Today the construction market presents a very wide range of floor coverings. The combination of a reasonable price and high quality is what distinguishes linoleum from other coatings. Most of the linoleum is of artificial origin. This material is easy to install and maintain, which to some extent provides such a popularity of the coating. However, if the floor in the room is cold, it will have to be additionally insulated before laying the linoleum. This article will help you figure out what kind of insulation to put under linoleum on wooden floors, as well as on a concrete base.

Types of linoleum

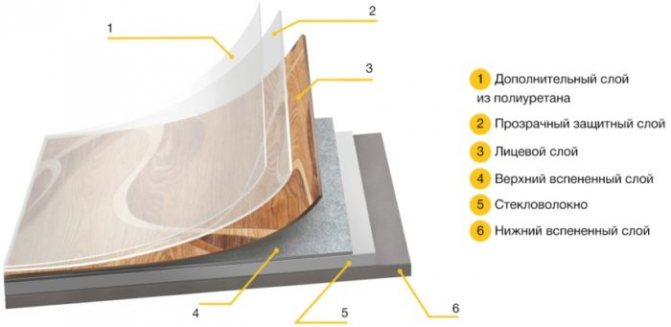

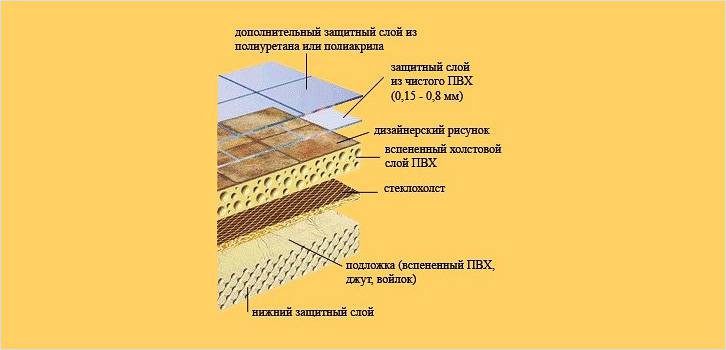

Linoleum structure

Linoleum can be base or baseless. Baseless linoleum is very thin and requires special preparation before laying, as it tears and wipes quickly on an uneven surface. Such a coating will last up to five years, but it must be borne in mind that it has absolutely no sound and thermal insulation properties.

If there is a base, there are:

- Foam base... It has a small thickness of about 1.5–3 mm. The foam backing retains some heat and absorbs sound. It is very soft and elastic, easily glued in the corners. The base can be supplemented with fiberglass, which will protect the coating from deformation and dents. The top decorative layer is covered with a protective film that will extend the life of the linoleum.

- Warm base... It consists of natural or artificial jute or felt, protected by a polymer layer. The soft and elastic coating up to 5 mm thick is perfect for bedrooms, keeping enough warmth. The disadvantages include insufficient strength of the top layer. It requires special care and is not suitable for rooms with high air humidity.

Jute-based linoleum

Linoleum with a base will protect your feet from the cold to some extent, however, if the floor is too cold, it still needs to be insulated.

Insulated plywood floor

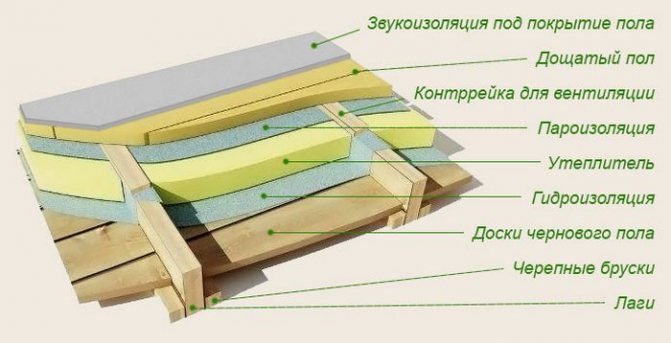

Installation of logs and insulation

High-quality insulation of the base can be carried out by installing an insulated plywood floor along the logs. Lags can be used regular or adjustable. Adjustable joists are convenient to use if there are uneven floors. If the irregularities are small and ordinary logs fit, the differences can be leveled with a wedge lining.

