The main types of insulation

Thermal insulation in twisted rolls can be used for both external and internal filling. There are options specially designed for pipes and utilities. Roll insulation for walls directly under the wallpaper are also on sale.

The raw materials for their production are also used in different ways. Thermal insulation from mineral components is the most common. Foamed polyethylene is also popular. Natural heaters like corks are less common and used. Some species have an extra layer in the form of foil or paper. Let's consider each option in more detail.

Purpose and application of roll insulation

Roll insulation is a versatile material, so it can be used for a wide range of construction and finishing works.

Walls

Thin lightweight heat-insulating material allows you to insulate, soundproof and level the walls for finishing with wallpaper or wall panels. The material is cut into separate canvases and glued to the cleaned, dust-free wall. As an adhesive, a composition containing cement is used, which provides high adhesion to the substrate.

Pipes

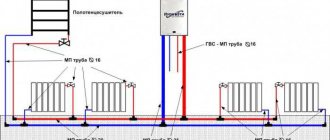

Most often, foil insulation is used to insulate pipes of the underfloor heating system. It is laid on a flat prepared base. The water contours are fixed from above. During heating, thermal energy is reflected from the substrate and directed upward. Thus, heat loss through the bottom ceiling is excluded, and the system itself becomes economically viable and efficient.

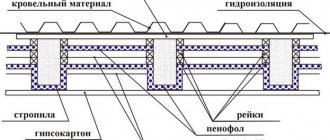

Roof

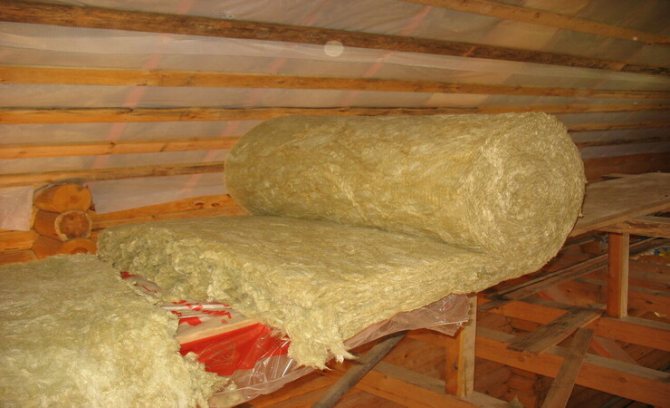

The widespread use of roll insulation for roof insulation is associated with the complex structure of the rafter system. This material is great for flat and pitched roofs.

Thin foil material is also used to insulate enclosing structures on loggias and balconies. With a sufficient area and height of the room, mineral wool is used, which is placed between the elements of the lathing from the bar. Using a piece of foil-clad insulation, you can make a reflective screen for a heating radiator.

Minvata for roofing

Glass wool for pipes

Mineral wool for walls

Special coating of thermal insulation

To improve the characteristics of their products, companies that produce roll thermal insulation add certain coatings. The basis under them can be different.

