DIY heating system installation

Before you cook heating in a private house, you need to stock up on the following tools for soldering polypropylene pipes:

- Shaver that allows you to remove the reinforcement from the soldering area and chamfer the pipe;

- Pipe cutter;

- Soldering iron for polypropylene pipes with a set of nozzles of the required diameter.

The pipe connection technology is as follows:

- First, you need to put the shaver on the pipe and turn it several times to remove the aluminum layer. If this is not done, the metal, upon contact with the liquid, will gradually be damaged, thereby having a negative effect on the entire heating system.

- The soldering iron nozzle is heated to the desired temperature, then a pipe is inserted into the socket, and a fitting is put on the opposite side of the nozzle.

- When the parts melt a little, they need to be combined with some effort and held in this position for a few seconds. After the plastic has solidified, you can proceed to soldering the next section.

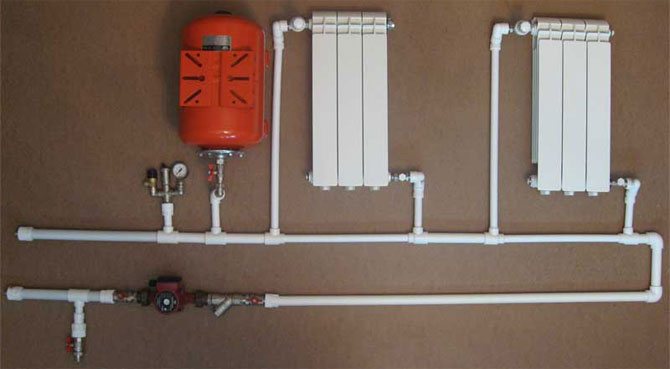

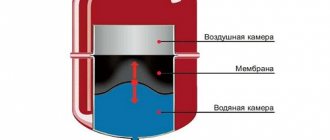

A safety group is installed near the boiler outlet. The place of installation is due to the fact that it is on this section of the system that the pressure rises when the system malfunctions. The expansion tank can be mounted anywhere, but there is one caveat: when installing the tank in front of the pump, the distance between them should be more than two filling diameters, and if the tank is attached behind the pump, then the distance increases to ten filling diameters. Failure to comply with this rule leads to premature failure of the membrane - and it is unlikely that it will be possible to immediately determine the problem, so you will also have to think about how to check the heating in a private house.

Sometimes the question arises as to whether the gravitational system can be converted into forced circulation heating. The answer to this question is affirmative - if necessary, the pump is installed in any circuit, which allows you to completely redo the heating in a private house.

- The diameters and configuration of the wiring are selected so that the system can work with natural circulation;

- In parallel to the wiring, two connections are cut in front of the boiler, to which a circulation pump is connected;

- The tie-ins are separated by a check ball valve.

When the pump is running, the valve closes and completely closes the passage in the bypass, thereby providing forced circulation of the coolant. When the pump is turned off, the heating automatically switches to natural circulation - the valve opens, the coolant continues to move. Of course, the check valve can be replaced with a valve or a ball valve - but in this case, you will have to manually switch the operating mode of the system.

Conclusion

This article gives a superficial idea of how to install heating a private house with your own hands. Each element of the design can be considered in more detail, therefore, if there is such a need, you can search for the corresponding article for a deeper understanding of a specific issue. In general, it can be noted that the heating system has a fairly simple design, and with due attention it can be easily assembled on your own.

Choice of materials

Please note: when heated to 95 degrees, the maximum allowable pressure decreases to 6-7 kgf / cm.

For a person who is not by hearsay familiar with the operating modes of various heating systems, it is not difficult to draw conclusions from the figures given: polypropylene should be used only in autonomous heating circuits.

Why? After all, the standard parameters of the central heating (4 - 6 kgf / cm2, 50 - 95C) seem to fit into the typical characteristics of polypropylene?

Yes, because the actual operating conditions of the central heating plant sometimes differ from those stipulated by GOSTs and SNiPs.

- At extremely low street temperatures, the operation of the elevator unit is practiced without a nozzle, with a muffled suction.In this mode, the heating system is supplied with a coolant from the supply line of the heating main, which has a temperature of up to 150C.

- With a water hammer (arising, in particular, with excessively fast filling of the circuit) at the front of the water flow, the pressure can reach 25 - 30 kgf / cm2.

Polypropylene is clearly not designed for such pressure.

Paired with polypropylene, aluminum sectional radiators are traditionally used.

Aluminum radiators with different center distance of connections.

What is the reason for such an unambiguous instruction?

Why are cast iron, steel or bimetallic products worse?

- The price of aluminum radiators is lower. than any analogues, except perhaps the registers made by hand from steel pipes.

- Due to the highest thermal conductivity of aluminum, all section fins have the same temperature. which ensures maximum heat transfer with minimum dimensions of the heater.

- Overpaying for a bimetallic radiator with comparable thermal characteristics is pointless. since the strength of any circuit is equal to the strength of its weakest link. In our case, the weak link will be polypropylene.

