Types of carbon systems

Carbon fiber underfloor heating is laid as the main heating in small rooms, or as additional heating in separate cold zones of an apartment or a private house. Thermal film, sheets with continuous application of a carbon mixture, rods are used as heating devices. What are the characteristics of the systems?

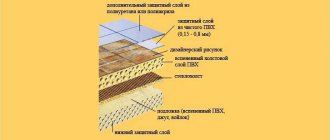

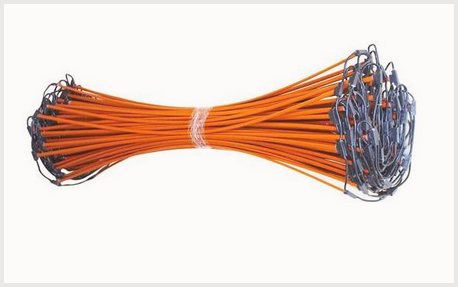

- The thermal film is produced in rolls. It is thin, no more than 0.42 mm thick. The material is made of polypropylene. The carbon mixture is applied between the layers of the film in horizontal or vertical stripes. A spray method is used. A copper and silver heating element runs along the top and bottom edges. Electrical wires are connected to it. Depending on the floor surface, a material with a power of 100 to 220 W / m2 is chosen. The thermal film is laid in a room with the correct configuration. It can be cut into ribbons only according to special markings, which does not allow violating the integrity of the carbon layer.

- Carbon floor heating with continuous application of the mixture has the same properties as thermal film. A distinctive feature is that there are no markings on the sheets. Any contour can be cut, therefore the system is used to heat rooms with non-standard geometry. Stationary furniture can be installed on the sheets without fear of clamping the heating element, which can lead to overheating and shutdown of the system.

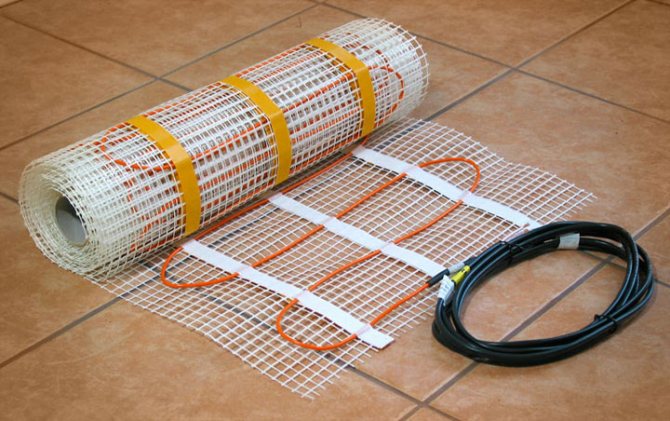

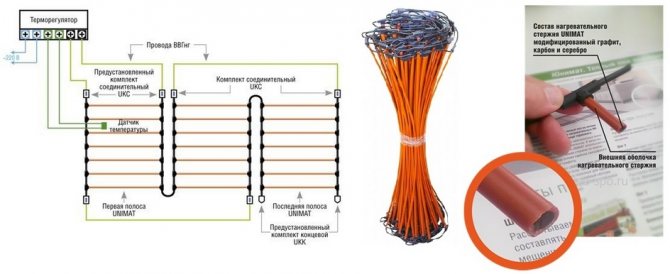

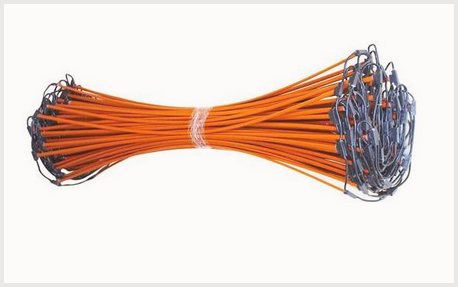

- Carbon fiber rods increase the heating surface of the floor. They are assembled in a contour with a step of 10 cm; connected by copper wire, which is insulated with a plastic sheath. This coating can withstand high temperatures over 100 ° C. The system is produced in rolls. The tape is not cut during installation. Make an incision in the wire, turn the roll in the desired direction, continuing the installation.

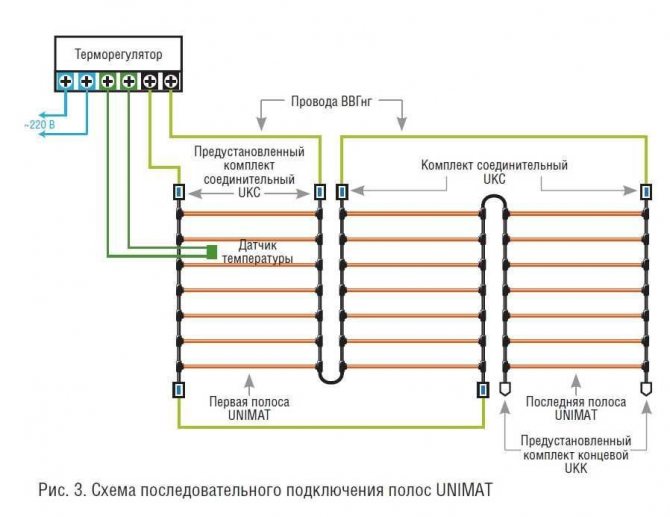

It is proposed to use the core system from "Unimat" for heating the premises; manufacturer Korea. The heating works from a 220 V network. The maximum temperature of the rod heating is 60 ° C. Average energy consumption 24 W for 1 running. m.

