A wooden house (dacha), not connected to central heating, needs a heat source that allows you to live in it at any time of the year. By tradition, fireplaces or stoves are used for these purposes, which can have a wide variety of designs.

The order of the arrangement of stoves in a wooden house is governed by the current regulations (SNiP), and is also specially stipulated by the requirements for fire safety.

Choosing a place for the oven

Any metal or brick oven in a wooden house is installed based on the following considerations:

- the possibility of arranging a chimney with reference to the design features of the ceiling and roof;

- free access to the stove for the purpose of its maintenance;

- compliance with fire margins, ensuring its distance from flammable surfaces.

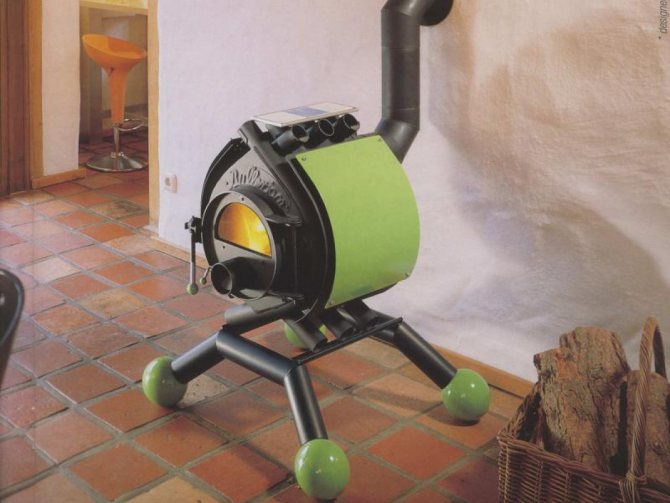

For such types of furnace devices as a stove or buleryan, special requirements are imposed on the possibility of free movement of convection air currents.

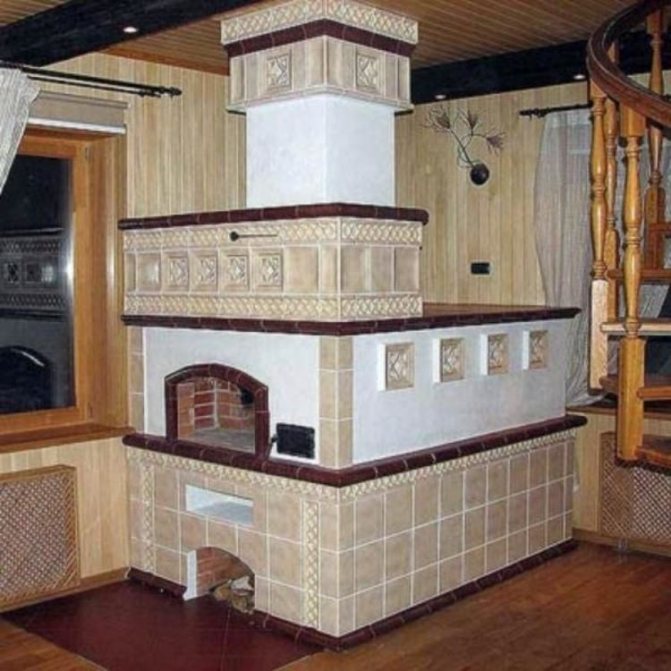

Note! For the purpose of heating adjacent rooms, a brick oven is sometimes built directly into the partition.

