Penoplex heaters - technical characteristics, properties and areas of their application

Heaters of the Penoplex brand are nothing more than extruded polystyrene foam. It belongs to a new generation of heat insulators that are highly efficient in terms of keeping warm. In this article, we will take a closer look at Penoplex: technical characteristics, pros and cons and areas of its application. To begin with, we note that this material is durable, almost does not absorb water at all and has a low coefficient of thermal conductivity.

The specifics of the production of Penoplex and its special properties

The first extrusion plant appeared in America more than half a century ago. During the production process, polystyrene granules are subjected to high pressure and temperature. The catalyst is a special foaming agent. Usually it is a mixture of carbon dioxide and light freon. The resulting fluffy mass, reminiscent of well-whipped cream, is squeezed out of the extrusion unit. After a while, freon evaporates, and air enters the cells in its place.

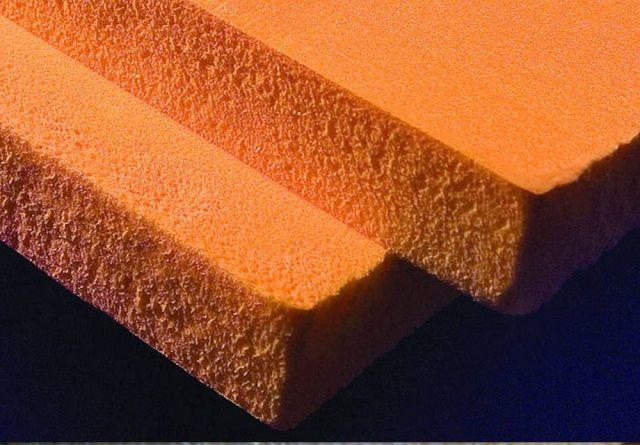

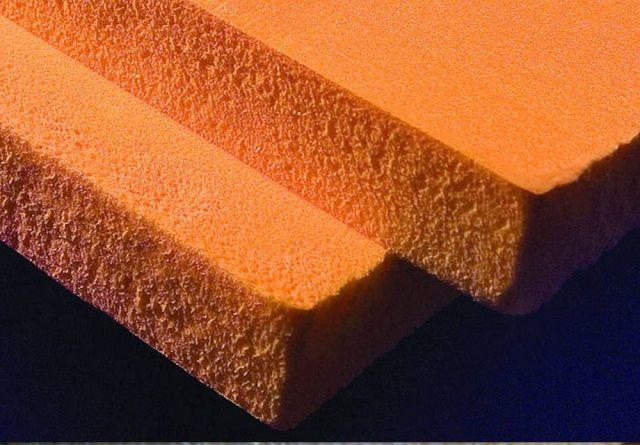

Thanks to extrusion, the manufactured material has a finely porous structure. Each of its identical tiny cells is isolated. The size of these cells is from 0.1 to 0.2 millimeters, they are evenly spaced inside the material. This makes the material strong and warm.

Water absorption - minimal

For heat insulators, the ability to absorb moisture is an important characteristic. The following tests were carried out: Penoplex plates were left in water for a month, immersed in it completely. Water was absorbed by them in a small amount only for the first 10 days, after which the material ceased to pick up moisture. At the end of the term, the amount of water in the slabs did not exceed 0.6 percent of their total volume. That is, moisture can only penetrate into the outer cells of the Penoplex insulation, which were damaged when cutting the material. But there is no access to water inside the closed cells.

Thermal conductivity coefficient - small

Compared to many other heat insulators, the thermal conductivity of Penoplex is much lower. Its value is 0.03 W * m * 0 C. Since the material practically does not absorb water, it is quite possible to use it where there is high humidity. At the same time, its thermal conductivity remains almost unchanged - it can fluctuate only from 0.001 to 0.003 W * m * 0 C. Therefore, Penoplex plates can be used to insulate both roofs with attics and foundations with floors and basements, without using an additional moisture protective layer.

Water vapor permeability - low

Like any extruded polystyrene foam, Penoplex is also distinguished by its increased resistance to moisture evaporation. A layer of slabs made of this material with a thickness of only 2 centimeters has the same vapor permeability as a layer of roofing material.

