Is it possible to connect the warm floor to the boiler or not?

When constructing water heating floors, owners of apartments or private houses should:

- make a structure that will warm the air in the room to the required level;

- choose a profitable option in terms of installation and operation, which is inexpensive.

First, we suggest that you find out the device and principle of operation of a water heated floor and the possibility of combining the system with various devices (radiators, three and two-way valves, etc.)

Gas or electric boilers are used to heat the coolant. More often, gas-fired boilers are installed in private buildings. Such equipment cannot be installed in apartments with central heating.

In addition, a special permit is required for connection to a common heating system. Therefore, there is a need to find an alternative method - such is the arrangement of an electric boiler.

Boiler - a device for heating water from electricity for domestic purposes. But it is worth noting that initially it was not intended to heat the liquid for underfloor heating. Therefore, this will be an additional load for him, as a result of which the water heater may fail.

However, it is still possible to supply the floor from the boiler, but it will not work to heat large areas in this way. This option is ideal only for a bathroom or toilet.

For your information! The correct calculation of the load on the electric heater is important.

Invisible connection moments

In order for the structure to work completely, during the design and connection, it is necessary to take into account the following invisible moments:

- placement of an electric water heater - it is better that it is close enough to the heated room;

- difficulty heating circuit - the longer and more difficult the pipe contour, the very slowly water flows through it, therefore, the heat loss increases;

- the power of the electric water heater must exceed the calculated energy consumption by 15-20%;

- with the aim of improving working efficiency heated floors it is recommended to connect a circular pump to the system.

At the same time, it will be necessary to provide for a very high load on the boiler. Thanks to this, he needs to arrange regular prophylaxis.

Circular pump

It is not very difficult to make underfloor heating from an electric heating water heater. He will be able to ensure sufficient heating of the room, and the work on the installation process of the system is the most simple. However, it is necessary to take into account the low power of such a device and rely on heating small areas.

Types of boilers

Water heater is an electric boiler equipped with a tank in which heated liquid is accumulated. For domestic purposes, constructions up to 100 liters are used, and for industrial purposes up to 300 liters. For the arrangement of underfloor heating, an industrial type is recommended.

By their design, boilers are flow-through and storage.

Flowing

Flow-through - a compact tank with a square-shaped tena, which is connected to a cold water supply. When turned on, the water heats up almost immediately. The power of such heaters is 6 - 10 kW, so they put a heavy load on the power grid.

An instantaneous water heater is not suitable for underfloor heating.

Cumulative

A storage heater is a container with two bodies, between which a protective layer of heat-insulating material (polyurethane foam) is placed. Outside body - enamelled steel.

The inside of the flask has a glass enamel coating, the process of its application is spraying, which makes it possible to obtain a smooth surface on which scale does not form. In addition, the enamel does not react to salts present in the water and does not corrode.

Some models have an internal coating not of glass enamel, but of glass porcelain - the surface is of high quality, but cracks may form upon prolonged exposure to high temperatures. However, manufacturers guarantee that the device will work without interruption for at least 10 years.

Another type of coating that is used for boilers is stainless steel with titanium, which can withstand high temperatures. A water heater with such a coating will last for more than one year.

Inside the tank there is a ten (in the form of a tubular heater), it heats the coolant. Ten is placed in a metal tube, this protects it from scale. In addition, the flask contains a magnetic anode - a rod with positively charged particles that neutralize the negative charge.

This helps to reduce corrosion build-up. The rod needs periodic replacement, as it exudes quickly enough. The water heater is equipped with branch pipes through which cold water is supplied and hot water comes out.

For your information! Today, models of electric water heaters with a volume of 250 - 300 liters have appeared on the market, which have been specially developed for use in heating systems. Their difference is in the location, and the size of the cross-section of the supply and return holes.

The standard power of storage models is 1.5 - 3 kW. The device is similar to a thermos, the water heats up and then slowly cools down, thereby maintaining a high temperature for a long time.