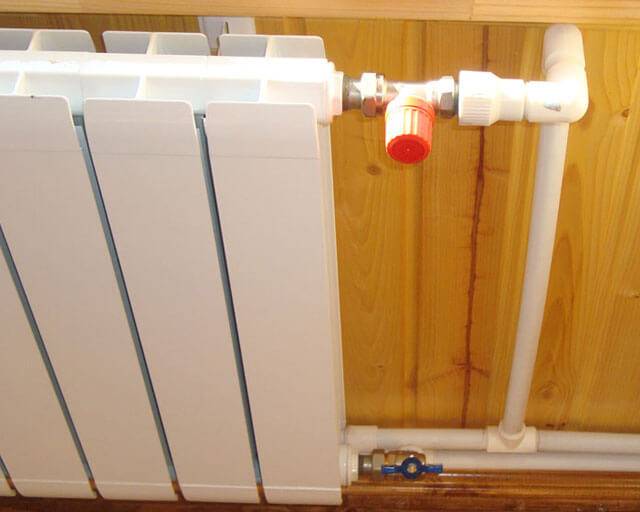

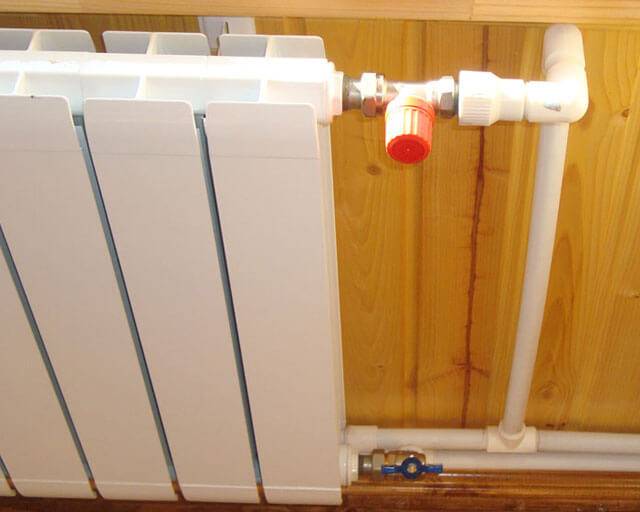

Connecting aluminum radiators with polypropylene pipes implies that they are equipped with shut-off valves. Which one and why?

The simplest and cheapest option is a pair of valves. Better - ball: unlike screw and cork, they are extremely reliable, always remain tight and do not require maintenance. The valves perform only one function - they allow, if necessary, to completely turn off the heater for repair or replacement.

The battery is equipped with a pair of ball valves.

An advanced option is to equip the battery with a choke or a pair of chokes.

What are they needed for?

- The choke allows you to manually reduce the heat dissipation of the device at high room temperatures.

- A pair of throttles are used in cases where the two-pipe system requires not only adjustment, but also balancing - limiting the flow through the radiators closest to the boiler or pump. For balancing, a throttle on the return line is usually used, to regulate the temperature in the room - on the supply.

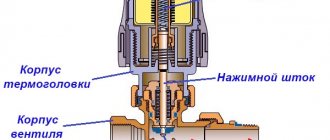

Finally, the most convenient (but also the most expensive) option in terms of ease of use is the connection of the radiator with a polypropylene pipe using a thermostatic valve and a thermal head.

The thermostat uses the already familiar thermal expansion of some media: when it heats up (and increases the linear dimensions of the bellows in the thermal head housing), it closes the valve, limiting the flow of the coolant; on cooling, the valve opens. This ensures a constant temperature in the room with any change in external conditions - the weather outside or the parameters of the coolant.

The thermostat must not be located in the upward flow of warm air from the radiator or piping.

Note: in a two-pipe heating system, the thermostat is often equipped with a balancing throttle on the second connection.

In addition to shut-off and control valves, at the bottom connection, the radiators are equipped with air vents - valves for bleeding air after the circuit has been reset.

The role of air vents can be:

- Mayevsky's cranes. Their advantages are compactness and low cost.

- Regular valves or water taps installed in the upper drain plug of the radiator. They are convenient for their high flow capacity: air is released through the valve much faster.

- Automatic air vents that remove air bubbles from the circuit without the participation of the owner.

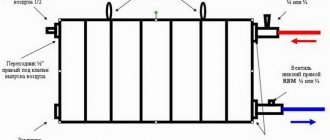

What fittings and how to connect a heating radiator with a polypropylene pipe?

- Tapping into horizontal filling is performed through a union tee with a diameter transition.Typical dispensing diameters in a reasonably long, forced circulation circuit - 25 - 32 mm; the outer diameter of the connection to a separate heating device is 20 mm.

The tapping in the filling is made with socket welded tees.

- 1/2 ”weld to thread adapters allow connection of valves, throttles or thermostatic valves.

- To connect the shut-off valves with radiator plugs, American women are used - quick-disconnect fittings with union nuts and rubber gaskets. They can reduce the time for dismantling the radiator to 30 - 45 seconds.

In the photo - a combined solution: a ball valve with an American.

The popularity gained by polypropylene pipes. associated with a number of their positive qualities:

- The price for them is much lower than for metal counterparts.

- High durability, due to the fact that the plastic does not rust, moreover, there is practically no sediment deposited on it.

- Do not need painting.

However, it should be borne in mind that not all types of polypropylene pipes are suitable for heating systems. The fact is that they must necessarily have a reinforcing layer that prevents significant thermal expansion of the pipeline.

Reinforced polypropylene pipe

Moreover, it is desirable that the reinforcing layer be aluminum, since the fiberglass reinforcement leads to the saturation of the coolant with oxygen. This, in turn, causes rusting of the metal surfaces of boilers and other heating elements. Pipes that have aluminum reinforcement and are suitable for heating systems are designated PN25.

Note! When choosing pipes, you should pay attention to the uniformity of the thickness of their walls. To do this, you need to look at their cut.

As for the diameter, the optimal parameter is 25 mm.