Service life - long

By freezing Penoplex slabs many times, and then exposing them to thawing, the researchers found that all the characteristics of the material remain unchanged. According to the conclusion of the NIISF Institute, these plates can serve as thermal insulation for houses for 50 years, no less. Moreover, this period is far from the limit, it is given with a large margin. In this case, atmospheric influences are also taken into account.

Very stable when compressed

As already mentioned, extrusion allows you to achieve uniformity in the structure of the material. Evenly distributed cells of a tiny size (tenths of a millimeter) improve the strength characteristics of Penoplex insulation. It does not change its size even under heavy loads.

Installation and processing - convenient and simple

This material is easily cut with the most common knife. You can quickly sheathe walls with Penoplex plates, without using much effort. When working with this insulation, there is no need to be afraid that it will rain or snow. After all, Penoplex does not need protection from the weather.

Environmental friendliness - at a high level

Perhaps someone may be frightened by the fact that freons are used in the manufacture of this material. But the fact is that freons of this type are absolutely safe - they do not burn, are not poisonous and do not destroy the ozone layer.

Chemical activity - almost zero

Most of the chemicals used in construction are not capable of reacting with Penoplex. There are, of course, exceptions - some organic solvents can soften the insulation plates, disrupt their shape, or even completely dissolve.

These substances include the following:

- Toluene, xylene, benzene and similar hydrocarbons (aromatic);

- formalin and formaldehyde;

- substances from the class of ketones - methyl ethyl ketone, acetone;

- ethers, both simple and complex - methyl acetate and ethyl acetate solvents, diethyl ether;

- gasoline, kerosene and diesel fuel;

- polyesters used as epoxy hardener;

- coal tar;

- oil-based paints.

We also give a list of substances that are not capable of damaging Penoplex:

- Any kind of acids - organic and inorganic;

- salts in the form of solutions;

- alkalis;

- alcohols and paints based on them;

- water and water-based paints;

- chlorine (bleaching) lime;

- oxygen, carbon dioxide;

- butane, propane, ammonia;

- oils (both animal and vegetable), paraffins;

- cement and concrete mortars;

- freons.

It is also worth noting that the biostability of the slabs of this insulation is also high - they do not rot or decompose.

However, for the shape and size of the Penoplex boards to remain unchanged, it is necessary to withstand the permissible ambient temperature at which this insulation can be used. Usually this parameter is indicated in the material passport. With excessive heating, not only the dimensions, but also the characteristics of Penoplex can change, since it can not only melt but also ignite. However, this is a drawback of all foams, as you can see by watching the following video:

Video. How Penoizol, Styrofoam and Penoplex burn

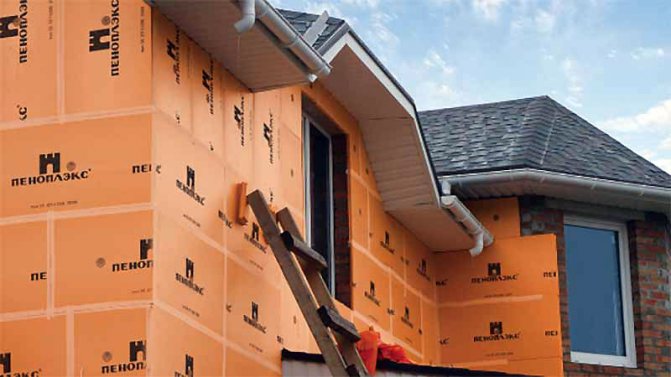

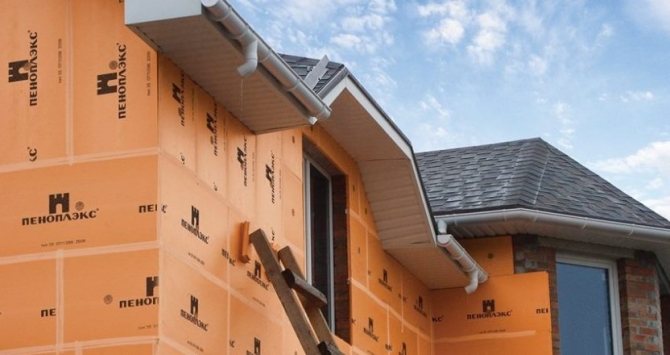

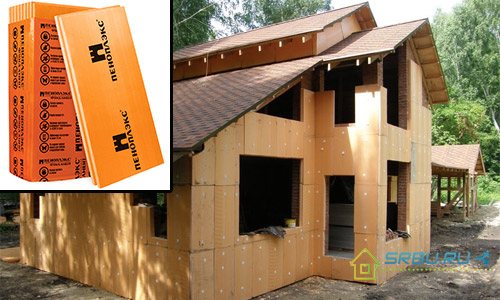

Penoplex Wall is used to insulate the walls of houses.

This name is newer - earlier this heat insulator was called PENOPLEX 31 with fire retardants. However, the essence of this has not changed. Plinths, facades, partitions, internal and external walls of buildings are very well insulated with this material.

Moreover, from the inside, the walls are isolated only if, for some reason, it cannot be done from the outside. Or, in case of urgent repairs, it is also convenient to sheathe the walls with insulation from the inside. PENOPLEX STENA® is excellent for these purposes - it is very easy to install.

As for external use, this material has shown itself very well when laying well walls. Compared to traditional brick walls, such walls are much thinner (several times), but they are in no way inferior to them either in reliability or in their ability to retain heat.

Insulation Penoplex Wall can be used to create plastered facades. Since decorative plaster, sold everywhere, shines with a variety of types and colors, the house will turn out to be original and unique.

Varieties

At the moment, Penoplex is available in five types:

- Penoplex Foundation (35 without fire retardants) - for deep rooms, basements, foundations.

- Penoflex Wall (31 С) - for insulation of walls and basement base.

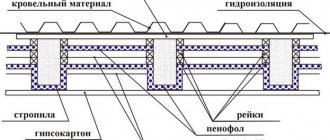

- Penoplex Roof (35) - for all types of roofs.A special L-shaped chamfer around the perimeter allows you to perfectly accurately join the sheets.

- Penoplex Comfort (31) - for walls, plinths and insulation of pitched roofs.

- Penoplex 45 - designed for use with high mechanical stress. Suitable for laying under asphalt, in industrial and warehouse premises.

Using Penoplex 45 when building a road

Material cost

Penoplex is sold in packs, from 4 to 20 pieces, depending on the thickness. On average, each package weighs 15 kg.

According to online stores, the wholesale price (from 10 m3) per cubic meter. meter looks like this:

- Comfort - 4050 rubles.

- Roof - 4350 rubles.

- Foundation - 4250 rubles.

- Penoplex 45 - 5500 rubles.

Production specifics and special properties

The first extrusion plant appeared in America more than half a century ago. During the production process, polystyrene granules are subjected to high pressure and temperature. The catalyst is a special foaming agent. Usually it is a mixture of carbon dioxide and light freon. The resulting fluffy mass, reminiscent of well-whipped cream, is squeezed out of the extrusion unit. After a while, freon evaporates, and air enters the cells in its place.

Thanks to extrusion, the manufactured material has a finely porous structure. Each of its identical tiny cells is isolated. The size of these cells is from 0.1 to 0.2 millimeters, they are evenly spaced inside the material. This makes the material strong and warm.

Water absorption - minimal

For heat insulators, the ability to absorb moisture is an important characteristic. The following tests were carried out: Penoplex plates were left in water for a month, immersed in it completely. Water was absorbed by them in a small amount only for the first 10 days, after which the material ceased to pick up moisture. At the end of the term, the amount of water in the slabs did not exceed 0.6 percent of their total volume. That is, moisture can only penetrate into the outer cells of the Penoplex insulation, which were damaged when cutting the material. But there is no access to water inside the closed cells.

