Sealing roof folds - from 140 rubles. per m.

10.12.2019

Modern technologies and equipment have made it possible to establish the production of high-quality products for seam roofing. Smooth joints, reliable locks make it possible to obtain a good and reliable roof covering. But for 100% waterproofness, proper sealing of the roof folds is required.

| The use of support systems for such work is not always practical. The assembly and dismantling of scaffolding, the use of scaffolding towers or attachments requires a significant investment of time and money. In this case, it is more profitable to order the services of industrial climbers in Moscow. |

When it is required to seal the seams of a folded roof

| Sealing seams and joints on seam roofs avoids moisture penetration under the sheet metal sheets. This protects all structural elements of the building from destruction by water. |

Get advice by phone

+7 (495) 997-24-50 Request a call

When it is necessary to carry out waterproofing work:

- Separate metal sheets with a special joining system have long been used for roofs with a low slope. Previously, gutters were made by hand. The fastening of the canvases to each other was carried out using a special seam - a fold. It was produced using conventional tools. This technology did not allow a completely sealed coating to be obtained. Old roofs require periodic repairs and sealing of the joints on the roof.

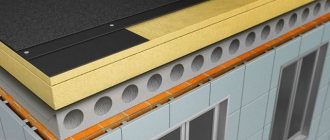

- Coatings made of modern materials are largely devoid of the drawbacks that arose during the handicraft production of sheets. For additional sealing, special sealing gaskets are laid in the folds. But over time, they can also leak at the joints of the canvases. This is often due to the use of poor quality materials. An important role is played by professional installation and adherence to the technology of laying a metal roof.

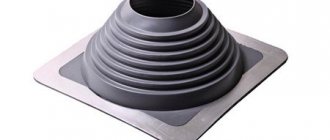

- Violation of tightness is also possible in the places where sheets adjoin pipes, ventilation shafts, pipes. Double folds are more resistant to moisture. Single seams are less reliable and require additional sealing.

- Folds can diverge and leak due to improperly positioned battens. Unprofessional removal of snow and ice from the roof also often leads to a violation of the construction of the joints.

| Industrial climbers can quickly and efficiently seal seam roof joints. Availability of professional equipment, high-quality materials, experience in high-altitude work allows you to restore the tightness of the metal coating on the roof in a short time, without significant costs. The cable harness to secure the worker can be attached to any type of roof. |

Order roof sealing

The specialists of our company carry out a wide range of high-rise works on roofs and facades. We will plaster or paint the facade in the shortest possible time, repair cracks and chips, insulate the outer walls, and seal the interpanel seams.

Our specialists have extensive experience and provide high-quality roof sealing in Moscow and the region. At the initial stage, our manager visits the object to assess the condition of the roof, then the estimate documentation is drawn up and the contract is concluded. We use only safe materials that can reliably protect the building from heat loss and leakage.

Choice of materials

The correct selection of materials for sealing joints from galvanized smooth sheets or other types of metal plays an important role in the tightness and durability of the coating. It is made depending on the place of repair. Special sealing tapes and roofing mastics are used here.

Materials are exposed to high temperature extremes, prolonged exposure to moisture and UV rays. They must be resistant to vibration loads, compression when securing the folds. Sealing is usually done with bitumen or polyurethane based compounds.

| Butyl rubber or bitumen sealants are characterized by increased adhesion to metal, good resistance to moisture. Materials must be inert to atmospheric precipitation. The mastics are suitable for flat or ribbed surfaces. They completely fill the gaps in the joints and seams of the roof. |

- Oxyplast is a two-component white polyurethane sealant. Cold curing mastic is suitable for sealing roofing, interpanel joints. Differs in good adhesion to metal, brick, wood, concrete, glass, plastered surfaces. It is characterized by increased elasticity, the ability to paint with various paints.

- TechnoNIKOL-45 is a cold curing butyl rubber sealant. The composition of white or gray color is characterized by high elasticity, resistance to ultraviolet radiation, fast drying time. It can be used for a wide range of operating temperatures. Designed for waterproofing and sealing joints and seams of various building structures. Suitable for protecting metal from corrosion.

- Sazilast - surfaces can be insulated at temperatures from -15 ℃ to + 40 ℃.

- One-component polyurethane sealants.