In addition, these types have a thermostat, which allows you to set the heating temperature required for underfloor heating. And when the required temperature level is reached, the boiler is automatically turned off, this contributes to the rational consumption of electricity.

In shape, boilers are horizontal and vertical. The vertical construction is recommended for the arrangement of underfloor heating.

It's important to know! To heat 15 liters of water to 60 degrees, you will need ten with a power of 1 kW, the heating time is 1 hour. A 100 liter tank will reach this level in 3 hours, with a power of 3 kW.

Features of electric boilers

In terms of the degree of autonomy, one of the key criteria, depending on which the boiler is selected, its electrical type is in the lead, due to the absence of combustible substances. Having automatic settings, it does not require human intervention, independently restoring the mode in cases of short-term power outages. It is also attracted by its reliability, compactness, and affordable price.

Arrangement with such a floor heating boiler does not require expensive piping, due to the initial temperature of the water, which is the heat carrier, at 25 ° C. It is enough to mount the collector to connect several circuits.

A modern electric boiler for a warm water floor has three types.

- Safe electric boilers operating on heating elements have already received recognition, since they have a fairly simple technical structure. The main weakness of this type of device is the short service life of the heaters, which is compensated by their low cost and simple replacement technology.

- Electrode boilers are a fairly new type of heating equipment that is distinguished by its durability. Compared to the previous analogue, they are more capricious, since for perfect functioning a certain composition of the coolant is required, which must conduct current.This is due to the principle of operation of such a boiler: between two electrodes under an alternating voltage of 50 Hz, placed in a liquid, ions begin to move with the release of heat. Positively charged particles move towards the cathode, and ions with a negative charge move towards the anode. The electrodes change polarity 50 times per second, so heating occurs quickly.

- Induction models are based on heating a conductor placed in a magnetic field. The role of the core is played by the boiler body in the form of a labyrinth through which water flows. Such a device is reliable, requiring only the control of the constant presence of a coolant in the system. The widespread use of induction boilers is limited by their high cost.

Environmentally friendly, not littering the atmosphere of the house with combustion products, the electric boiler is convenient because it can be placed almost anywhere. The only difficulty may be the need for local wiring. Among the disadvantages is an increase in energy consumption (consumption per 30 cubic meters ≈ 1 kW / h). In private households, where frequent power outages are possible, it is advisable to install a combined type, providing for the option of a reserve boiler with solid fuel.

The principle of operation of the water heater

The principle of operation of an electric boiler is mixing cold and hot heat carrier. Heated water rises to the top, and cold water is at the bottom, where it is heated.

The process of the water heater is as follows:

- The storage tank is filled with water through a special pipe. The inlet is equipped with a safety valve, it retains the liquid and does not allow it to flow back.

- The required temperature indicator is set on the thermostat, but not more than 80 degrees.

- The ten turns on automatically and water heating starts.

- Hot liquid rises up, and it is released through the intake pipe located on top of the tank.

- The coolant moves along the intake pipe into the floor pipeline.

Which boiler to choose?

For the construction of warm water floors, the model of a flow-through electric boiler is practically not suitable. The main disadvantage is the significant power consumption.

The only suitable option for underfloor heating is a storage water heater. When choosing the type of shade, attention should be paid to the power of the equipment, it depends on how intensively and quickly the heating medium is heated, as well as its volume.

For your information! Devices with a power of 6 - 10 kW are specially designed for installation complete with heating systems. Their main disadvantage is the high consumption of electricity.

When calculating the power of an electrical appliance, one should proceed from the fact that a water heater with a capacity of 1 kW is required to heat an area of 10 square meters, therefore, a household model of a boiler for underfloor heating is not suitable. It can only be used for small spaces - bath or toilet.

The second point that you need to pay attention to when buying is the volume of the tank. The greater the amount of hot coolant obtained, the less often the water heater will be periodically turned on in order to save the resource.