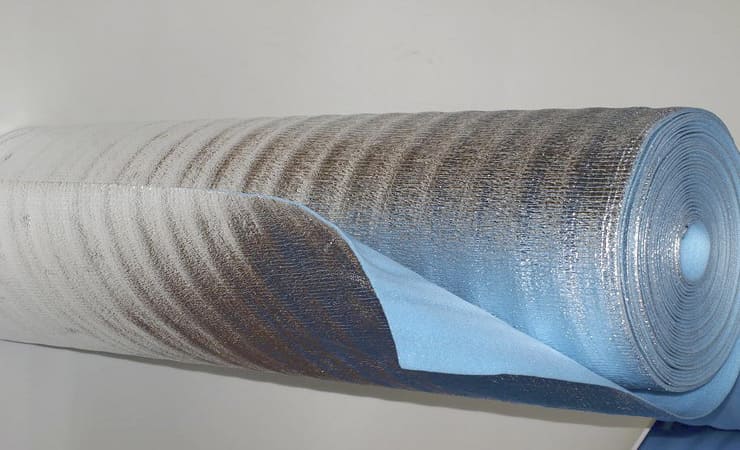

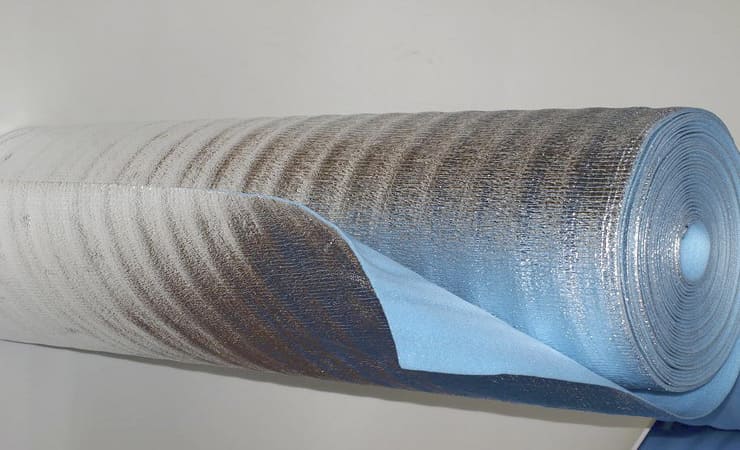

- Foil - tends to reflect heat. Basically, it is fixed on one side, the one that will face the interior of the room. This will protect the walls from moisture as well. Initially, the technology was developed for warm pipes, but over time it has been applied to other surfaces as well. Foil insulation is produced by almost all well-known companies in this field.

- Metallized coating, it differs from the previous vapor and breathability. But it has a drawback, the layer decreases from mechanical influences or completely disappears, which increases heat loss.

- Paper layerwhich improves the adhesion of the rolls to the walls. It can be on one or both sides. The latter option is used for subsequent wallpapering.

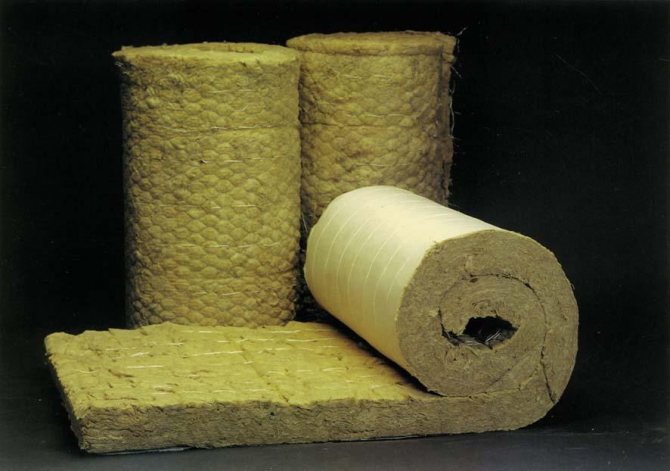

Types of mineral wool in rolls

There are several varieties of insulation in this group. Their structure is the same, they differ in composition.

- Basalt wool. This material is made by melting rocks into the finest fibers, which are intertwined randomly. By adjusting the density of the material, manufacturers get hard or elastic cotton wool. The latter is applicable to rolls.The thermal conductivity of the material is the lowest of all such options. This allows it to be a fairly common type of insulation. The weight of one cubic meter of cotton wool ranges from 30 to 100 kg. The maximum temperature that it can withstand is 700 degrees. Manufacturers declare that the basalt components of cotton wool are safe for health. Over time, however, particles of fibers and binders are found in the air.

- Glass wool. The same fibers are melted, but already based on glass waste... Differs in the lowest cost and density up to 25 kg / m³. Withstands high temperatures, its maximum is about 450 C °. Indicators above destroy glass wool thoroughly. She copes with her main task well. A negative aspect is the effects on the respiratory tract and skin during installation and use. Therefore, thermal insulation made of glass fibers is mainly assigned the role of only the outer layer.

