Fum tape: what is it ↑

Plumbing tape: production and types ↑

PTFE sealing material, or fum tape for short, is a PTFE film used to seal pipe joints. It is made by rolling a fluoroplastic rope to the required thickness. The seal is produced in the form of a tape of a certain size, wound on a reel (by analogy with electrical tape). They are used for the installation of systems under pressure: water supply, gas supply, central heating. The material acts as a deformable filler and thread lubricant at the same time, which improves the sealing of joints.

Types of fum tapes:

- fum-1 - designed for sealing pipelines operating with aggressive media. Contains lubricant - refined petroleum jelly;

- fum-2 - used in systems in contact with strong oxidants, therefore it is not impregnated with grease;

- fum-3 - used in systems working with clean environments. Does not contain grease.

Fum plumbing tape also differs in size: thickness ranges from 0.075 to 0.25 mm; width starts from 10 mm; length from 1000 mm.

They produce a special yellow gas fum tape with a thickness of 0.15-0.25 mm. For gas pipes operating at low pressure, ordinary plumbing tape can be used.

Special gas fum tape is denser than ordinary plumbing tape

Technical characteristics and properties of fum tape ↑

Main properties of PTFE:

- Low coefficient of friction. Fluorinated plastic polymers (PTFE) have a very low coefficient of friction - they are slippery, which makes it easier to connect fittings. They act as a kind of pipe thread gasket, improving fit and sealing.

- Heat resistance. PTFE has an extremely high melting point for plastic - 327 degrees. They are designed for use at temperatures up to 260 degrees (they release toxic fluoride compounds when heated above). PTFE are excellent dielectrics (electrical insulators), which is an added plus.

- Plasticity and strength. Resistant to mechanical stress. They work at constant pressure up to 10 MPa, withstand drops up to 41 MPa. Average service life is 13 years. Prolonged exposure to light will slightly impair properties.

- Chemical and biological inertness. They are highly resistant to acids and alkalis. There is no solvent for PTFE yet. The polymers are, as it were, uniformly sheathed with fluorine atoms, which makes the material inert with respect to almost all chemicals. Decomposition is possible only under extreme conditions created in special laboratories. Not subject to decay.

The ductility of PTFE allows the plumbing tape to stretch and fit snugly around the thread

Specifications

Fum tape, the technical characteristics of which meet the requirements for the quality of work at a particular facility, will flawlessly serve for at least 10 years. In order to accurately select the most suitable product, it is recommended that you familiarize yourself with the characteristics of the 1st and 2nd grade films.

| Characteristics | FUM-1 | FUM-2 |

| Film thickness (mm) | 0,1-0,14 | 0,035-0,2 |

| Film width (mm) | 10-60 | 5-60 |

| Elongation at break (%) | 100-200 | 100 |

| Availability of lubrication (%) | 20 | 0,3 |

| Maximum tensile stress (kg / cm2) | 40 | 60 |

It is difficult for a beginner to plumbing work to understand the first time in all the intricacies of the choice of sealing films.Therefore, you can focus on the recommendations of experienced craftsmen and use the same materials in your work.

Often questions arise about which films to use when installing household water pipes. These are the most demanded plumbing works, during which the mistakes made will be noticeable immediately after the water is supplied or will be discovered in the near future.

The most suitable fumlent for water is as follows:

- for small threaded connections - width 12 mm, thin (0.075-0.1 mm);

- for large threads - width 19 mm, thickness 0.12-0.2 mm.

Oaklya: what is it and how to work with it ↑

Before the appearance of fum tapes on the market, sanitary tow, which was flax fibers, was used to seal threaded pipe joints. Optimum results were achieved by smearing a layer of tow, wound on the threads, with a small amount of oil paint. Such a connection was difficult to make out after a few years.

Nowadays, sanitary flax in the form of long silky threads is used along with new sealing materials. Only now a layer of sealing paste is applied over the winding, which ensures a reliable and durable connection. The paste protects the flax from rotting, and if necessary, makes it easier to dismantle.