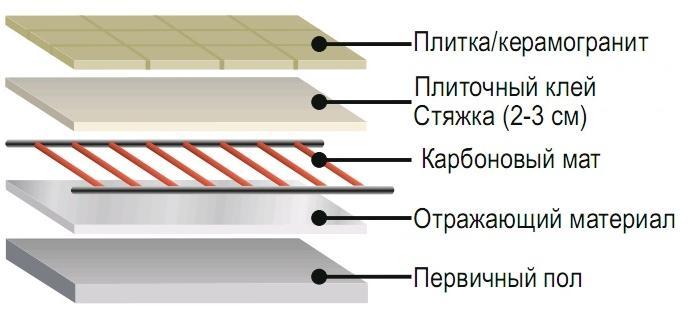

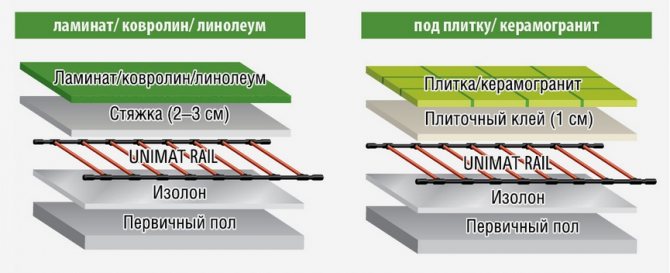

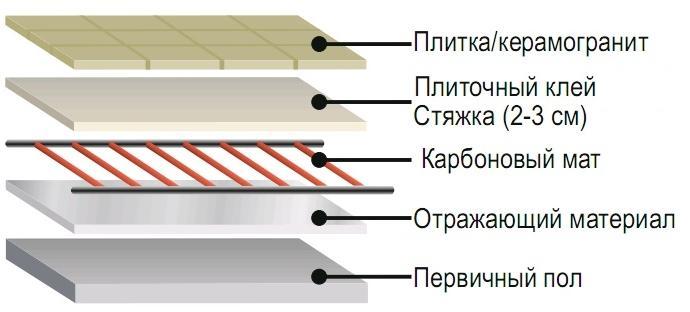

When installing, it is recommended to use a reflective screen based on a mylar base. A thermostat from "Kaleo" is installed as a control unit. The technical passport describes the capacity of the system, depending on the conditions of the room and on the nature of the topcoat.

Rod carbon underfloor heating

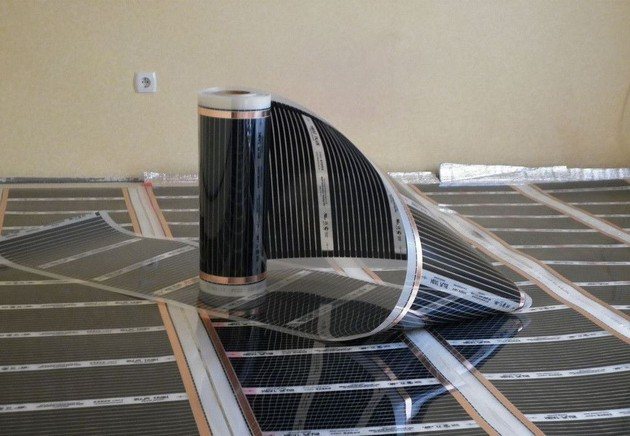

Today, core floors (infrared mats) are the newest and most progressive type of floor heating. For the ability of the system to self-regulation, it is often called the "smart floor" system. The structure of a carbon core floor is more complex than a film one. Despite the fact that carbon also acts as a heating element here, it has a different configuration.