- Slagged. The third type of insulation is produced from metallurgical waste (blast furnace slag). The price of rolls is also reasonable. However, this type of cotton wool is outdated, it was popular back in the USSR. Due to the fragility and allergy of fibers, it is not used in residential premises. The density of the material is different: cotton wool with an indicator of 75 kg / m³ is used for floors, 125 kg / m³ is suitable for walls. The hygroscopicity is high; it loses its properties when wet. Non-flammable, melts at temperatures above 300 C °.

Any kind of cotton wool should be covered with a vapor barrier, especially in rooms with high humidity. And it also holds back the smallest particles of fibers that appear over time, which negatively affect a person. Formaldehydes are often used in the composition of raw materials, which also affects health. Quality rolls should have a minimum of this substance.

For laying mineral wool the installation of the frame is mandatory. On the walls, the panels that hold it are pressed strongly so that over time the canvas does not slide out. For the necessary protection from the cold, the number of layers can be increased.

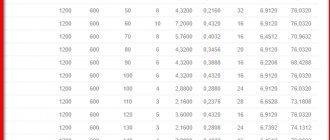

Manufacturers often divide their products according to the purpose of the insulation. For ceilings and slabs, the rolls will be lightened. For base floors, walls, and other surfaces, the density of the material is usually increased. Due to this, the dimensions of the roll also change:

- length from 3 to 8 meters;

- thickness in 3 options (50 mm, 100 mm, 150 mm);

- width from 0.6 m to 1.22 m.

The role of the foil surface

The main feature of such insulation devices is the presence of a thin but durable foil coating. In this way, the material is protected from the negative effects of ultraviolet rays and high humidity, which is very important when equipping industrial premises, kitchens, bathrooms, baths, saunas.

Foil insulation tolerates high temperatures well

Foil insulation is laid in accordance with a special technological process. A gap of 1-1.5 cm is necessarily created between the thermal insulation and the finishing material.This is very important, since at elevated temperatures the insulation retains a given degree by transferring it to the back wall and then returning it back to the walls, but not to the room.

In comparison with roll materials made of slag wool, glass wool and basalt base, the foil product should be fixed on the crate. The layers are overlapped, their joints are carefully insulated.

Insulation wool manufacturers

Hardware stores offer a wide variety of mineral wool. Consider the features of the materials of some companies specializing in this area:

- Isover. This manufacturer produces mainly glass wool, which has decent characteristics. The materials are breathable and recover their shape well after mechanical stress. Do not emit harmful substances when heated.However, when installing any kind of mineral wool, it is necessary to use personal protective equipment... Roof options offer high moisture protection and good sound insulation. Wool brand "Sauna" (for baths and other wet rooms) has an aluminum coating, reinforced with a reinforced mesh, which makes it possible not to use a vapor barrier.

- Ursa. Both universal and specialized glass wool are produced under this brand. For example, for hot pipelines or equipment that heats up to 270 degrees. And also the manufacturer offers a product with Pure one technology. It allows you to bend around irregularities due to the "spring" effect. Safe acrylic serves as a binder for raw materials, it does not allow fibers to break. It is a good option for rooms with children.

- Rockwool. Produces durable basalt wool for technical use that can withstand temperatures up to 1000 ° C. It is environmentally friendly and does not lose its thickness over time, as the manufacturer claims.

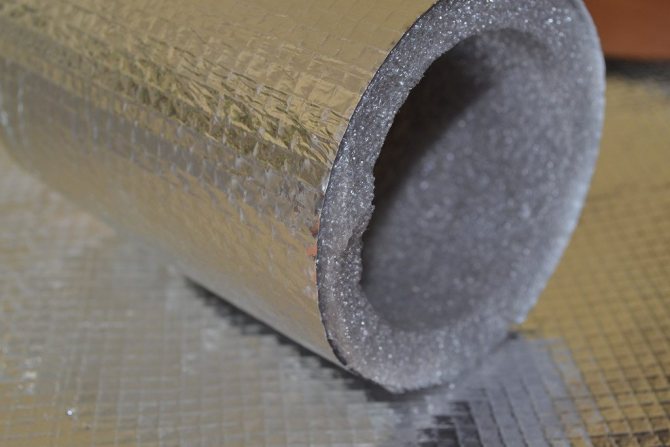

Foamed polyethylene for insulation

Has many positive qualities. It is obtained by filling heated polyethylene with gases. As a result, a mass is formed with many closed bubbles inside, which subsequently solidifies. For special strength, it is also "stitched", that is, the bonds of molecules are strengthened by chemical means.

