Thanks to the widespread use of modern floor coverings, for a long time the popular wooden flooring has practically supplanted such a practical and affordable material as laminate. However, no matter how high-quality the floor is, without heating it will not add comfort either to a home atmosphere, or in an office or any other room. However, this problem is being solved today without any special problems: there are several options for autonomous heating. One of the most common is the electric underfloor heating under the laminate. You can familiarize yourself with the technology of installing a warm floor on our website, and in this article we will consider what kind of heat-reflecting material is suitable for laying a warm floor.

Why thermal insulation is necessary

The water circuit heats the floor surface due to thermal radiation, while the heating is directed not only upwards, but also downwards. Without installing a heat-insulating layer under a warm floor, a significant part of the radiation will be absorbed by a base made of concrete or wood. If a cold basement or ground is located under the room where the floor heating circuit is supposed to be installed, heat loss can reach 40%. If there is a heated room below, the heat loss will be about 20%.

A decrease in the efficiency of an underfloor heating system leads to an increase in energy costs. In addition, the boiler unit is forced to operate in the increased power mode, which is why it wears out faster. To avoid the problems associated with reducing the life of the equipment, as well as to reduce the financial costs of heating, it is necessary to insulate the base of the floor using a suitable insulation.

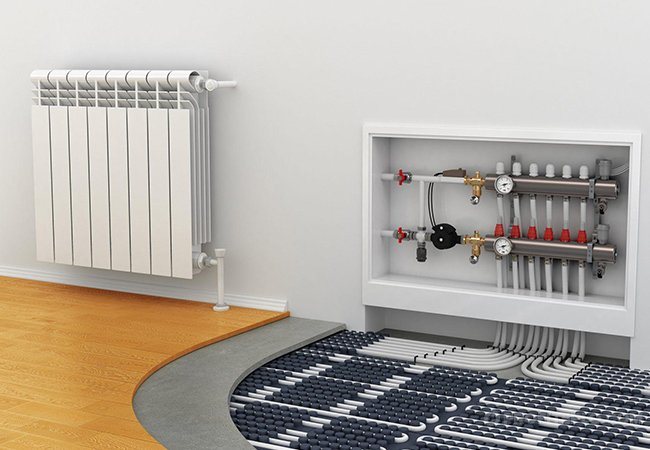

On top of the heat-insulating layer, which is mounted on a prepared waterproofed base, it is recommended to lay rolled foil material or immediately use a metallized-coated insulation. The foil reflects heat radiation upward, increasing the efficiency of the heating circuit.

Thermal insulation under a warm floor performs several functions at once:

- prevents heat loss through the ceiling and at the same time does not let the cold through from below;

- promotes the distribution of thermal radiation over the entire surface of the floor covering and, accordingly, uniform heating of the room;

- increases the inertia of the "pie" - after the boiler is turned off, the floor remains heated for a long time, this saves energy;

- serves as a sound insulator and dampens vibration, which increases the acoustic comfort in the house.

Expanded polystyrene smooth boards

Often the substrate for a warm water floor is made with smooth polystyrene foam plates for the underfloor heating system. Thickness - 4–5 cm, density - 40 kg / 1 m3, resistant to deformation. To protect the slabs from the aggressive effects of the concrete mixture, before pouring the screed, they are covered with plastic wrap. The pipes are easily attached to the slabs with plastic brackets.

Important

You can use polystyrene foam plates under a warm floor, which serves as the main heating of the room. The downside is the lack of markup on it. You will have to do it yourself before laying the heating circuit.

Advantages of expanded polystyrene boards:

- have a strong vapor barrier polystyrene foam layer, so condensation does not form;

- if there is a foil laminated coating on the plates, you can not be afraid to spoil the material with chemicals in the composition of the screed;

- easy to fit due to light weight and size;

- equipped with locks on the sides - there are no acoustic and cold joints when joining the plates;

- durable with proper operation - about 50 years;

- do not change the thickness under the weight of the screed.

Insulation thickness

On the Russian market there is a wide selection of heat-insulating materials of domestic and foreign production. When choosing a suitable option, you need to pay attention to the following parameters:

- the ability to withstand the loads from the heating circuit, cement-sand screed, flooring;

- resistance to dynamic influences that arise during the operation of the floor, and return to its original form after reducing the impact;

- health safety;

- resistance to biological damage (violation of the tightness of the circuit due to water hammer can lead to the development of fungus);

- fire resistance.