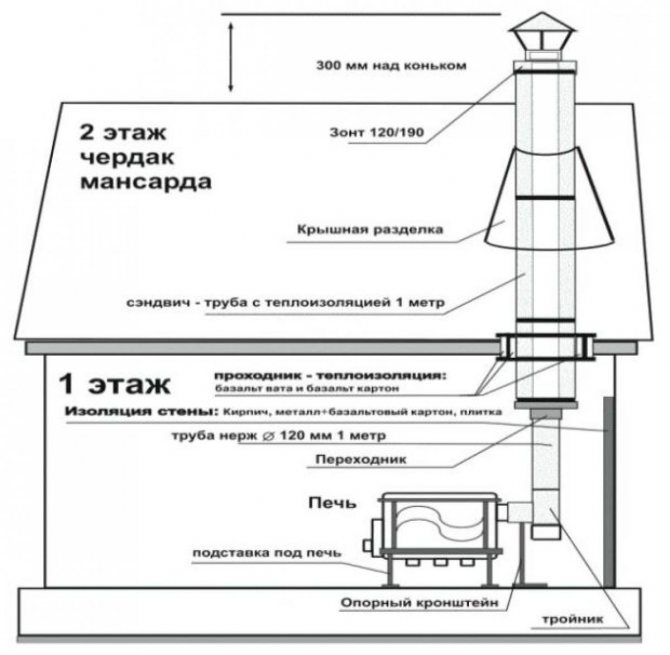

The installation of a stove in a wooden house should be tied to the location of the projected chimney. It is not enough just to move it as close as possible to the flue gas outlet. Correct installation of a heating stove for a wooden house should ensure ease of connection to the chimney, as well as the ability to maintain both.

This requirement is explained by the peculiarities of the design of furnaces, from which it is necessary to remove accumulations of ash all the time, to clean the combustion chamber, and also to clean the walls of the chimney. Leave some distance in the direction of opening the firebox door during installation.

According to the requirements of SNiP, the distance from the furnace to the walls must be at least 110–125 cm. The same gap is left on the side of the door of the furnace combustion chamber. The stove should be positioned within the house so that maximum heat transfer can be obtained from it.

How to install a potbelly stove in the country

When installing a potbelly stove, it should be remembered that the metal case heats up quite quickly. Stainless steel ovens heat up less and cool down faster. Potbelly stoves, which are made of cast iron, will store heat much longer, therefore, they must be installed so that during operation and for some time after the flame has died out, they are in sight.

In the case of installing stove stoves on metal legs, it must be remembered that these auxiliary structures will also heat up. The heating temperature will be lower than that of the case, but still not too low. You will need to install stove stoves in the country on a non-combustible base. In this case, you can use:

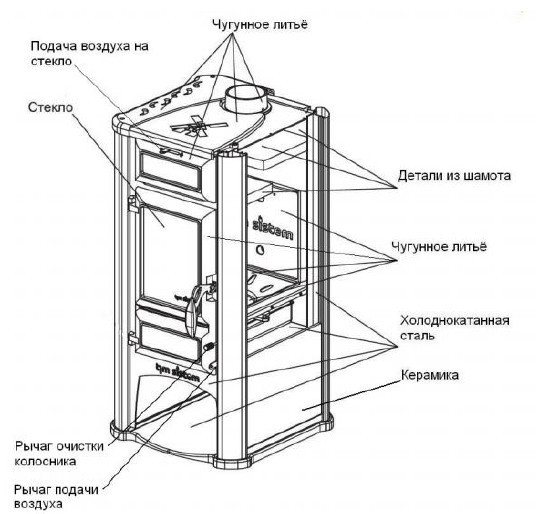

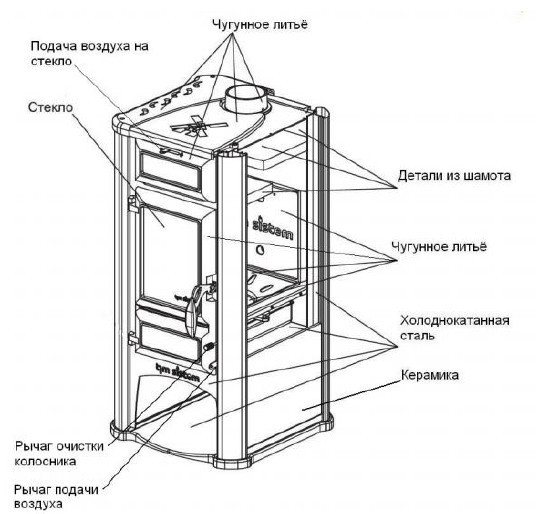

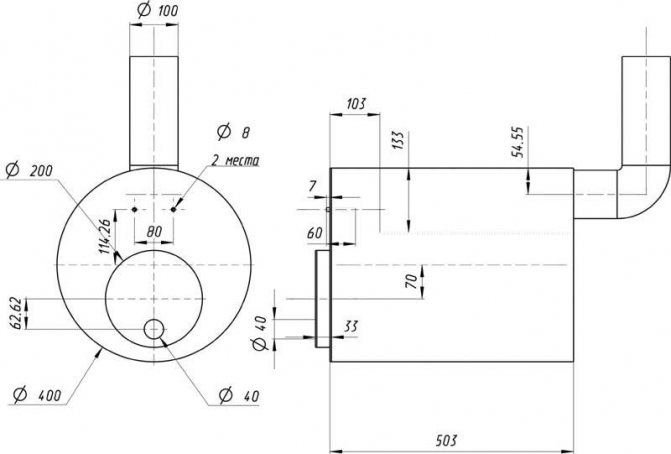

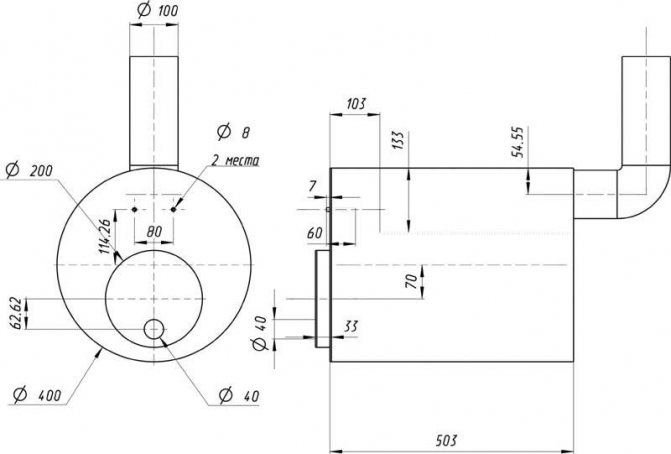

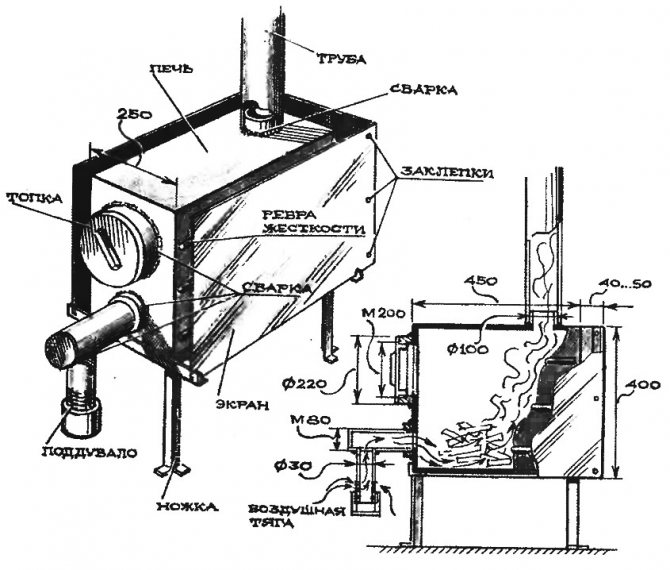

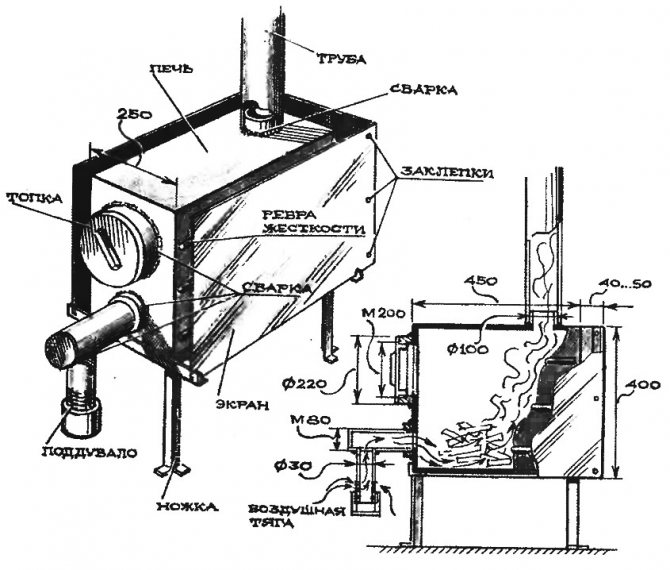

Diagram of the stove stove device.

