Warm flooring systems, popular with many people, are now being installed not only in main living areas. For example, underfloor heating in a bathroom can significantly increase the level of comfortable living in the entire home, reducing humidity and maintaining the air temperature at the proper level.

Warm floor in the bathroom

Considering that in many bathrooms and bathrooms tiles are used as a finishing material, it is in these rooms that the use of an additional source of heating will be very useful. Bathrooms have two types of underfloor heating: hot water and electric underfloor heating in the bathroom.

The owners of apartments give the greatest preference to the second option - an infrared (electric) warm floor. To a greater extent, its popularity is due to the ease of installation of the structure and its further operation.

Infrared floor heating

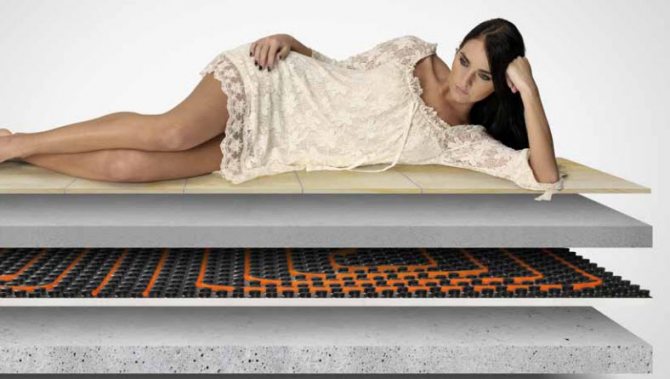

Infrared underfloor heating in a bathroom refers to an electric heating system based on heating mats. These mats are a textile base with built-in heating elements. With the help of a thermostat, you can easily set the required temperature mode for underfloor heating.

Water underfloor heating under the bathroom also belongs to one of the underfloor heating systems at home. Their distinctive feature during installation is the use of hot water as a heat source in polymer pipes located under the floor of a bathroom or toilet. This method of floor heating is used in most cases in country cottages and houses.

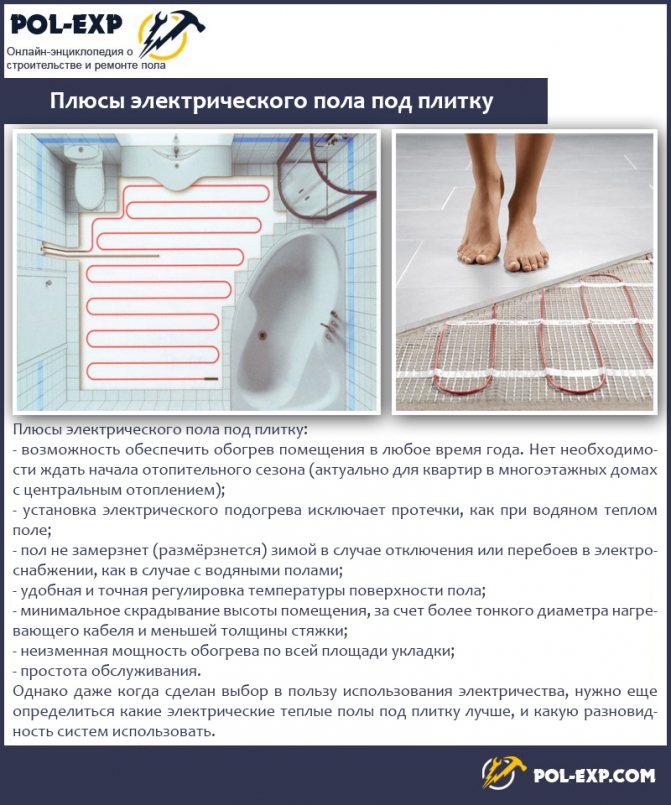

Electric underfloor heating in the bathroom has many advantages: reasonable cost of equipment, inexpensive installation and installation, ease of use.