Features of the design of a warm floor connected to a boiler

When designing an underfloor heating system from a boiler, it is necessary to take into account:

- the size of the pipeline and the number of branches, the longer the circuit, the slower the circulation of the liquid;

- power of the heating element - if the size of the lower threshold of the heated room corresponds to the power of the boiler, then after a while the efficiency of heating the coolant may decrease, the way out is to buy a heater with a power reserve of 20%.

In addition, the system requires constant maintenance - periodic descaling of the storage tank and shade.This procedure will help keep the underfloor heating pipes in good condition and increase their service life.

It is recommended to connect the boiler in a bath or room that is located near the heated room.

And to increase the performance of the device, the structure must be equipped with a circulation pump.

Observing all of the above points, you can build a hydro-floor, which is able to provide heating to your apartment.

Features of the calculation of materials

When calculating materials, it is recommended to use ready-made tables of manufacturers of warm cable floors. In accordance with the calculation of the heat loss of each room, the total length of the wire per room and its laying step are determined.

If an infrared (film) system is used, the calculation is much easier: the number of elements is selected that will cover the entire required area.

When calculating, it is necessary to take into account the wire for connecting the warm floor from the meter, as well as the regulator to the system elements.

Attention! It is forbidden to directly connect the warm floor to an electrical outlet.

After calculating and determining the power of underfloor heating, the common electrical input is checked to withstand the load. If the input is insufficient, a replacement is made, and the necessary automatic fuses are mounted.

