25.08.2015

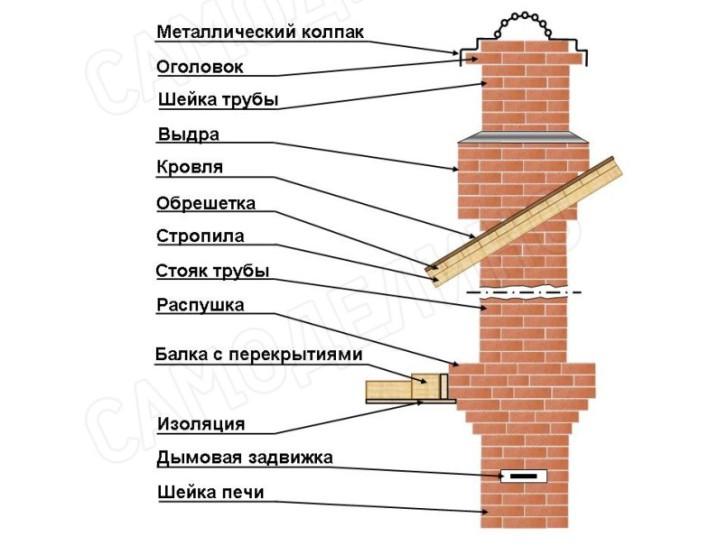

When planning the installation of a stove or fireplace in a house and connecting a chimney made of galvanized steel, you need to familiarize yourself with all possible options, as well as consider the strengths and weaknesses of each of them. For many centuries, brick or stone structures have been used for heating. We will not argue, they are still found now, but the creation of new materials allows the use of lightweight and reliable structures that meet standards and norms.

The most popular are high-quality steel products made of stainless steel or galvanized metal. But the topic of today's article is precisely a galvanized chimney pipe, its design characteristics, advantages and varieties.

Galvanized chimney pipe

- 1 About the main enemy - rust

- 2 Galvanized pipes 2.1 Video - Chimney sections

- 4.1 Option No. 1. Single-circuit products

- 6.1 Video - Installing a galvanized chimney

About the main enemy - rust

Corrosion is dangerous for all metal products. In particular, this applies to iron, because it is more susceptible to the negative effects of moisture and atmospheric phenomena. For this reason, designers are constantly developing new ways to protect against rust.

Note! Different steel alloys solve the problem only partially, but a zinc layer applied to the surface of metal products is an excellent barrier to rust.

They do it like this: steel is immersed in a molten mass, after which, by the action of special substances, iron combines with zinc and, as a result, a new protective ball is formed. The thickness of this layer is different, but not more than 60 microns. This technology both protects metal products and increases their service life.

Required tools

The soft and plastic material lends itself easily to bending, so galvanized pipes are made using simple tools:

- Manual scissors for metal. With this tool, you can effortlessly cut sheet metal, the maximum thickness of which is only 0.7 mm.

- A hammer with a soft head. This role can be played by a wooden hammer or a metal tool with a rubber pad on the striking part.

You need a wooden hammer to work

Note! A hammer with a metal striker is not suitable in this case. It can deform a thin sheet of galvanized sheet and damage the product.

- Pliers. Despite its softness, it is impossible to bend thin metal by hand.

In addition to tools, you will need equipment:

- Workbench, with the help of which the marking and cutting of workpieces is carried out.

- Calibrating element in the form of a steel pipe with a diameter of 100 mm or an angle with a side size of 75 mm.

Important! Calibration elements should be rigidly fixed, since they rivet the butt joint of future gutters or boxes.

In the process of marking blanks, one cannot do without measuring tools - a metal ruler, tape measure, square or scribe (a sharply sharpened steel rod with a hardened end).

Galvanized pipes

As many years of practice have shown, galvanized chimneys are many times superior to their stone and brick "competitors".As you know, when any fuel is burned, gases appear, which, when passing through the chimney channel, are cooled and condensed. And moisture already has a detrimental effect on both brick and metal, but the situation is aggravated by the presence of soot in it.