- tin products;

- concrete structures;

- ceramic tile products;

- brickwork.

Fire hazardous grounds are:

- those that are made of plastic of any kind;

- plank or parquet floors;

- laminate bases;

- linoleum bases;

- it is not allowed to use carpet or other soft surfaces.

If the house has wooden walls or panels, it is necessary to install a stove at a distance of 1 m from them. Indoor flue pipes are installed from 1 section, without the use of joints. If for some reason this cannot be done, you need to make a tight connection, while one section must necessarily go into another.If the pipe goes through a wall, you will need to make a ceramic or brick thermal barrier. In this case, concrete can also be used, but with temperature drops it will crumble.

The fuel storage container will need to be placed near the door to prevent sparks from entering.

Diagram of a stove stove with dimensions.

Quite often, stove stoves in the country are used not only to provide heating. There are many designs that combine multiple functions. These structures include a heating stove with a cast iron stove. They can be used for cooking and at the same time for heating a country house. A household cast iron stove with 1 burner can easily replace a gas or electric stove in the country. If there is a need to feed several people at the same time, you should make or purchase a stove with a solid cooking surface or with 2-4 burners.

Stoves with a water tank are also popular. Their design is similar to a samovar. A water tank is mounted around the wood-burning cast-iron stove.

Types of foundations

Among the known types of foundation foundations for arranging furnaces are suitable:

- concrete posts;

- strip foundation;

- monolithic slab.

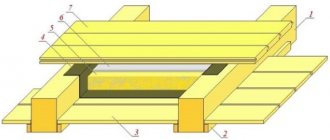

Each type has its own characteristics. Concrete pillars are suitable for both a heavy metal stove and a massive brick fireplace. The number of supports is selected based on the total weight of the structure and the condition of the soil at the installation site. For their arrangement, holes of the required size are made in the floor, and after installing the posts, a frame of welded metal channels is laid on them.

Strip foundations are erected according to the classical scheme. According to the technique, during their construction, formwork is first made around the perimeter of the supporting structure, into which liquid concrete is then poured. All other operations are done in the same way as described in the previous case.

Important! The strip base should not have a connection with the foundation of a wooden building, since due to its small mass in winter it can be squeezed out of the ground.

Monolith is mainly used when installing fireplaces in summer cottages. Its thickness can reach 15–20 cm, which is quite enough to withstand the design pressure on the foundation.

Any of the types of foundation considered above, after pouring, should settle for some time. It will be possible to start installing the oven on it in about 28-30 days.

Simple designs of stove stoves

There are several options for stove stoves, each of which has a set of both positive and negative properties.

Potbelly stove from a gasoline barrel

As already noted, this version of a home-made metal stove is fragile, but captivates with its cheapness and ease of manufacture. As a rule, it provides for placing the barrel in a horizontal position, but you can equip the stove in the form of a vertically located metal barrel. In the front wall of the barrel, rectangular windows of the firebox and blower are carefully cut out with a grinder, doors are made from the cut parts (awnings, a handle, a lock - latch, overall stripes around the perimeter are welded on), which are hung on the corresponding windows of the front wall of the barrel. The blower window need not be cut; instead, at the very bottom of the front wall, it is enough to drill a number of air inlet holes with a diameter of about 20 mm. In the back of the upper wall of the barrel, neatly, from the center marked with a core or punch, several radial cuts are made to the size of the future chimney opening.After that, the formed metal petals are bent upward, simultaneously forming a chimney hole and the likeness of its branch pipe.