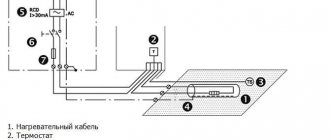

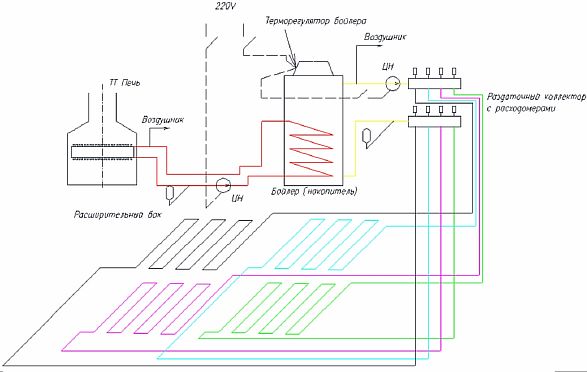

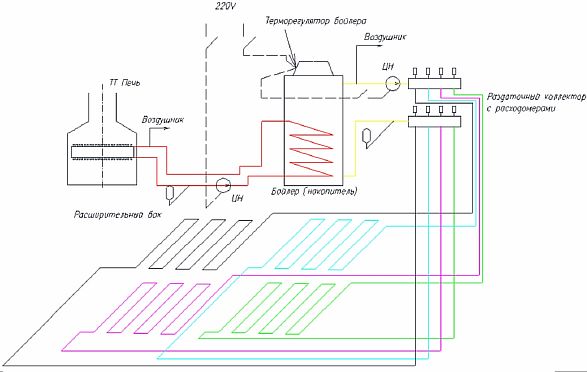

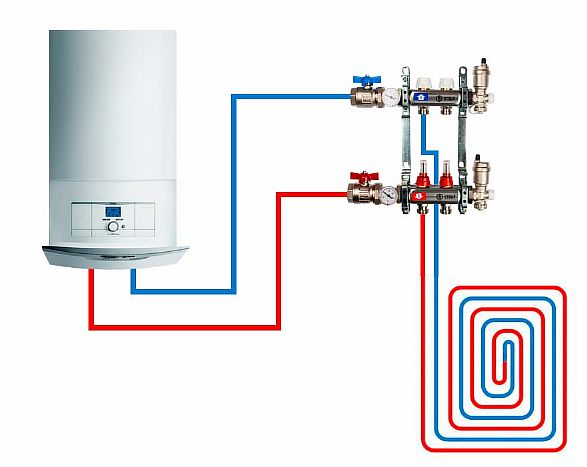

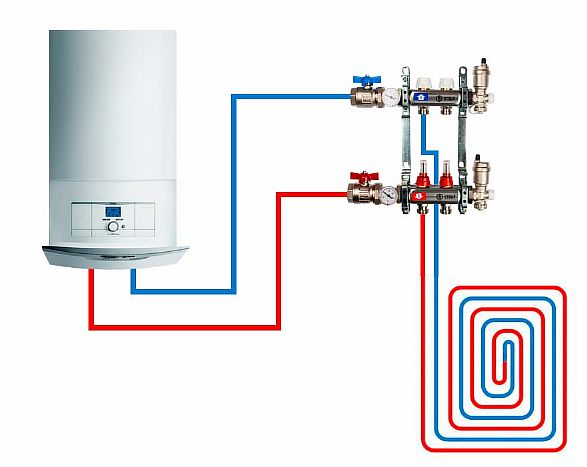

Connection diagrams of a warm floor and a boiler

There are several schemes on how to connect a warm floor to an indirect water heater. Let's consider the simplest ones:

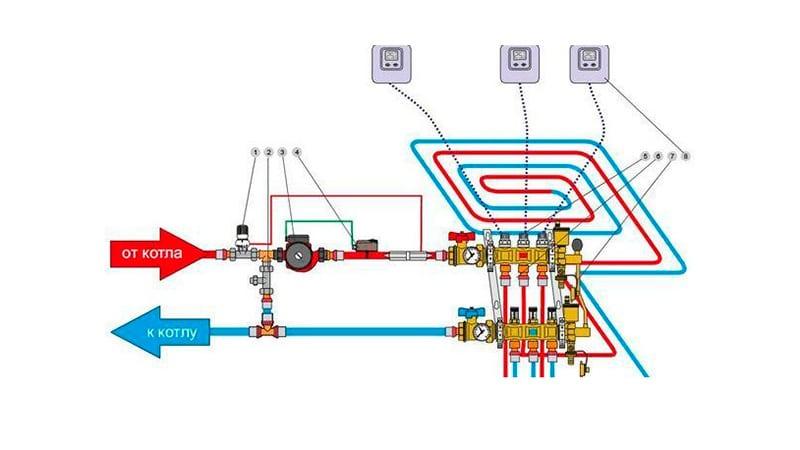

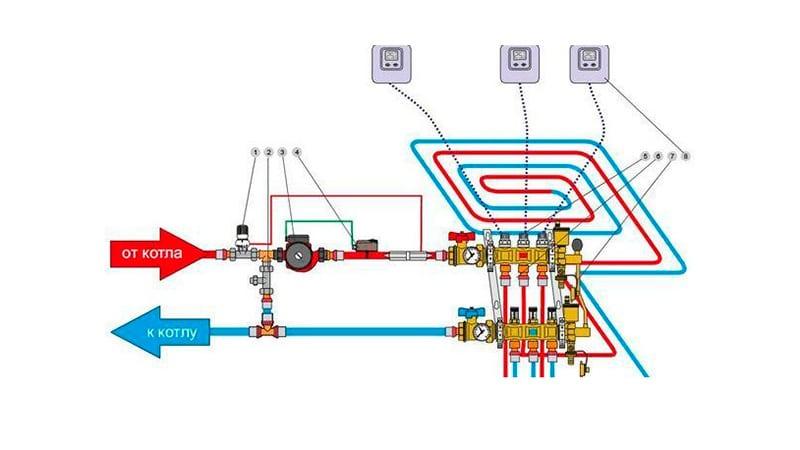

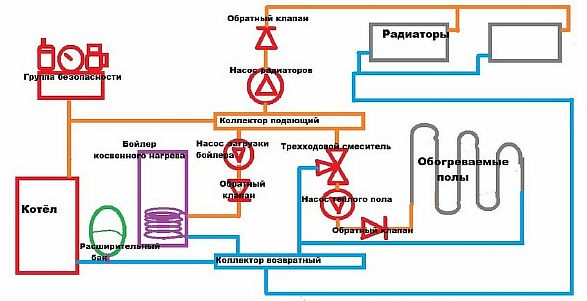

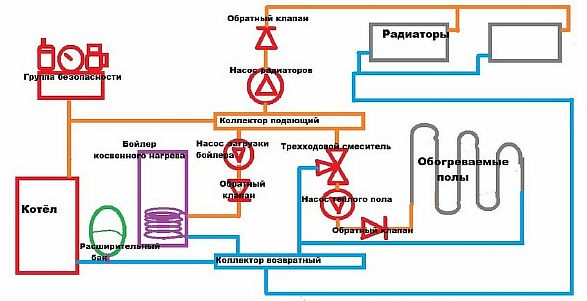

- With the help of a three-way valve - the essence lies in the interaction of two circuits: a warm floor and a water heater. This valve distributes the coolant between them. It is controlled automatically by a thermostat on the heater. Such a system contributes to the rapid heating of water in the boiler, while it is possible to completely turn off the DHW supply to the floor branches. And when the set temperature is reached, the valve is triggered and the flow is resumed. This strapping method is suitable for constant use of the boiler.

- With two circulation forced pumps - this option is recommended for non-constant, seasonal use of the device. One is placed on the supply pipe in front of the water heater, and the other on the floor contour.

A thermal relay is used to power the circulation pump, therefore it functions only when the temperature drops below normal. Heating is accelerated and forced circulation is activated. In this scheme, there is no three-way valve, and the connection is made using tees.

- Using a hydraulic switch - this method is recommended for boilers with a volume of 200 liters or more, and with several heating branches. The hydraulic distributor system makes the layout simpler and there is no need to install pumps on each floor contour. The hydraulic arrow provides equal coolant pressure in all loops. However, it is difficult to do the strapping with your own hands in this way, without experience.

Construction and connection of underfloor heating to the boiler

For clarity, we will consider how to make a warm floor from a water heater, using the example of using a 3 kW tena for heating an area of 30 m2, with the installation of a three-way valve.

We need a recirculation boiler with outlets to connect hoses for hot and cold water supply. The recommended diameter of the nozzles is 2.6 centimeters. In addition, you should stock up on the tools that you will need in your work so as not to be distracted during the installation process.

The sequence of construction of hydraulic floors from a water heater is as follows:

- Preparation of the rough base - it should be leveled and cleaned of debris.

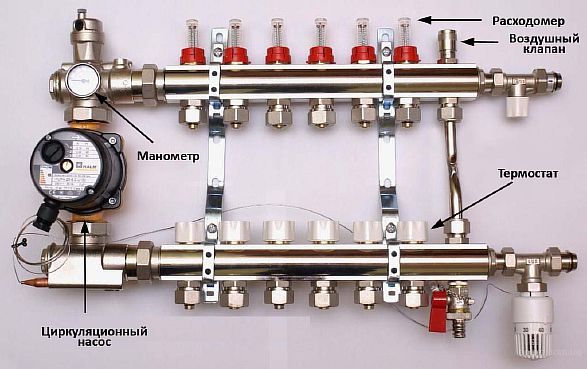

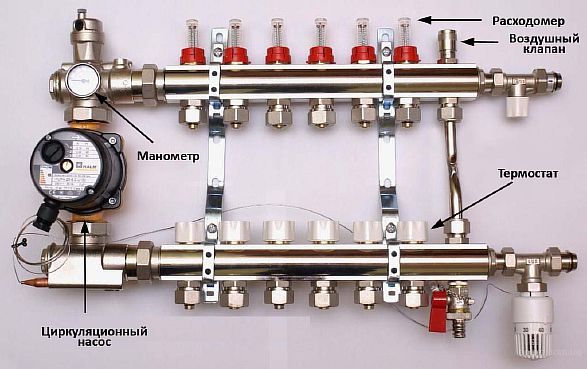

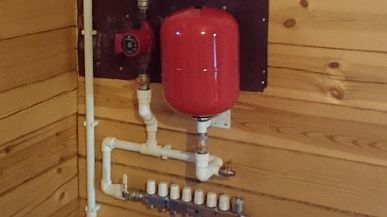

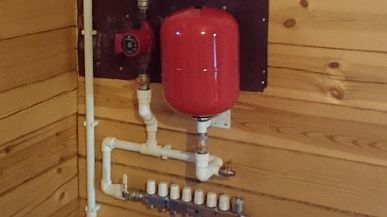

- Installation of the manifold assembly - it must be fixed on the wall, or mounted in a specially equipped metal box.