- Sealing tapes

| Self-adhesive tapes (one and two-sided) are popular. They are useful for perfectly smooth surfaces. |

When sealing folds, silicone compounds are sometimes used. They are able to withstand abnormal temperatures. But silicone isn't flexible enough. If the metal expands strongly, it can be damaged. In addition, silicone compounds often provoke cloth corrosion.

| Professional waterproofing materials and high quality sealants are produced both abroad and by domestic enterprises. When choosing, you should give preference to well-known brands and brands. |

Varieties of roofing sealants

There are various types of sealants. They are used in the process of repair and planned work, as well as during construction.

These can be completely different construction and finishing activities:

- sealing seams between individual elements, for example roofing sheets, especially for roofs with a slight slope;

- elimination of cracks near ventilation shafts, chimneys and gutters, antennas and other objects that violate the integrity of the coating;

- elimination of cold bridges;

- insulation of joints between the roof covering itself and other materials;

- sealing of inclined skates;

- fast disposal of leaks.

All existing sealants are conventionally divided into six main types. Let's consider each of them in more detail.

Tape

What are the main advantages of tape sealant? After all, this product is one of the most effective and inexpensive for roof protection.

Its advantages are as follows:

- very resistant to sunlight and negative temperatures;

- the ability to quickly and conveniently replace;

- excellent mechanical strength;

- ease of application;

- tight and durable bitumen layer;

- long-term operation.

This tape material is convenient to use for emergency repairs of bituminous roofs (in the form of neat patches), for sealing vapor barrier films, for repairing drainage systems and metal roofs,for sealing joints.

This tape is very simple and convenient to use. Therefore, it can be used without problems by people who do not have any construction experience. Like ordinary scotch tape, this tape is fixed at the joints and seams.

Bituminous, rubber

The advantages of this material are many.:

- excellent moisture resistance;

- good elasticity;

- affordable price;

- the possibility of painting to match the general color of the roof;

- durability and excellent strength;

- excellent grip on dry and wet surfaces.

This type of sealant is most often used for work with a metal roof (metal, corrugated board, etc.), roofing material and shingles.

Their disadvantages are poor resistance to high temperatures and rather high toxicity.

Silicone

Silicone mixtures are packaged in standard pistols or buckets. From large containers, they can be applied with a construction roller or with a special advanced spray gun.

This variety is one of the most affordable and common on the market.

All silicone products can be divided into neutral and acetate (acetic). The former are less toxic, odorless, but inferior to the latter in terms of strength.

Advantages of the composition:

- multifunctionality;

- fast hardening;

- good resistance to sunlight and temperature fluctuations;

- can be used for both long-term and temporary isolation.

Acrylic

Acrylic mixtures resemble high-quality silicone, but their prices are more affordable. The surface for their application must be perfectly dry.

Pros of acrylic:

- no irritating odor;

- excellent coated grip;

- lack of solvents in the composition;

- on sale has a wide range of colors.

Classic acrylic sealants do not have the best waterproofing properties, since they are based on a water-soluble dispersion.

If you decide to use this particular tool, then it is recommended to strengthen the protection with tape to seal the joints and seams.

Polyurethane

For the manufacture of polyurethane sealant, a resin is used, which undergoes a polymerization process under special conditions.

The resulting mixture is viscous and lightweight and can be easily applied to any type of surface.

This type of sealant can be considered one of the most expensive, moreover, it is quite toxic.

But all these minuses are compensated by his remarkable working qualities.

This type of sealant has the following characteristics:

- durability;

- ease of application;

- excellent resistance to corrosion, mechanical stress and high humidity;

- high efficiency;

- fast hardening;

- preservation of working qualities even at negative temperatures.

It matches perfectly with any type of roofing material, providing a reliable and durable insulation that can be considered ideal.

Two-component

The two-component compound is usually based on silicone rubber. It is represented by a special hardener and adhesive paste.

Separately, the composition can be stored for a very long time (in accordance with the indicated period). But after mixing, a chemical reaction begins, therefore the mixture must be used within a certain specified time.

What can such compositions boast of?

- The seam after application is smooth and even.

- The widest temperature range for the preservation of the properties of the product - from - 70 to + 70 degrees.

- Very easy to apply.

- They have excellent adhesion to the main building materials - brick, wood, metal, PVC, concrete, etc.