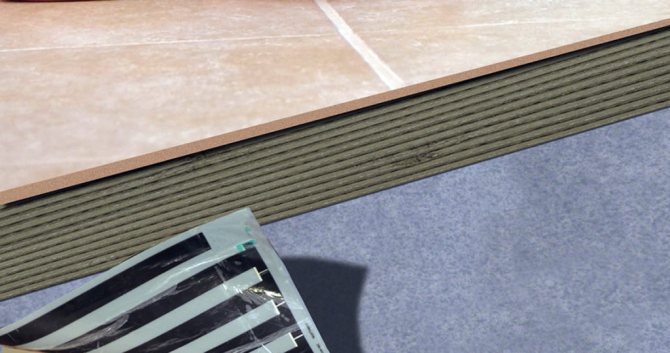

In addition, the finished structure raises the floor height by only 4 mm. A screed with a water floor in a bathroom, as a rule, raises the overall floor level by about 8-10 cm. This, of course, is not entirely convenient, so this feature can be safely attributed to the disadvantages of this type of structure. But at the same time, a water heated floor in a bathroom is much more economical than an electric option.

Maybe an electric heated bathroom floor is better?

The advantages of underfloor heating with water heat carrier over electric or infrared floors are obvious:

- There is no need to lay expensive electrical cables, the price of pipes, fittings and equipment used is much lower than the price of materials for electric floors;

- The costs incurred for the purchase of materials quickly pay off on energy savings;

- More uniform heating of the floor and the room, which allows you to create a comfortable temperature for a person's leg;

- Electrical fire safety. (no fire due to overheating and electric shock);

- Possibility to install under large and heavy objects or furniture.

With all its advantages, a water heated floor in the bathroom and not only requires a good preparation of the building surface. This is necessary in order to get the perfect underfloor heating. It must be mounted on a surface with irregularities with a height difference of no more than 30 mm.

Types of warm floors

Underfloor heating (TP) can be equipped in several ways, it all depends on the initial data of the room, the personal preferences of the owners and the desired result. Currently, three types are widely practiced:

- electricwhen an electric current passes through a conductor - a cable, thereby heating it;

- filmwhen infrared radiation is involved in the generation of heat;

- water heated floor in the bathroomwhen pipes that circulate hot water are laid under the floor.

In addition, there are such types of TP, which are heated by warm air from the ventilation holes near the floor (most often installed in the rooms of private houses) and a subspecies of electric - using thermomats.

The role of TP is to generate the required amount of heat in order to heat or simply warm up the floors in the room. All types of underfloor heating successfully cope with this task, albeit in a different way and with distinctive features. It should be noted that a floor with forced heating in a standard bathroom differs from another type in installation, complexity, and the involvement of specialists. Something is being installed at the stage of repair, i.e. opening the floors is mandatory, but you can do it on your own.

What type of underfloor heating in the bathroom should you prefer?

So, underfloor heating in the bathroom should be safe and comfortable, and therefore there is a variety in their types. Depending on the initial conditions.

To begin with, you should take into account the quality of the engineering networks at home. If the wiring is old and plugs often fly out, then the electrical TP will add loads that the network may not be able to handle. At the same time, the water floor does not deliver such troubles, however, if there is no own heating boiler or there are interruptions in hot water and central heating, you should not really count on it - there will be nowhere to take boiling water.

Further, the degree of arrangement and design of the bathroom, what materials are used in this case, are essential:

- If there is a lot of plastic, then it is generally better to refuse TP, because this material cannot always be heated.

- A film or infrared warm floor does not fit under a tile because of its fragility and capriciousness to external stimuli, but it is ideal for a laminate. Especially when the laminate is laid without the use of glue, but simply with a locking system. Such a floor covering is easy to disassemble if necessary.

- To install a water and electric transformer substation, it is necessary to overhaul the bathroom floor with dirty and wet processes, which is not always possible, especially when the main repair has already been done.

The personal wishes of the apartment owners can also serve as a guide when choosing a TP. How much area should be used for heating? Should heating be constant or temporary as needed? How warm should it be? Of course, a thermostat can be connected to any type of underfloor heating in order to regulate the temperature and a convenient switching system, lay structural elements to the desired area.

But there are also characteristic features of TP. A water-heated floor most often costs practically nothing in use, it can heat around the clock for a long time, but it is difficult and not precisely regulated. The electric one quickly heats and cools, it is convenient in everyday life, however, prudent owners can easily shock their electricity consumption. Film TP is complicated due to its design features and weak security system, therefore it is not always recommended.