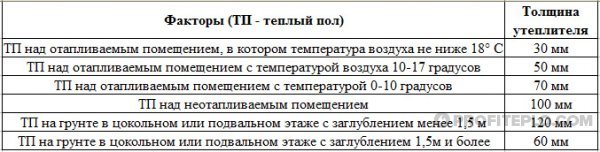

To correctly determine the required thickness of the thermal insulation layer, it is necessary to take into account the thermal conductivity of the selected material, as well as the intensity of heat loss through the ceiling in the cold season.

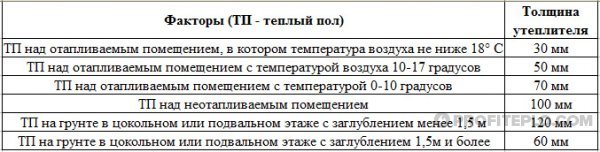

Information regarding the popular thermal insulator, expanded polystyrene, is presented in the table below. Based on the table, you can calculate the thickness for any insulating material if you know its thermal conductivity coefficient.

Insulation options for the underfloor heating system

To choose, it is worth having an idea of the different options.

Expanded polystyrene

In addition to retaining heat, thermal insulation also distributes it evenly over the surface and directs warm air upward. The most popular insulation option for a warm water floor is expanded polystyrene.

Usually it is realized already with applied foil and markings. This is a kind of foam plastic under a warm water floor. However, expanded polystyrene is more durable. It is made of dense materials. In rare cases, the material is presented with a laminated surface. It protects it from the negative effects of harmful chemicals.

Extruded polystyrene foam is a good insulation material.

Expanded polystyrene is available in various sizes. Since it consists of cells that are filled with air, it has high-quality sound insulation and low weight. In addition, the material is resistant to chemical and thermal stress.

A specialized master will easily select a product for thermal insulation according to the necessary criteria. For example, a ceiling with a thickness of 120 mm is laid on a cold basement, and between floors - 50 mm.

On the construction market, there are several options for expanded polystyrene under a warm water floor:

- smooth;

- foil;

- with grooves, etc.

To choose the right product, you need to build on not only the skills of the master, but also the price. The higher cost of the material guarantees easy handling. The cheapest option of expanded polystyrene is smooth. It can even be laid on gravel surfaces.

Manufacturers claim that smooth polystyrene foam is not hydroscopic, but it is recommended to lay it on a flat surface.

Important! Regardless of the thickness, expanded polystyrene under a warm water floor is fragile, therefore, it is recommended to lay a reinforcing mesh over the foil before installation. It helps to evenly distribute the weight of the pipes with the coolant over the surface.

Among the advantages of expanded polystyrene insulation, immunity to fungi and rodents is noted. For this reason, the product is considered durable and environmentally friendly.

Styrofoam

Polyfoam is a polystyrene foam insulation. It is effective for keeping warm in the water floor. Most often, the space between the wooden logs is filled with foam. They are attached to the bases of the boards. Next, a vapor barrier is attached, followed by a crate.This whole pie is sewn up with plywood sheets.

Laying of polystyrene foam boards.

The assembled structure is covered with a foil film. Only after that they begin to lay pipes. Such a cake is covered with sheets of GVLV. The last step is laying the flooring.

In addition, the system must be waterproofed. Styrofoam is not susceptible to getting wet, however, moisture that gets into it can worsen the thermal insulation qualities of a water floor. To protect the structure from rodents, a fine-mesh metal mesh is laid below.

Extruded polystyrene foam

This type of insulation is the most demanded in the thermal insulation market. It is produced by foaming solid polystyrene foam. This method is implemented in a chemical way. To effectively create foam, you need: a blowing agent, high pressure, the required temperature.

Foam insulation.

Carbon dioxide and freon are used as the blowing agent. During the production process, the size of the material increases 25 times. Then the resulting mixture is immersed in an extruder, where it is formed into blanks.

The production of extruded polystyrene foam for a warm water floor allows you to obtain insulation with air-filled cells. Their size is no more than 0.15 mm. The main difference between extruded polystyrene foam for a water floor and other types of insulation is the presence of these cells.

Mineral wool slab

The material is presented in two types: solid board and flexible mat. This type of insulation provides maximum heat transfer. Mineral wool is a fire retardant material. Empty spaces of premises for any purpose are filled with mineral wool. It will be an excellent insulator when installing a warm water floor.