It contains acids that form oxide, which, in turn, leads to destruction of the walls of the chimney. From the inside, drips often appear, as well as roughness; soot and fumes "catch" on it. This causes a deterioration in draft, due to which gas enters the house through the combustion chamber and poses a serious threat to the health of people living in it.

The situation can be corrected by regular cleaning, but not for long, since the condensate cannot be completely eliminated. For this reason, experts use products in which condensation is minimized as a chimney. These include a galvanized chimney pipe.

Coaxial chimney, what is it?

Previously, we described the main advantages, technical characteristics and features of the installation of a coaxial chimney, we recommend that you read this article in more detail Learn more here

Video - Chimney sections

Chimney maintenance

Besides the correct installation of pipes, they must be properly maintained. It is very important to know how to clean the chimney from the deposits formed there. There are three main ways: ⦁ Mechanical... In this case, a special tool is used - a brush or a metal brush. For severe blockages, a heavy metal weight attached to a chain can be used. The chimney brush has been known for a long time and is still considered one of the most effective devices. It allows you to precisely regulate the force and control the movement along the chimney. If thick deposits have formed on the chimney, then before cleaning the chimney, a weight should be lowered there and, swinging it from side to side, knock on the walls of the chimney, which will cause the layers of soot to collapse, which should then be removed through the hole in the base of the chimney.

Chimney brush

Advice! All shutters must be closed before cleaning, otherwise a cloud of soot can enter the boiler room or other room where the boiler is installed.

⦁ Chemical. For this, special chemicals are used, produced in solid or liquid form. They must be added to the fuel used and burned in the firebox. Liquid formulations are used to impregnate the walls inside the chimney, which in itself prevents soot deposits. ⦁ People's. It can only be used for cleaning chimneys made of refractory bricks. To get rid of soot, a high temperature flame is ignited and maintained in the firebox, which leads to the complete burnout of the soot. In this case, the fuel can be potato peelings, aspen firewood or a special log - "chimney sweep". This is the easiest way to remove soot with your own hands.

Advantages of using galvanized pipes

The main advantage lies in the presence of the protective layer described above. We found out that when exposed to condensate, any metal begins to rust, and therefore the tightness of the chimney channel and the efficiency of its functioning are disrupted. But if the product is well protected from moisture, then it will serve much longer. Because of this, galvanized chimneys have become increasingly popular lately.

Note! High-quality sheet steel is used in the manufacture. Before shaping, it is immersed in a zinc solution, where a chemical reaction occurs under the influence of reagents. The protective layer created in this way is quite sufficient for a significant extension of the service life.

And chimneys made from this material have the following advantages.

- High heating rate and, as a result, almost instant traction. This allows heating appliances to work as efficiently as possible.

- Such chimneys include several modules, which, if necessary, are easy enough to assemble.

- Installation of products can be done on any heating devices. Simply put, their versatility can be considered another advantage.

- All galvanized pipes are fire resistant, which means they are fireproof. And this is especially true for wooden houses.

- The installation requires a minimum free space.

- A wide variety of variations.

- High resistance to condensation (especially against the background of brick analogs). Only chimneys made of "stainless steel" are more effective in this regard.

- Finally, thanks to the smooth surface, soot does not collect on the walls, making cleaning faster and easier.

Note! In the light of all of the above, we come to the conclusion that galvanized products are much better than brick products, and are inferior in quality only to stainless steel pipes. Consequently, their main advantage is considered savings (both on purchase and on installation work).

But remember that often saving on the quality of the purchased material is fraught with significant costs for maintenance and repair work.

Galvanized steel, its advantages and disadvantages

Galvanized steel is a type of steel that has undergone a special zinc treatment to protect against corrosion. The essence of the processing technology lies in the fact that cold-rolled carbon metal is immersed in liquid zinc. As a result of the chemical interaction of substances, the steel is covered with a thin anticorrosive protective layer (layer thickness up to 60 microns), which extends the service life of products made of such material many times over.

