What is a collector for water supply - features and purpose

A collector, or "comb", is a short section of a metal, metal-plastic or polypropylene pipe, into which several nozzles of the same pipe are cut at an equal distance from each other - the number depends on the functionality and capacity of the pipeline. Thus, this system of pipes acts as a central distributor of water flows.

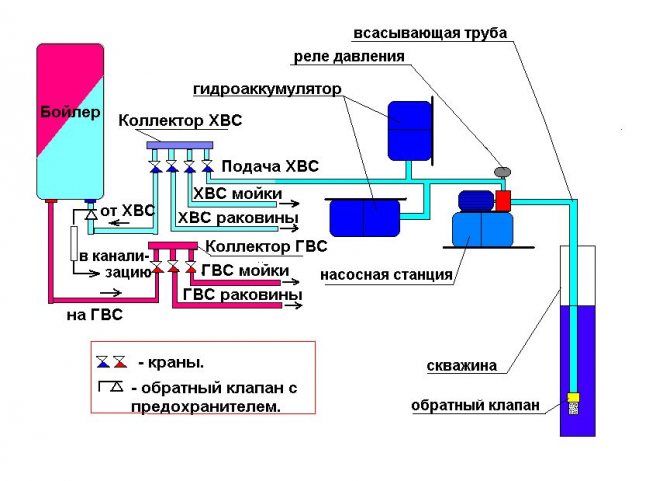

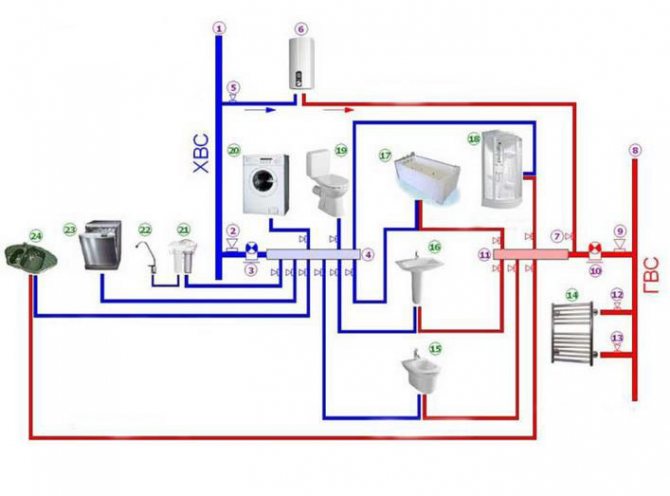

Further, the pipelines, control devices and devices are connected to the pipe outlets. Such a distribution scheme is also called ray, since pipe sections in the form of rays are diverted from the central collector in different directions. The main function of the collector pipeline is to ensure uniform water supply to devices and highways, as well as to ensure the independence of each of the connected collector branches (beams) in the general water supply.

Variants of collectors for a water supply system differ schematically and structurally in the following solutions:

- Inclusion in the circuit of auxiliary secondary equipment - with shut-off valves, control and regulating devices, pumps, reducers and manometers, sensors and pressure switches. But which one is recommended to choose a water supply collector can be decided only by relying on a specific water supply scheme in the house;

- Options for using materials for a home water supply comb: steel, non-ferrous metals - brass, copper, bronze, as well as plastic or silumin. The last nodes are the cheapest, but also the most short-lived. Usually, the material is chosen based on the material of the general household water supply: if it is metal, then the water supply collector is made of steel pipes, etc .;

- A standard factory comb has from two to four nozzles, but there are exceptions. For example, with a complex wiring diagram, experts recommend combining several combs into one, which means that the number of taps will increase proportionally.

In addition, the choice of a comb for water supply depends on the scheme, parameters of the water conduit and the functionality of the water supply system:

- Maximum system pressure;

- The throughput of the comb and the water supply main;

- The distance between the centers of the axes of the outlet nozzles, if it is a factory comb.

Sales leaders

For an even clearer understanding of what a distributor comb is and how to choose the best device for yourself, you need to look at the recent sales leaders. From this information, you can find out what requirements must be met and what new functions the manufacturers have added.