As you can see, the warm floor in the bathroom must be chosen carefully, clearly thinking over its further use and correlating with its capabilities. Only in this case will the choice be successful and effective.

DIY TP: is it possible?

Many people are interested in whether it is possible and how difficult it is to make warm, reliable floors of the selected type in the bathroom, and not only the room, by doing with their own skillful hands? Of course, it is possible to do this on your own, if you take into account several factors and observe the process technology.

It might be interesting

Thermal insulation

Distinctive features and variety of ceiling tiles ...

Thermal insulation

How to insulate the ceiling in a wooden house?

Thermal insulation

What is a heating cable?

Thermal insulation

Warm "pie" for a metal chimney

To do this, you will need: starting materials (details of the TP design), a little knowledge of physics and experience in construction work, a drawing of the planned bathroom environment, patience and attentiveness. It is necessary to accurately determine the boundaries of the warm floor, so as not to spoil household appliances with constant heating, not to waste resources on heating excess space under the bathroom, shower, cabinet.

So, how to make a warm bathroom floor yourself?

Installation of electric underfloor heating

TP, due to electricity, is a two-core shielded cable, which is laid out on the selected area of the room on the subfloor. There are some recommendations about the optional pouring of the cable with a concrete screed, so that it can be laid directly under the topcoat.

However, there are several points that only a specialist can calculate, so the easiest way is to use this scheme:

- apply waterproofing to the selected area, a special tape that will level the expansion and contraction of concrete during the operation of the TP, insulation; spread the cable over the selected area (the cable can be in a reinforcing mesh) without undercuts, bends, layering and all related elements (thermostat, fasteners, grounding, etc.), fix and connect everything according to the instructions;

- pour the system with a concrete screed, let it dry, then lay the topcoat according to the technology.

Electric underfloor heating in the bathroom is convenient and easy to use, warming up the room in a matter of minutes, simple temperature control. At the same time, there is no dependence on the availability of hot water or heating, which is especially important in the summer season or during maintenance work.

However, such a warm floor in the bathroom with your own hands requires an understanding of the electrician, the exact implementation of the instructions. Therefore, if there is an opportunity, it is better to entrust this work to professionals, because the correct connection is the key to uninterrupted work and safety.

Installation of a water heated floor

This type of TP is installed much easier and faster. The schemes are quite similar to laying an electric floor, because the essence is the same, the difference in performance:

- a layer of waterproofing is applied to the subfloor;

- the pipe system in the form of a coil is laid on the prepared surface, secured with clamps;

- then, depending on the source of hot water, there is a connection to a riser with hot water supply, a boiler or a central heating system;

- screed is applied - dry or in the form of cement diluted with water;

- the floor covering is laid: tiles, laminate.

It is preferable to lay ceramic tiles on floors with heating from hot water, because there is a difficulty in regulating the temperature.

The water floor can be made in several circuits, for this they make the required number of closed systems connected through a plumbing comb. In this case, the heating area can be changed by simply switching the tap to the comb. If you install a thermostat and a thermostat - of course, this is a rise in the cost of the structure, then you can change the degree of floor heating at your discretion.

Installation of the film floor

Film TP - these are sheets of special thermal film, which, when connected to electricity, will begin to emit heat.

Installation of such a floor is never done under a screed or tile due to the fragility of the thermal film, it is allowed to use it under carpet, laminate.

The process of laying the foil floor is as follows:

- heat-insulating material is laid on a flat surface of the full area of the room;

- lay the thermal film on the required area in the correct way, observing the direction of the copper strips downward, if necessary, cut the film in the permitted places;

- install a special clip on the strips and process the edges with insulation;

- fix the entire structure with tape to avoid shifting;

- connect to the thermostat according to the instructions.

Film TP is the most capricious and difficult to install, however, it has undeniable advantages: ease of use, accuracy in adjustments, the ability to install without dirty processes with a screed.