- It can be applied both in winter and in summer: the temperature for application is from -25 to +40 degrees.

Work technology

| Careful adherence to the technology for performing waterproofing works guarantees reliable sealing of the roofing, 100% elimination of leaks for a long time. |

Stages of carrying out:

- Inspection of the place of work, preliminary determination of the scope of repair, selection of materials and tools.

- Preparation of the roof surface - the coating must be cleaned of dirt, dust, old sealant, degreased materials from galvanized steel or other metal with a solvent.

- If there are foci of corrosion, the metal must be cleaned.

- Laying sealing tape in joints and seams. To improve the adhesion to the metal surface, it is worth pressing the edges of the tape with a roller.

- In dangerous places where there is an increased likelihood of moisture getting under the coating, it is necessary to reinforce with fiberglass.

- Spreading the gaps with mastic is done with a special pistol or brush.

| When sealing the roof abutment, strict adherence to the application conditions and temperature conditions indicated by the manufacturer of the waterproofing material is necessary. The vast majority of materials are not applied to a damp surface. |

Carrying out work on sealing the roof folds will be a good option if the roof covering itself is in a satisfactory condition. When repairs are required to metal roofing sheets, sealing is a temporary solution to the problem of leaks.

Sealing of roof junctions to walls and technological shafts

It is impossible to achieve perfect adhesion of the roofing to walls, ventilation shafts, skylights. To eliminate cracks, it is necessary to seal the joints.

| Small gaps are eliminated with gaskets, tapes. Then it is coated with waterproof mastics and sealants. |

If the embedment area is quite large, then a waterproofing apron is required. This is true for the places of abutment to the walls of the building, around the chimneys. At the joints of the openings of the roof windows, a multilayer insulating seam is made.

Transparent roof sealing

The joints of translucent roofs are treated with sealants with a curable or non-curable structure. There are also special elastic profiles that allow you to make a sealed transparent roof joint. The choice of sealing method and material depends on the type of structure with its anticipated future loads. For example, glass greenhouse roofs are optimally sealed with structural silicone. The paste adheres perfectly to glass without losing its high insulating properties for a long time. A transparent roof is subject to wind and snow loads, which is important to consider when choosing a sealant.

Operating principle

Bitumen in its natural environment is a derivative of oil. This mountain resin has been used for many centuries as a finishing or building material. With his help, wood was processed, a mosaic was created.

And artificial bitumen is made on the basis of materials such as:

- slate;

- oil;

- coal.

The material does not dissolve in water; therefore, it is water-repellent and amorphous. Due to its "fluidity", it is easy to applied to any surface and has good adhesion to a variety of materials. For this reason, it has excellent contact with the following materials:

- a rock;

- concrete;

- wood;

- metal;

- brick.

The sealant works effectively at ambient temperature conditions from -40 to +90 degrees. Resistant to aggressive chemical media and UV radiation.

Roof waterproofing.

Roof waterproofing: sealing roof joints and abutments, sealing roof folds will certainly eliminate leaks. But you need to understand that with existing defects in the roof structure, this is a temporary measure.Therefore, it is necessary to qualitatively inspect the condition of the roof truss system, the condition of the folded locks, gutters. If defects in the roof truss system lead to gaps between the elements of the roof, then, despite the deformability of the sealant, after a while, leaks through the roofing may again appear. Therefore, to eliminate leaks for a long time, it is necessary to qualitatively repair all elements of the roof. But if funds are not provided for the overhaul of the roof, sealing the folds, joints and gaps of the roof is a good temporary measure to eliminate roof leaks.

UP

Metal roofing repair.

A leak in such a tile appears as a result of the fact that the installation of the coating and the roofing cake was done incorrectly, after cleaning the roof from ice, mechanical damage appears (scratches, dents, holes), self-tapping screws are loosened. If there is such damage, then the following measures must be taken to correct it: - In order to prevent the appearance of corrosion, we cover all visible scratches with a special paint. - Sealing (use silicone sealant) in all places where there are leaks. - If there is a gap on the sheet, it can be removed with a soldering iron and a steel patch, and if there are more such gaps, the entire sheet must be changed. - The reason that the screws are loose in their low quality. Therefore, instead of such self-tapping screws, it is best to install new high-quality fasteners. If the design itself is not done correctly, then in this case more serious repairs will be needed, which will incur more significant financial costs. The fact is that for such a repair it will be necessary to remove the roof covering completely. Most often, in this case, more insulated pitched roofs leak. When waterproofing them, a low-quality and cheap perforated film was used. Such a film must be replaced with a special diffusion membrane using a sealant.