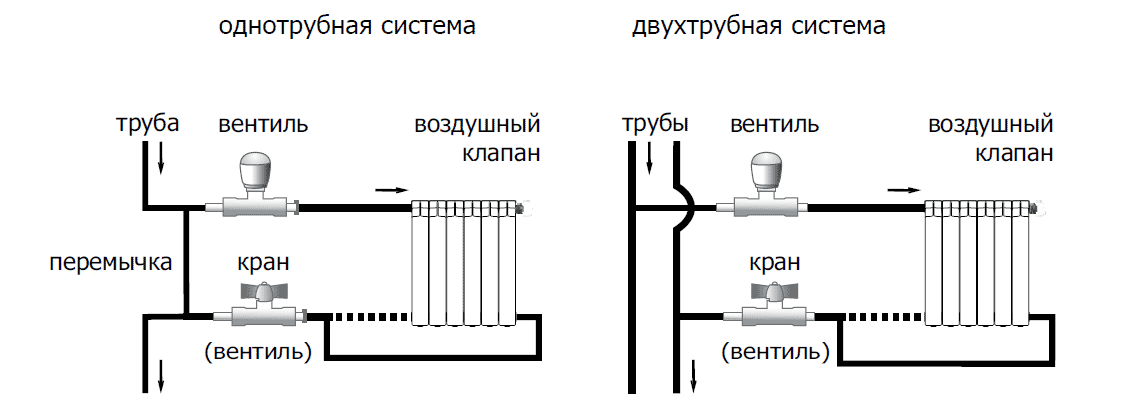

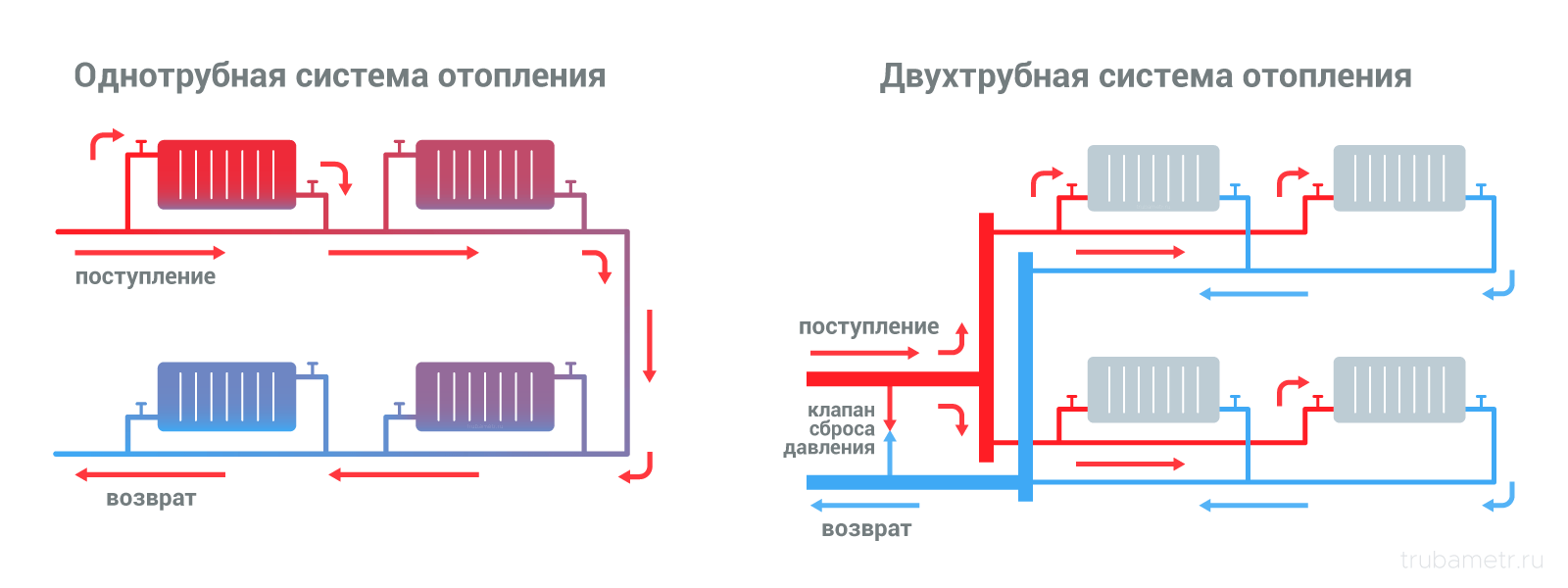

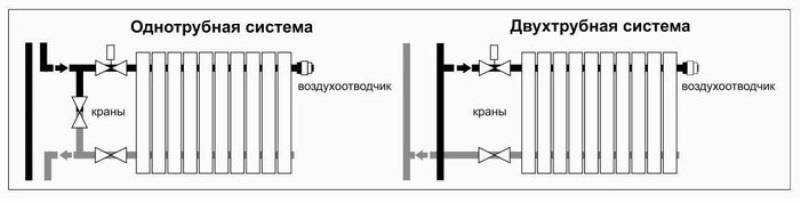

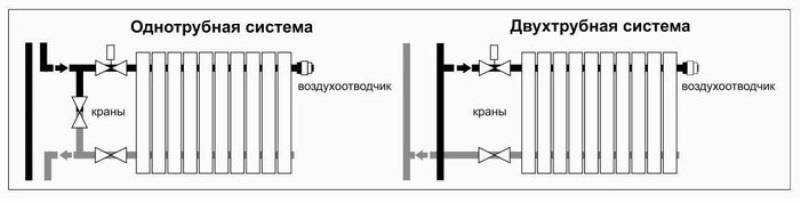

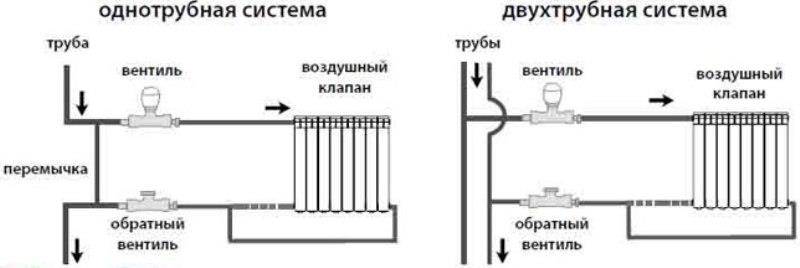

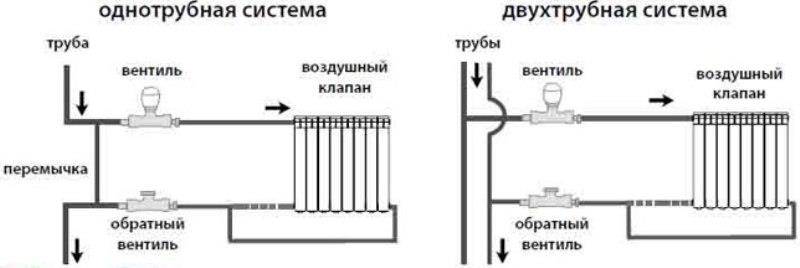

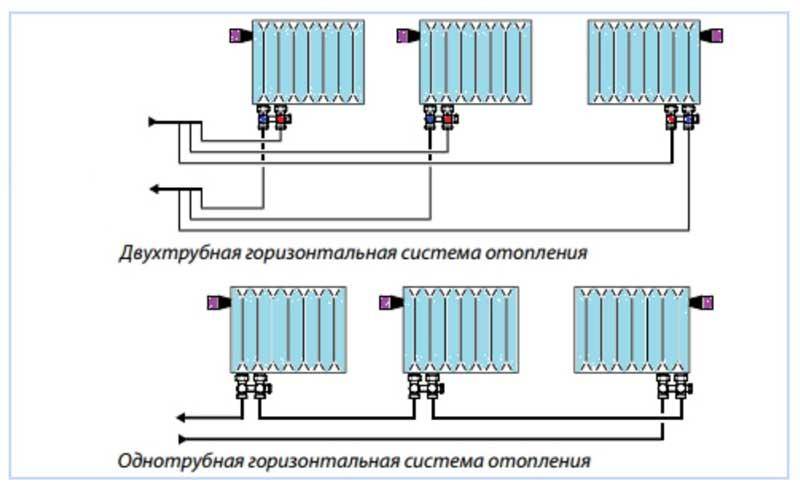

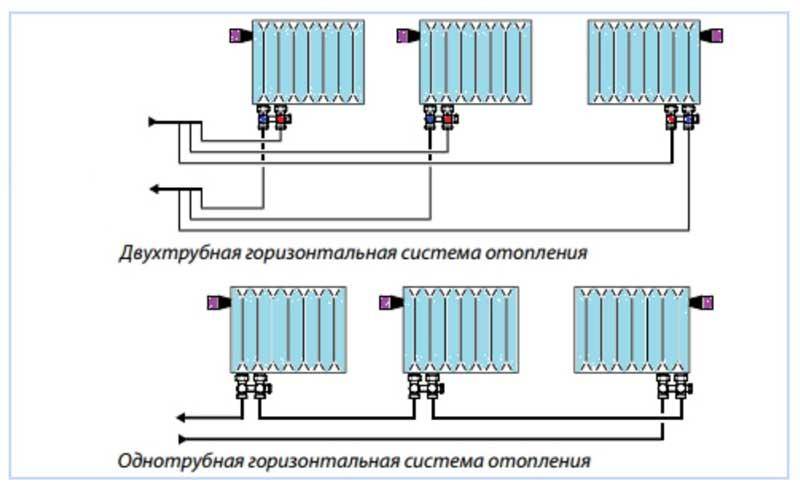

Diagram of one-pipe and two-pipe connection of radiators

- The price of aluminum radiators is lower than that of any analogues, except perhaps the registers made by hand from steel pipes.

- Due to the highest thermal conductivity of aluminum, all fins of the sections have the same temperature, which ensures maximum heat transfer with minimum dimensions of the heater.

- Overpaying for a bimetallic radiator with comparable thermal characteristics is meaningless, since the strength of any circuit is equal to the strength of its weakest link. In our case, the weak link will be polypropylene.

Battery harness

Before you make your own heating in the house, you also need to think about the amount of fittings that will be used in the system. In the event that it is planned only