Potbelly stove for giving from a gas cylinder

As a rule, it is equipped with a horizontally located cylinder, the thick-walled metal body of which forms the combustion chamber of the future stove. The end part of the cylinder with a tap is neatly cut off by a grinder, and a firebox door is made from it (awnings, a handle, a lock - a latch are welded), which is hung back on the cylinder - a firebox. In one of the side walls of the cylinder, which will become the lower wall of the combustion chamber, a number of holes are drilled in a staggered manner (with a diameter of about 20 - 30 mm, and with a step of about 20 mm). The drilled holes will serve as a kind of fixed grate for the future stove. From the bottom to the cylinder, completely overlapping the grate, a separately made iron ashtray box with doors hung on its window is attached (seized by welding), and the support legs are welded.

Rectangular stove - potbelly stove

The stove body is made in the form of a rectangular welded box made of metal with a thickness of 3 mm and more, inside which a horizontal partition made of a sheet of metal of the same thickness is equipped (welded in), dividing the internal space into two chambers: the upper, most part, the firebox and the lower part, the blower ... A grate window is cut into the horizontal partition, which can be equipped both in a removable and non-removable version. In a simpler, non-removable version, the grate is formed by metal rods, laid in parallel with a certain gap and welded across this window. The removable grate is made in the form of a metal frame according to the size of the grate window, to which, in parallel with the gap (the gap is the size of the thickness of the bar used), rods - grates are welded. In the front wall of the box, rectangular windows of the combustion chamber and ashtray are cut, on which the corresponding metal doors are hung. The rectangular shape of this stove is convenient in that its upper wall can be additionally equipped with a cooking hole with a hob, and a metal box with sand can be installed on it, which will significantly increase the heat capacity of the stove and smooth out its heat transfer.

Oil-operated metal stove

The structures of metal portable stoves, which use used engine oil as a fuel, stand somewhat apart. Their field of application is rather narrow, and it is determined both by the emitted specific vapors, unacceptable in rooms where people are for a long time, and by the corresponding fuel, which in sufficient quantities for heating can only be in car garages, auto repair shops and industrial enterprises. The design of this stove is relatively simple. It consists of a "pot" - a container for oil with a filler hole closed with a throttle plug for air passage.

Fire safety requirements (PPB)

The PPB requirements stipulate the conditions under which the correct installation of any type of furnace equipment is possible. To a greater extent, they relate to the protection of the floor and walls of the building from accidental fire (due to the contact of wood with hot surfaces).

Protective measures will allow you to protect housing and people:

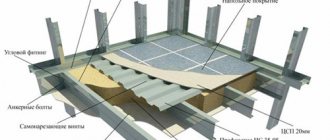

- The use of special fire-resistant materials that protect the walls and ceiling in the area of the stove and chimney (if the house is two-story, the overlap between the floors should also be protected);

- Impregnation of elements of wooden structures adjacent to the hot parts of the furnace with special compounds.

Compliance with all the requirements of the PPB and the correct use of fire protection means are the main condition for the safe operation of home furnace equipment.

Safety recommendations

dry firewood and logs

What must be observed for the safe operation of the stove:

- The installation of the stove must be done on a non-combustible base;

- All objects and flammable surfaces should be no closer than 70-80 cm from the stove;

- Do not put more than three kilograms of fuel into the stove at a time;

- The firebox door must always be closed, excluding the moment of loading firewood;

- It is forbidden to operate the stove in case of malfunctions with the chimney;

- Do not leave a working oven unattended for a long time or with small children;

- It is forbidden to touch the furnace body while it is operating or immediately after the flame is extinguished in it, the entire surface heats up to a very high temperature;

- Do not leave or keep flammable objects and materials near the working stove.

Subject to all the rules, the potbelly stove will heat the room for a long time.

Wood processing

The most common protective agents include special impregnations (flame retardants) and transparent mastics. The following elements of wooden structures are usually processed by them:

- ceiling beams;

- floorboards in the area where the stove is installed;

- the walls adjoining it.