- Bonding the room around the perimeter with a damper tape - this will help preserve the integrity of the concrete screed.

- Hydro and thermal insulation - polyethylene film can be used as a waterproofing material. The choice of thermal insulation material is huge, from regular foam to expanded polystyrene mat with lugs.

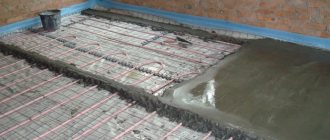

- Installation of the water circuit - it can be pipes made of copper, polyethylene or heat-resistant plastic. Heating elements are laid according to a planned scheme and with a set step. The pipes can be fastened to the reinforcing mesh, which is laid on the thermal insulation, with plastic clamps, or fixed between the grooves of the polystyrene plates.

- The connection of the circuit to the distribution manifold is one end to the cold tap and the other to the hot one.

- The connection of the boiler to the distribution unit is carried out using metal pipes.

- Installation of a three-way valve with a thermal head on the collector - to regulate the temperature level of a warm water floor.

- Connecting the circulation pump to the underfloor heating - it provides the flow and the required pressure of water in the floor pipeline.

- Installation of an expansion tank - it is necessary to remove excess water from the heating system. It should be mounted on a cold metal pipe near the outlet to the boiler. And in front of it you need to equip a tube for air outlet.

- System performance check - to identify possible leaks and malfunctions. Pressure testing is carried out within 24 hours under operating pressure.

- Pouring the screed - the floor contour is poured with concrete. The procedure is done when there is pressure in the pipes. The concrete layer must be allowed to dry well, this will take about a month.

- Laying the topcoat - it is laid only on a completely dried out concrete base.

It is possible to turn on the water system only when the screed, as well as the tile adhesive, if ceramic tiles were used as the flooring, are dry. Raise the temperature to working condition gradually, over several days.

The principle of operation of this circuit is to heat the water in the tank, then it is brought out through the collector to the floor circuit. The spent heat carrier is returned through the distribution unit to the return pipeline.

If the water temperature exceeds the required level, the three-way valve automatically shuts off the hot water supply and opens the cold water supply. The mixing process is carried out in a special chamber. When the coolant reaches the desired degree of heating, the thermal head closes the flow of cold water.

The heater and manifold are equipped with separate automatic temperature control devices. The device on the collector is responsible for the coolant in the floor line, and in the shade - for the water heating level.

It is possible to equip a warm floor from a boiler both in the house and in the apartment. Installation is not difficult, the main thing is to follow the technological process and instructions. In addition, the low cost of the installation plays an important role, because a water heater costs less than an electric boiler.

However, it should be noted that the operation of such a heating system is accompanied by a large consumption of electricity. Therefore, it is up to you to decide how to heat your house - with an ordinary radiator or underfloor heating from a boiler.