Your attention will be presented to 2 types of distribution manifolds and distribution manifold, which are widespread around the world, which have the most modern functions:

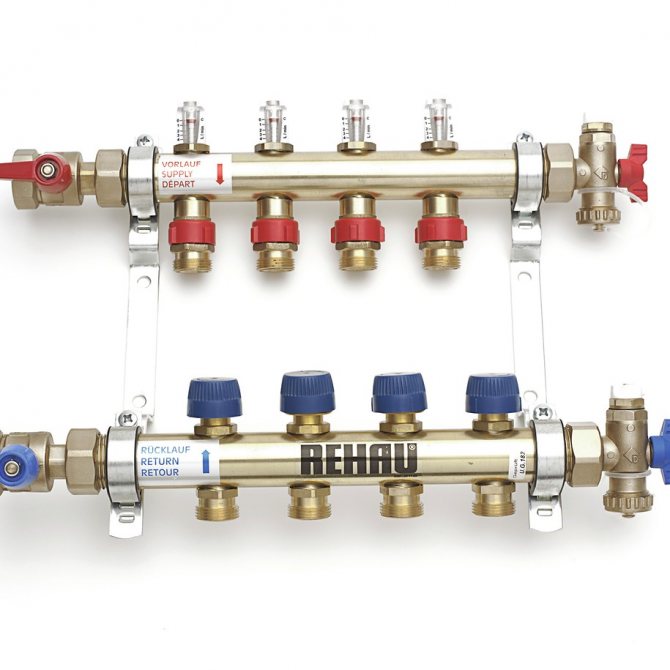

- Distributor comb Rehau Rautitan for 2 pipes.It combines a low price and excellent quality. The manufacturer is the famous Rehau company. The average price in Russia is 700 rubles. Serves to regulate the coolant on several circuits. The device can be connected to both ordinary cold water passing through the pipes, as well as the underfloor heating system, as well as other heating devices. The installation of the comb is facilitated thanks to the sliding sleeves with the help of which it is connected to the pipes. Made of brass, this material is characterized by a long service life and high strength.

- Distribution manifold Rehau Rautitan HLV 11 groups.The collectors have the same functions as the combs, the only difference is in the number of connections - the collector has much more of them, connections are made in groups, for cold and hot water separately. The Rehau company has proven the high quality of its products. This is evidenced by the numerous purchases of collectors and combs by the Russians from their company. Distribution manifold Rehau Rautitan HLV forks the circuits of radiator distribution systems. All devices passed mandatory quality control and required tests, including pressure testing in emergency situations. Like the comb, the manifold of this company is made of brass, which indicates high quality and durability. The average price in Russia for the Rehau Rautitan HLV distribution manifold is 11,000 rubles. The kit includes: Eurocone, ball valves, connecting nipples and a built-in air valve.

This article will help you assemble a collector for a warm one yourself:

The market for modern technologies is filled with new products every day, distributing combs and manifolds are supplemented with convenient functions for ease of use. They all have their own positive and, in rare cases, negative qualities. To choose the right distributor comb or collector for your house or apartment, you should find out the maximum about these devices, then it will be difficult to make a mistake in choosing.