to turn off the radiators, then two ball valves installed on the connections on each side of the heating devices will be enough. Such cranes are quite reliable and durable, so there will be no problems with them.

It's another matter if the system needs to be configured. Radiator valves are required to regulate the flow of the coolant. Structurally, they are conventional valves in which a metal valve is installed. To automatically adjust the patency of the connections, it is better to take valves with thermal heads, which regulate the heat transfer of the batteries when the air temperature in the room changes.

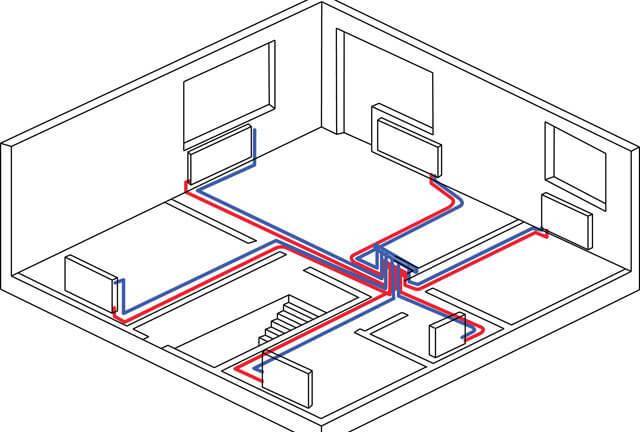

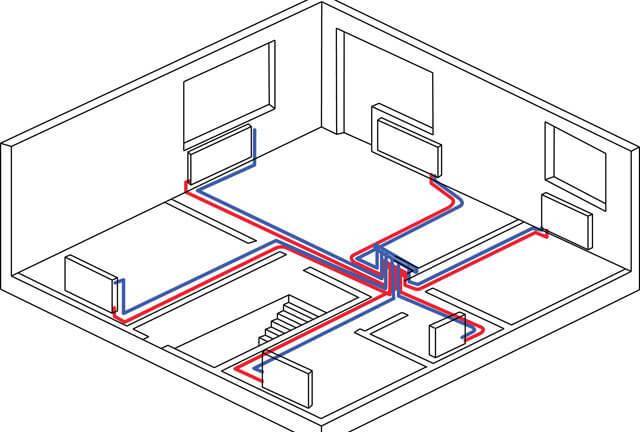

Heating distribution

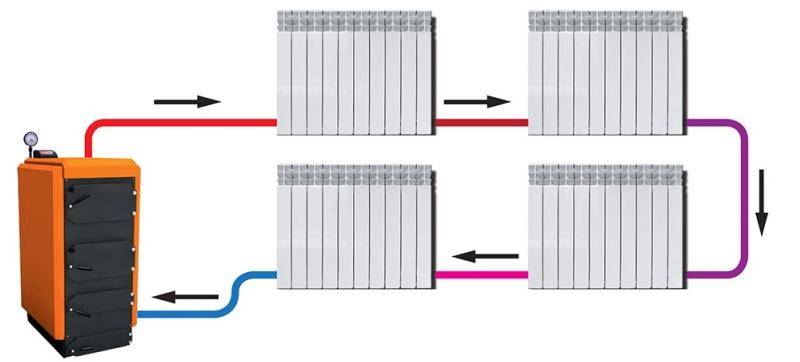

The simplest and most reliable heating wiring diagram is "Leningrad", or one-pipe system wiring. Such a system is constructively a looped loop that runs along the entire perimeter of the building. Radiators are connected to the pipeline in parallel. The main disadvantage of the "Leningrad" is the uneven heating of the radiators connected to the circuit.