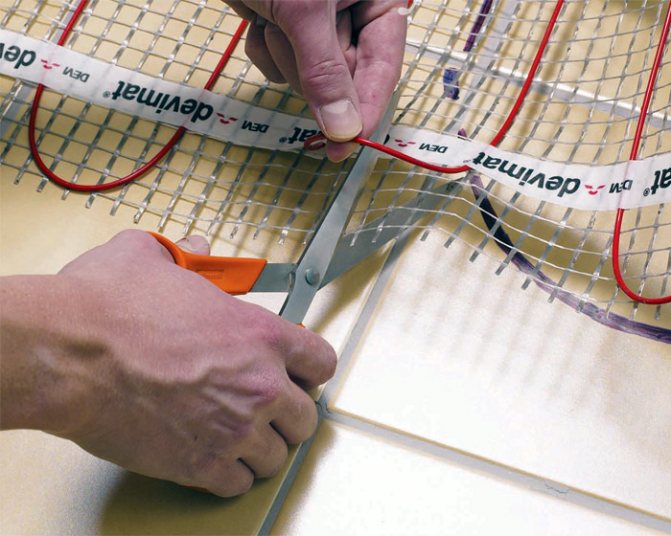

Electrolux heating mats

You rarely meet people who are satisfied with the temperature in the house in winter. During the cold season, most of them dress warmly even in their apartment and only dream of how to take off their sneakers and socks that have become hated. But technologies are developing faster and faster, and now things appear on the market that were even difficult to imagine a few years ago. One of the next useful inventions was the warm floor Electrolux.It allows you not only to maintain a comfortable temperature in the room all year round, but also has some properties that distinguish it from similar systems from other manufacturers.

Advantages of underfloor heating Electrolux

Electrolux products find their customers not only in Russia, but also in foreign countries. In order to better understand what caused this demand, it is necessary to carefully familiarize yourself with the various features of this system and evaluate its advantages.

Underfloor heating Electrolux consists of a steel cable on a stretchable base. The cable itself contains aramid strands, which are practically not subject to combustion and melting. And due to the fact that it is 5 times stronger than steel in strength, the resistance to stretching and all kinds of damage is improved.

Thanks to the textile backing, it is possible to increase the heated area by 35%, select separate zones with different degrees of heating and even create new styling patterns, including diamond-shaped and trapezoidal ones, in rooms of unusual configuration.

Do not forget that the Electrolux heating system is recommended to be used even in the bathroom. Moreover, among the advantages of the installation there will be not only a warm floor, but also a decrease in humidity.

We also note that this floor heating system is easy to install, does not need a concrete screed. Many independently cope with the installation of a warm floor. But still, if you are not completely confident in your abilities, it is better to call a master in order to avoid unfortunate consequences. Most often, there is no need to resort to professional maintenance, repair or replace certain components. But there is always the possibility that the heating system will fail. Fortunately, thanks to modern equipment, the malfunction is easily detected by special devices and quickly corrected without dismantling the floor covering.

It is important to take into account the insulation of all cores with fluoroplastic, as this improves wear resistance and electrical durability. The base of the mats is impregnated with a special glue, which ensures a secure connection and the absence of bubbles on the surface. The heating mat is only 3.5 mm thick and therefore fits any floor covering. And the floor temperature is easily changed by the thermostat and allows you to choose the optimal one.

Electrolux uses a new version of the thermostat with a touch-sensitive display. You can also choose between different modes: six for weekdays and two for weekends. Functions are also provided for those whose schedule differs from the usual, for example, 6 working days and one day off, or all 7 working days. In these modes, you can choose the temperature that suits you. The peculiarity of the "working" mode is that while no one is at home, the intensity of heating decreases and due to this, the consumption of electricity decreases, but a comfortable temperature remains.

For families with small children, a floor heating system is essential. How much effort it takes to get a child to put on warm socks when he so wants to run barefoot on the floor! But many can be stopped by the fact that the kids are very curious and always strive to click somewhere. It is for such cases that the Electrolux underfloor heating system provides an auto-lock function for the display. Therefore, you will be calm that no one will press anywhere and will not break anything, and your child will be satisfied.

Why choose an Electrolux underfloor heating system?

The main reasons why it is better to choose Electrolux from a variety of underfloor heating systems are as follows:

- uniform and rapid heating of all areas;

- the possibility of thermoregulation and the choice of various modes;

- durability;

- the possibility of fixing in any room by design;

- all products are certified;

- high protection;

- does not require repair;

- fire safety;

- not afraid of moisture;

- display auto-lock function;

- easy installation.

It is to be expected that this floor heating system from a multinational corporation producing appliances and professional equipment has a decent price. However, taking into account all of the above, we can safely say that in the case of a warm floor from Electrolux, the quality justifies the price.