Galvanized chimney pipes have a number of advantages not only in comparison with a brick chimney, they are also inferior to tin pipes. This is indicated by the following parameters:

- The heating of the system and the overcoming of the cold plug occurs much faster than in the case of a brick structure; in a short time, a powerful thrust is created.

- Condensation resistance is good enough.

- The anti-corrosion resistance is higher compared to the easily rust-prone tin pipes.

- The galvanized structure does not need constant maintenance, regular cleaning from soot, unlike a brick building. Cleaning is carried out, but once a year. On the round and smooth inner surface of galvanized steel, in contrast to brick and rough, soot retains weakly.

- The versatility of the galvanized device allows it to be installed on equipment running on any fuel: gas, gasoline, wood.

- The construction of a galvanized chimney does not require a large installation site (in comparison with a brick chimney). Installation is so simple that it is available for DIY.

- The pipeline is fire-resistant and fireproof in operation.

- A variety of pipe configurations and modifications enables the consumer to choose a product in accordance with quality and cost.

- The product has a democratic price.

Of course, a galvanized steel chimney is many times superior to a brick one. But it is an order of magnitude worse than a construction made of stainless alloy steel, which includes chromium (12-20%), titanium or molybdenum, which form an increased metal resistance to corrosion even in an acidic environment. Despite the fact that the quality of stainless steel is superior to galvanized metal, completely chimney pipes are rarely made from it: this is too expensive material.

Classification of galvanized chimneys

The products described in this article are produced in two types - one- and two-circuit (with a layer of insulation). Let's get acquainted with each of them in more detail.

How to make a chimney cap on your own

Earlier we told you about how to properly install the hood on the chimney, we advise you to read this article additionally.

Option number 1. Single-circuit products

They consist of such basic components as pipes and other fittings (these include tees, adapters, various kinds of revisions, and so on). The most popular uses are as follows:

- use as an in-house chimney duct;

- use inside a brick chimney.

Such designs are not without drawbacks, the main of which are large volumes of condensate, especially when the heating system is connected to modern equipment with a low temperature of the exhaust gas and excellent efficiency. In order to eliminate this problem, the chimney is insulated or, as an option, the rate of condensation formation is reduced and heat loss is minimized.

As we just said, such a galvanized chimney pipe is often used for efficient and prompt repair of brick smoke channels. The purpose of this is extremely simple: instead of repairing half-destroyed masonry, a modular structure of the required size is mounted in the channel. A special mineral heat insulator is installed between the new element and the brickwork, which significantly increases the efficiency of the structure.

Note! The use of galvanized pipes from the outside is undesirable. But if there are no alternative options, then the pipe should be properly insulated.

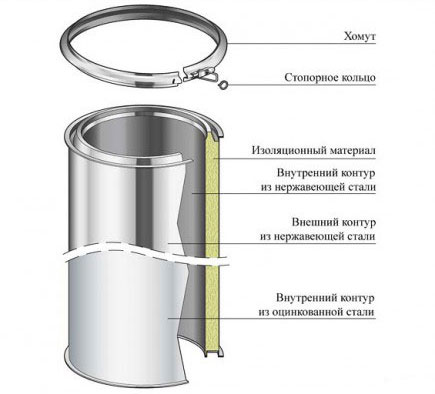

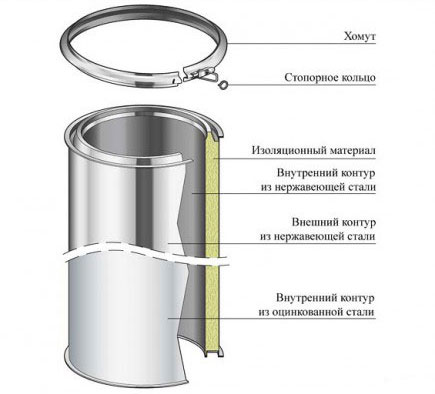

Option number 2. Double-circuit products

For obvious reasons, such designs are also called sandwiches. Of course, predominantly stainless steel is used for their manufacture, but galvanized pipes are also quite common, often due to their lower cost. There are several sandwich chimneys made of galvanized steel, consider them.

