Any private house needs a stable, trouble-free water supply system, with a normal water pressure in the taps. It would seem: laid pipes, connected a pump for water supply - and use it. But it’s not that simple.

Firstly, when the water is turned on and off, the pump will constantly work and quickly fail. Secondly, when the tap is closed, the risk of water hammer - a sharp jump in pressure in the system - and possible rupture of pipes and their connections, damage to the connected plumbing equipment (washing machines, water heaters ...) increases.

In order to avoid such troubles, it is necessary to use equipment such as an expansion tank in the water supply system. What it is?

An expansion tank (accumulator) is a container that is used in an autonomous heating and water supply system in an apartment or private house. Its main task is to prevent the occurrence of increased pressure in a closed system filled with liquid, and thereby protect it from water hammer.

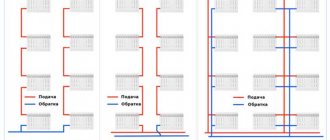

Hydraulic tanks connection diagrams

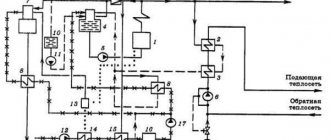

For a hot water supply system, the expansion tank is installed in the section of the circulation line, the suction line of the pump, closer to the water heater.

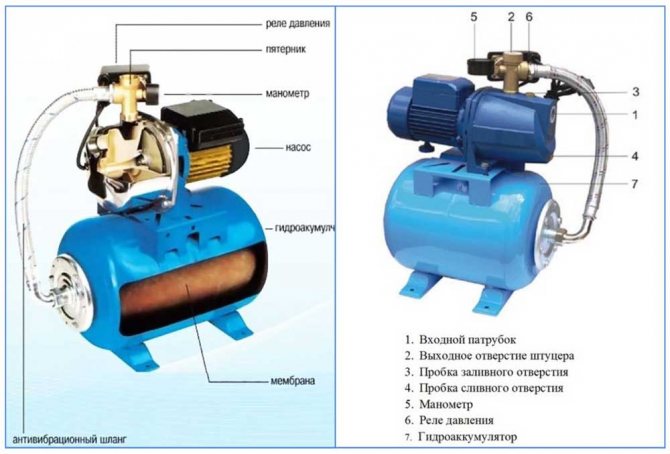

The tank is equipped with:

- pressure gauge, safety valve, air vent - safety group;

- shut-off valve with a device that prevents accidental overlap.

In a plumbing system where water heating equipment is present, the device takes over the functions of an expansion tank.

Installation diagram in the GW system: 1 - hydraulic tank; 2 - safety valve; 3 - pumping equipment; 4 - filtration element; 5 - check valve; 6 - shut-off valve

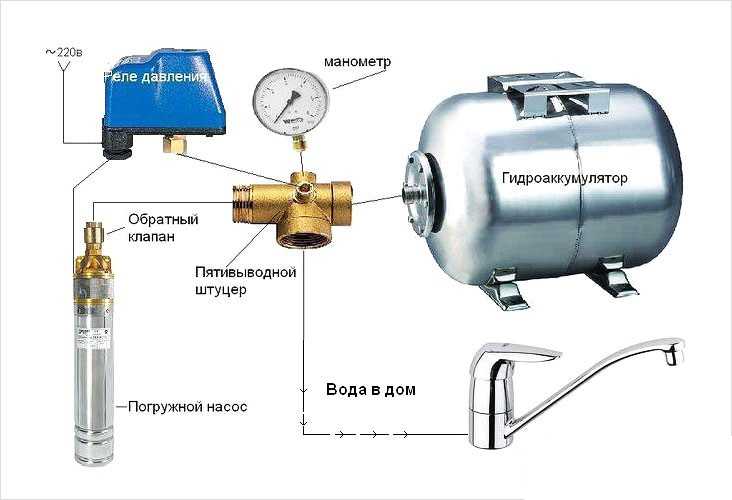

In the XB system, the main rule when installing a hydraulic accumulator is installation at the beginning of the piping, closer to the pump.

The connection diagram must contain:

- non-return and shut-off valve;

- security group.

Connection diagrams can be very different. The connected hydraulic tank normalizes the operation of the equipment, reducing the number of pump starts per unit of time and thereby extending its service life.