The cost

The prices in the table are valid in the spring of 2020:

| Brand | Price in rubles per package |

| Foundation (thickness 50 mm, 8 pcs.) | 1400 |

| Roof (80 mm, 5 pcs.) | 1420 |

| Comfort, (40 mm 10 pcs.) | 1200 |

| Base, (50 mm, 8 pcs.) | 1665 |

| Facade, (50 mm, 8 pcs.) | 1350 |

| Wall, (50 mm, 8 pcs.) | 1 350 |

That's all the information about Penoplex that I wanted to share with you.

Thermal conductivity coefficient - small

Compared to many other heat insulators, the thermal conductivity of Penoplex is much lower. Its value is 0.03 W * m * 0 C. Since the material practically does not absorb water, it is quite possible to use it where there is high humidity. At the same time, its thermal conductivity remains almost unchanged - it can fluctuate only from 0.001 to 0.003 W * m * 0 C. Therefore, Penoplex plates can be used to insulate both roofs with attics and foundations with floors and basements, without using an additional moisture protective layer.

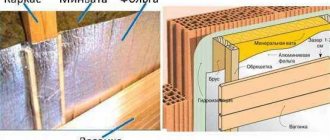

Installation technology

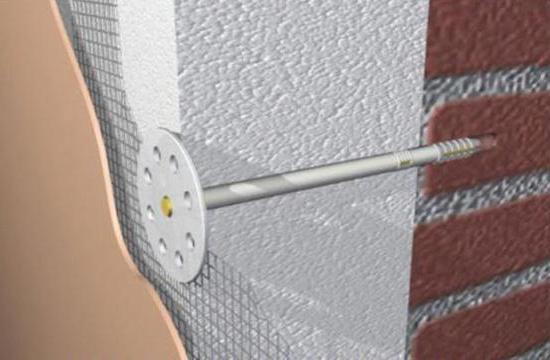

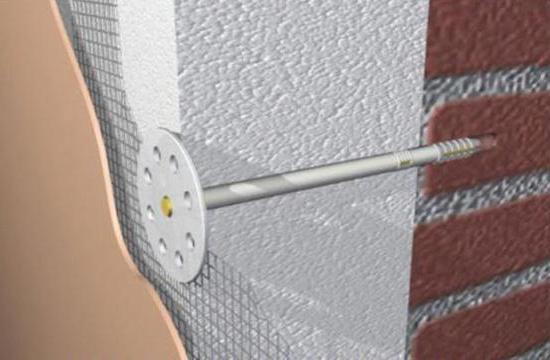

The problem of how to sheathe a house with "Penoplex Comfort" is solved in several main stages:

- Preparatory.

- Directly installation of insulation.

- Finishing the surface of the insulation.

Initially, it is necessary to prepare a surface that will be insulated. It is leveled, excess solution is removed, exfoliating pieces of the structure. If painting was previously performed, then paint and varnish materials should be completely removed. Places of formation of fungus, mold or moss are cleaned and treated with bactericidal solutions. Structures made of unplastered blocks or bricks must be primed or plastered. The prepared substrate must be absolutely dry.

Due to the exact geometrical dimensions, the assembly is carried out according to the principle of assembly of the constructor. Insulation sheets are glued to the surface with special adhesives. The glue is applied to the surface of the Penoplex Comfort board. Additionally, the construction of the thermal insulation is reinforced with construction dowels. Particular attention should be paid to fastening in the area of openings, sheet joints and in the corners of the structure.

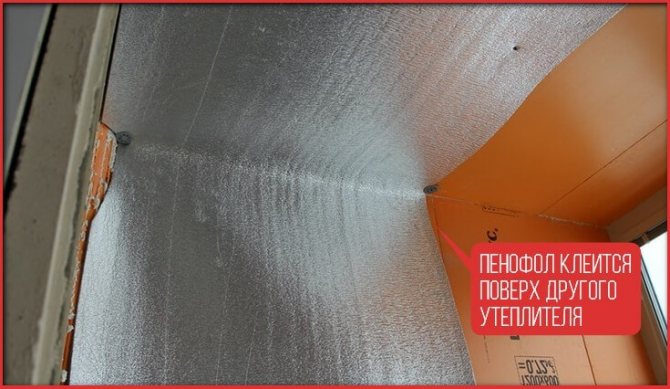

To protect the insulation itself, plastering, finishing with facing facade materials, and roofing are required. When insulating internal surfaces, it is imperative to use a vapor barrier of a heater.