- Only the outer contour of the structure is galvanized, while the inside is a stainless steel pipe.

- Two pipes are galvanized at once.

And due to the fact that the bulk of the loads falls on the inner pipes, the material from which they are made should be at least 0.6 millimeters thick. If we talk about the outer pipe, then 0.5 mm is quite enough for it.

Note! The outer surface of the structure is covered with special heat-resistant enamel and powder coatings, which give them a more aesthetic appearance.

The described double-circuit chimneys increase the efficiency of heating devices, and also increase the efficiency of their functioning. Of course, metal pipes are not very aesthetic, which is why they are often not combined with the overall design of the house. But this kind of disadvantage is quite easily eliminated by brick laying along the contour of the structure (although any other material can be used for this).

Species variety of steel pipelines

- Single-circuit type. The system itself consists of the galvanized steel pipe itself and various fittings (shaped). These include tees, bends, gate valves, revisions.

- The double-circuit insulated chimney pipe, called "sandwich" due to its design, is produced in two versions: It consists of three parts: an inner pipe made of stainless, acid-resistant steel; external casing made of galvanized iron; insulation - basalt wool. High-quality, with a long shelf life and much cheaper construction than completely made of stainless steel.

- Consists of three parts. The first is the inner pipe, which will be subjected to a large thermal load, made of galvanized steel with a thickness of 0.6 - 1 mm (at least). The other is an external, also galvanized pipe, with a wall thickness of 0.5 mm. To give a better aesthetic appearance, the outer pipe is coated with special heat-resistant agents: enamels, powder coating.Polishing of the product is also possible.

Double-circuit chimneys contribute to an increase in the efficiency of heating devices, therefore it is advisable to install just such structures. True, it is necessary to work on the design of their visible part, to give it an aesthetic appeal. For example, build a chimney box from a profiled sheet with a polymer coating, or cover it with a brick.

Comparison of stainless steel and galvanized

As already noted, in some respects, galvanized structures are inferior to those of stainless steel. People who are poorly versed in this want to know which option is better and why. In order to answer the question, we will compare the most important specifications.

- The condensation resistance of stainless steel is higher than that of galvanized steel.

- In terms of fire safety, both options are not inferior to anything. They are, in other words, equal.

- In double-circuit versions of a galvanized structure, we recall that a heater is used. But sandwich chimneys made of stainless steel have not yet been manufactured.

- They have about the same warm-up time. Both designs provide good traction in record time.

- Finally, both options can be installed on any heating appliance. They are not oversized, so they take up little space. Their installation is extremely simple and quick enough. To do this, you don't even need to hire professionals, but do everything yourself!

As you can see, both options are good, but you will have to pay more for quality (read: stainless steel).

Benefits

If we talk about the price, then galvanized steel is an order of magnitude cheaper than a similar product made of ceramics or copper. At the same time, it does not require any additional maintenance during operation.

Video

At a time when chimneys from brick luggage become clogged very quickly, soot is quickly deposited on the porous structure of the brick, and it requires regular cleaning.

Galvanized pipes do not have such a problem; soot simply does not accumulate on a smooth surface and therefore does not require constant maintenance and cleaning.

If heating was not previously provided in the house, for example, in country houses, but with the onset of cold weather they decided to equip the dwelling with heating equipment, then the galvanized pipe for the chimney of the stove can be displayed outside the house along any of the walls.

Installation features

The diameter of a galvanized chimney pipe depends on a number of factors, including:

- heater power;

- number of devices connected to the system;

- the type of fuel used for heating.

If the purchase of a galvanized sandwich is too expensive for you, then you can make its own analogue. For this, the galvanized pipe is wrapped in a layer of refractory insulating material and all this is placed in another pipe, painted or also galvanized.

Note! If the structure consists of several modules, then with each part the diameter should decrease - this way moisture will not penetrate into the chimney from above.