A much more effective option for how to properly lay heating, especially in multi-storey buildings, is a two-pipe heating system. Such a system has two varieties, one of which is called a dead-end system. This scheme must be balanced, i.e. limit the permeability in radiators located close to the boiler - otherwise the heating of the heating devices located in the distance will be insufficient.

In a passing scheme, there are several parallel circuits of the same length. It is not required to balance the passing wiring, since the heat transfer of all batteries in it is initially almost at the same level. If no obstacles interfere with the creation of a circular passing scheme, then it must be done, otherwise a dead-end two-pipe wiring is quite suitable. In any case, in order to know exactly how to properly lay heating in a house, you need to think over all the known nuances in advance.

Place of radiators in the heating system

The use of radiators in heating living quarters plays an important role today. Most residential buildings, especially apartments in multi-storey buildings, due to design factors, cannot be equipped with underfloor heating, which requires a significant thickness of interfloor slabs. Therefore, the main work on heating internal living spaces is performed by wall radiators, often called batteries.

Radiators transfer thermal energy from the coolant to the surrounding space. The intensity of heat transfer depends on the temperature of the coolant, the thermal conductivity of the radiator material and the heat transfer area. The design of modern models of radiators has a number of technical improvements that allow them to be connected in heating circuits of almost any wiring diagram.

On a note:

in the old-style cast-iron batteries, there were only pipes for supplying and leaving the coolant, while modern models are additionally equipped with built-in air vents to eliminate air congestion.

The new design of the batteries radically facilitated the operation of the heating system and increased its efficiency - if there are air locks in the heating devices, it is enough to open the drain valve and bleed the air.

Bimetallic hot water heating radiator with fins increasing the heat transfer area

Thanks to modern models of heating batteries, it has become possible to choose the optimal connection scheme, install heating devices as efficiently and efficiently as possible. But the efficiency and durability of the water heating circuit depends on the quality of the piping - a condition necessary when using polypropylene pipes, despite the many advantages of this material.

Important!

The connection of polypropylene pipes to a metal riser is made by means of special adapters, one end of which, a metal one, has a threaded connection, and to the other, a polymer polypropylene pipe is connected by hot welding. When cutting a heating radiator into a polypropylene pipe circuit, it is necessary to use connecting fittings, adapters and couplings made of a similar material.

Polypropylene pipes have a high coefficient of thermal expansion, therefore, when installing the heating circuit, it is necessary to leave gaps between the ends of the pipeline sections and the wall, so that during linear elongation due to the influence of the hot coolant, the pipe span does not rest against the wall with its ends and does not deform. It should be borne in mind that the longer the pipeline span, the more it will lengthen.

Reinforcement of polypropylene pipes with aluminum or fiberglass reduces linear expansion, but does not completely solve the problem, therefore, in sections of considerable length, it is necessary to provide U-shaped or, if the location allows, spiral expansion joints.

Heating boilers

The choice of a heat source is a key factor on which the further selection of heating elements and the efficiency of the assembled system will depend. The cheapest fuel today is gas, therefore, if a gas main is connected to the site, a gas-fired boiler will be the best solution.

Condensing gas boilers with electric ignition proved to be the most economical ones, which have a couple of features:

- When the coolant is heated to too high a temperature, the gas is simply not consumed, which reduces its costs by about 25%;

- The heat given off to the steam is also used for heating, which saves another 10-12% of the energy resource.

If we arrange heating equipment operating on other types of fuel in order of decreasing efficiency, we get a list of the following type:

- Wood-fired boilers;

- Pellet boilers;

- Coal boilers;

- Diesel boilers;

- Electric heating devices.

When choosing a heat source before heating in a private house, you need to pay attention to a number of nuances:

- For gas boilers, you can use not only main gas, but also bottled gas. True, the cost of heating in this case increases several times.

- Before purchasing a heating device that runs on a certain type of fuel, it is worthwhile to at least roughly study the dynamics of price increases for different types of fuel, and when studying, it is necessary to tie fuel prices to geography.

- Coal boilers use firewood for kindling. This must be taken into account - firstly, kindling and warming up the system will take more time, and secondly, the purchase of firewood will require additional costs.

- Gas, diesel and electricity boilers function smoothly in the presence of fuel. Pellet boilers with an automatic feeding system can work for a week. Solid fuel boilers must be heated and cleaned at least (and often more often) once a day. A long-burning boiler can work on one tab for several hours longer, and the most expensive and modern devices work without problems throughout the day.

- Development can be used as fuel for diesel boilers - this will reduce heating costs by several times. The disadvantage of such savings lies in the scarcity of used oil, which is very difficult to obtain in sufficient quantity and on an ongoing basis.

Electricity in such devices is required only for the operation of the compressor. Such schemes turn out to be quite profitable - the cost of heating can ultimately compete on an equal footing with the savings when using solid fuel boilers and gas.

Of course, you have to pay for the savings somewhere - the cost of heat pumps is very high, and the installation of such equipment costs a round sum. Suffice it to give a simple example: to install a geothermal pump, you need to drill a well several tens of meters deep, or dig a pit, the area of which will be three times the area of the heated building.

There is a solution to this problem - you can use a type of heat pump in which the air outside the house is the coolant. Heat energy is pumped out of it, which is used later to heat the building. In fact, such a scheme represents the operation of a conventional air conditioner set to heating mode.

Choice of pipe diameter

Another important issue that needs to be decided in advance is how to carry out the heating and with what pipes. It is necessary to select pipe diameters depending on what kind of heat transfer is planned in a certain section of the heating circuit. For example, on the wiring, this value corresponds to the power of the boiler, the connections to the radiators must transmit enough coolant to heat the radiators themselves, and the throughput of the risers must ensure the normal heat transfer of all heating devices connected to them.

In principle, if it is possible to increase the circulation rate of the coolant (by increasing the pump power), the diameter of the pipes can be reduced

But in this moment it is important not to overdo it - the acceleration of the coolant leads to an increase in noise in the system. The standard speed is about 0.4-0.6 m / s.

When using a gravitational heating system, the diameter of the distribution pipes must be increased by at least one step. It's all about the very low pressure characteristic of systems with natural circulation of the coolant. Too wide pipes will reduce the hydraulic resistance of the circuit, sometimes up to a complete loss of system performance. Knowing such points is already a large part of the answers to questions about how to make efficient heating in a private house.