Chemical activity - almost zero

Most of the chemicals used in construction are not capable of reacting with Penoplex. There are, of course, exceptions - some organic solvents can soften the insulation plates, disrupt their shape, or even completely dissolve.

These substances include the following:

- Toluene, xylene, benzene and similar hydrocarbons (aromatic);

- formalin and formaldehyde;

- substances from the class of ketones - methyl ethyl ketone, acetone;

- ethers, both simple and complex - methyl acetate and ethyl acetate solvents, diethyl ether;

- gasoline, kerosene and diesel fuel;

- polyesters used as epoxy hardener;

- coal tar;

- oil-based paints.

We also give a list of substances that are not capable of damaging Penoplex:

- Any kind of acids - organic and inorganic;

- salts in the form of solutions;

- alkalis;

- alcohols and paints based on them;

- water and water-based paints;

- chlorine (bleaching) lime;

- oxygen, carbon dioxide;

- butane, propane, ammonia;

- oils (both animal and vegetable), paraffins;

- cement and concrete mortars;

- freons.

It is also worth noting that the biostability of the slabs of this insulation is also high - they do not rot or decompose.

However, for the shape and size of the Penoplex boards to remain unchanged, it is necessary to withstand the permissible ambient temperature at which this insulation can be used. Usually this parameter is indicated in the material passport. With excessive heating, not only the dimensions, but also the characteristics of Penoplex can change, since it can not only melt but also ignite. However, this is a drawback of all foams, as you can see by watching the following video:

Three questions buyers are most concerned about

The answer to this question is unequivocal: yes, it is on. Perhaps it is this feature that prevents the widespread distribution of Penoplex. However, on the building materials market, there are products labeled "G1" and "NG", which means low-combustible and non-combustible material.

In this case, antiperenes are used - a substance that prevents the spread of fire. It is worth noting that it is spread, not fire. Of course, Penoplex will require a fairly high temperature to ignite, however, the essence is the same: the material is flammable!

The material does not contain natural substances and therefore cannot attract rodents. However, this feature does not prevent mice and rats from chewing on insulation, arranging nests there and breeding offspring. To avoid these problems, a fine-mesh mesh is installed over the insulation.

In principle, Penoplex is an environmentally friendly material, provided that the material is created without disrupting the production technology. However, given that we are talking about an artificial material, chemical components can evaporate under the influence of certain factors, for example, prolonged exposure to direct sunlight. Therefore, Penoplex is not on the walls in its pure form and is always covered with finishing materials.

In addition, when the material burns, it emits acid vapors, carbon dioxide and other hazardous substances, including hydrogen chloride.Accordingly, in the event of a fire, there is a direct threat to human life.

As a fire retardant, hexobromocyclododecane can be used, which is a bioaccumulative toxin and is currently permitted in our country, but banned for use in the EU countries since 2020.

Penoplex Wall is used for wall insulation

This name is newer - earlier this heat insulator was called PENOPLEX 31 with fire retardants. However, the essence of this has not changed. Plinths, facades, partitions, internal and external walls of buildings are very well insulated with this material.

Moreover, from the inside, the walls are isolated only if, for some reason, it cannot be done from the outside. Or, in case of urgent repairs, it is also convenient to sheathe the walls with insulation from the inside. PENOPLEX STENA® is excellent for these purposes - it is very easy to install.

As for external use, this material has shown itself very well when laying well walls. Compared to traditional brick walls, such walls are much thinner (several times), but they are in no way inferior to them either in reliability or in their ability to retain heat.

Insulation Penoplex Wall can be used to create plastered facades. Since decorative plaster, sold everywhere, shines with a variety of types and colors, the house will turn out to be original and unique.

Benefits

Which insulation is better? 6 simple rules for choosing:

- Rule # 1. Havethe heater MUST BE WATER RESISTANT!