Additional Information! When choosing products, it must be borne in mind that mastic has a higher fire protection rate than colorless impregnation.

Fire-retardant processing of wood elements can be done not only by representatives of the Ministry of Emergency Situations, but also by the owners of the house. In the second case, they will need to get a special certificate confirming the correct installation of the oven.

Self-installation of a stove

When choosing a stove option for a country house, it is important to carefully calculate the required power for heating the selected area. A potbelly stove with an area of 1 sq. M can heat a room with an area of 35 sq. M.

When choosing a stove for a country house, it is important to carefully calculate the required power for heating the selected area

An important factor in the operation of the device is the blowing out of heat from the room and the influx of cold air there. For example, cracks in windows or floors that create a draft will noticeably disrupt the work of the stove. An excellent solution for a two-story country house is a two-story stove with a common chimney. Read more about installing a homemade potbelly stove in a country house on our website.

Video: installing a stove and chimney

If you want to reduce the cost of installing and purchasing a stove, you can try to make it yourself in accordance with the instructions.

Self-assembly of a potbelly stove

Advice! The simplest model has a round shape with a diameter of about 45 cm and a height of 80 cm. The thickness of the walls is about 10 mm, and the main feature is the unregulated draft.

Sheathing for ceiling and walls

In addition to treating elements of wooden structures with fire retardants and mastics, you can protect them from the hot parts of metal furnaces by upholstery with refractory materials. When preparing for this procedure, it should be borne in mind that the filing of the ceiling in the area of \ u200b \ u200bthe exit to the roof is carried out only with non-combustible materials that do not spoil the interior of the room.

Important! It is strictly forbidden to use combustible panels for upholstery.

The optimal cladding option is fibrous gypsum boards treated with refractory putty. To protect the walls, basalt cardboard can be used, sheathed with steel sheets on top. Most often, special decorative screens made of stainless steel are used. They not only protect surfaces well from burning, but also look quite aesthetically pleasing.

Another option for protecting the walls from hot stove parts involves covering them with bricks placed on the edge.

Device and principle of operation

What is the difference between Burzhuiki Loginov and other metal stoves? The bottom line is the L-shaped blower. The ash-pan door is replaced with pipes welded perpendicularly. The end of the horizontal pipe is tightly welded, and the end of the vertical pipe is threaded for a plug. Holes are made on the thread - screwing the plug can reduce the air flow, thereby regulating the combustion process.

Loginov's original stove

It is important to make a plug with a slight backlash, so the expansion of the metal when heated will not cause problems. On the sides and back on the stiffeners, a screen is welded to increase efficiency

Without such screens, it is extremely uncomfortable near the stove - the temperature is too high and fraught with burns. The firebox door is also threaded. A 200mm pipe serves as an opening for the furnace, and a 220mm diameter plug with a handle is screwed onto this pipe.

12918027525f238194e21c71fdf01c56.jpe

More details about Loginov's stove can be seen in this video:

Modification

N. Pyankov's model is distinguished by the presence of an additional combustion chamber. Unlike more complex designs of slow combustion furnaces, Pyankov's stove is made even faster, according to the model proposed by Loginov. It is enough to weld steel sheets 140-160 mm long at different distances from the top to the rear and front walls of the furnace. The distance between the sheets should be 80mm. The grate is installed 80mm from the bottom. Pyankov transferred Loginov's firebox door to the upper part of the stove and began to use it as a hob.

It will not be difficult for a good craftsman to evaluate all the advantages and disadvantages of the two drawings. If you wish, you can make a new model of a potbelly stove using only these two developments, changing the rectangular shape to a round one.