Flax fibers are long, thin, strong, fit tightly into the grooves of the thread and do not deform when wrapped

What do you need to remember?

The surface of the material is quite slippery, which makes it difficult to repair the breakage.

After the connection is tight, you should not unwind the tape back. If it was incorrectly applied, it is necessary to completely strip the product and rewind.

If it worked out too much belt tension, it must be removed from the thread and wound on a new layer.

Fum tape is an excellent material that can be used to seal various joints. In order for the product to provide an excellent result, it is necessary to choose the right variety, as well as learn how to wind the tape in accordance with all requirements.

How to wind tow on a thread ↑

To prevent flax from slipping along the thread, notches are provided on it.

Please note: in the absence of factory notches, they should be applied independently, otherwise, when screwing on the fitting, the flax will run off the thread.

Impregnation of flax with a special paste, coupled with the correct winding - a guarantee that the connection will last a long time

For winding, a small strand of flax is separated. The length and thickness of the "strand" is determined visually depending on the diameter of the pipe. The winding is done as tightly as possible, the threads are guided along the thread, the free end of the tow is fixed with a finger, and after a couple of turns it is brought into the guide strand. The tightness of the connection is ensured by the optimal layer thickness. It is rather difficult to calculate the density: you need experience, a certain "plumbing" eye.

How to use?

In addition, despite the fact that the installation work with the product is quite simple, in the process of their implementation it is necessary to observe a certain technology of winding the tape, otherwise it will not be possible to avoid depressurization of the connection made. The work should be done by adhering to the following scheme in the strict sequence of the steps described.

In order to organize the most comfortable conditions in the process of working with fum tape, it is worth remembering its physical features, which primarily relate to the fact that the product is rather slippery and may be inconvenient to work.

www.stroy-podskazka.ru

FUM tape. Properties. Dimensions. Application. (PTFE sealing tape)

reference: Fluoroplastic Sealing Material (FUM)

These are profiled products made of fluoroplast-4D (finely dispersed modification of polytetrafluoroethylene), produced in round, square and rectangular sections.

There are three brands of FUM:

FUM-V - for various aggressive environments of general industrial type;

FUM-F - for strong oxidants;

FUM-O - for extremely clean environments and strong oxidants.

It is used as a chemically resistant, self-lubricating stuffing and cushioning material operating at a medium pressure of up to 6.3 MPa (64 kgf / cm2) in the temperature range from -60 to + 150 ° C (brands FUM-V and FUM-F) and up to + 200 ° С (brand FUM-O).

Indicators of physical and mechanical properties of the material FUM

FUM tape

FUM tape - an unsintered film made of fluoroplastic-4D, a finely dispersed modification of polytetrafluoroethylene. The tape is intended for sealing threaded pipe connections made of all materials and medium pressure up to 9.8 MPa (100 kgf / cm2) in any corrosive environment.

The declared temperature range is from -60 to + 200 ° C, but our experience shows that for compounds constantly operating at temperatures above 100 ° C, it is desirable to find another solution. Withstand temperature fluctuations (up to 200-250 ° C), provides easy connection and easy disassembly. This allows the use of couplings on pipes made of any metal, including stainless steel, aluminum, etc. Requires relatively good quality threads.

FUM tape is used in pipelines for sanitary and food purposes.

Prevents re-sealing, loosening-tightening. It is used like this: it is wound against the thread with an overlap (provides thickness), from the end of the pipe, the connection is tightened. If the tightness is not ensured, tighten (you cannot loosen it). If it doesn't work out again, unwind, remove the tape, start over.