Installation diagram in the cold water system with a well: 1 - tank; 2 - check valve; 3 - shut-off valve; 4 - pressure control relay; 5 - pumping equipment control device; 6 - security group

In the scheme with a booster pumping station, one of the pumps runs constantly. Such a system is installed for houses or buildings with high water consumption. The hydraulic tank here serves to neutralize pressure surges, and a container of as large a volume as possible is installed to accumulate water.

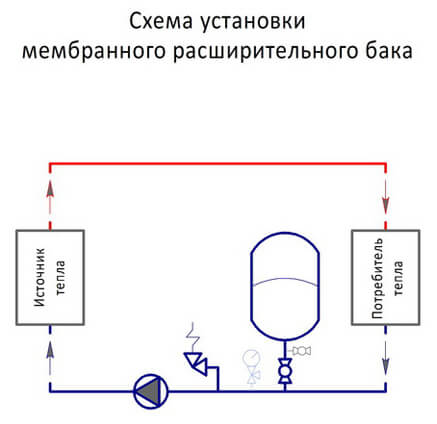

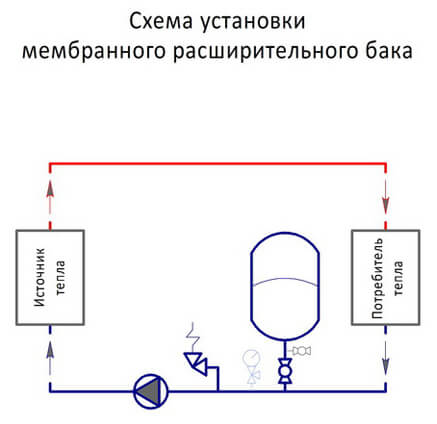

Installation of diaphragm expansion tanks

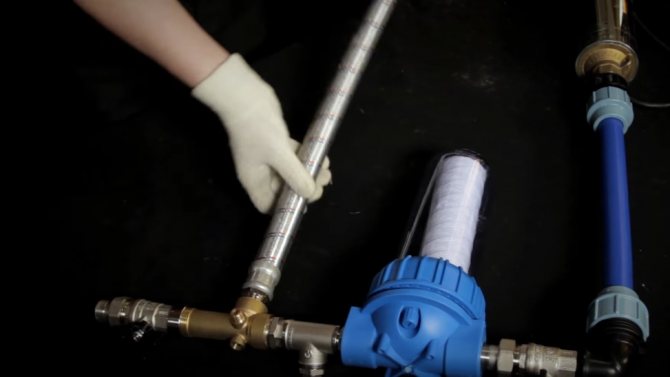

Before installing the expansion membrane tank, it is necessary to familiarize yourself with the instructions attached to the device, which are included in the technical documentation. Initially, it is supplied with an overpressure of gas that completely fills its entire volume. Before installation, the tank is pumped to a pre-calculated pressure.

A safety valve must be installed. As a rule, the diaphragm expansion tank connection diagram provides that drainage is arranged in front of the device. The installation should be carried out by a specialist, in extreme cases, his consultation is needed.

When installing, there are a few things to consider:

It is imperative that the diaphragm expansion tank for water supply or heating must be grounded to avoid electrolytic corrosion. A check valve is placed at the inlet to the device when it is not provided in the design of the circulation pump. At the outlet, a pressure gauge and an air release valve are mounted.

Features of adjusting the accumulator

Expansion tanks for water supply are sold with the manufacturer's standard settings - often the pressure in the air compartment is already set at 1.5 bar. The permissible pressure is always indicated on the label and the manufacturer does not recommend deviating from the specified parameters, especially in the direction of increasing it.

Before proceeding with the adjustment, the system is disconnected from the mains and the shut-off valves are closed. The diaphragm tank is completely emptied by draining the water - an accurate pressure reading can only be measured when the water compartment is empty.

Further, the pressure readings are taken using an accurate pressure gauge. To do this, remove the decorative cap from the spool and bring the device. If the pressure differs from the required one, then it is adjusted by pumping or bleeding off excess air.