Therefore, on sale there are two options: stitched and, respectively, unstitched... Both types have very low thermal conductivity, but the first one still has better characteristics, therefore it is more expensive (its density is 30 kg / m³). The general properties of materials are as follows:

- they are durable;

- absolutely do not absorb water;

- easy to assemble;

- do not harm the environment and humans;

- organic destroyers like bacteria and fungi are not afraid of them;

- the layer thickness required to retain heat is much less than, for example, mineral wool.

The difference is that cross-linked polyethylene foam is capable of absorbing sounds well, but its counterpart cannot boast of this. As a sound insulator, it works worse. Under mechanical stress, the unstitched version loses its shape irrevocably. Stitched has a high compressive strength, which means it can be used for thermal insulation of horizontal surfaces.

Due to the fineness of the material, the length of the rolls can be up to 30 meters, the width is from 0.6 to 1.2 m.The thickness reaches 1 cm.Negative nuances for polyethylene are flammability and current conductivity (electricity passing nearby should be well insulated) ... Special glue is required to secure the material to the wall.

Foil heat insulator and its properties ↑

It is worth noting that manufacturers often cover the heat insulator on one side with a layer of foil, which makes it possible to protect the coating from the negative effects of ultraviolet rays and moisture penetration. Its use is advisable when insulating a room from the inside, while the base can be made of a variety of materials.

Optimal solution for internal thermal protection

Types of insulation and features of each type ↑

The backing is made of expanded polyethylene, cork or expanded polystyrene. Expanded polystyrene is an affordable and very practical roll foil insulation that copes well with noise absorption, does not have hygroscopicity and is able to extinguish even minor vibration manifestations.

The Thermo-Tap insulator has excellent reviews among consumers, the roll length of which reaches 10 m with a width of 0.5 m.Practice shows that such insulation perfectly resists fungus and moisture, but at the same time has lower thermal insulation values, yielding in this aspect foamed polyethylene products.

The cork base for the heat insulator should also be noted.The material is characterized by high strength, light weight, excellent aesthetic data and absolute harmlessness to humans. For rooms with a high level of humidity, it is recommended to use a wax-impregnated cork backing. The length of the roll does not exceed 10 m, its width is 0.5 m.

Cork backing is used for the floor

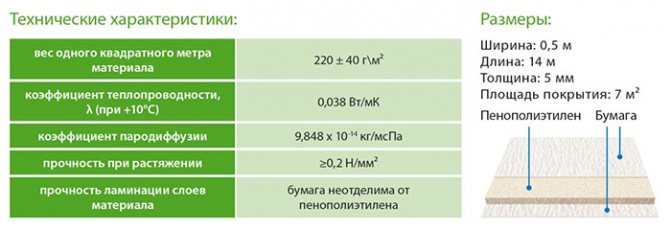

Foam-based polyethylene is a sheet, consisting of the smallest cells filled with air, covered with a layer of paper on top, which is attached by lamination. Thanks to this, it is possible to achieve the most durable and reliable connection with any type of base.

Thermal insulator with frost protection

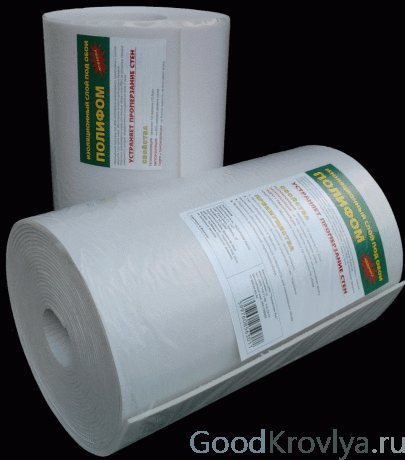

The most widespread is the foamed roll insulation "Polifom", produced in rolls with the following dimensions: length - 14 m, width - 0.5 m, thickness 5 mm. Its density is 30 kg / m3, it perfectly absorbs sounds up to 22 dB, while offering a minimum thermal conductivity of 0.039 W / mK.