Rod carbon underfloor heating

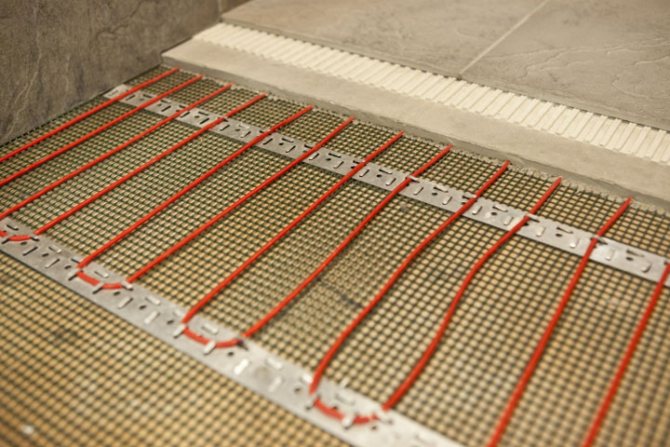

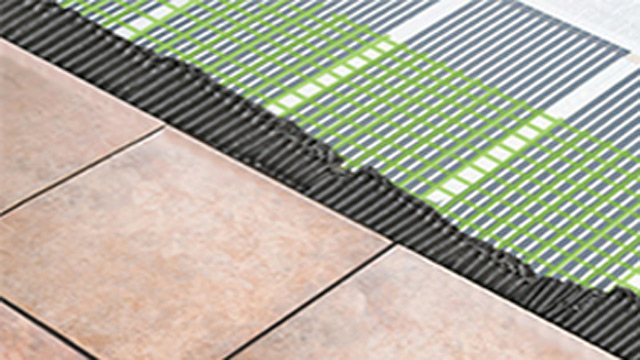

Installed rod underfloor heating

Heating element of a carbon-fiber rod floor - a rod filled with carbon-polymer filler. The rods are connected using a stranded copper wire (2.5 mm thick) with an additional protective insulating sheath made of polyester and polyethylene.

Scope of use of the core floor

Due to its increased operational characteristics, the core floor can be used in a living room, in a bathroom, on a loggia, in a room, in a winter garden, in a gym, in office buildings, warehouses, as an element of an anti-icing system.

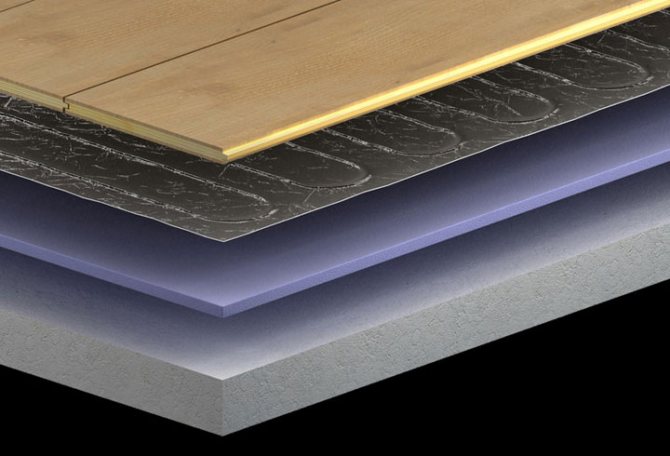

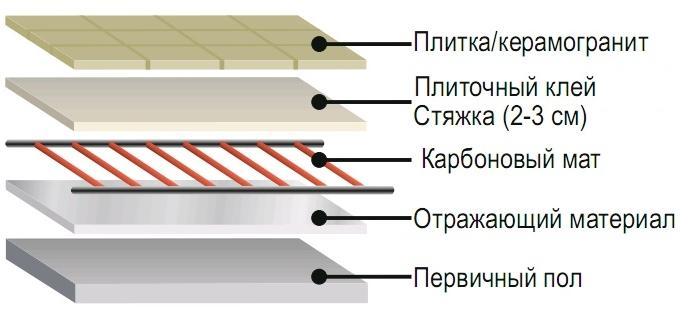

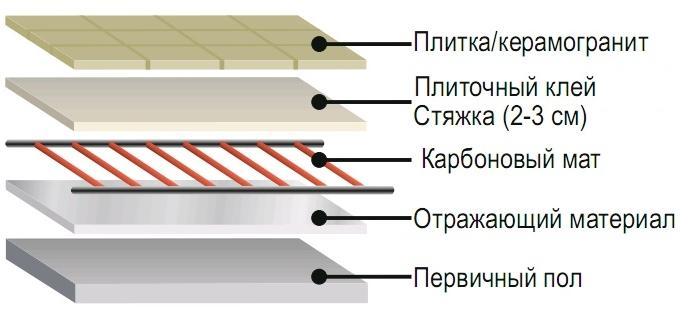

The core floor can be installed on any type of flooring, no exceptions.It matches perfectly with finicky materials such as natural wood, parquet or laminated board. And due to the fact that a rod carbon floor is mounted on a thin layer of screed, such an electric floor heating system is the only one suitable for installation under tiles or porcelain stoneware. In addition to the possibility of installation, the core system allows you to save on labor, in the case of using an adhesive solution instead of a screed and direct laying of tiles.