With the help of the FUM tape, systems are sealed with both concentrated and dilute solutions of acids and alkalis, systems with mediums of general industrial type and operating on strong oxidants. Depending on the application, the FUM tape is produced in three grades:

grade 1 - for sealing systems with general industrial media, as well as systems with strong aggressive media (concentrated or dilute solutions of acids and alkalis); contains lubricant - 17-20% medical vaseline oil (GOST 3164-78);

grade 2 - for sealing systems operating on oxygen and other strong oxidants, does not contain grease;

If you suddenly come across grade 3, then you should know that grade 3 is the edge parts of the FUM tape of grades 1 and 2, as well as the SKL film, manufactured according to OST 6-05-405-80. Serves for sealing systems with mediums of general industrial type, as well as systems with strong aggressive media (concentrated and dilute solutions of acids and alkalis);

Dimensions and properties of the FUM tape:

tehtab.ru

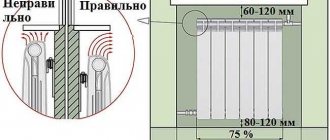

How to properly wind a fum tape on a thread ↑

The tape is wound around the external thread of the fitting. When repairing plumbing, the old connection must be cleaned of rust, dirt, and then degreased with a solvent. Winding is done only after drying. The main requirement: the fum tape should be tightened quite tightly so that it fills the grooves and fits snugly around the thread. Experienced plumbers say that tearing the tape is better than loose winding. The number of layers varies from 4-6 to 20-25 and depends on the thickness, width of the tape and the diameter of the pipe - the main thing is that the entire thread is hidden. Plumbing tape requires a little more than tow, since, unlike flax, it will shrink. When working with fittings Ø from 1 inch, it is more convenient to wind the entire width of the trench, making sure that it is pressed into the turns. After screwing the nut, the fibers of the fum tape break into threads that fill the interturn space - the seal remains in the thread and seals it.

Important: adjustment (adjustment) without loss of tightness is impossible - you cannot even slightly unscrew the twisted fitting.

Fum tape is quite elastic, therefore, with tight winding, the threads are clearly visible

What it is?

In order to protect the pipeline from water leakage and to seal the joints, you can use fum tape. The products are sold in the public domain and have a low cost, so the acquisition of such a useful product will not cause any difficulties.

It is worth noting that when using a sealant to perform installation work at a household level inside residential premises, for example, when arranging a hot and cold water supply or heating systems, the disadvantages of the products are not critical, and the results from the work have high quality indicators, as well as aesthetic appeal all formed compounds.

Which is better: tow or tape fum ↑

Each material has its own advantages and disadvantages. Plumbing flax is used to seal steel pipe joints (especially rusted and / or large diameter).

Advantages of tow:

- the ability to adjust the connection: it is permissible to unscrew it back by 45 degrees;

- reliable tightness: absorbs moisture well;

- resistance to mechanical stress;

- easy dismantling of the connection.

The disadvantage is a tendency to rotting / decomposition, since tow belongs to natural materials.

Plumbing tape is preferable to use on small diameter pipes, plastic pipes, in the case of thin-walled fittings. It is easier to work with fum tape, it takes less time for installation.

There is no single answer to the question: "Which is better - fum tape or sanitary flax". It all depends on the specific plumbing work. Let's say that it is more convenient to connect a kitchen faucet with a flexible hose using fum tape, and it is better to seal the fitting on the water pipe using tow.

Better compaction is achieved by winding a small amount of flax and then securing with several turns of tape.

Types of fum tapes

Currently, the following varieties of this product can be found on sale:

- Fum-1

... Used to ensure the tightness of pipe connections. The composition contains a lubricant, which allows the product to be used in a system with an aggressive environment. Creates a very durable joint seal. - Fum-2

... This variety is used where oxidizing agents may be present. There is no grease on the surface. The tape creates a strong layer in the joints. - Fum-3

... Plumbing fum tape is used only in pipelines with clean water without impurities.

Anaerobic gel sealants: santechgel ↑

Another modern material for sealing pipe threads is santechgel. Reliable sealing is due to the polymer component of the gel. After hardening, sanitary gel does not shrink or expand, is resistant to temperature extremes (from -60 to +150) and pressure surges, has proven itself in various environments: water, natural and liquefied gas, heating antifreezes.