External coverage and its relevance ↑

The outer coating can be foil-coated or metallized. Each of the options has its own characteristics, and its use can be justified in a given situation. So, metallized material perfectly retains steam, but at the same time it does not have the highest heat reflection rates.

It is indispensable when carrying out insulation work in bathrooms and shower rooms, as well as other rooms with high humidity levels. It should be noted that such spraying does not have high strength - even a slight mechanical effect is enough to violate its integrity.

Roll insulation with foil has excellent heat-reflecting data and is resistant to all kinds of external influences. It can be placed behind the radiators without any problems in order to better retain heat inside the room.

Simple styling

As for the shortcomings, the foil insulation has poor vapor permeability, does not withstand direct contact with concrete, and the cost of a product with a thick layer of foil will be quite impressive.

The main advantages of foil heat insulator ↑

Among the main advantages of foil-clad heat insulators, it is especially worth noting the following:

- excellent heat shielding performance, about 97%;

- good functionality and the ability to use not only walls, ceilings and floors for insulation, but also all kinds of industrial units;

- minimum roll weight and ease of installation without the need for arranging frames and other structures. Fastening is possible with construction glue or ordinary polyurethane foam;

- acceptable cost;

- environmental friendliness and safety.

Polyethylene foam of the Penofol brand

Insulation Penofol - appeared recently, but has already stood out among their own kind. It does not deteriorate from weather conditions and aggressive environments. Heat insulators of this company have several varieties:

- the foil coating can be fixed on both one and two sides;

- rolls with an adhesive layer (further simplifies installation);

- specialized type of isolation for communication networks;

- insulation for harsh conditions with a thickness of up to 40 mm.

The combined technology makes it possible to further reduce the thermal conductivity of the surfaces to be insulated. Moisture-resistant and durable material that does not require the cost of vapor barrier, can be used in various directions. Does not lose its properties in the temperature range from -60 to +100 C °.

Mezhventsovy heat insulator and its features ↑

There are also mezhventsovye rolled insulation, which is a rather specific solution designed to fill the voids in the space between the wedges. A crown is a level in a house made of a bar or log.No matter how well the installation was carried out, including with the use of a profiled bar, there is a free space between the crowns, just filled with this type of insulation.

It is produced in extremely narrow rolls, while it is always made from natural and harmless materials, including:

- batting;

- jute;

- flax and others.

Close-up of inter-crown seams

The laying of the material is carried out not only during construction work, but also after several years after their completion - as the operation progresses, the tree dries up, which causes the need for additional caulking (driving insulation into the existing cracks using a wide chisel and mallet).

Cork surface insulation

An environmentally friendly and durable raw material for the production of thermal insulation is the bark of cork oak. Absolutely natural ingredients make rolls safe for health. The crushed bark is bonded with organic glue and pressed. The thickness ranges from 2 to 6 millimeters. The length of the roll reaches 10 meters, the width is mainly one meter. Most often, in this form, the cork goes under the wallpaper, on the substrate for the laminate or "warm floor".

Thermal conductivity index not inferior to mineral wool, but the layer is used much thinner. Cork insulation is low flammable, does not absorb water well and retains noise. However, its density is high, and accordingly its weight is large. The safety margin is high, the service life is declared up to 50 years. The negative side is the price for "naturalness", in comparison with the rest it is quite high.

This insulation is mainly produced by Portuguese companies: Wicanders, Izora, Amorim. They offer a wide range of insulation rolls, which can also serve as wall decoration. Installation is also simple, basically the cork is "put" on glue.

Modern technologies provide a huge selection of heat insulators for any premises and structures. The selection criteria are based on which surface should be covered and how much the buyer is willing to pay for it in order to maintain comfort in their home.