Considering that the manufacturer is against deviations from the recommended pressure indicators, it is necessary at the design stage to select suitable equipment, the parameters of which will not conflict with each other.

When adjusting the pressure in the gas compartment of the tank, the manufacturer fills it with an inert gas, for example, dried nitrogen. This prevents corrosion of the inner surface. Therefore, users are also advised to use technical nitrogen to increase the pressure.

Setting the tank pressure in the water supply system

The pressure in the closed tank is always set slightly lower (by 10%) than the pressure level when the pump is started. By adjusting the pressure in the device, you can adjust the water pressure. The lower the gas pressure in the hydraulic tank (but not less than 1 bar), the more it will hold water.

At the same time, the pressure will become uneven - strong when the tank is full and increasingly weaker when it is empty. To ensure a strong and even flow of water, the pressure in the chamber with air or gas is set within 1.5 bar.

The water pressure in the water supply system is set using a relay. When adjusting the pressure in the expansion chamber, these values must be taken into account.

Adjustment of the hydraulic tank in the piping of the water heater

The expansion tank, which is used for hot water supply, should initially be free of water. The pressure in the device is set at an indicator that is 0.2 more than the upper threshold for turning off the pump.

For example, if the relay is set to shut off the equipment at a pressure of 4 bar, the pressure in the gas compartment of the expansion vessel should be set at 4.2 bar.

Installed in the piping of the water heater, the tank does not serve to maintain pressure. It is designed to compensate for expansion when the water is heated. If you set the pressure in it to a lower value, then there will always be water in the tank.

Types of expansion tanks

The installation location of the tank is determined by the type of the heating system itself. She may be:

This is what a closed expansion tank looks like in an already installed heating system.

Important! An open heating system is used very rarely today. In everyday life, they are used only in old buildings.

The expansion tank in open heating systems is made in the form of a container, the top of which does not close. It is connected to the heating system using a threaded connection located at the bottom of the tank.

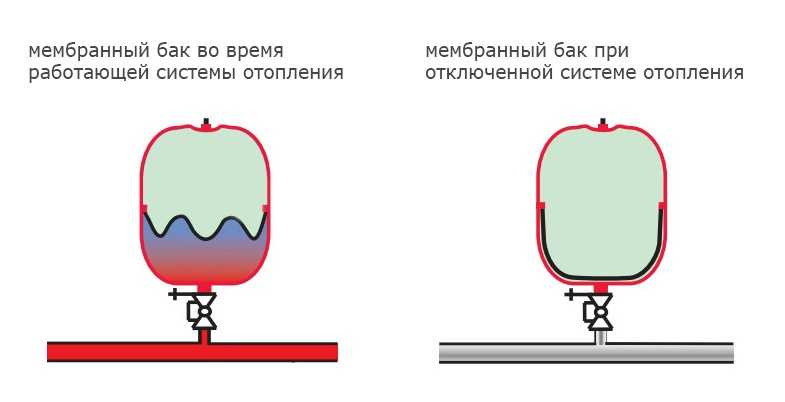

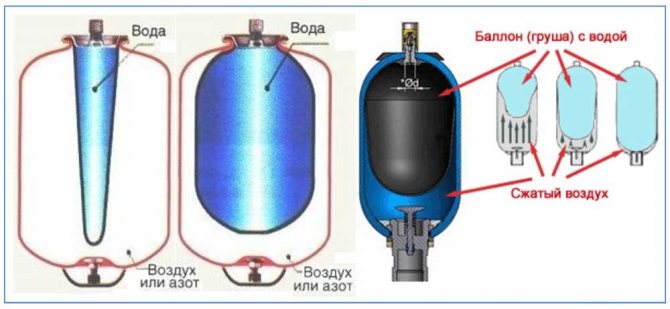

The installation and operation of a closed expansion tank in a heating system also has its own characteristics. The closed-type tank design is made in the form of a hermetically sealed capsule, which is divided into two parts using a rubber membrane.

Hydraulic tank maintenance rules

Routine inspection of the expansion tank is to check the pressure in the gas compartment. It is also necessary to inspect the valves, valves, air vent, check the operation of the pressure gauge and water pressure switch. To ensure the integrity of the tank, an external inspection is carried out.