How to connect a heating radiator with a polypropylene pipe

Connecting a radiator to polypropylene pipes is a process consisting of several stages:

- Drawing up a drawing, marking.

- Fastening batteries to walls with brackets.

- Installation of pipes, connection of individual parts.

- Pipeline testing.

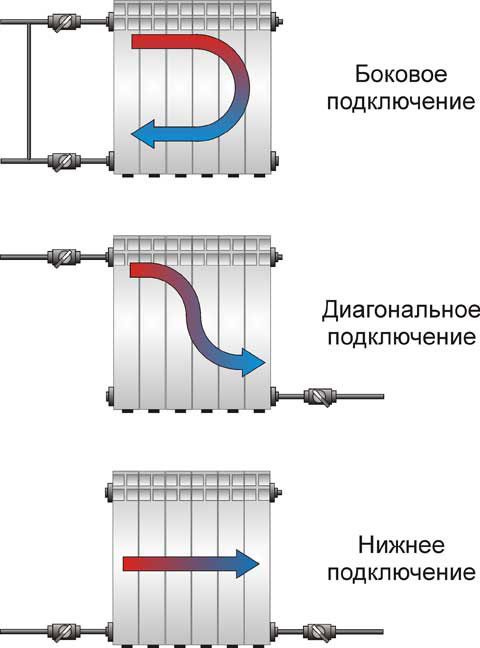

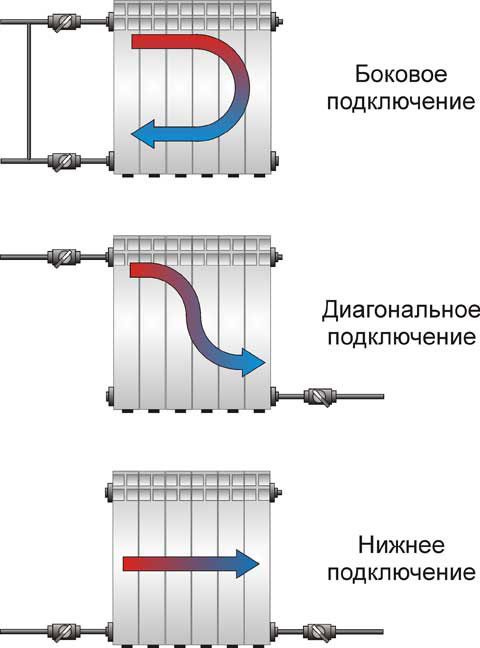

There are several ways to connect the battery to the pipes:

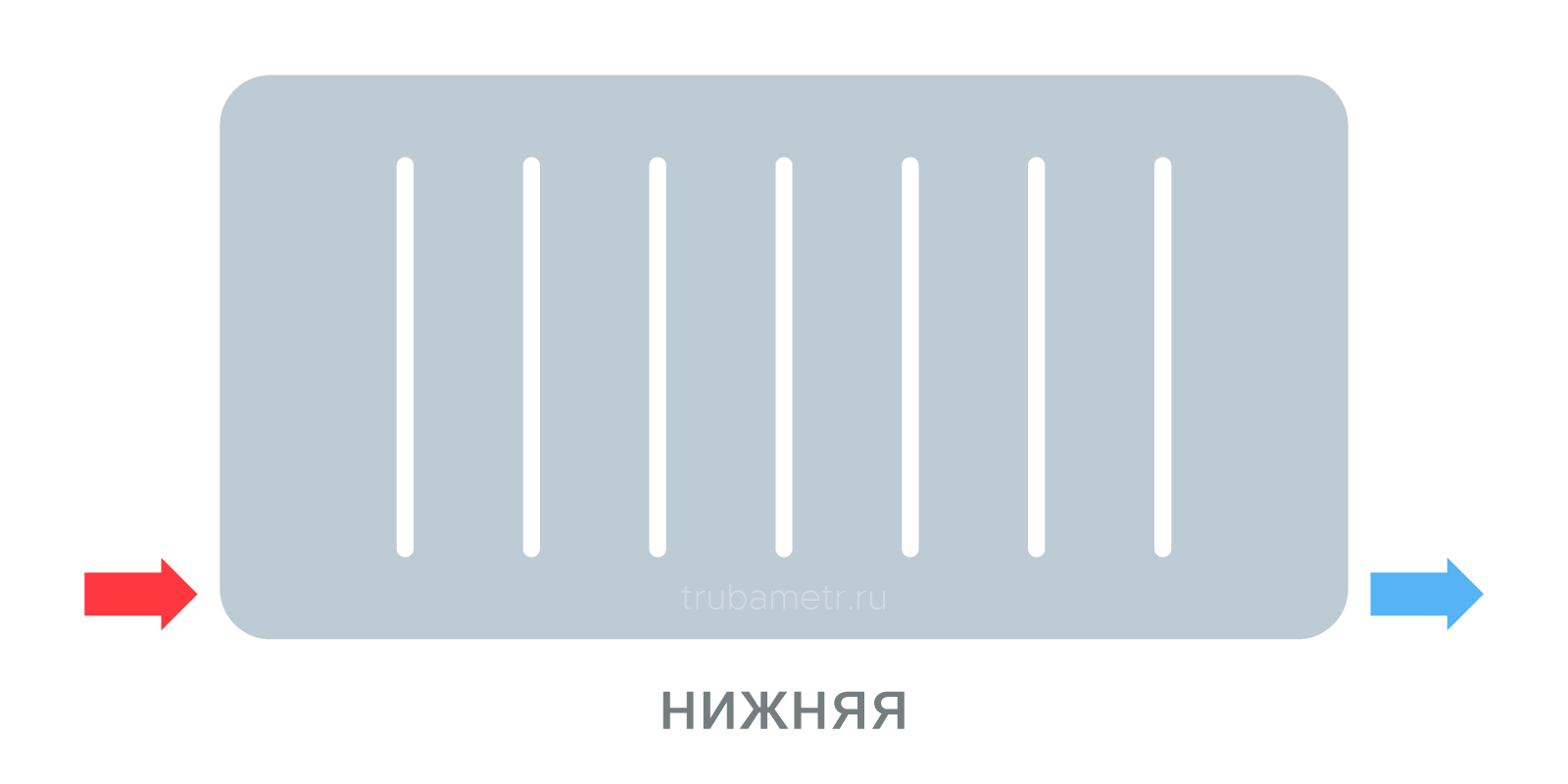

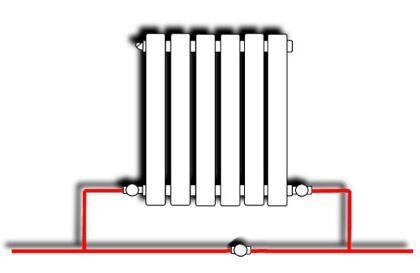

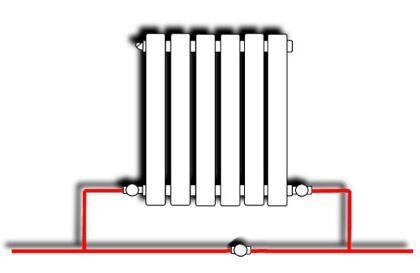

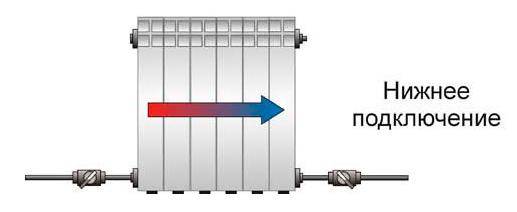

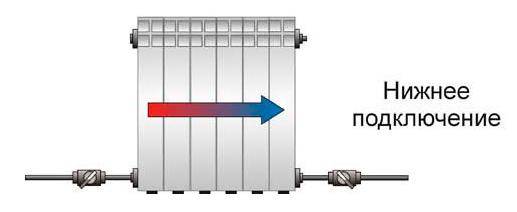

- Bottom connection. The pipes are connected on both sides of the radiator at the bottom. Suitable for horizontal installation of a single-circuit pipeline.

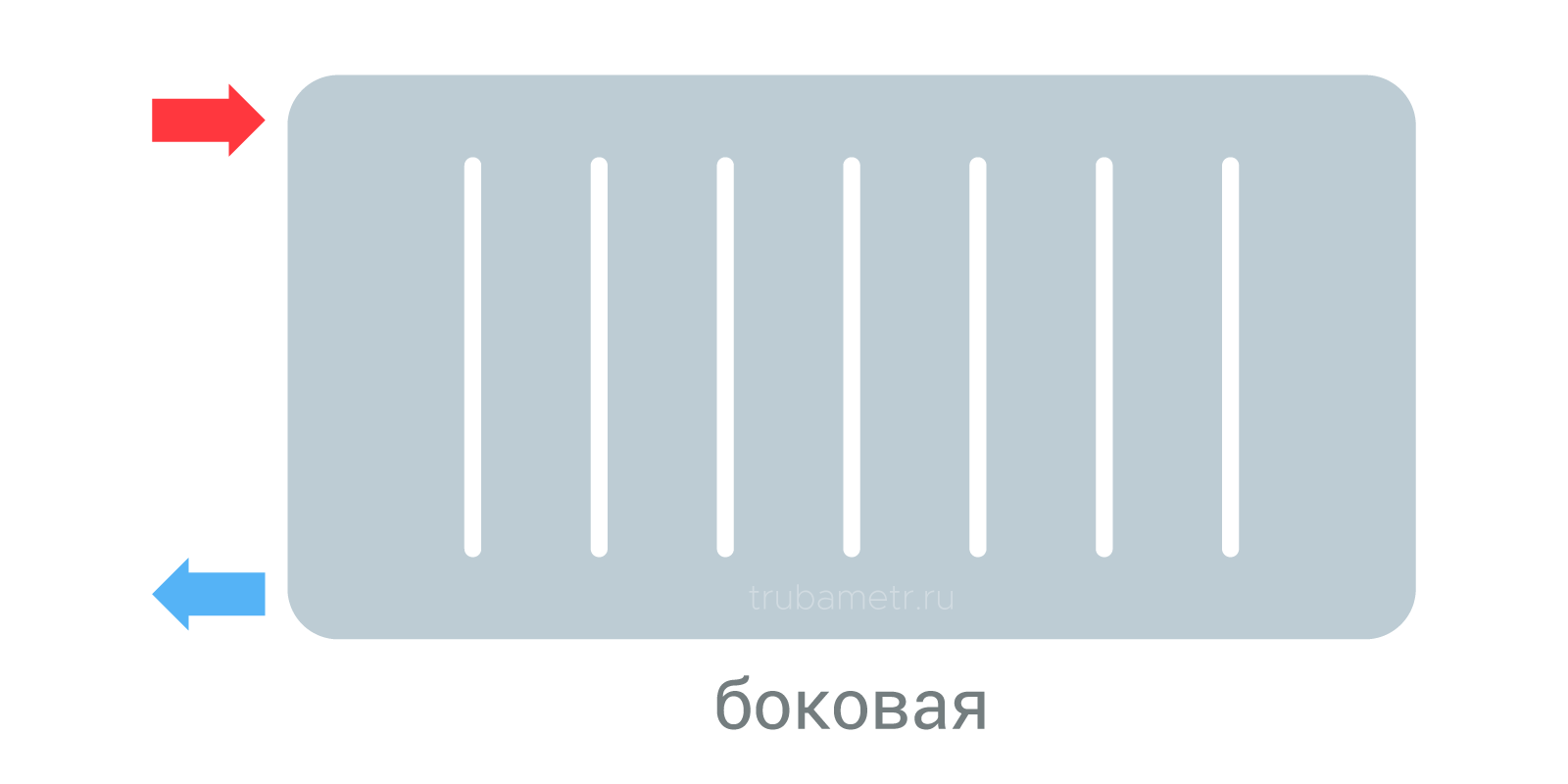

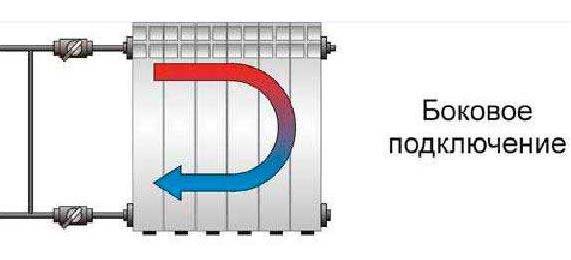

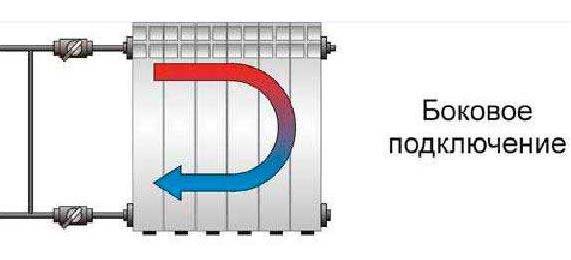

- Side connection. On one side of the battery there are two openings for the fluid supply, the outlet of the working off.