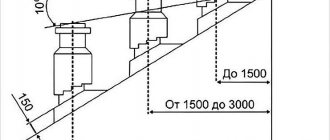

It is advisable to cover all joints with a refractory sealant. In the absence of any gaps, the traction will be excellent. In addition, the joints of the elements must be secured with clamps. For this, fixing brackets are installed along the length of the pipe in increments of about 150 centimeters (although this depends on the strength of the structure).

Note! If horizontal sections are planned, then know that their length should not exceed 1 meter!

In addition, when installing a galvanized chimney, fire safety requirements must be observed. This means that it must not touch the gas line, electrical wiring or combustible materials. If the structure was placed in a brick casing, then additional fasteners should be equipped in the attic to increase the strength of the chimney.Where the pipe connects to the oven, a hole must be made for cleaning and servicing the device (it will be closed during operation).

Video - Installing a galvanized chimney

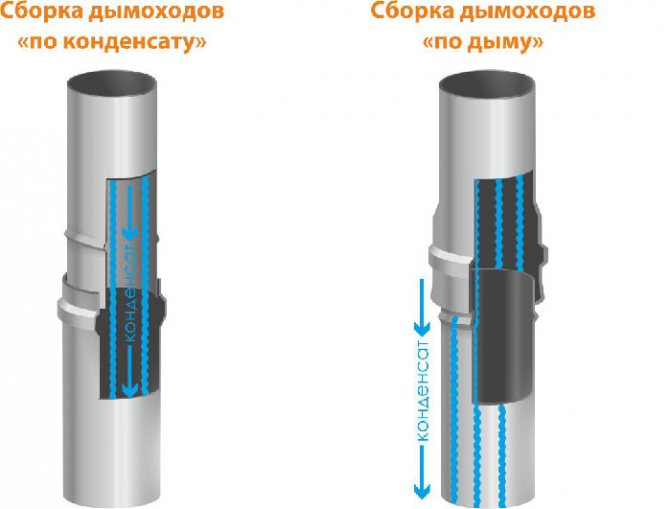

Features of the flue assembly

After preparation, you can proceed directly to the design of the system in the following sequence:

- The installation of the chimney pipe should be started from the heating unit, leading upwards.

- Gradually build up sections by inserting the narrowed part of the segment into the wider one.

- The joints of the modules should be treated with a refractory hermetic compound and connected with clamps.

- Install fasteners along the entire length of the pipe. The distance between them is determined individually, approximately 1.5 meters.

- Install an umbrella and a cover on top so that water does not get on the insulation.

The pipeline, as you can see, is easy to assemble. Although it is better to do this for professionals in order to avoid various unforeseen situations.

Of course, a galvanized steel chimney needs regular maintenance: cleaning from soot, sealing small cracks that may arise due to high temperatures. You can clean it yourself once a year. A cleaning tool should be used - a pole to which a metal brush is attached. The diameter of the bristles of the brush should be larger than the diameter of the pipe. Cleaning is carried out through the windows along the entire circuit of the system. Finishing cleaning, you need to treat the inner surface of the chimney with an anti-soot compound that prevents the formation of soot. Finally, heat the oven well.

Article Rating

Low resistance to mechanical damage

The galvanized coating on the pipes is not strong enough. In places of accidental impacts and other mechanical damage, pipes quickly begin to rust. Because of this, they quickly become unusable, which means that it is required to replace individual sections or repair the entire boiler chimney. During transportation, as well as installation, extreme care should be taken to avoid mechanical damage.

Service

In order for the operation of the stove to be safe, it is necessary to systematically carry out preventive measures, that is, check the chimney for cracks or burnt areas. Found faults must be eliminated by replacing the defective part of the pipe with a new piece.

To ensure good traction, timely cleaning of the inner space of the pipe from soot is also necessary. When using solid fuel (coal, wood), its accumulation occurs quickly. Cleaning and maintenance is carried out by burning special briquettes, aspen wood or mechanically.

do-it-yourself potbelly stove from Dimona

Making galvanized pipes with your own hands

The main feature of a prefabricated galvanized pipe is a reliable weld seam.