Rod carbon underfloor heating - pros and cons

Benefits:

- resistance of core floor elements to aggressive media and mechanical loads;

- the estimated life of the system is 50 years;

- parallel connection system, which ensures the preservation of performance in the event of damage to the heating mat;

- high heat transfer rate;

- efficient heating (the most economical system with the highest efficiency);

- uniform and fast heating of the room;

- eliminates unpleasant odors thanks to infrared radiation;

- fire safety (the presence of silver in the rod does not allow the system to ignite);

- no electromagnetic radiation;

- low weight (no load on the floors);

- can be used in rooms with high humidity levels;

- relative ease of installation;

- the ability to install heavy objects of any size on the floor (in particular, furniture and household appliances). The system will automatically adjust the floor temperature in different places.

- the presence of self-regulation protects the floor from overheating.

- heating of premises of a large area is possible.

If you look at it, when purchasing a rod infrared carbon floor - the user buys a floor heating system, which is significantly ahead of systems for a similar purpose in terms of its characteristics.

Disadvantages:

- installation is carried out only with screed filling. These are wet jobs and lack of mobility. Unlike the film system, you cannot take it with you when you move;

- high cost (retail price - 1500-2685 rubles / sq. m.)

Technical characteristics of core underfloor heating

General characteristics differ slightly depending on the manufacturer, but the analysis of different systems makes it possible to give averaged data:

- roll width - 830 mm;

- length - 25000 mm;

- mat thickness - 3-3.5 mm;

- power for 1 sq.m. mat - 125 W / m. (rod temperature 60 ° C) - 170 W / m. (rod temperature 20 ° C);

- power consumption for 1 lm - 20-50 W;

- maximum surface temperature - 60 ° C.

The best manufacturers of core underfloor heating

- K-Technologies - trademarks GTMat, Unimat, RHE (Russia);

- GH Systems - trademarks of HOTmat (South Korea);

- SamMyungTech LTD - EcoOndol trademark (South Korea);

- GT - GT trademark (South Korea);

- Felix is a trademark of Excel (South Korea).

Why carbon floor heating is better than others

A heated carbon floor is more often used for heating houses. Such a heating system has such advantages.

Self-regulation

The carbon flooring independently controls the temperature and reduces the consumption of electrical energy. In such a situation, the homeowner does not need to buy expensive electrical equipment.

As the temperature rises, the distance between the parts of the heating elements increases, and the heating of the room becomes less - an increase in resistance occurs. As a result, the carbon floor reduces the consumption of electrical energy.

When the temperature drops, everything happens exactly the opposite.

Reliability and safety of continuous floor technology

The infrared carbon underfloor heating never overheats, so it keeps parquet, laminate and other floor coverings intact.

The infrared radiation of the heated floor has no side effects.

The scope of use of such infrared floors is expanding every year. They are installed in spas, modern saunas and other places.

Cost-effectiveness of imported options

The carbon floor has a power of 116 watts per running meter.

When the glue layer or screed is heated, under which such a heating system is placed, the power consumption decreases - and it becomes equal to 87 watts per 1 running meter. Carbon fiber underfloor heating is considered one of the most effective.

Description of carbon fiber underfloor heating

The basis of the carbon underfloor heating is a cable with a carbon fiber winding

The basis of the electrical system is the heating cable. When turned on, the electric current heats the wire, it transfers heat to the floor surface, and the latter gives it off to the air in the room. This option has 2 drawbacks. The resistance of the cable practically does not change with increasing temperature, so it is impossible to regulate the degree of heating along the length of the cable. More importantly, heat transfer occurs in 2 stages, which increases electricity consumption.

The first problem is partially solved by laying the cable in loops at regular intervals. This is not very convenient, since only modules of a certain size are received. During installation, they have to be docked with each other. The standard modification does not solve the second problem.

The construction of a carbon floor heating is devoid of these disadvantages:

- The base of the underfloor heater is made of carbon rods. Carbon is an amorphous carbon, it has a high electrical resistance - when an electric current passes, it heats up strongly and emits thermal radiation in the range of 5–20 microns. Infrared radiation transfers heat to objects and objects, and not to air - such a system heats the floor, furniture and people in the room, and the air heats up secondarily. To improve the efficiency of the heater, elements of graphite and silver are included.

- Carbon rods are assembled in blocks and interconnected by stranded copper cables in polymer insulation. The area of such a structure is practically unlimited.

- The role of temperature regulators is played by polymer inserts. When the air temperature reaches a threshold value - from +18 to +22 C, the material increases in volume, which leads to an increase in electrical resistance. In this case, the current decreases, and the heating temperature of the rod decreases.

Carbon heaters generate heat radiation. At the same time, the air heats up slightly and retains its natural humidity.

Properties of film KTP

The carbon fiber underfloor heating system heats up quickly and evenly. It can operate in a continuous mode for quite a long time, is very durable, is not afraid of mechanical stress and is not subject to corrosion.

Due to lamination in a special film, the possibility of water and steam getting on the contacts is completely excluded. The film is also fireproof and has a high melting point (120 degrees).