Mineral wool.

Mineral wool is hygroscopic and therefore needs a good vapor barrier. For this reason, there are many basalt and fiberglass heaters on the market. This material is capable of withstanding high loads and is suitable for the first floors.

Foamed polyethylene - penofol

It comes in rolls and in various sizes. One side is usually covered with foil. Its thermal insulation qualities are in no way inferior to insulation made of cork materials.

Expanded polypropylene.

Penofol is suitable for insulating interfloor ceilings. For ease of installation, penofol is produced with markings applied to it.

Natural insulation - cork

The most important advantage of cork insulation is sound insulation. Natural materials are expensive, however, they provide a solution to two problems at once: heat and sound insulation.

In addition, cork insulation is fire and moisture resistant. It is resistant to decay. Also, cork material has a high level of strength. For this reason, the cork is used for thermal insulation.

Technical plug.

The beautiful texture and appearance allow you to leave it without using another coating. Then it is covered with a protective varnish, which in particular emphasizes its beautiful pattern.

Insulation made of cork in rolls with a thickness of 3-200 mm is realized. Thermal insulation with the maximum thickness of the insulation under the warm water floor is laid in one layer. However, it is not cheap (1 square meter of this will cost about 5 thousand rubles).

Material 200 mm thick is used for laying above the ground. If the floor of the first floor of a private house with a basement is insulated, then a thickness of 100 mm is taken. For intermediate floors, a layer of 50 mm is sufficient, and for an apartment building - from 10 to 30 mm.

Substrates reduce the level of thermal insulation. Each case is considered individually, since much depends on the selected material, as well as the area and purpose of the room.

Types of heaters under a warm water floor: pros and cons

Manufacturers produce a wide range of heaters that are suitable for use when arranging a warm floor. Thermal insulation for the floor is produced in the form of roll and slab materials, in addition, specially developed profile systems are on the market. It is worth choosing taking into account not only the functional parameters of the insulation, but also the features of the installation of the material and the system as a whole.

Roll materials

Rolled heat insulators (penofol and its analogs) are a foamed polymer material with a one-sided or double-sided foil outer coating. The advantages of roll materials include:

- small thickness (up to 12 mm), which makes them convenient for use in rooms with low ceilings;

- the presence of a reflective metallized layer;

- ease of installation - lightweight roll material is rolled out over the surface with a reflective layer up, cut to size with ordinary scissors, the joints are glued with aluminum tape.

Despite its advantages, roll materials are not without drawbacks. They reflect heat rays well, but poorly insulate the system from freezing from below. Laying in two layers with a shift is allowed so that the seams of the joints do not coincide. Penofol and similar materials with a metallized coating can be used in combination with a thin plate heat insulator, which will act as a cold insulating substrate. This will help to reduce the overall thickness of the "pie" in rooms under which there is soil or cold basement. It is important to know that aluminum foil is damaged in an alkaline environment when pouring a sand-cement screed. There are two ways to work around the problem:

- Use rolled material, the metallized surface of which is a foil protected by a polymer film, or made of lavsan with metallized inclusions.

- It is safe for aluminum to use a screed solution prepared on the basis of gypsum instead of cement.

Aluminum tape used for gluing seams must have a polymer outer coating.

Slab materials

Materials of this type are suitable for use in rooms with a ceiling height of 260 cm, since the thickness of the slabs “eats up” several centimeters. For the manufacture of rigid plates used:

- polystyrene (expanded polystyrene);

- extruded polystyrene foam;

- bung;

- mineral wool.

The most functional option is extruded polystyrene foam. It is characterized by high density and quickly regains its shape after high point loads. Expanded polystyrene material is not afraid of moisture, it is mounted with a continuous flooring under the screed. Polyfoam, unlike its "brother", is vapor-permeable and less resistant to deformation. It is recommended to mount the heat-insulating layer in the cells between specially mounted lags, closed with waterproofing. This will reduce the risk of destruction of the insulation under strong mechanical stress. The main advantage of foam is its low price. Cork thermal insulation for a warm floor is effective in its insulating properties, but it also requires installation between the lag and the arrangement of steam and waterproofing, since the cork is a hygroscopic porous material. In addition, it is important to consider that this is one of the most expensive materials. Rigid mineral wool slabs are suitable for insulating the subfloor under the underfloor heating circuit, but the fibrous material needs to be reliably protected against possible water leakage. In a residential area, mineral wool slabs of small thickness are laid. So that the insulation does not squeeze under loads, it is advisable to install the installation between the logs.