Roof seam sealing.

The roof of any building wears out. The load-bearing structures of the roof bend and deform due to the load of snow and ice. Roof folds, joints and abutments are deformed and diverge. Before winter, planned diagnostics and subsequent sealing of the roof folds should be carried out. All folds of a galvanized roof must be coated with a sealing mastic. Sealing the roof folds, as well as joints and abutments to the facade, will protect against moisture penetration and ice will not destroy the roof.

Features of materials and technologies for roof processing

The form of sealants can be completely different. For example, it is advisable to use mastics on large-area roofs, while mastics should not only fill up cracks with high quality, but also have waterproofing properties. To shorten the time of work, it is recommended to use special sealing tapes.

It must be remembered that attention should be paid not only to the correct choice of material for processing joints on the roof, but also to the technology of its application.

If the roof is tiled, then with the correct technology of its installation, tightness will be ensured. However, in the case of a slope of less than 18 degrees, it is recommended to lay roll material under the shingles, which will provide an additional degree of tightness.

Pitched roofs with a slope of more than 18 degrees are sealed only where there is a possibility of leaks. As a rule, this is where antennas, ventilation hatches, roof-to-wall joints are installed, and so on. It is imperative to process the attachment points of the cornices and overhangs from the ends of the building.

Thus, the integrity of the roof is largely determined by the observance of the technology of its installation.For example, for some types of roofs it is necessary to melt a special self-adhesive layer and carefully glue each element of the roofing material, which requires significant labor costs.

Sealing tapes

One of the most economical and effective method of sealing roof joints is butyl rubber tapes. They have all the necessary qualities:

The polyurethane sealant forms an elastic joint that prevents moisture from entering the building.

- Butyl tapes are resistant to low temperatures and ultraviolet radiation. Liquid sealants can harden and crack when exposed to atmospheric conditions. Sealing tapes do not have this property. Therefore, the service life of these materials is much longer than that of their counterparts.

- Ease of installation. To attach the tape to the desired surface, simply attach and press down on it. This ease of use is due to the good tackiness of the material.

The assortment of tapes is quite diverse. The most popular are tapes.

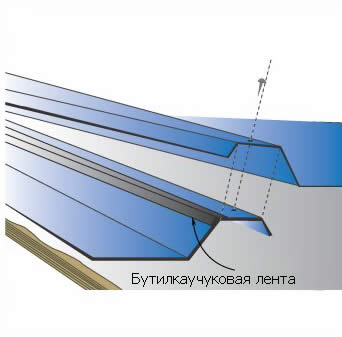

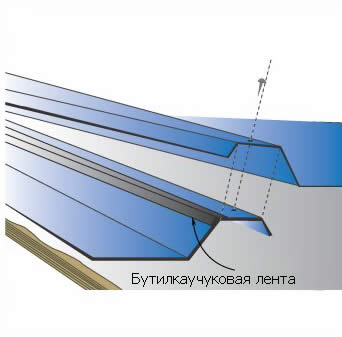

KISO-358 tape is a butyl rubber material with adhesive applied on both sides. This makes the tape ideal for sealing roofing sheet joints. If the roof is covered with corrugated board, the sheets of which overlap, then the tape is glued to the border of the sheets: between the previous and the next. This action serves as an excellent barrier against water leakage between the roofing sheets.

Scheme of sealing the side seams between the profiled sheets using butyl rubber tape.

This tape is perfect for fastening roofing films and other thermal insulation materials. It leaves no gaps, which prevents the loss of heat and moisture in the room.

KISO-501 is another type of sealing tape, which has adhesive on one side and aluminum foil on the other. This material is intended for repair work, such as: closing small holes, cracks, rusty places.

The tape is used to seal the space between the roofing material and the chimney. Also, this self-adhesive material perfectly protects fasteners from corrosion and cracks. For this, the attachment point is covered with tape, which insulates the penetration of moisture.