- Rule # 2. The insulation must be DURABLE!

- Rule # 3. Insulation must provide high HEAT PROTECTION!

- Rule # 4. Insulation should work LIKE THERMOS!

- Rule # 5. The insulation should be WARMING, not burning!

- Rule # 6. The insulation must be SAFE!

How to choose the best insulation for a country house?

The fact that any building needs to be insulated is known today to everyone who has thought about building or reconstructing their own home. The reliability of the structures of the entire building, the comfort of living, the health of your loved ones and the amount of funds that will be spent on heating or air conditioning of the whole house depend on effective thermal insulation. When it was decided that the house needs to be insulated, how to understand which insulation is better? Today, the market offers several groups of insulation: glass wool, penoplex and stone wool. This article offers 6 universal rules "how to choose insulation" that will help you choose the right material for your home on your own.

Which insulation is best? 6 SIMPLE RULES TO CHOOSE:

Rule # 1: Insulation MUST BE WATER RESISTANT!

Water absorption of a good insulation = 0!

To understand the connection between water absorption and heat protection, it is enough to draw a simple analogy: each of us remembers from childhood that “Feet should be warm”, if we wet our feet, we have a cold. If caught in the rain - you need dry clothes to keep warm. The same applies to the "clothing" for the house: the foundation, walls (facade), roof every day are exposed to the influence of the environment: groundwater, sudden temperature changes, precipitation - all this can lead to the formation of condensation in the heat-insulating layer, and therefore deprive your thermal protection house: in winter it will be cold in such a house, and hot in summer. The formation of condensation is also dangerous because it leads to the formation of mold, fungi and other harmful bacteria that destroy the material and pose a potential threat to the well-being and health of households.

Recommendation: when choosing a waterproof insulation, pay attention to the structure of the material, the harder and more uniform it is, the less chances for moisture penetration. There is also a more reliable way: the water absorption indicator is usually indicated in the technical specifications for the material and published on the manufacturers' websites.

Rule # 2 Insulation must be DURABLE!

The compressive strength of high-quality insulation is not less than 20 tons per m2!

Strength is especially important when insulating foundations, plinths and floors, since the insulation in these structures is constantly in a loaded state. The insulation must be durable so that it does not crumble or break during the construction period and does not settle over time. The strength of the insulation helps to prevent shrinkage and deformation of the insulation during vertical fastening in the walls, which determines the effectiveness of the insulation throughout its entire service life. High-quality insulation guarantees 50 years of efficient operation!

Recommendation: when choosing which thermal insulation is better - pay attention to the evenness of the edges, try to press on the sample. A high-quality insulation will always have an even edge, a homogeneous structure and minimal changes when pressed.

Rule No. 3 Insulation must provide high HEAT PROTECTION!

Insulation Penoplex: technical characteristics

Currently, there are many different thermal insulation materials on sale. One of them is Penoplex insulation whose technical characteristics fully meet the highest requirements for thermal insulation of almost any building elements.

Insulation Penoplex technical characteristics

Modern technologies with the use of non-toxic components make it possible to produce lightweight and easy-to-install heaters. "Penoplex" is produced by extrusion using various chemical additives, so the material cannot be called absolutely environmentally friendly.

The technical and operational characteristics of "Penoplex" clearly show that today it is one of the most effective heat-insulating materials. and the parameters of this insulation should be considered more closely.

What is Penoplex?

"Penoplex" is, in fact, extruded polystyrene foam, which is an improved form of a long-known foam plastic.

Thermal insulation extrusion line

The first installation for the production of this material appeared more than half a century ago in the USA. The production process is as follows: polystyrene granules are sent to a special chamber, where, in the process of manufacturing the working composition, they are melted and foamed using porophores under the influence of high temperatures. The result is a lush, thick foam similar to whipped cream, which is squeezed out in an even layer of a set thickness from the nozzles of the extruder, and then enters the conveyor belt and is cut into separate panels. The whole process takes place in a closed mode, and you can only see the finished product.