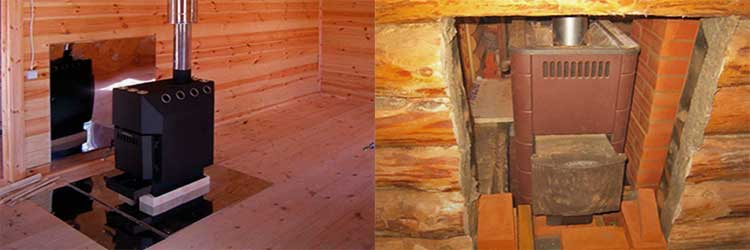

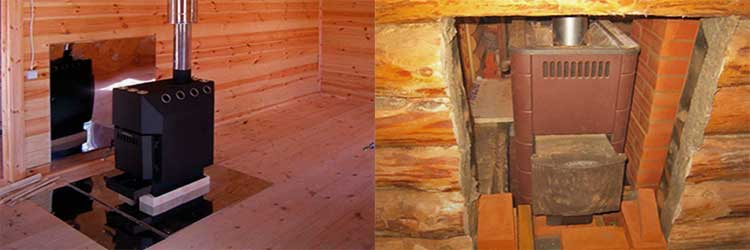

An example of a home-made design (in this photo, a modernized Pyankov furnace), but there is practically no difference in the manufacturing process.

Installation of a metal furnace

When considering the features of the placement of metal and brick ovens, the approaches to their installation are somewhat different. Iron stoves may not be too heavy, so they do not need a foundation during installation.

Important! According to the provisions of SNiP, only metal furnace products with a mass exceeding 80 kg need a reliable foundation.

With a lower weight index, such a product is installed on a substrate of refractory material directly on the floor. After the place has been chosen, and the issue with the foundation has been resolved, you can proceed to the procedure for installing a metal furnace. When installing the heating device, all the requirements specified in the section on the protection of wooden elements of house structures must be met.

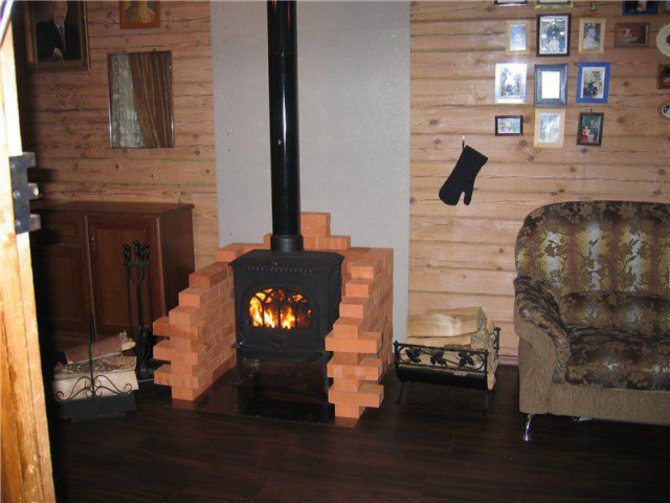

For this purpose, a metal stove with a water boiler is sometimes simply lined around the entire perimeter with ordinary bricks. In all other respects, its installation is reduced to installation in an already prepared place. The only thing that should be paid attention to is compliance with the rules for removing the chimney to the outside.

What is a stove stove

A small historical excursion

Initially, a "stove" was a steel furnace of a certain design, the creation of which took place during the dramatic years of the Civil War for our country. It is not known exactly which of the Russian engineers came up with a very simple, but very effective steel furnace, relatively easily made in a handicraft way from more or less available materials. In the days of "war communism", after the urban economy with centralized heating in large cities collapsed, this tiny stove, which could be installed almost anywhere in the "bourgeois" apartment compacted by the house committee, saved many lives. By the way, the statement that the stove got its name due to excessive consumption of firewood is a stupid legend, born in the vastness of the Internet. In fact, the potbelly stove is very economical for its type.In conditions of the most severe shortage of coal and firewood, the owner of Master Gambs's walnut set had the opportunity to survive the terrible winter, using precious furniture as firewood. The name of the furnace was determined by the fact that at first it became widespread among “former” engineers, civil servants, and intellectuals who did not emigrate from the country. That is, according to the concepts of the proletariat, "bourgeois".