A significant advantage is the mobility of the film KTP. It can be easily dismantled and taken away with you when you move, used on walls, inclined surfaces and heat separate areas of the apartment.

Absolute noiselessness, the ability to ionize the air and hygiene allows you to install a film carbon heat-insulated floor in medical institutions.

Advantages and disadvantages

Carbon film warm floor is mounted under a material that conducts heat well

General advantages of rod mat and IR film:

- Efficiency close to 100 is not an exaggeration. Carbon generates infrared radiation. It heats the floor, objects and people, not the air. The elimination of the intermediate stage of heat transfer makes the carbon floor much more efficient.

- The systems do not emit electromagnetic radiation.

- The air heating temperature during the operation of the IR heater is low. It stays humid and the room climate is pleasant.

- The film and core mat are very lightweight. They do not load the floor and do not require installation equipment.

- Both systems are fireproof. However, at temperatures above 120 ° C, polymer parts melt.

- They are not afraid of water, moisture, condensation, steam. The carbon floor is laid for heating bathrooms, kitchens, saunas.

- The heating area is not limited: from a staircase to a hall of 100 sq.m.

- If the material is damaged in one area, the performance of the heater in other areas does not change. Repairs are performed at any time.

There is a common disadvantage: high operating costs.

Each modification has its own design advantages and disadvantages. A core carbon floor is placed under any surface - from parquet to porcelain stoneware. High humidity or poor insulation of the room is not a hindrance. The system is self-regulating, so that overheating of the elements and excessive consumption of electricity are excluded.

At the same time, the core mats are laid under the screed - installation involves wet work. The system cannot be dismantled and moved to another location.

IR film is even thinner than mats, so it is placed directly under the finish coat. It can be dismantled, reused. IR film is more economical, consumes 30% less electricity than standard heating cable.

The infrared film is not pressure-resistant, so furniture cannot be placed on such a floor. It is selective in relation to the coating material: it is not recommended to put it under tiles or porcelain stoneware.

Preparatory work before installation

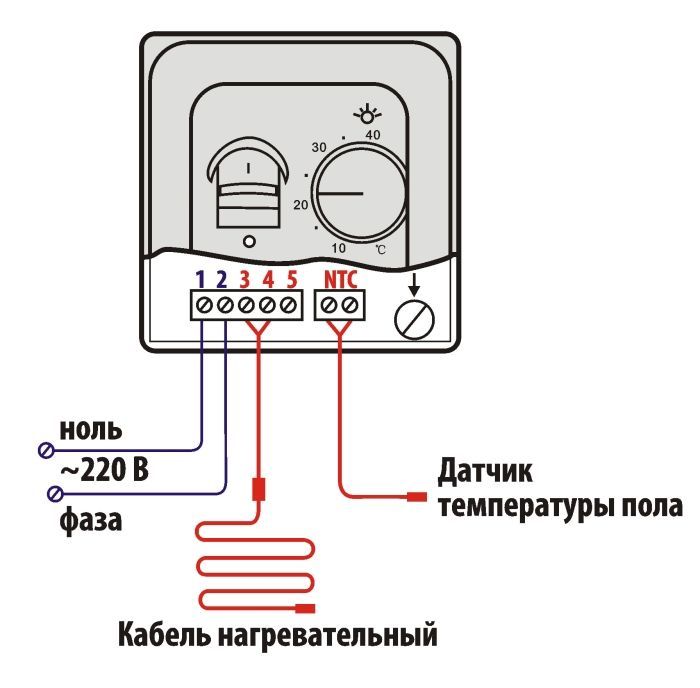

Before you start installing underfloor heating, make sure you have all the materials you need:

- A large number of carbon mats. During the calculation, it is necessary to take into account that the coating is allowed to be cut and laid in any desired direction.

- A sensor that measures the temperature of the floor.

- Required number of UTH thermostats. It must be remembered that they are selected taking into account the power consumed by the film floor system.

- Temperature sensor responsible for activating the "overheating protection" mode.

- Heat reflective backing material. Allows for more beneficial use of the system by reflecting downward radiated heat.

Before laying underfloor heating

need to prepare the surface

Important: A specialized coating based on polypropylene or mylar film is used as a substrate. It is absolutely forbidden to use aluminum-based foil, which can provoke a short circuit and system failure.

conclusions

When planning your home's heating system, consider carbon fiber technology. Perhaps the carbon underfloor heating will be the only source of heat. In fact, the best use case is a redundant system. You can always choose which energy carrier is more profitable in a certain period. In addition, underfloor heating can be used simultaneously with traditional heating.

And if you are leaving the house for a long time, you can set an economy mode with intensive heating on a timer by the time you return.