It is worth considering:

- when planning a TP, avoid places for placing household appliances and furniture: excessive heat will negatively affect this;

- when installing the transformer substation, do not allow connections and cuts under the screed: violation of integrity does not guarantee water leakage or short circuit;

- if there are doubts about the safety of using the TP - invite the foreman for diagnostics and inspection.

Heat exchanger for water floor. Is it necessary?

Still, some 20 years ago, during the installation and operation of such a floor, there was a problem of regulating the temperature of a separate circuit. underfloor heating in the bathroom... The problem was that when connecting a parallel water heated floor of the bathroom to the heating system of the house, consisting of a hot water boiler, a mixing device and a collector, it became necessary to reduce the temperature of the water in the pipes of the underfloor heating. The reason is that the boiler of the home heating system heats the water to a temperature of about 100 degrees, and to lower it to the 40-45 degrees necessary for the operation of the underfloor heating, it is necessary to install a heat exchanger. A heat exchanger is a rather bulky and expensive unit that requires highly qualified installers of thermal equipment to install it. In addition, it needs to be monitored more frequently in operation and its operation, unlike hot water boilers, is difficult and expensive to automate.

Benefits of using a floor heating system

A water, infrared or electric heated floor under the bathroom is an excellent and practical solution, which, if implemented correctly, has a number of significant advantages:

- simple and fairly reliable design with the possibility of self-installation;

- users can use several heat sources, including alternative energy;

- the ability to connect additional equipment for automation and control of the installation;

- economical consumption of energy resources required for floor heating in the bathroom;

- a practical opportunity to create thermal zoning of a room and install the floor in the desired location.

The possibility of economical consumption of energy resources requires the installation of such modern equipment as a thermostat with floor and air temperature sensors.

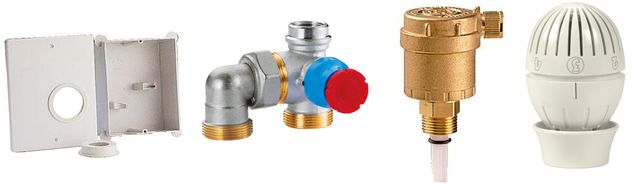

Connecting underfloor heating in the bathroom using a thermostatic kit

To solve this problem in modern conditions for rooms no more than 20 sq. M., It is possible to connect the pipes of the water heated floor in the bathroom to the heating system using a thermostatic kit. For example, Thermo-floor R508M Giacomini (Italy). This kit allows you to perform the whole range of work on the installation of a warm floor in the bathroom. With its help, you can parallelly connect a water heated floor in the bathroom to the heating system. The advantage of a parallel connection, in contrast to a serial one, is that there is no need to take out of operation the entire heating system of the house, in case of any accidents or malfunctions in the bathroom floor.

The use of the kit in the conditions of the Russian winter is becoming especially relevant. Indeed, in the baths, usually for better heating of the room, heating radiators are also installed, as a rule. The capabilities of the kit allow you to connect the pipes of the water heated floor in the bathroom directly to the heating radiator, but even if there is no radiator in the bathroom, you can connect the heated floor to the heated towel rail.With this connection, you can turn on or off the water heated floor at any time, regardless of the heating in other rooms. And what is important, it takes a little labor to connect the warm floor using the kit to the heating system. Anyone who has ever worked with modern fittings and metal-plastic pipes or XLPE pipes with a diameter of 16 inches can install underfloor heating equipment in the bathroom.

Preparation for the installation of a water heated floor under the tiles

To organize the smooth operation of the heating system, it is necessary to prepare the base before laying the pipes. At the initial stage, preparatory work ensures the overall quality of the system. Therefore, it is necessary to clean the base from debris and dirt for laying, eliminate various chips, potholes, protruding areas and irregularities over the entire surface. Without these works, the floors will have different heights, this can lead to uneven distribution of heat in the room. Levels are used to adjust the height of the floors.

At the further stage of the preparatory work of the base, a screed is performed, which must be of the same thickness and perfectly flat along the entire perimeter of the room. This ensures uniform and high-quality heat distribution. Then you can proceed to work on laying the layer of thermal insulation. This material is needed to minimize the likely heat loss. The waterproofing film is laid around the entire perimeter of the room. For the same purpose, a special tape is also used, the width of which is about 10 cm.

