pressure gauge built into the device. Such pumps can be used for small systems - pumping is quite difficult.

The crimp method is the most popular because

It takes about 15 seconds for an experienced technician to install the crimp connector, greatly reducing the time it takes to create cable assemblies. This is very important in today's cable market where time is of the essence and fewer technicians have been asked to support more and more equipment. Corrugated joints performed correctly can be better than brazed joints A good threaded joint deforms metal well above the yield strength, but not too much, so that the “spring back” provides a secure connection even with thermal cycling and vibration. A good crimp joint is gas tight and was not a wick: it is sometimes referred to as a "cold weld". Like the soldering method, it can be used on solid or stranded conductors and provides a good mechanical and electrical connection.

The disadvantages of the crimp method are

Crimp head position outside the crimp area Pin body is no longer concentric The resistance of the connector will be affected. If not done well, the crimped pin will not be properly inserted into the connector, causing the interface to fall outside the specification. In many cases, this means that the entire connector assembly must be disposed of and replaced with a new one. Solid wire crimp connections can be poor and prone to failure if they are not crimped with proper dies using professional crimp handles. Sometimes, although rarely, and under conditions of frequent bending, a stranded wire can move inside the crimped joint and loosen. This happens more often with clips than crimp connectors. Some important points to keep in mind when using the crimp method is to select the correct connector for the coaxial cable you are using. Avoid double crimping, especially at the contact; this is known as "tagging" or "dog ears".

Good hex shaped cuffs with equal pressure on all sides Dog ear deflection causes uneven pressure and excessive shape of the ears material. Possible cause is improper punching, too much pressure, or too complex material.

- No soldering required; therefore, the installation time is reduced.

- Today, digital video, computer and network cables are almost universally compressed.

- Equal compression on all 6 crimp faces.

- Crimping die located in the drop.

- The pin has been distorted, no longer straight.

- The pin began to break when crimped.

- The pin shows the "dog's ear" of excess material.

- Possible cause: Wrong crimp head or too much pressure.

- Both signal continuity and quality will suffer.

- Crimp contacts cannot be crimped and reinstalled.

When crimping the contacts of contacts and lugs, careful selection of the correct tools is important.

Electric pumps for pressure testing are more complex and expensive equipment. They usually have the ability to create a certain pressure. It is set by the operator, and it "catches up" automatically. Such equipment is bought by professional crimping firms.

It is an investment of time and money that increases productivity and reduces effort. Select the correct crimp head for the cable, connector and crimp handle. Coaxial crimps are designed to distribute the crimp pressure evenly around the connector.

A properly crimped connector will slightly accelerate in your mouth.This is called a bell condition and helps relieve stress on the coaxial cable. If you are planning a very large commercial job, significant savings can be gained by having your supplier prepare the cables in advance.

According to SNiP, a hydraulic test of heating systems should be carried out annually, before the start of the heating season. This applies to private houses too, but very few people comply with this norm. At best, they check it every 5-7 years. If you are not going to test your heating annually, then there is no point in buying a crimping machine. The cheapest manual one costs about $ 150, and the good one - from $ 250. In principle, you can rent it (usually available in companies that sell components for heating systems or in offices for renting equipment). The amount will be small - you need a device for several hours. So this is not a bad way out.

DIY water supply for the cottage

Equal pressure from the crimp head on all sides. A "bell" on the back of the lug provides flexibility to the cable. A crimp die located on the front of the ferrule, near the connector. ... Some technicians prefer a combination of the two contacting methods when the assembly will be used in harsh environments or when assembling test probes. The contact joint is first carefully crimped and then soldered into it. Although the technique is difficult to master, it creates a connection that will never happen, except in cases of extreme mechanical damage or heat.

Heating system pressure test

This document displays the following information:

- What kind of crimping method was used;

- The project according to which the circuit was installed;

- The date of the check, the address of its carrying out, as well as the names of the citizens who sign the act. This is mainly the owner of the house, representatives of the repair and maintenance organization and heating networks;

- How the identified malfunctions were eliminated;

- Check results;

- Are there any signs of leakage or reliability of threaded and welded joints. In addition, it is indicated whether there are drops on the surface of the fittings and pipes.

Permissible test pressure during pressure testing of hot water heating

Many developers are interested in the pressure under which the heating system should be checked. In accordance with the requirements of SNiP presented above, during pressure testing, pressure is allowed 1.5 times higher than the working one, but should not be less than 0.6 MPa.

There is also another figure specified in the "Rules for the technical operation of thermal power plants". Of course, this method is "softer", the pressure in it exceeds the working pressure by 1.25 times.

In private houses equipped with autonomous heating, it does not rise above 2 atmospheres, and it is adjusted artificially: if excessive pressure appears, then the relief valve immediately turns on. Whereas in public and multi-apartment buildings, the working pressure is much higher than these values: five-storey buildings - about 3-6 atmospheres, and tall buildings - about 7-10.

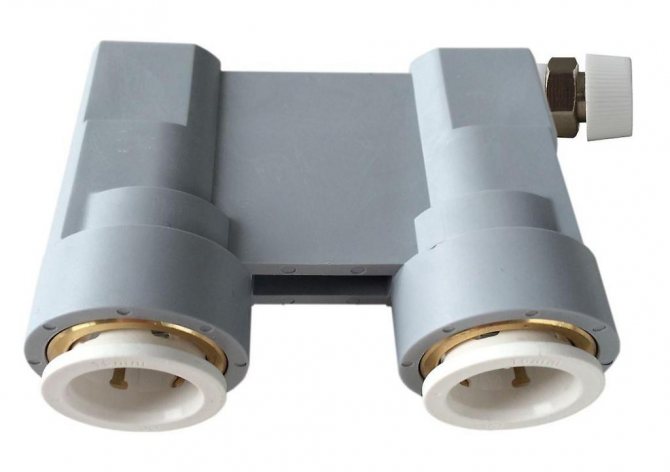

Air separator what is it

Air separators or their other name - air collectors for heating systems are designed to remove air from the coolant that circulates in the circuit. Suitable for all types of systems, in underfloor heating systems and in heat pumps. Water is passed through a separator to remove dissolved gases and various contaminants that have a bad effect on the system and contaminate various valves. The air separator makes the question of how to properly remove air from the heating system completely irrelevant.But to increase the reliability and durability of the system, a separator and manual or automatic air vents are installed in the heating system of a house or enterprise.

Air separators have many useful properties to improve heating circuits:

- installing a separator improves heat transfer;

- high reliability due to the extreme simplicity of the design;

- significant improvement in the quality of the water in the circuit;

- cleaning from accumulated dirt can be done without stopping the system;

- cheapness and ease of installation;

- removal of the smallest particles of dirt from the coolant.

Consequently, the answer to the popular question - how to bleed air from the heating system, is simplified. There will be so little air in the system that scanty residues can be easily removed manually. For this, Mayevsky's taps and automatic air vents are used. There is a fundamental difference between manual and automatic air vents. The Mayevsky crane removes, for example, air locks that have accumulated at the top points.

The separator extracts the air dissolved in the water and removes it.

That is, when the water that has passed through the separator is heated, air will not be released. Of course, it is expensive to use a separator for small systems, removing air manually can be easy and simple. Air separators are most commonly used in complex, large heating circuits. If you decide to buy an air separator for heating, the price will depend on the performance ranging from 3000 to 40,000 rubles.