Note!

This option is suitable for rooms with high ceilings.

Plywood can be laid on a flat concrete surface without logs, however, if the room is located above an unheated one, this option will not save in winter in frost.

Installation of plywood

Installing a plywood floor:

- Logs are installed on the screed at a distance of 300–600 mm from each other.

- If the insulation does not tolerate moisture, waterproofing is laid.

- Then carry out the installation of thermal insulation between the lags.

- Plywood is sawn into squares and laid with small gaps between the sheets, both between each other and against the walls.

- The sheets are fixed with self-tapping screws, sinking them into the thickness of the plywood.

- The gaps and caps of the screws are putty with elastic putty.

Video: installation of a plywood floor with foam insulation

Benefits:

- Environmental friendliness.

- Low price.

- Strength.

- High degree of thermal insulation.

Disadvantages:

- Moisture instability.

- Not installed in rooms with low ceilings.

Note!

About the technology of leveling the bases using plywood, read our article on leveling the floor with plywood with your own hands.

Which will fit

Today, every person who has decided to insulate a concrete floor under linoleum has ample opportunities to choose the ideal option. You can buy natural materials or artificial insulation.

Bung

This insulation belongs to the category of natural. For its production, an agglomerate of cork granules is used. The advantage of the insulation is that it is environmentally friendly. And this is not surprising, because natural cork is used for manufacturing. In addition, it is very comfortable to walk on such a coating, because the resulting surface is soft and pleasant.

In the photo there is a cork under the linoleum:

But not everything is so rosy. The cork floor has one drawback, which is that after installing heavy objects on it, dents are left. To avoid this problem, it is necessary to choose cork insulation with the utmost rigidity. Insulation is sold in rolls.

Jute

This natural material is 100% natural jute fiber. The manufacturing process is carried out by punching jute with a needle and subsequent rolling on rollers under the influence of high temperatures.

In the photo - insulation jute under linoleum

Thus, the linoleum substrate becomes resistant to the formation of fungi and combustion.

Linen

Linen backing is a natural insulation. In addition, the linen backing has excellent moisture resistance. Moreover, they are the best when compared with previous materials. When using it, it is possible to create an excellent microclimate under the linoleum.

This result is achieved due to the fact that the concrete base can breathe. There is a free circulation of air between the subfloor and the final coating. From here, excess moisture will not accumulate, so there should be no fungi and mold.

In the photo - linen insulation under linoleum

Considering that flax is a natural material, you need to be prepared for the fact that it is susceptible to insects. To prevent this from happening, the substrate must be treated with a special compound that will protect it from beetles. The linen backing is also resistant to decay, perfectly absorbs noise and does an excellent job with heat-insulating functions.

Infrared insulation

This Martial belongs to the innovative category. Infrared equipment must be positioned under the finish floor covering. This floor is very pleasant to walk barefoot, even in winter. Apart from this, infrared insulation is an auxiliary heating element in the house.

In the photo, infrared insulation for the floor

Of course, not everyone will be able to install such a heater, because its cost is high. In addition, the installation process requires the involvement of specialists, because it is impossible to cope with such work on your own. But all your expenses will soon pay off quickly, because you can reduce your heating costs at home.

Foamed polymers

When insulating a concrete floor under linoleum, special polymer foam materials can be used. Most often, isolone and penoplex are purchased.

In the photo - foamed polymers for linoleum floor

Heat insulators of this type are perfectly mounted on a concrete surface and have excellent adhesive properties to the linoleum flooring layer. This reduces the likelihood of damage to linoleum on concrete. The installation process is carried out using glue. It must be applied pointwise or over the entire surface of the concrete slab. The presence of excellent adhesive properties eliminates the need for additional fasteners. Linoleum is laid on top of isolon and foam, the thickness of which is 5 mm.

But how to glue linoleum to concrete and what material is the easiest to use. described in this article.