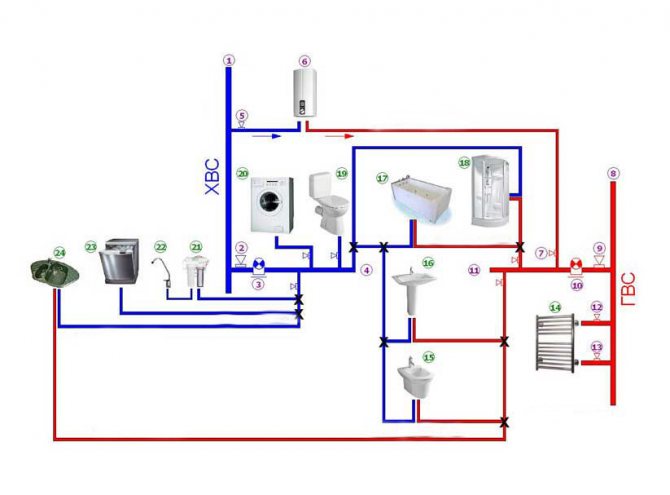

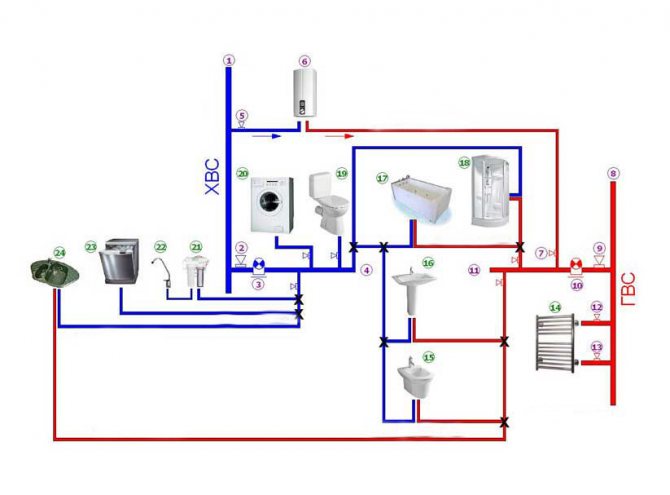

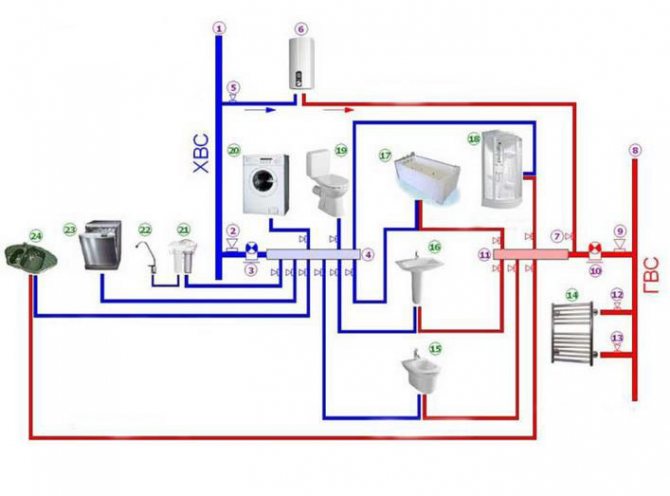

Classic wiring diagram

The usual wiring diagram for water supply pipes around the house is tee or sequential: a pipeline is diverted from the main riser, to which the necessary devices and equipment are connected through tees and taps.

This connection technology is beneficial in the following points:

- Minimum total pipe length;

- Low hydraulic resistance in the water supply system.

In practice, this scheme has not proven itself from the best side - it turned out that it is better to implement a connection via a comb. The disadvantage of the traditional connection is that when several valves are opened at the same time, the pressure in one of them, or in both, drops.

Collector water supply system

If a collector is included in the system, then whatever device is installed in the circuit, a separate branch will be laid to it. At the same time, the total length of the pipes increases, but the following positive aspects appear:

- At all points of the water intake there will always be a stable and equal pressure;

- When tapping into the collector outlet of the reducer in this branch, suitable for any plumbing fixture, you can adjust the pressure, and it will be different from the total value;

- Each cut-in between the collector and the water draw-off point is a single piece of pipe that can be secretly fixed in the floor, in the wall or in a wall niche;

- Any plumbing fixture can be turned off without stopping the entire cold water or hot water supply for repair or replacement.

Disadvantages of the collector circuit:

- Longer pipe lengths automatically increase the hydraulic resistance in the line;

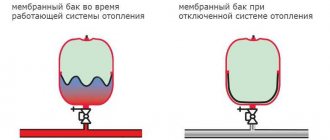

- Due to the increase in the length of the line, the collector will not work in the mode of natural circulation of water, which may affect the choice or change of the heating system;

- If it is impossible to make the pipe system secretly fixed in walls or niches, then a large accumulation of pipes can force to change the interior or even the design of the premises.

Rules for the installation of water supply and heating systems

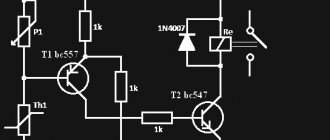

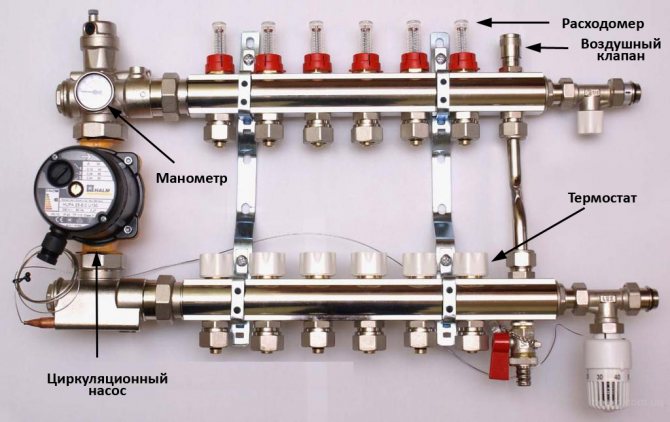

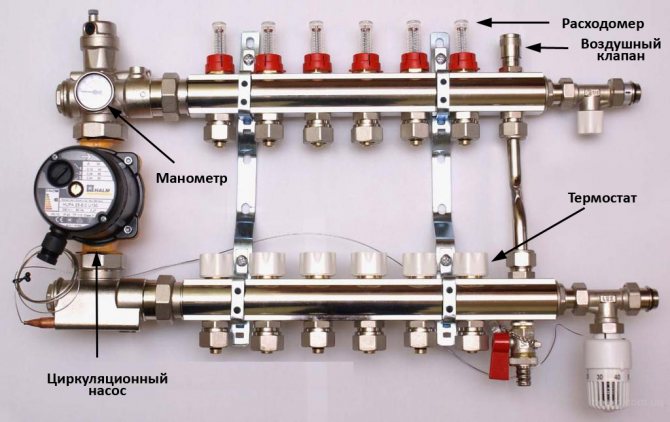

In systems with the participation of a working fluid, two collectors are cut into the line - for supply and for return. When manually balancing the system, control valves and balancers-flow meters are connected to the outlets of the supply manifold, and valves or taps are cut into the fluid return pipe.