Then you can perform full thermal insulation. The thickness of the thermal insulation material significantly depends on the design features of the floors, on the location of the room. Sometimes the thickness of the insulation needs to be increased to retain heat. Thermal insulation can be made using different materials, for example, dense and durable foam can be laid.

Thermostatic kit advantages

The kit allows using a head with a thermostat and a valve to regulate the water temperature from +8 to 32 degrees. This does not require electricity. The air is released from the system using a special automatic valve. All components of the kit are mounted in a junction box, which is fixed at a height of at least 40 cm. Connection to the underfloor heating water supply network is carried out using fittings for metal-plastic or polypropylene pipes. The junction box is mounted on the wall using special fasteners. The design of the junction box allows it to be installed both in cement plaster and behind walls made of plasterboard or other building materials. After installing the floor with this system, no protruding parts remain. Turning on the floor heating or adjusting its heating temperature is done by simply turning the thermostatic head protruding slightly above the wall.

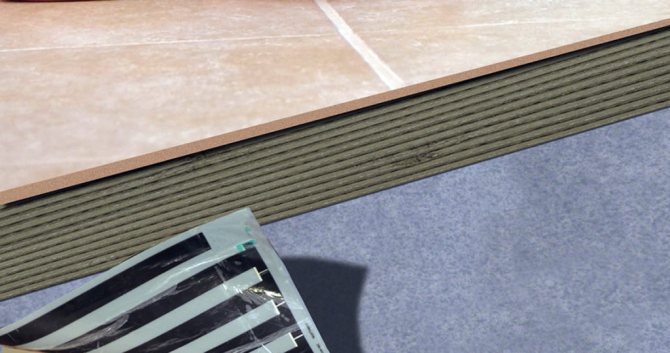

Laying tiles on an electric floor

The underfloor heating system in the bathroom includes only a few components:

- Heating element.

- Thermostat used to control the system.

- Thermal sensor - monitors the floor temperature and turns off the heater to avoid overheating.

- Wires for connecting all components in a single circuit.

We offer you to familiarize yourself with the Washing machine under the sink: the secrets of selection and installation

Heating elements are of two types:

- resistive cables;

- infrared films (thin polymer base with graphite tracks applied to it).

The second option - IR-film - cannot be used in the bathroom and in other humid rooms: in case of insulation breakdown and wetting, the heater closes on itself, so that if the user is struck by a current, the RCD does not work.These heaters are intended for use in dry rooms only.

It is simply a long wire of metal with high electrical resistance, enclosed in an insulating sheath.

It is cheap, but has an important drawback: with limited heat dissipation (for example, a piece of furniture or something else was placed on the floor) it can burn out.

It is difficult to repair the cable - you will have to knock down the floor covering and the screed.

A two-core cable consists of the same wire, but folded in half. Thus, it connects only on one side and the route can be laid as you like.

A single-core cable must be connected from both sides, so the route must be closed, that is, both ends of the cable should be close to each other after laying the circuit.

Block 1

Self-adjusting

These are resistive cables, so to speak, of a new generation. The resistive, that is, the heating core is made of a polymer with semiconducting properties, and ordinary copper cores, that is, conductive, are laid on both sides of it. The current flows from one copper core to another through the polymer along its entire length, as a result of which it heats up.

The peculiarity of the used semiconductor polymer is that when the temperature rises above the prescribed value, its resistance increases sharply, that is, the electrical circuit in this area is actually opened. Thus, cable burnout is impossible in principle. At the same time, other areas remain functional.

Resistive and self-regulating cable

With such an advantage, a self-regulating cable is certainly more preferable than a conventional cable, but you need to be prepared for the fact that it costs much more.

Components for underfloor heating can be purchased separately or as a set. In the first case, the components must be selected correctly, because the amount of current flowing through the thermostat depends on the resistance of the resistive cable. In the kit, everything is already selected, so the probability of error is reduced to zero.

In order for the resistive cable to heat the floor correctly, it must be installed at the correct pitch. Otherwise, either overheating (with a small step) or a "thermal zebra" (with a larger step) is possible.