For those who want to know more about whether it is possible to use FSF plywood under linoleum, you should follow the link and read the content of the article.

What thickness of plywood under linoleum on a wooden floor should be used is described in detail using a photo, in this article: https://resforbuild.ru/leso-i-pilomaterialy/presovanyj/fanera/na-pol-tolshhina-na-derevyannyj-pol .html

But how to lay insulation with foil under linoleum and how to do it correctly, the information from this article will help to understand.

Mineral wool

This insulating for a long time pleases with its unique qualities. Thanks to mineral wool, you can not only protect the house from heat loss, but also create excellent insulation from noise. The main advantage of the material is its environmental friendliness.

In the photo, mineral wool under linoleum

Minvata are produced in rolls. The installation process is simple and fast. You can install mineral wool yourself, even for those who do not have much experience. But what is the thermal conductivity coefficient of mineral wool is described in great detail here in the article.

Glass wool

This option is also classified as environmentally friendly. In its manufacture, no glue or other harmful chemical components are used.

In the photo, glass wool on a concrete floor under linoleum

Since the thickness of the glass wool is insignificant, it will not be possible to level the floor surface in this way. It is not worth using such material when arranging a room where there is maximum permeability. The substrate obtained from glass wool can be used when it is impossible to raise the floor to a specific height, but at the same time noise and thermal insulation of the room must be achieved. But what are the characteristics of basalt wool and where exactly such a building material should be used in construction is described in this article.

Insulation of the floor with a cork

Cork roll

Cork is made from the bark of a cork tree and is considered an environmentally friendly product. Installation is carried out in two ways:

- By floating method. The roll material is rolled along the surface joint to joint. The sheets are connected with construction tape.

- With glue. When laying cork boards. Cork flooring can also be used as a finishing floor.

Video: installation of a cork backing

Pros:

- Naturalness of the material.

- High sound and heat insulation.

- Wear resistance.

- Resistant to moisture.

- Can also be used for laminate and carpet.

Minuses:

- High price.

Insulation technology

Before laying insulation under linoleum on a wooden floor, you should prepare all the required materials and tools.

To work you need:

- insulation isolon or penoplex;

- linoleum backing made of natural materials;

- plywood or fiberboard sheets;

- polyethylene film;

- Scotch;

- fastening materials (screws, glue);

- screwdriver;

- knife;

- scissors;

- jigsaw.

After that, you can proceed directly to the warming process:

- First you need to inspect the surface under the top layer of the deck. For this you need to remove it. If the boards are good, then insulation can be done from this level.

- The substrate is being laid. It is better to make a choice in favor of natural materials, as they are safer. However, there are also disadvantages here: rapid abrasion of such substrates and the appearance of insects are possible. Also, when choosing a substrate, you need to take into account its thickness so that it does not work out, so that because of it the floor level will rise so much that it will be impossible to open the door.

- So that in the future there are no problems, an isolon or penoplex is laid on top. All existing sheet joints must be glued with construction tape.

- The next layer is plywood or fiberboard. Next, everything must be fixed with self-tapping screws.

- If fiberboard is selected, then waterproofing should be performed to prevent its swelling. To do this, first a polyethylene film is laid, then a fiberboard is laid on top, which must be primed, a film is laid on top again (in more detail: "How to lay fiberboard on the floor under linoleum correctly").

To prevent water from getting on the lower layers of the floor, you should choose rectangular skirting boards for linoleum.