If you have an argon plant at home and you are a great welder, that changes the matter. Surely you will not get a pipe, but a feast for the eyes.

First, you have to choose a galvanized sheet for the pipe. Professionals make bends with walls 0.55 mm thick. At the same time, it must be borne in mind that the thinner the material, the easier it is to bend.

Required tools and materials

You will need:

- hand scissors for metal,

- mallet hammer with a wooden percussion part,

- roulette,

- square,

- metal ruler,

- pencil, better construction,

- pliers.

For the convenience of bending work, a simple workbench is equipped, where the markings are made. A metal corner (4040 mm or more) with a length of at least 100 cm, a steel round shape of the required diameter is fixed on the table.

Cutting out the workpiece

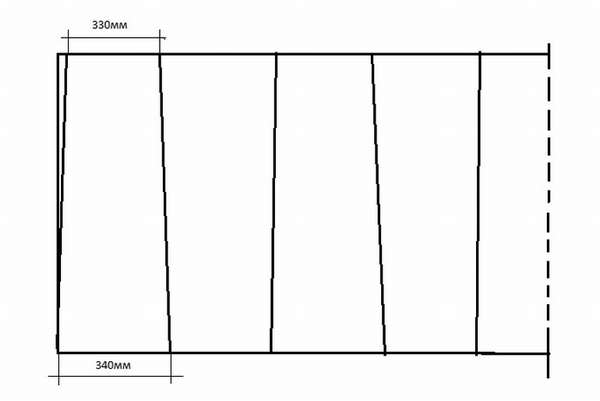

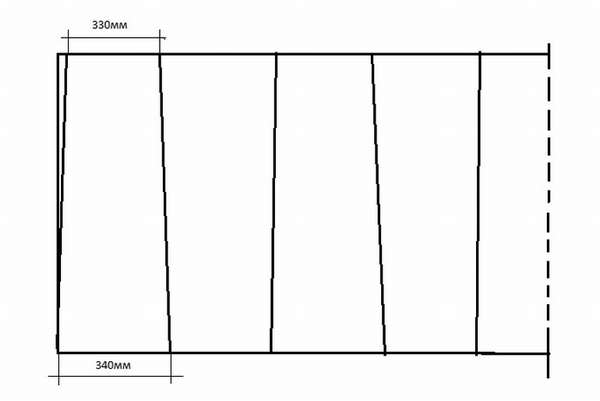

Let's consider how to make a pipe with a cross section of 100 mm.

Calculate the width of the workpiece:

- determine the circumference as the product of the section and the pi value equal to 3.14,

- 15 mm are allocated for the bends for the connecting seam.

For a total of 100 mm bend, a workpiece with a width of 3.14100 mm + 15 mm ≈ 330 mm is cut.

It is taken into account that the pipes are made slightly tapered for ease of installation in a bell-shaped manner. Therefore, one side is measured 330 mm, the other - 340 mm (in the picture).

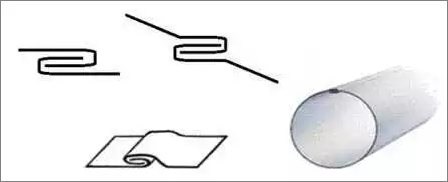

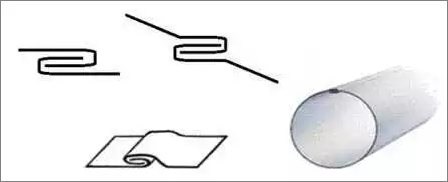

Profile formation

On the cut out workpiece, a fold line is marked for a fold of 5 mm on one side, twice 5 mm on the other.

The sheet is laid on a workbench, the edge is aligned with the corner. With a mallet, gradually bend it at a right angle. Then the workpiece is turned over and the fold is poured onto the canvas.

In the same way, a 10 mm fold is made on the other edge of the sheet, and another 5 mm wide on it.