Penofol, energoflex and the like

Unfortunately, one of the most common materials used as insulation for a water-heated floor. This material is always in sight in most heating equipment stores.It is used by both installers and those who make water-heated floors with their own hands. The opinion is this:

♦ firstly, it is a heater;

♦ secondly - it has a reflective foil and directs heat upward;

♦ third - lightweight and fits into any car, even if you can bring it by tram;

♦ fourth - easy installation, rolled out and that's it;

♦ fifth - well, very cheap !!!

Let's say right away - this is the most unsuccessful option for insulation for a water-heated floor. Let's explain why. 1. The foil will effectively reflect heat when there is air in front of it. There is no such air in the screed. Everything is plump. 2. Mortar or concrete will corrode the foil very quickly. Take a look at the picture. A chipped piece of screed to which the foil from penofol is stuck.

The same piece of solution, only after three days:

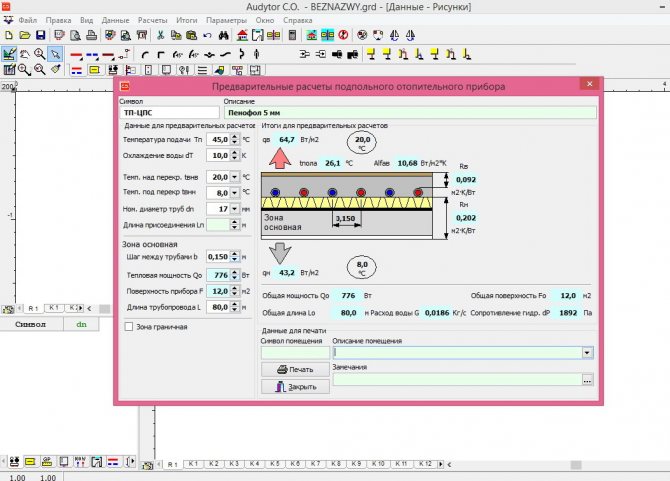

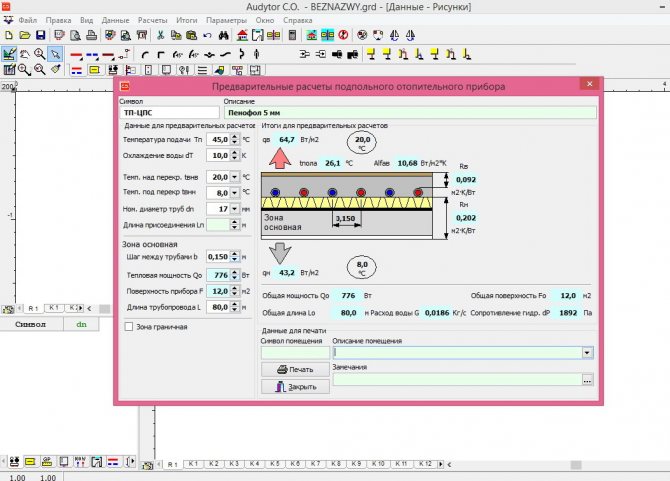

We think it's better not to experiment without comments or on yourself. There was no trace of the foil. Some may say that it can be covered with plastic wrap, and some manufacturers have already started producing such material with a film applied. Yes, in this case the foil will be protected and preserved, but the reflection effect will still not appear. 3. The thickness of the insulation. Most often, penofol or a similar material is used for laying under pipes of a water-heated floor with a thickness of 3.5 or 10 mm. Is this thickness enough? Let's say right away, you will lose heat to the ground. If you have main gas, it may not be very noticeable financially, but if you are heated with electricity, cylinders or diesel, then the amounts will not be small. We offer several calculations. The thermal conductivity coefficient of penofol ranges from 0.37 to 0.50 W / m * C. Filling with cement-sand mortar.

Calculation with a foam foam thickness of 5 mm

More than half of what goes into the room goes into the ground.