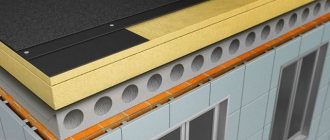

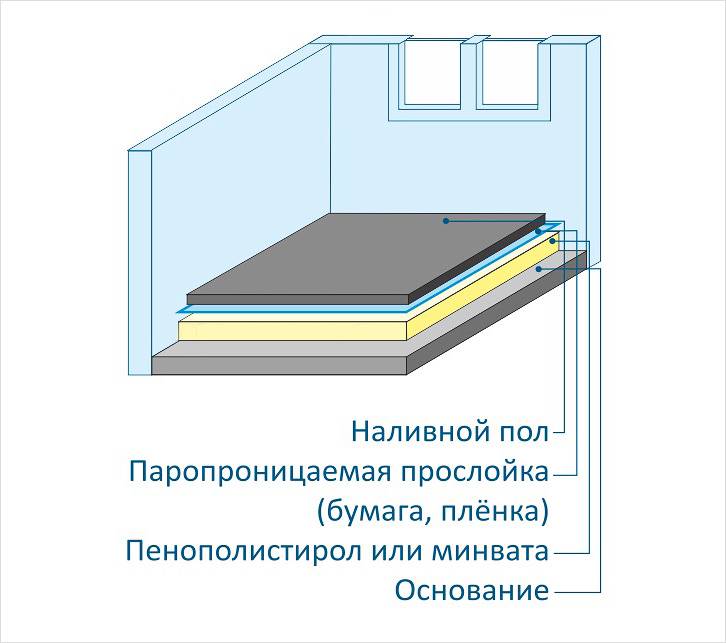

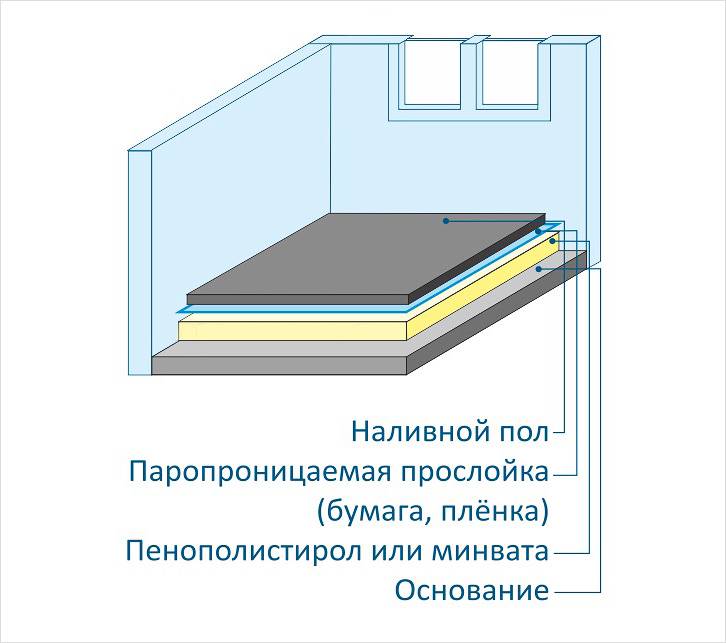

Expanded polystyrene for linoleum

Floor insulation scheme with expanded polystyrene

Expanded polystyrene has a porous structure, which is a great advantage.

Method of installing expanded polystyrene under the screed:

- Expanded polystyrene can be laid on concrete or ground. When laying on the ground, the surface is covered with crushed stone and sand in layers of 10-15 cm.

- Expanded polystyrene plates are laid out.

- Beacons are being installed.

- A screed with a thickness of 5–8 cm is poured.

Expanded polystyrene plates can be fixed with nothing

Benefits:

- High thermal insulation.

- Durability;

- High heat and sound insulation.

- Safety.

No waterproofing required

Disadvantages:

- Flammable material.

- Poor air permeability.

- Housing for rodents.

Video: floor insulation with expanded polystyrene

Warming the floor and laying linoleum in the corridor

The article describes the stages of work on warming the floor surface, using fiberboard and foam sheets, and laying linoleum. All stages of work are shown step by step in the photo in order to clearly demonstrate how to properly insulate the floor and lay linoleum.

All the work that is indicated in this article was carried out with his own hands in a private house of Soviet construction. The basis for linoleum was originally a wooden floor, which lost its appearance, thermal insulation and ceased to perform its basic functions.

The corridor is located at the entrance to the house and is a small room with an area of 2 by 2 meters. Given the small size of the corridor, the work is complicated by the fact that it has three doors.

When carrying out work, it is better to remove all the doors if they exist and interfere with the work, as in my case.