How to seal the plumbing connection: flax, fum tape, anaerobic sealant - the specialist decides

Santekhgel is produced in three types:

- In green tubes - easy dismantling.

- In blue - medium dismantling.

- In red (Stop Master Gel) - heated dismantling.

Installation using sanitary gel is simple: shake the tube and apply the gel in a thick layer along the entire circumference of the thread, distribute it evenly (with a brush, a special spatula), and assemble the structure. Remove excess gel with a cloth. Gel polymerization takes 15–20 minutes.

Important: plumbing gel should only be applied to a clean, grease-free surface.

Santehgel

Sanitary gel sealant is a modern tool for sealing pipe threads. Reliability is ensured due to the fact that this material contains polymers. Once a given substance is solid, no shrinkage or expansion occurs.

Santekhgel has a high level of stability and can withstand sudden changes in temperature. Pressure surges are also not terrible for this product. Santechgel can be used in a variety of applications: for gas, for water, and so on.

In total, there are three types of sanitary gel:

- Material that can be easily dismantled. It is sold in a tube that is green;

- plumbing gel for medium dismantling is sold in blue tubes;

- dismantling with heating is typical for the material that is sold in red tubes.

Installation using plumbing gel

First you need to shake the tube. Further, a layer of sanitary gel must be applied along the entire circumference of the thread. The layer must be thick. Spread the gel sealant evenly. This can be done with a brush or a specially designed spackle.

At the end, the entire structure is assembled. Polymerization takes 20 minutes. Remember to degrease the surface. Santechgel is better than fum tape. This product is suitable for pipes regardless of what they are intended for.

To work with gaskets, you must have some experience and knowledge. Therefore, it is recommended to entrust the work to real specialists, regardless of what you use: linen threads or fum material. They know how to rewind fum correctly and will do the reeling in a quality manner. Then the joint is sealed. This product is suitable for hot water and gas.

With the advent of the water supply system, a person was able to bring the most important natural resources - gas and water - into his home. But at the same time, it became necessary to make the pipeline as tight as possible in order to protect yourself and your home from gas leaks and flooding. The main problem is to ensure the tightness of threaded connections, which are used in the laying of many modern pipes. Currently, many materials are used for this, with different properties and characteristics. A special place among them is occupied by fum-tape, which will be discussed in this article.

Applications

The advantages and disadvantages of each of the materials determine their specific areas of application.

Plumbing linen is used for sealing threaded connections on steel pipes. It is preferred for thread diameters of more than 1 ", and if the thread has obvious defects.

This type of seal has proven itself perfectly on lines intended for transporting hot media, for example, heating pipelines.

Better to use flax and in the case where a connection with high reliability is required, for which there is no need to dismantle.

Fum tape is used:

- when installing plumbing fixtures, installation of measuring equipment and control valves;

- on steel pipes with a diameter up to 1 ”with high quality threads;

- when connecting sections of copper pipelines using threaded fittings;

- on pipelines made of polymeric materials and metal-plastic, when using thin-walled fittings, products made of copper, brass, bronze;

- when working with fine threads.

It should be noted that for use in work inside an apartment or a private house - installation of a cold and hot water supply system, heat supply systems, the disadvantages of FUM are not critical.

It is faster and more convenient to work with it, while high-quality and aesthetic-looking connections are obtained.

Therefore, for a person performing the listed work with his own hands, the choice in favor of this material is completely justified.

Attention!

Regardless of the choice of material, it is possible to obtain high-quality sealing of threaded connections only if the technologies for using seals are observed!

Flax fiber: characteristic

No one will remove tow from store shelves, because this type of fabric is not capricious, but it is not entirely easy to work with it. Indeed, a situation often arises in which it is not easy to untwist a thread with flax fiber wound on it, sometimes such undertakings remain unrealized. And in the Soviet era, such compounds were additionally treated with enamel (red lead), then tightly twisted. Once the paint was dry, the joint was perfectly bonded. This method was distinguished by its strength and reliability.