Where can you apply a carbon floor

The underfloor carbon underfloor heating is a type of infrared structure that can be placed under laminate flooring, for example. It is a stationary intelligent heating system based on infrared floor heating mats. Each of them consists of parallel placed thin carbon rods, which are connected to each other by a hermetically insulated power cable.

Experts say that there are almost no restrictions on the use of such a floor. The system can be used for heating:

- loggias, covered terraces, balconies;

- apartments;

- premises for industrial needs;

- private country houses and houses;

- hotels and motels.

Underfloor heating is considered a good replacement for conventional radiators. All a decent number of developers are showing interest in him and are going to collect them in their own apartments or offices. But before purchasing the material, you should familiarize yourself with the good qualities that it has over similar options:

- Relatively light weight and, as a rule, low floor load.

- Most economical energy consumption.

- Possibility of installation in large areas.

- No need to install large and heavy heating devices and, on this basis, equip a separate area for them.

- Possibility of installation under all kinds of floor coverings.

- Ability to work during the life of the structure.

- Explosion and fire safety.

- Can be installed in rooms with high humidity.

- If necessary, it can be turned off without harm to the properties of operation, even at low temperatures.

- Does not undergo corrosive processes.

- Lack of electromagnetic radiation.

- Fast heating.

- The presence of a special self-regulation system that protects the system from burnout even in the event of a defect in the screed. Moreover, thanks to it, heavy furniture can be installed on top of the mounted floor.

The practical infrared carbon floor heating has only one drawback: the mats can only stand in a thin screed or in a layer of tile adhesive. In a similar way, a stationary system is obtained, which cannot be dismantled with all the desire.

Infrared carbon floor consists of rods connected by a power cable

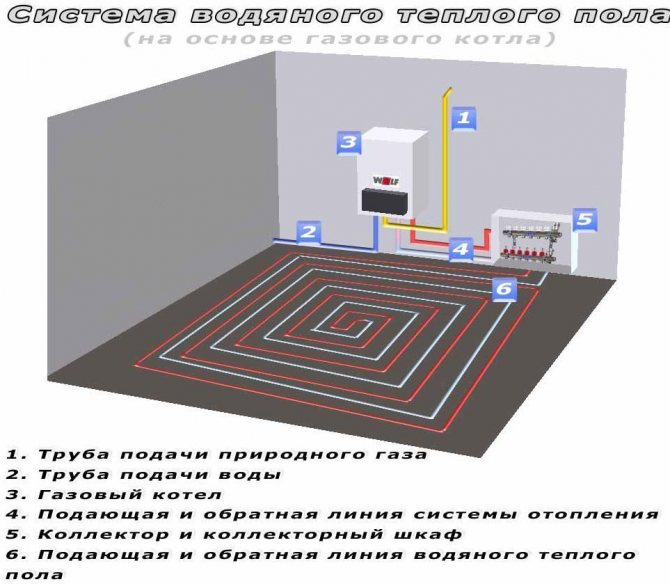

Carbon underfloor heating - what is it?

Consider one of the new electric infrared heating systems - carbon floor heating (carbon, carbon fiber). This is a progressive floor heating system, which is based on the use of far infrared radiation. A distinctive feature of this range is the absence of electromagnetic radiation and "live" heating of the room. Infrared radiation is harmless to human health, and in medicine it is generally used for medicinal purposes.

What is the difference between carbon and carbon floor heating?

Carbon is the international name for all composite materials based on carbon nanostructure and various binders. Thus, what is known to the domestic consumer as carbon and carbon are one and the same substance. Those. the carbon film floor and the carbon film floor are one and the same system.

Manufacturers offer two types of carbon floor systems:

- film carbon fiber heat-insulated floor (solid);

- rod carbon underfloor heating.

There are two more types of carbon floors on the market:

Bimetallic underfloor heating

Bimetallic heat-insulated floor Heating system based on a bimetallic film. A distinctive feature of the carbon film is a patented two-layer compound (the upper layer is made of an alloy of copper and additives, and the lower one is an alloy of aluminum with additives). The heating plates emit infrared waves. Such a warm floor is laid only "dry", it is forbidden to use a screed or tile adhesive.

Amorphous underfloor heating (ANT)

Amorphous underfloor heating (ANT) Israeli company Advanced Heating Technologies (AHT) Ltd has developed a new technology - underfloor heating based on amorphous metal tape. The main feature is fire safety, because floors do not heat up above 35 ° C (for example, cable floors can heat up to 60-70 ° C). Made in the form of thin heating mats. The heating element is made of amorphous metal (ultra-thin tape, 30 microns thick). Underfloor heating on an amorphous tape can be installed under all floor coverings (tiles, parquet, laminate, linoleum and carpet).

Film floor installation

All carbon systems are laid on a flat surface. The base is recommended to be leveled. Differences of 1 mm per 1 running meter are allowed. m. Thermal foil and rods heat the entire surface around: not only the floor covering, but also the lower base, the foundation. In order for warm air to pass upward, thermal insulation and a reflective screen are placed on the base. In the future, the installation of thermal film is carried out.