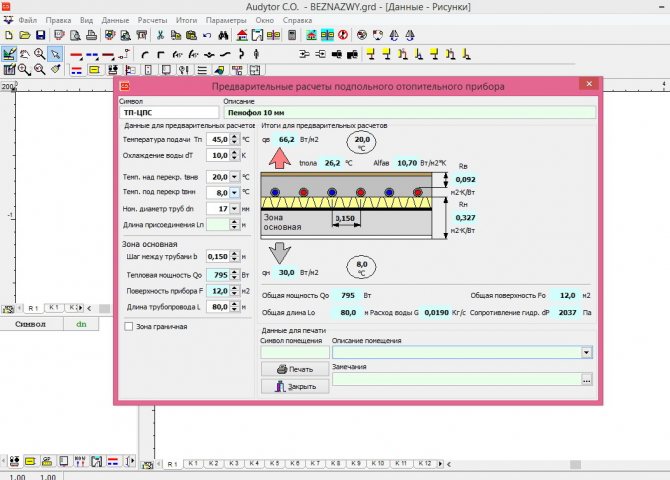

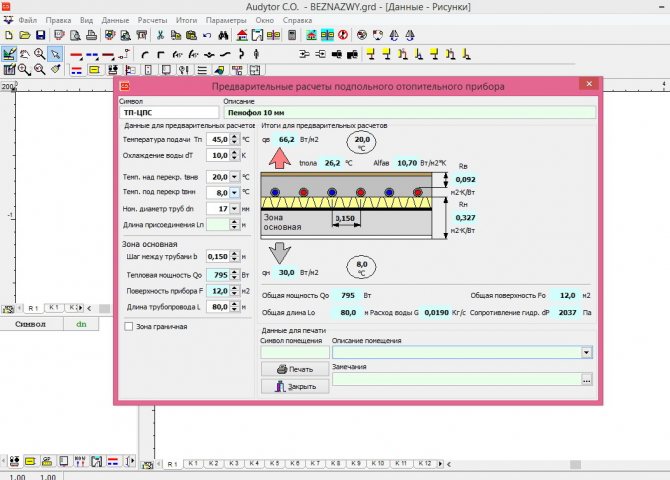

Calculation with a thickness of penofol 10 mm

Also big losses. When 45C is applied to the floor, 30 watts are consumed. Let's count and draw a conclusion. Every hour it takes 30 watts per m2. 30 * 24 * 149 = 107,280 W or 107 kW for the heating season. 24 - hours a day 149 - heating season in Krasnodar. In other regions, it can be much higher. Today, the cost of 1 kW of electricity is about 3.5 rubles. 107 * 3.5 = 374.5 rubles will cost each square meter, every year. That kind of money will be enough for any good insulation and will even remain, and next year there will be continuous savings. If you are pouring, instead of a cement-sand mortar, use a semi-dry screed ... This will be even greater loss of heat and your hard-earned money. And less heat will go up. We will get the most irregular and most wasteful floor heating in the world. Conclusion: penofol and similar materials cannot be used as the only insulation for a water-heated floor system. If you put, for example, extruded polystyrene foam under penofol, and roll out penofol with markings on top, for the convenience of installing a warm floor with a certain step, this will be correct.

Profile systems

There is a growing demand for specialized profile systems - mats made of extruded polystyrene foam. Hydropellet punching technology makes it possible to obtain panels of a certain size and profile. The panels can have a laminated outer skin. The profiled edges of the panels allow quick installation of a one-piece thermal insulation coating. On the front side of the panels there are special shaped protrusions, between which it is easy to lay the heating circuit pipes, without the need to use additional fasteners. This greatly simplifies and speeds up installation work. Profile systems are produced in the form of panels of various thicknesses - from 10 to 34 mm. Their only drawback is their high cost.

Conclusion on the topic

The need for thermal insulation of warm floors is obvious, but it is important to choose the best option for a heat insulator.Extruded polystyrene foam is considered the leader among heaters. It is practical and easy to install. If there is a financial opportunity, it is recommended to purchase a profile system, but ordinary board material has also proven itself well. Foam plastic is also in demand, but this is due to its cheapness. Roll materials have their own specifics, their use is determined by the height of the ceilings. Cork and mineral wool are not the most budgetary option, in addition, their installation is complicated by the need to provide reliable waterproofing to protect against accidental leaks of the circuit. If the floor heating circuit is electric, it is still required to insulate the floor in order to minimize heat leakage, but at the same time, the use of a profile system does not make sense, and there are no increased requirements for the protection of hygroscopic heat insulators.