The device and principle of operation of the stove

Today the term "potbelly stove" is used, by all means. Often all steel furnaces are called this way. But we believe that only those stoves that have inherited the basic design features and properties of the prototype are worthy to bear the proud name "potbelly stove". In the modern version, the stove often has a horizontal design, it is more convenient for laying full-size firewood with a length of about 40 cm, and is also equipped with a blower and grate, which makes it easier and more accurate to regulate the air flow and the rate of fuel burning.

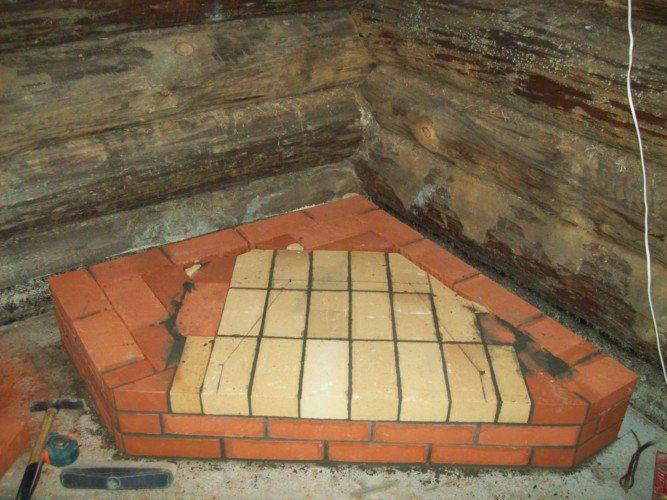

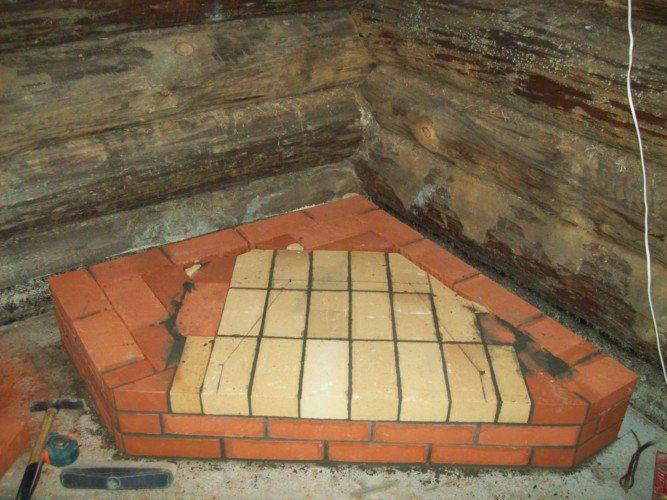

Installing a brick oven

It is preferable to lay out the base of a brick stove in advance (at the stage of designing a house or when pouring a foundation for it). For a brick wood-burning stove weighing about 300 kg, it is best to prepare a monolithic concrete base, poured over the entire area of the structure. If the house has already been built and inhabited, you will have to disassemble the floors in the chosen place, then go deep into the ground by about 25 cm.

After that, it is necessary to prepare a cushion of sand and gravel, tamp it thoroughly, pour concrete mortar on the pre-reinforced base. It is allowed to make a foundation in the form of concrete pillars or a strip structure constructed according to a typical scheme.

Important! The dimensions of the base should exceed the dimensions of the stove or fireplace by about 10-15 cm.

Upon completion of the installation of the fireplace stove in houses from a bar, it remains to insulate the wall in any way convenient for a person.

Where is it better to install a stove in a garden house

From the point of view of planning, the stove is installed based on the placement of rooms (if any) and the arrangement of furniture. But there is also a technical aspect that affects the location of the oven. The fact is that according to existing standards, in order to create sufficient draft, the height of the chimney from the grate to the head on the roof must be at least 5 meters. Garden houses are not high, and if there is a mansard roof, it often has a significant slope. Based on the foregoing, we can conclude that the best place for a stove in the house is closer to the ridge, the highest place of the roof. Ideally, in the center of the ridge. This arrangement makes it possible to locate almost the entire chimney inside the house. As a result, the heat from the chimney heats the attic, and the draft is stable due to the fact that the chimney is not cooled from the outside.