According to calculations, it is possible to replace the control valves with shut-off valves, but then there is a risk of faster failure of taps and valves due to the unforeseen operating mode of the equipment.If a thermostat is embedded in the circuit, then manual valves on the supply manifold can be replaced with valves with a servo drive to automate the operation of the system. In this case, the liquid supply manifold is mounted above the return manifold, and the water pipes can be fixed at any height.

Distributor types

There are two main types of manifolds.

Firstly, these are combs without the ability to control water flows. In appearance, these are metal bars with holes for the passage of water and its branches.

Secondly, these are combs with the ability to regulate water flows. These devices allow you to change (regulate and / or shut off) the flow of water in the branches.

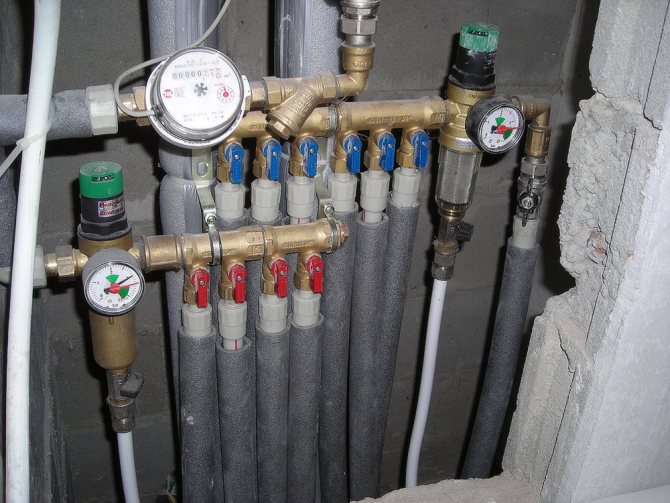

In turn, the combs with flow control can be either with shut-off ball valves, or with control valves (examples in the photo).

Features of the design of water supply in heating a house

If the heating system is made according to a combined scheme, then the radiators work in tandem with the underfloor heating system pipeline, and the water supply manifold is equipped with a mixing unit, so that when the liquid in the underfloor heating circuit cools down, water from the collector is added to this circuit by mixing.

When buying a ready-made collector, it is recommended to pay attention to the distances between the outlets of the supply and return collectors, since in Asian devices these values may not correspond to European standards, and the water mixing unit may simply not fit.

Collector for underfloor heating

The collector for "warm floors" has outlet pipes Ø 16 mm, 18 mm and 20 mm. For highways laid in country houses, it is recommended to install pipes with Ø ≤ 16 mm. If several "warm floor" circuits operate in the house, and they have different lengths, then a balancing system with a flow meter is needed in the collector, since without a balancer the floor with a shorter pipe route will always be hotter.

By rotating the ring on the flow meter, its throughput is changed, which means that the temperature in the circuit is regulated. Hot water consumption is visually controlled through a special slot with a scale.

Installation rules for water supply systems

For the water supply main, the collectors are also installed in the amount of two units: one collector for hot water supply, the other for cold water supply. When implementing such a solution, adjusting fittings are not needed - only shut-off valves or taps are installed. Such taps in the cold water supply main are equipped with blue handles, for hot water supply - red handles. The main pipe of the water supply collector is mounted in a dry place, but the ideal solution would be to install a separate collector cabinet. For this, the factory units are equipped with special fasteners, and there are places for them in the factory cabinets. When making a collector with your own hands, the method and scheme for placing and fixing the collector will need to be thought out separately - choose any option while ensuring the conditions described above.

How the comb works

Distributor manifold drawing pretty simple. If you do not go into technical details, then even a novice master will not be difficult to deal with the device. It is not difficult to weld a pipe with branches, the main thing is to make the correct calculations. Dimensions, nominal passages, the distance between the nozzles are determined taking into account the characteristics of the connected devices.

The connection corresponds to the standard pipe thread. Most collector connections have a diameter of 15, 25, 32 millimeters, the same dimensions are for distributors. In this way, installation time and costs are reduced. It is enough to correctly install and start the strapping.