The boundaries of the "warm floor" are marked on the floor. The film is placed at a distance of at least 5 cm from the wall and from the furniture.The gap between the strips is 2 cm

Pay attention to the roll width. If the width is 50 cm, then the length of the tape should not exceed 13 m

The wider the roll width, the smaller the allowable tape length will be: width 80 cm - length 10 m; width 100 cm - length 7 m. It is recommended to pre-mark and divide the film into separate tapes. A place for a thermostat is allocated on the wall. A hole is made into which a plastic cup is inserted. It will contain the entire electrical part of the system and the control unit. The control panel is left on the wall surface. Thermal foil tapes are laid along the markings. They are connected with scotch tape. Contacts are connected to each sheet. The terminals are installed in the area of the copper and silver busbars. Strengthen the terminals with pliers. Mount the wiring; connect the terminals. The connection diagram is parallel. The joints are insulated with bitumen tape. Insulation is used to seal the cuts in the area of metal tires. So that the joints do not stand out on the surface and do not experience a large load from the floor cladding, a recess is made for them in the substrate or in the reflective screen. A temperature sensor is installed on one of the belts. A distance of 60 cm is maintained from the wall to the sensor, 10 cm from the edge of the film. A niche is cut out in the substrate for the sensor. All wires are led out into a corrugated tube, which is connected to a thermostat. For the tube, a groove is made in the floor and in the wall, which is then sealed with mortar. The system is being tested. If the result is positive, the carbon floor is covered with a substrate and the laminate is laid. Tile glue is used to lay the tiles.

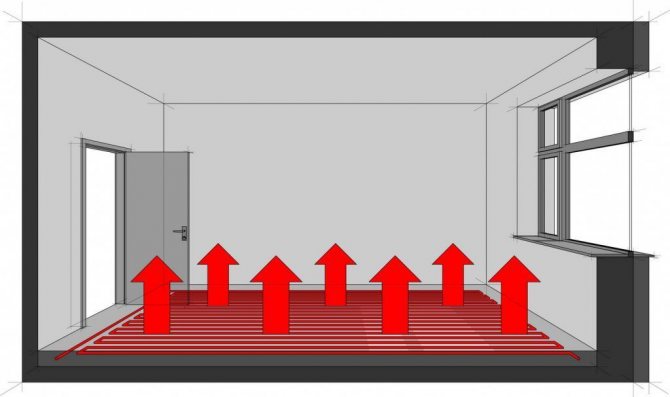

Why electrical floor heating systems are so popular in modern homes

- The heated air is formed at the lowest level, evenly rising through the volume of the room.

- Large heat transfer area minimizes losses.

- You can walk barefoot on a warm floor in winter;

- Flat heating elements fit perfectly into the interior: they simply cannot be seen under the floor covering.

- Electric cable underfloor heating makes it possible to fully automate the climate system. The controller does not just maintain a preset temperature, you can set low cost modes (when you are not at home), or turn on heating by a timer.

- There are no problems with the delivery of energy: almost 100% of the housing stock is electrified.

- Simple installation: no need to lay pipes for liquid heat transfer agent, installation of heating radiators, fans, pumps.

- No maintenance required: a properly organized underfloor heating system lasts a long time. Any self-respecting manufacturer provides a minimum 10-year warranty.

There are also disadvantages, which, however, are covered by advantages:

- To install the system, you will need to open the floor covering. In the case of linoleum or laminate, no problem. And if you want to implement a carbon underfloor heating under the tiles, you will have to carry out a full renovation of the room.

- Relatively high cost of equipment, especially thermoelements. True, this problem occurs only once, when buying.

- The cost of generating heat is higher than using gas or solid fuels.

And yet, the main plus: the carbon floor can be laid and connected independently.This requires an ordinary household tool and the basic skills of a home craftsman.

Types of carbon floors

Currently, there are two types of carbon flooring, they are core mats and a film. Each model has general advantages over other systems, but they also have their own differences. Therefore, in order to make the right choice, it is worth considering them in more detail.

Rod mats

This model of electric floors is produced in rolls with the following standards: width - 83 centimeters, length up to 25 meters, thickness no more than 3.5 millimeters. They include a thermostat and a temperature sensor. For rod mats, the power consumption depends on the heating temperature, on average, it ranges from 110 to 180 watts per linear meter. Energy consumption per linear meter is no more than 50 watts per hour, with power supply from the mains with a capacity of no more than 220 volts. This type of underfloor heating can be combined with any flooring, but the ideal solution would be to lay a core carbon underfloor heating under the tiles.