Materials (edit)

For floor insulation and linoleum laying in the corridor, you need to purchase the following materials:

- linoleum;

- penofol (insulation with foil);

- fiberboard sheets;

- plastic skirting board;

- plinth fittings;

- metal sills;

- screws, nails, tape.

How to insulate a wooden floor for laying linoleum

More often than not, we insulated the walls and did not pay attention to the floor ... but in vain! Heat escapes through the floor no worse than through the walls. The first step is to remove the old floor covering, if any. I immediately put linoleum on the wooden floor, which over time sold out and broke.

The floor in the hallway was very cold, because cold air was coming from all the cracks and holes. The skirting boards were wooden under the linoleum, which was simply laid on top. This linoleum has served for seven years, which is not bad enough, but nevertheless I drew many conclusions from my previous mistakes and decided to insulate the floor before laying the new linoleum.

I approached the choice of linoleum, too, more seriously than the first time. I chose linoleum with a dense surface (about 3 millimeters) and insulation below. Such linoleum will be less prone to punctures, deformation and other damage. Laying linoleum is a simple process, following the link you will find interesting tips.

After removing the old floor covering, I immediately removed the wooden skirting boards so that they did not interfere with the laying of linoleum and floor insulation.

For my corridor I needed two sheets of fiberboard. One was not enough, and two were many. But it's better to let the material remain. The thickness of the fiberboard sheets is 3 millimeters. You can take a thicker one, but then you will have to cut the doors, of which I have as many as three. Therefore, I took a not very thick sheet of fiberboard.

Cut the fiberboard sheets to the size of the floor. This can be done with an ordinary garden pruner or metal scissors.

A sheet of fiberboard can also go over the sills, if they are level with the floor and do not protrude, like mine.

Prepare tools and nails to secure the fiberboard sheets. (photo 6) Nail the sheets of fiberboard, which have already been cut to the required size and laid on the wooden floor.

Penofol (insulation with foil) is sold in meter width, and you can buy the length as you need. I got four meters. In general, penofol is not an obligatory component, you can safely use thin foam, as in this photo report. Put penofol on the attached sheets of fiberboard. In the center, fasten two strips of penofol with wide tape.

The base for linoleum is ready, we proceed to laying the linoleum.

How to properly lay linoleum on an insulated surface

Cut linoleum to the size of the room, taking into account the size of the sills. Lay out linoleum and level.

The joints of linoleum with the surface of the floor of other rooms should be fixed with a special metal sill, as shown in the photo. Screw the straps to the floor with self-tapping screws.

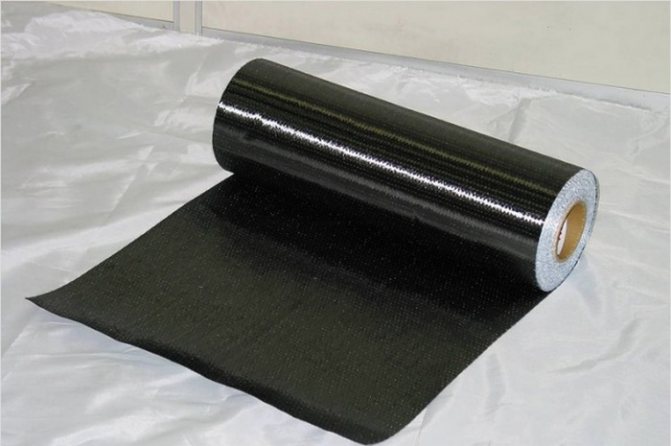

Covering the floor with a jute backing

Jute backing for linoleum

Jute backing consists of primary refined fiber.

Pros:

- Naturalness.

- Heat and sound insulation.

- Coating strength.

- Smoothing out concrete imperfections.

- Durability.

- Easy to install.

Minuses:

- Expensive.

- Sagging under the influence of heavy objects exerting a load over time.

Types of substrates

To insulate the floor for linoleum, you first need to choose a substrate. There are several types of such material. Here are the most popular ones:

- cork;

- jute;

- linseed.

Let's consider each separately.