In order not to be mistaken, it is better for the user to purchase a so-called thermomat as a heating element.

This is the same cable, only already laid and attached to the fiberglass cloth. When installing the mat, you just need to spread it out, not worrying about anything.

Tiles can be laid on the thermomat immediately, using tile glue instead of a screed. In other cases, the coating is laid on the screed in the same way as usual.

Due to the high humidity in the bathroom, it is useful to add an anti-fungal additive to the tile adhesive and grout.

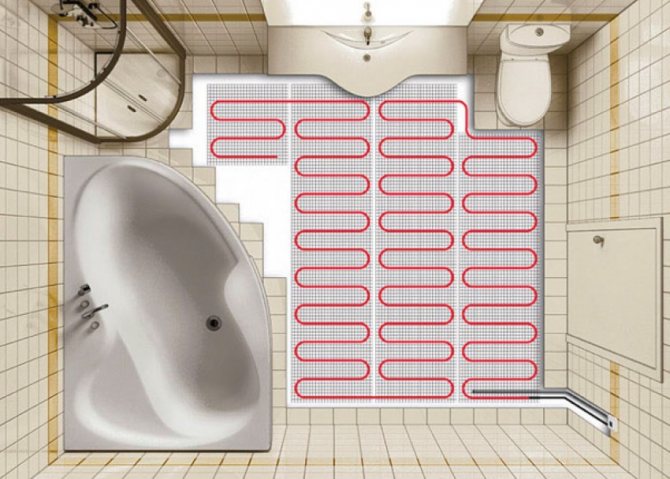

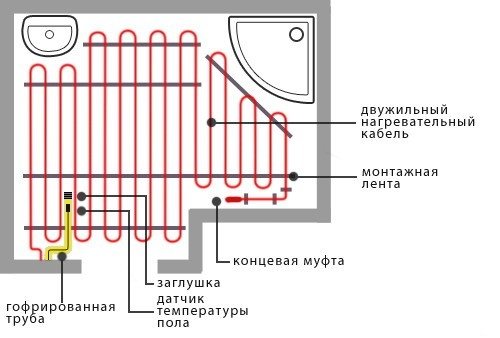

Laying scheme

The electric heating cable warms up evenly along its entire length, so it is laid in a snake with a pitch of 10-15 cm between turns. In this case, the main task is to evenly distribute the cable over the entire area of the sub floor. When planning and drawing up a cable laying scheme, the following aspects are taken into account:

- The heating cable is not laid under plumbing equipment and furniture, as heat transfer will be disturbed. The exception is attachments that do not have contact with the floor.

- The distance from heating pipes and heating devices is about 20 cm, from the walls 10 cm.

Heating cable laying scheme in the bathroom.

To prevent the heat produced by the heating cable from going into the underlying building structures, it is necessary to lay insulation under the warm floor.

Today, from all sides, you can hear recommendations to use Penofol material, which is foamed polyethylene with a foil coating.

It is impossible to call such advice otherwise than ridiculous: polyethylene foam is soft (that's why it is supplied in rolls) and under load from only one screed will flatten to a thickness of 1 mm. In addition, experiments have shown that the alkaline environment of the screed eats up the foil almost immediately (there are many videos on this topic on the Web).

Extruded polystyrene foam should be laid under the load. Outwardly, it differs from granulated polystyrene foam, which we used to call polystyrene in everyday life, in the absence of granules - the structure is homogeneous. The material is designed for loads up to 50 t / sq. m and is even used as a warming substrate for road surfaces.

To make the thermal insulation more effective, it is better to lay the expanded polystyrene plates in two layers with bandaging the seams.

Expanded polystyrene for underfloor heating

Expanded clay can be a cheap alternative to extruded polystyrene foam. This bulk material is also capable of withstanding high loads, but its thermal conductivity coefficient is much higher than "expanded polystyrene" (0.1 W / m * C versus 0.038).

So that there is no direct contact between the heating cable and the insulation, a metal mesh must be laid on top of the latter. We will screw the cable to it, if it is not made in the form of a thermomat.