During preventive maintenance, the pressure in the hydraulic tank should be measured and corrected if necessary.

Despite the simplicity of the device, expansion tanks for water supply still do not last forever and can break. Typical reasons are diaphragm rupture or air loss through the nipple. Signs of breakdowns can be determined by the frequent operation of the pump, the appearance of noise in the water supply system. Understanding how the accumulator works is the first step to proper maintenance and troubleshooting.

Expansion tank functions

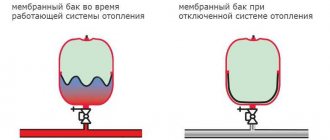

For what purpose is the expansion tank mounted? The heating system is filled with a fixed amount of liquid (water or antifreeze) that tends to expand thermally. This means that an increase in the temperature of the coolant inevitably leads to an increase in pressure in the system. Since pipes, radiators and other elements of the engineering structure are inelastic, the increased pressure will lead to depressurization of the system - a breakthrough will occur in the weakest point.

Water is characterized by low compressibility, therefore a special device is built into the system - a membrane or open tank. Its function is that as the pressure rises, air will be compressed. This makes it possible to provide protection against water hammer. The installed expansion tank protects the system from excessive pressure build-up.

The main task is to perform a reliable installation of the tank

For a closed-type heating system, membrane tanks are intended - they are a container with an elastic waterproof membrane inside, which divides the internal volume into two parts. The membrane is needed so that the air does not come into contact with the coolant. Otherwise, airing the network and increasing the risk of corrosion of the steel elements of the system cannot be avoided.

In an open system, the tank is in communication with the atmosphere, thereby bleeding air from the pipes. For this reason, the installation location of an open tank is strictly regulated - it must be located at the highest point of the system.

Open type hydraulic tank installation

An open-type device is used less and less, since it requires constant user intervention in its work. An open expansion tank is a leaky container that serves to build pressure in the water supply system, accumulate water, and also serves as an expansion chamber.

Connect to the tank: a drain valve, branch pipes for recirculation and supply pipes, control and overflow pipes

The tank is installed above the uppermost plumbing point, for example, in the attic, water enters the system by gravity. Each meter the device rises increases the pressure in the water supply by 0.1 atmospheres.

To automate the process of providing water, the tank is equipped with a float switch and an automatic relay is installed that will turn on and off the pump.

The container is mounted in a frost-proof room, covered with a lid from dust and debris, the walls are wrapped with mineral wool or other insulation

This method of organizing water supply requires regular monitoring by the user, otherwise the water at negative temperatures may freeze (if the room is not heated). The liquid will evaporate, so you will have to constantly top up.

In addition, such a container is bulky and not aesthetically pleasing, for it you must definitely have an attic room in the house. But the main drawback of the device is that the tank is not adapted to work under conditions of high water pressure in the system.

Conclusions and useful video on the topic

Movie # 1. Everything about expansion tanks - classification, purpose, adjustment and signs of problems:

Movie # 2. Incorrect operation of the pumping station is often associated with malfunctions of the accumulator:

Movie # 3. The nuances of choosing hydraulic tanks for water supply:

Even at the planning and development stage of the water supply system, it is necessary to think through all the fundamentally important points and calculate all the parameters. If you are not sure of the infallibility of your calculations and the correct choice of a hydraulic tank for water supply, it is better to contact a specialist.

Most firms that sell professional equipment provide advice or even carry out calculations for free. This will help you avoid mistakes and unnecessary expenses.

We are waiting for your comments with stories about our own experience in using the expansion tank, with questions that arose during the review of the information provided. We are interested in your comments and possible suggestions. You can comment on the material in the block below.

Diaphragm tank selection

In heating systems, the membrane load, like the expansion of water, does not change very much, but the temperature of heating the liquid can be about 90 ° C.

When choosing an expansion membrane tank, special attention should be paid to the material from which the membrane is made. The material must be of high quality, reliable and resistant to high temperatures and extremes

You should also pay attention to the following characteristics of the membrane:

- Operating temperature range;

- long service life;

- sanitary and hygienic requirements;

- resistance to high temperatures;

- dynamism.

Advice. When choosing an expansion membrane tank, it is necessary to select tanks with a strong and reliable body so that it lasts longer.