As soon as silicone-based sealants appeared on the Russian markets, linen compounds were forgotten. Although many experts consider the latter type of material to be a thing of the past, it does not leave its positions today.

Despite some laboriousness of working with tow, its installation is carried out through the following steps. First, the tow is spread over the fibers, then they are placed in the grooves between the threads. There should be no kinks through the turns. Then the sealant must be applied. When screwing in flax fiber, remember that there should not be an excess of this fabric. Indeed, with further operation of the connection, excessive stress appears, as a result of which the parts may break.

What to choose: FUM or LEN?

Linen, or tow, as it is called, is an outdated material for sealing.

The process of its application is rather laborious and takes place in several stages. At the first stage of wrapping the tow joint, it is necessary to divide it into fibers and lay it in the grooves, making sure that there are no overlaps.

At the second stage, apply the sealant using a brush.

Experts do not recommend using tow without experience with this material, and here's why. The use of this material suggests some features:

- With an insufficient amount of tow, the connection will be depressurized

- And with an excess amount - during twisting, it is cut off by pipes, and excessive stress is created - hence the various deformations of parts during operation.

It is difficult for an inexperienced specialist to maintain this balance, and FUM-tape does not have such drawbacks, so its use will be quite expedient.

The only case when it is better to use tow is when working with metal pipes, which are often found in old houses.

Synthetic seal

FUM-tape (what is it) is a thin polymer waterproofing tape made of fluoroplastic-4.

Tape with a thickness of 0.1 to 0.14 mm and a width of 10 to 60 mm is becoming more and more popular due to its properties:

- FUM demonstrates high strength tear and elasticity;

- the material is not affected by moisture, active chemicals, biological degradation;

- fluoroplastic sealant can be used in a wide temperature range - from -60 to +200 degrees.

Important note! At temperatures above 260 degrees, the fluoroplastic, which forms the basis of the material, releases volatile fluoride compounds that pose a danger to human health.Therefore, synthetic materials are recommended for use when laying pipes for cold water supply, for example, when creating a self-irrigation system with your own hands;

- FUM tape is easy to fitfilling in the unevenness of the thread, which ensures the rapid creation of a tight connection;

- properties of fluoroplastic, practically, do not change for a long time;

- joint sealed with FUM tape, easily dismantled;

- thin material does not pose a danger of mechanical destruction of parts when using polymer and metal-plastic pipes, thin-walled fittings and fine threads.

The list of advantages of the material makes an impression, but disputes about the advisability of using FUM tape for sealing arise due to its shortcomings:

- on pipes of large diameter, with an increase in the gaps between the parts of the joints and the width of the thread pitch, it is problematic to ensure reliable sealing with a material with a thickness of the order of 0.1 mm.

In such conditions, a significant consumption of an expensive sealant will be required.In this case, there are additional problems associated with the limited length of material on the spools;

- with increasing clearances there is another problem of using FUM.

When heated, significant changes in water temperature (what should be in the hot water pipes, you will find out here), especially if the connection parts have different coefficients of thermal expansion, the packing density is violated, which leads to the formation of leaks; - when working with FUM difficulties may arise due to the low friction coefficient of fluoroplastic and the use of the most common material FUM-1 lubricant - vaseline oil (up to 20%);

- defects and imperfections in thread, such as cavities and burrs formed when using hand tools for cutting, or sharp edges resulting from blade processing of workpieces, violate the integrity of the tape, making it impossible to obtain a high-quality seal;

- when using fluoroplastic tape it is impossible to release the tightened connection or turn back the installed fittings by more than 45 degrees without loss of tightness.

If such an operation is necessary, the connection of pipes (which diameter is better for the water supply in the apartment is written here) must be disassembled and reinstalled.