Cork backing made from pressed crushed cork oak bark. Such insulation is produced in rolls. The advantages of this material include:

- environmental friendliness - made from natural cork;

- pleasant sensation when walking on this surface, as it is quite soft.

It is because of the last given positive quality that a problem may arise: if you put a heavy object on the coating, then after a while dents may form on it. To avoid this, choose the toughest cork backing.

Jute backing Is a material that is 100% natural jute fiber. It is made as follows: jute fibers are pierced with a needle, then rolled on rollers under the influence of high temperature. This backing is fire, mildew and rot resistant.

Linen backing Is 100% pure natural linen. It is made by double punching with a needle and then impregnated with anti-fire and anti-fungal agents. Linen backing is a good material for thermal insulation under linoleum.

Foamed polyethylene: insulation under linoleum

Foamed polyethylene

Foamed polyethylene has a closed-porous, lightweight and elastic structure. A certain degree of insulation can be provided by dense and fairly thick types of foamed polyethylene. If you buy an inexpensive thin substrate with large cells, it will not cope with the tasks assigned to it.

Pros:

- It is not toxic.

- Moisture resistant.

- Easy to install.

Minuses:

- May wrinkle under load.

- Only dense and thick types of substrate can be used as insulation.

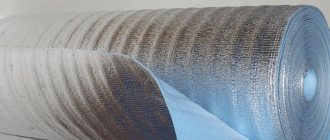

Foil insulation

Foil insulation consists of a foam base and a reflective foil surface.

The installation technology is very simple. The material is rolled over the surface. The joints are sealed with aluminum tape.

Material advantages:

- Reflectivity.

- Resistant to temperature extremes.

- Easy to install.

Disadvantages:

- Cannot be used for finishing with building mixtures.

- Additional insulation is required.

Preparatory and basic work

No special tools are required to mount the substrate. First of all, before carrying out work, it is necessary to clean the surface on which the material will be laid. To remove debris and dust, it is better to resort to using a vacuum cleaner, after which it should be washed.

It is not required to level the floor under linoleum additionally without the need, but if the surface has significant defects, then it is better to pour a concrete screed, for which a leveling compound and a rule are needed.

If the insulating material is laid on an old wooden floor, then before carrying out installation work, it is necessary to lay sheets of fiberboard or plywood on it and only after that put the substrate under the linoleum. To avoid swelling of the fiberboard, a plastic wrap should be placed under it.

In the course of the work carried out, in addition to the most selected and purchased insulation material, it is necessary to have:

- knife;

- scissors;

- masking tape.

In other cases, you may need plastic wrap, sheets of plywood or fiberboard, as well as screws and a file or an electric jigsaw.

If the installation of the linoleum substrate is carried out on a warm floor, then you need to acquire an additional thermostat and a temperature sensor.

When laying the substrate on the parquet without using plywood or fiberboard, the first step is to sand the sharp sides of the workpieces.

When installing insulation under linoleum on a concrete base, the installation must be performed with exact placement along the length of the floor. In this case, the substrate needs to be cut into strips and laid. Basically, this uses a floating method, during which the material is not fixed to the floor. Laying the roll substrate must be done joint to joint along the surface of the base, using masking tape to fix the strips together.

Note! Natural insulation is required to be placed on the base only after preliminary laying of a protective film on it.

Insulating paint should be applied with a spray gun, roller or paint brush. The layer thickness should be up to 1 mm. For a good result, it is necessary to carry out the autopsy three times.

It is possible to lay linoleum after warming after a day, but at the same time the joints of the substrate should not coincide with it.

Floor insulation with plywood

You can perfectly insulate the base when laying plywood on logs, which can be ordinary or adjustable. The latter are more comfortable to use if there are irregularities on the floor surface. If they are insignificant, then it is enough to place ordinary logs, since the present drops can be removed by placing pieces of chipboard, OSB or boards.

Note! This solution is suitable for rooms with high ceilings.

If the concrete base has optimal evenness, then laying the log can be avoided, but only if the room is heated in frosty winter period.