Penoplex prices

Foaming of polystyrene occurs by adding porophores to it - chemical compounds, when heated, there is an active release of gaseous products - carbon dioxide, nitrogen and others, which foam the polystyrene mass. The composition of porophores for the manufacture of extruded polystyrene foam may include the following substances:

The composition is prepared and molded at a temperature of 130 - 140 ° C at a rate of up to 60 kg / h. In this way, not only Penoplex is produced, but also Technoplex, Extrol and other domestic and imported heaters.

In the form of additives to such materials, light stabilizing agents, antioxidants, flame retardants, modifiers, antistatic agents and other components are used.

- Antioxidants are added during the extrusion process - they prevent thermal oxidation during processing and rapid destruction during storage and operation of the insulation.

- Fire retardants reduce the flammability of the material or make it completely non-combustible.

- Other additives protect the material from aggressive environmental influences.

Porous structure of "Penoplex"

When the extruded polystyrene foam solidifies, an air gap remains inside it, evenly distributed throughout the entire structure of the material. Therefore, the finished insulation has a homogeneous porous structure with small cells ranging in size from 0.1 to 0.3 mm, filled with air (gas). Each of them is isolated from the other, which ensures the highest thermal resistance and material strength.

You may be interested in information on how walls are insulated inside a house with mineral wool

Technical and operational characteristics of "Penoplex"

The main characteristics of the material are shown in the table:

As you can see, several varieties of "Penoplex" are produced, which are designed for a specific area of application. Therefore, slabs of material have a retail density and a certain range of standard sizes. The insulation is easy to install, lightweight, perfectly cut to the required size. All this makes it possible to carry out the process of thermal insulation of building elements independently.

Plates "Penoplex" are very easy to install

The table gives "dry numbers", but it is worth considering each of the parameters in more detail.

- Coefficient of thermal conductivity

"Penoplex" has a low thermal conductivity: this parameter is one of the lowest among all modern heaters, about 0.03. The thermal conductivity of the material remains practically unchanged with changes in humidity or ambient temperature (fluctuations do not exceed 0.001 ÷ 0.003 W / m2 × ° C). Therefore, "Penoplex" is suitable for both external and internal thermal insulation - it is used for insulation of roofs and ceilings, basements and foundations, and it does not require additional external protection with moisture-resistant materials.

- Hygroscopicity

Scope of application

Facing the base of the foundation with penoplex

Despite the fact that different types of foam have almost the same thermal conductivity, it is necessary to take into account the thickness and strength characteristics, as well as design features, when selecting building materials for various works.

For thermal insulation with foam plates of different surfaces, a material of a suitable brand should be selected:

- Wall and floor insulation is carried out with C series expanded polystyrene. Its density is approximately 30 kg / m3. The load on the walls is minimal. A feature of this category of material is that stripes are made on the surface of the sheet with the help of a router, which improve adhesion to the wall or finishing materials. Thermal insulation is allowed both inside and outside the building.

- For thermal protection of a balcony and a loggia, as well as a sauna or a bath, a heater of the Penoplex Comfort series is more suitable. Plates with a density of 25–35 kg / m3 have an L-shaped edge, which, when installed, ensures that there are no through seams.

- The foundation base and the plinth are faced with F-series foam, the density of which is 29–33 kg / m3. It is also used for thermal insulation of septic tanks. This material has increased strength and moisture absorption coefficient is almost zero. For buried foundations, the specialized "Penoplex GEO" is also used.

- Thermal insulation of the roof with foam is carried out using sheets of category "K" with a density of 28-33 kg / m3. The plates have a U-shaped edge, which increases the reliability of the connection. Lightweight, tough, moisture resistant material perfectly protects flat and pitched roofs. If there is a recreation area or a pedestrian zone on the roof, Penoplex 45 with a density of 45–47 kg / m3 is used. It is also used as a heater for road surfaces, in particular for runways, to prevent heaving of the ground at negative temperatures and destruction of the upper layer of the canvas.

For any type of work where insulation is required, you can use Penoplex 50. This is a dense material for universal use, it can protect both the attic space and the foundation base.