Next, the workpiece is manually bent on a forming tube using a mallet.

Butt weld processing

After obtaining a round shape of the workpiece, it is laid on a round shape or an additional corner, the folds are connected into the lock, tapping them along the edges with a mallet. At the narrow end of the future pipe, the folds are slightly punchy. They tap the entire length of the butt seam with a mallet, sealing the folds. The seam becomes practically one-piece.

Thermal insulation of the pipe

A galvanized chimney from a single-walled chimney is subject to abundant condensation due to the difference in temperature between the smoke and the environment. And if the chimney itself suffers little from moisture, then the condensate has a negative effect on the operation of the heater - the draft worsens, and the drops formed on the outer surface of the pipe flow down and have a destructive effect on the roof. Thermal insulation of the smoke channel helps to cope with this problem.

For thermal insulation, refractory insulation materials are used:

- basalt mineral wool, produced in the form of elastic fibrous plates or ready-made dense cylinders;

- backfill: broken brick, slag, expanded clay.

A pipe is wrapped with rolled mineral wool, and then a brick shaft is erected around the resulting structure. When using a cylindrical basalt insulation, first put the cylinder on the pipe, and then erect a mine or put on a steel casing on top. When using filling materials, a smoke channel is collected, a mine is built around it, and then a heater is poured into the mine.

The resulting combined chimney can be painted if its outer surface is metal, or plaster if the shaft is built of bricks.

Varieties

Galvanized pipes of two types are produced: one - and two-circuit. Both varieties are available ready-to-assemble, with all the necessary connecting and functional elements.

Double-circuit pipe

The easiest to install are double-circuit sandwich pipes, which you just need to buy and assemble, like a designer.

Each section consists of two pipes and a layer of thermal insulation between them. Shaped elements have a similar structure and do not require modification.

We recommend that you familiarize yourself with: Why does condensate form in the chimney and how to get rid of it?

This design allows you to erect a chimney without much effort: the inner pipe plays the role of a smoke channel, and the outer one serves as a protective casing, and to equip a full-fledged working system, it is enough to simply assemble the sections in the right order.

The chimney can be assembled inside the house or outside. In this case, the inner part of the sandwich chimney will be absolutely fireproof, since its shell does not get very hot.

The sandwich chimney located outside is reliably protected from natural whims, since the insulating layer prevents heat exchange between the smoke channel and the external environment, and the external galvanized pipe protects against mechanical and chemical influences.

In addition, the assembled double-circuit pipe is a completely aesthetic structure that can be successfully used in any design projects.

Single-circuit pipe

For the construction of the internal part of the chimney, for arranging a smoke channel in a combined structure or for a barbecue, single-circuit pipes are used. A single-wall pipe and corresponding fittings are cheaper than a double-circuit pipe.

However, when choosing, you should evaluate the features of the structures, which in different situations can be both pluses and minuses:

- when the heater is in operation, the outer surface heats up strongly, which can be a fire hazard, but on the other hand, such a pipe will quite cope with the role of an additional source of heat in the room;

- a single-circuit chimney on the street cannot be installed without insulation and a protective shaft or casing, however, for location inside an existing brick or asbestos-cement chimney, such a pipe is ideal;

- the use of a single-wall pipe in the construction of a combined chimney or chimney for outbuildings will significantly save energy and money.

Unpresentable appearance

The galvanized chimney very quickly becomes unattractive, due to the formed external plaque. It appears due to the oxidation of zinc, which reacts with air, or rather with oxygen. Some people use paint to make their chimney more attractive. This option is not suitable for solving the problem, because due to temperature changes, the paint quickly begins to peel off and fall off. As a result, the look of the chimney becomes even worse.

From what to make a chimney for a gas boiler, it's up to you, but keep in mind that galvanized pipes are significantly inferior to the characteristics of stainless steel. Due to poor resistance to high temperatures, corrosion and mechanical damage, savings are questionable.

Similar articles:

You have questions? We can call you absolutely free!

We will contact you and answer any questions you may have!