Installation of rod mats

Due to the fact that the manufacturers have done most of the work, the installation of a carbon underfloor heating is carried out several times faster than devices made of electrical cables. Installation of cable models is rather painstaking. Since, before fixing the elements, you need to lay the cable, with the correct distance. If we take into account that such work will take more than one meter, then we can assume that it will take quite a lot of time. In a carbon fiber rod heat floor, the distance between the rods has already been taken into account, therefore, for installation, it will be enough to spread the mat on the floor surface and fix it with construction tape or glue. Where you need to unfold the mat, you will need to remove the rods from the mesh, cut the mesh along the outlined lines and lay it parallel to the first strip at a distance of 6 cm, carefully making sure that the cables do not touch each other. After the installation is completed, the concrete screed is poured in a thin layer.

Infrared film

The film carbon fiber underfloor heating consists of a continuous layer. Its elements are connected by soldering, due to which such fastening is more reliable than clipping. The carbon film can be cut into strips of different sizes, in any direction. There are currently two types of infrared film:

- Regular. Such a film consists of one or two layers of polypropylene, on which a layer of carbon-graphite mixture is applied in stripes.

- Solid. This film has great protection against overheating, since it consists of 13 layers, where on each side there are 5 layers of safety and 3 layers of workers between them. Such a film is made of pure carbon, so its price is much higher than that of a conventional film.

Both of these films of carbon floors are absolutely safe, as they can withstand temperatures up to 120 degrees. But if a continuous film can be laid under overall furniture and electrical equipment, it is strictly forbidden to use the usual one in these places, for the reasons that the effect of thermal locking can occur.

Installation of infrared film

A feature of film floors is that during their installation there is no need to pour a concrete screed. In order to mount them, it will be enough to spread the film on a clean base of the room, and then lay the floor covering. But here it is worth noting that the film warm floor is not combined with carpet and tiles. Since in the first case there will be insufficient thermal conductivity, and the tile requires a concrete screed. Wood flooring has its limitations too. In order to avoid the formation of cracks when the wood dries up, film floors should not exceed a temperature of 28 degrees. The ideal option would be to place the warm floor under laminate or linoleum.

Views

The carbon floor is installed exclusively permanently (it is not mobile). Today it is possible to buy and install a warm carbon floor of a film or rod type. Such floors differ in the method of fastening, features of operation and price.

Film

The thermal film is visually similar to a continuous canvas with black stripes, 0.23-0.47 mm thick. Such a continuous warm floor is welded together, and pure carbon acts as heating elements.

Less commonly, a mixture of carbon and graphite is used. Such a nuance does not affect the efficiency of heating.

By means of spraying, the liquid composition is applied to polypropylene with heat-resistant characteristics. On both sides, the canvas is covered with a 3-layer protective film, which subsequently protects the carbon from scratches and deformations. This plastic film can withstand incandescent temperatures up to 120 ° C. Power consumption - 130 W / m. It has high strength and does not lose its original characteristics. Copper tires are used to interlock multiple strips.

Film floors are not used:

- for felt-based linoleum;

- under the carpet;

- under carpet tiles;

- under ceramic tiles, self-leveling floor.

In the latter case, the installation of the coating is a “wet” installation process.

Natural wood parquet or board is used when the operating temperature of the flooring does not exceed 28 ° C.

The convenience of using carbon sheeting on the floor is that it can be cut to fit non-standard spaces. In this case, the roll width is 50 or 100 cm. If one section breaks during the heating process, the entire system continues to work efficiently without temperature changes.

Rod infrared

This type of heating element has a complex structure consisting of flexible rod systems that are connected in parallel to each other. The rods are made from heat-resistant polymer. The design necessarily includes a thermostatic sensor. The parallel connection method helps the system to work without changes in the event that one element is out of order somewhere. Same feature as tape type.

A distinctive characteristic of the system is the ability to self-regulate. So, with an increase in temperature readings in one of the sections to a critical norm, the power consumption of the elements decreases. This is convenient, for example, if you put furniture on the floor. Carbon will not heat up, as in an open space, evenly distributing temperature values.

The unique characteristics of the carbon floor allow installation in any room. In this case, it is not necessary to take into account the further prohibition on the arrangement of furniture in an arbitrary order.

What is needed for installation?

In order to properly mount the core underfloor heating, it is necessary to collect all the fixtures and materials. So, you will need:

- A backing that will direct heat upward. Please note that the use of foil materials is not recommended.

- Multiple thick-walled heat shrink tubes, sleeves.

- Two thick-walled heat shrink tubing for each strip. They are used to insulate the ends.

- Thermostat.

- Corrugated tube with plug and probe. A thermal sensor will be inserted into it.

- Connecting wire. Please note that it must be double insulated.

- Tongs (thanks to them you can remove some of the insulation from the wires).

- Nippers.

- Crimping pliers.

- Scissors and a knife.

- Screwdriver.

- Construction tape.

- Special construction hair dryer for heating heat shrinkable tubes.