Installation of a plywood floor is carried out as follows:

- On a concrete base, it is required to lay the logs with a distance of 40-60 cm between them. To fix them, you need to use dowels or anchor bolts, checking the evenness of the horizontal position using a building level.

- If the selected insulation material does not tolerate moisture well, then you need to place the waterproofing.

- At the next stage, it is necessary to lay the insulation between the lags.

- Next, it is required to cut the plywood into square blanks and lay them in compliance with minor gaps between the sheets and near the walls, using self-tapping screws as fasteners, the caps of which should be slightly recessed into the wood material.

- Upon completion of the installation, it is necessary to cover the joints and caps of the screwed fasteners with putty.

At the end of the above steps, you can start laying linoleum. It is important just before that to choose not only high-quality material, but also to familiarize yourself with how it should be laid.

Having learned how to insulate the floor under linoleum, it will be possible to choose the most optimal option from a number of available substrates and insulation, and then it is quite easy to install any of them with your own hands.

Video:

Thermal insulation paint for insulation

Heat insulating paint

The components of the paint are: water, acrylic dispersion, additives of fiberglass, perlite, foam glass or ceramic microspheres.

Paint is applied to the surface with a thickness of 2–4 mm with a spray gun or a paint brush. The thickness of the paint layer affects the effectiveness of the thermal insulation.

Pros:

- Resistant to high temperatures and atmospheric influences.

- Low heat dissipation.

- Ability to last up to 50 years.

- Does not require special equipment for application.

- Thermal insulation.

- Corrosion protection.

- Fire resistance.

Minuses:

- Cannot be used as a primary heat insulator.

- The high price of paint.

Video: technology of using thermal insulation paint

Waterproofing for insulation

Various waterproofing materials are used to provide the required level of protection.

To provide the required level of protection, various waterproofing materials are used. It is especially important to cover the sub-floor so that the surface lasts a long time and guarantees the desired level of comfort and use.

Types of floor sound insulation in an apartment, materials and installation technology

The types of work differ in their properties and technologies. You also need to pay attention to the simplicity of execution, the financial component and the area of the premises.

Coating insulation

Made on the basis of oxidized bitumen resins with the addition of organic solvents

It is made on the basis of oxidized bitumen resins with the addition of organic solvents and inert fillers. The additives are crumb rubber, plasticizers or latex, which make it possible to achieve the plasticity of the coating. Possessing high adhesive properties, mastics fit perfectly on any base, while the use of reinforcing fiber for the screed will further increase the resistance to abrasion and deterioration. Coating insulation minimizes the appearance of shrinkage cracks in concrete, which means that a screed insulated with expanded clay will serve as a subfloor indefinitely.

Okleechnaya

Performed on the basis of bituminous resins, but using roll materials

It is also made on the basis of bituminous resins, but using roll materials reinforced with fiberglass fabric, polyester and enriched with modified polymers. Ease of use is that the material has a self-adhesive base and therefore does not require fusing. Affordability also makes this method better than others.

Important! The use of combined techniques to create waterproofing will better protect thermal insulating compounds in rooms with high or high humidity.

Paint shop

The technique is suitable for wood and concrete floors, on which it is planned to lay heat-insulating material with absorbent properties

The technique is suitable for wood and concrete floors, on which an absorbent thermal insulation material is supposed to be laid. It consists in processing with bitumen or polymer varnish. An effective but short-term protection method. The maximum service life is no more than 5-7 years.

Cast

Cast waterproofing is most often used for monolithic concrete foundations

Most often used for monolithic concrete foundations. Bituminous mastic and mortar are used; cold-type mastic is better suited. For work, preliminary priming of the base is required, installation of a low-height fence and long-term drying with leveling of the filling layer.Therefore, it is useful to apply the technology only on large areas.

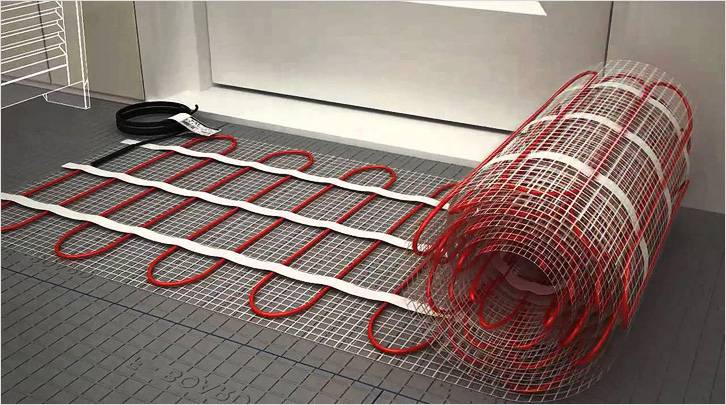

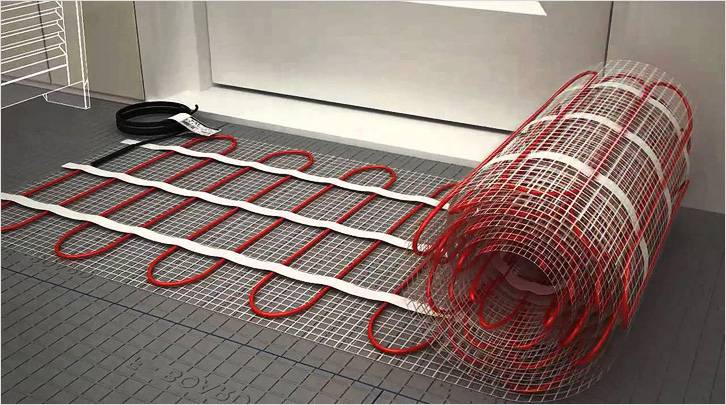

Warm floor

Water heat-insulated floor

In addition to the above options, underfloor heating systems are widely used to insulate cold substrates for linoleum. They can be water or electric. Thanks to such a system, you can provide a comfortable temperature regime.

Advantages of water systems:

- Creation of a comfortable temperature.

- The ability to adjust the temperature.

- Profitability.

- Safety.

Disadvantages:

- The possibility of breaking through pipes with a coolant.

- Time consuming installation.

Video: instructions for installing a warm water floor

Electric underfloor heating

Benefits of electrical systems:

- Does not dry the air.

- Warms up quickly.

- Long lasting.

Disadvantages:

- Increased power consumption.

You can use any of the insulation methods you like. Each of the insulation options can be mounted independently. If you have any questions, you can ask them on the site.

Video: installation of a cable electric floor

Types of heaters

It is recommended to insulate the floor with penoplex or isolon.

Penoplex under the linoleum levels the floor and prevents material tearing

Penoplex or extruded polystyrene foam is a heat-insulating material with a porous structure. It is easy to use - the slabs are easily cut with an ordinary knife. Possesses high heat and sound insulating properties. The material is safe and durable.

Izolon or polyethylene foam is not foil-clad and foil-clad. The foil can be on one or both sides. Such insulation has high rates of steam and heat insulation, waterproof, safe, durable. In addition, the price of isolon is low.

Another way to insulate the floor under the linoleum in an apartment or in a private house is the "warm floor" system. There are the following types:

- water;

- cable;

- infrared.

The best option for a warm floor for placement under linoleum is infrared. The film system takes up little space. The warm floor is laid on a substrate, covered with moisture-resistant plywood on top. This is followed by the flooring.

IR film for linoleum on a wooden or concrete floor allows you to maintain a comfortable temperature in an apartment or in a private house. In the same way, you can insulate the balcony.

Helpful tips for choosing

If you have never encountered such coatings before, then you probably do not know which one to choose. Next, we present to your attention a few clever tips that will help you.

- In rooms with high humidity (especially a bathroom), models based on felt or jute cannot be used. They are "afraid" of moisture, so pretty soon the warm base will rot.

- If high physical activity is expected on the floor, then it is better to purchase a model on a foam basis.

- When combining several models in one room (for example, to divide it into working areas), take into account their thickness - it can be different.