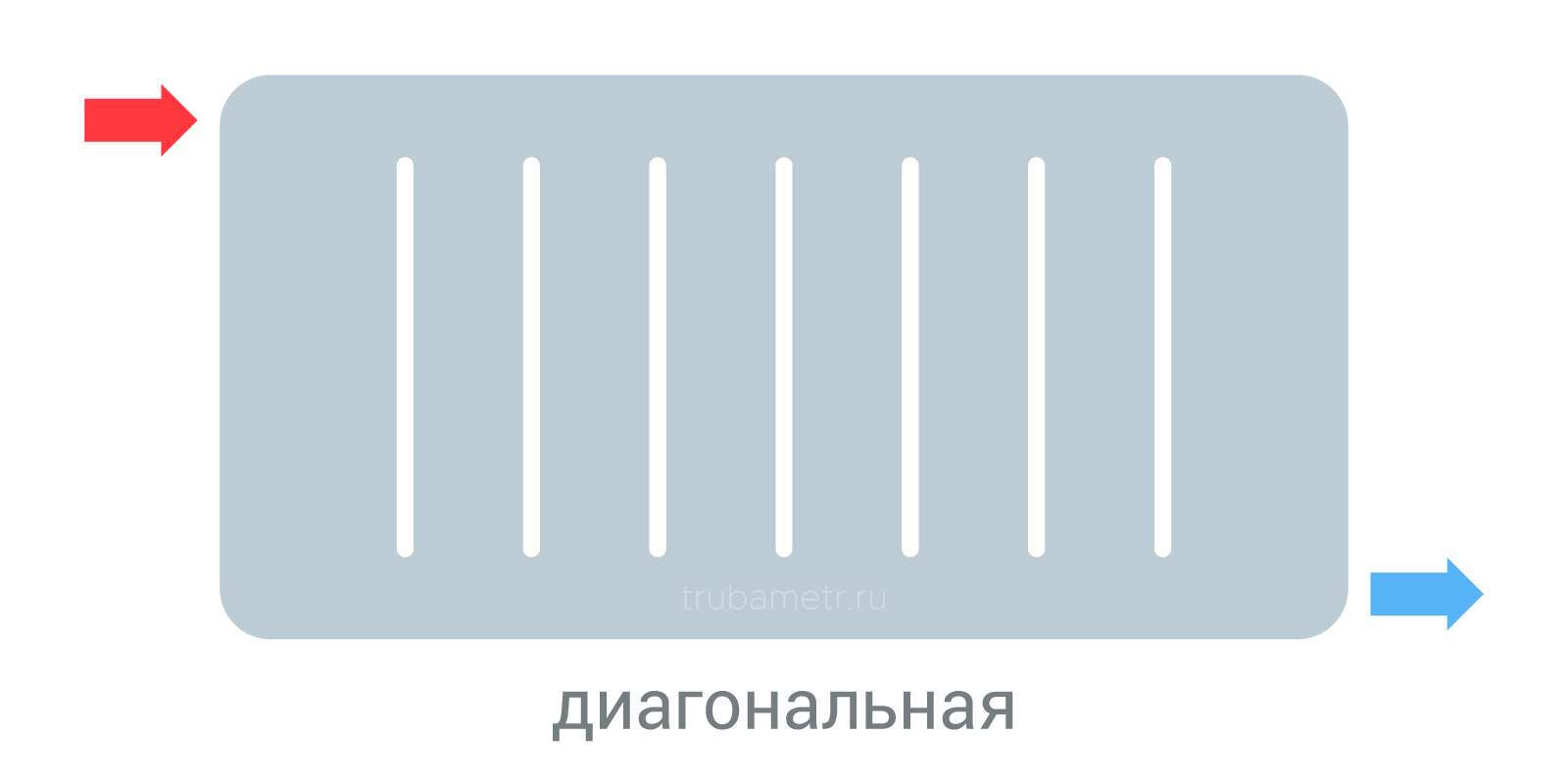

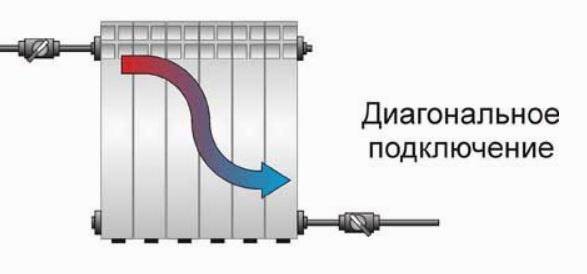

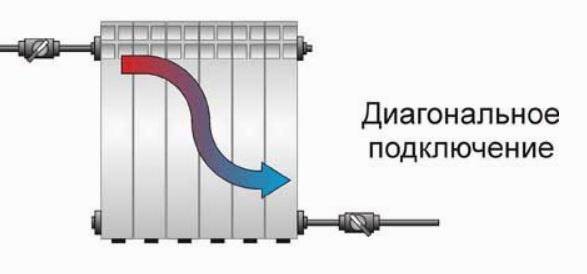

- Diagonal connection. The classic version of connecting radiators to pipes. The openings for supply and outlet of the coolant are located on two sides in the lower and upper parts.

How to make the boiler piping correctly

The next component of the heating system is the boiler piping. The first step is to look for a circulation pump with good performance. If it can deliver a pressure of 2 meters, then such a device is quite suitable even for the functioning of heating in multi-storey buildings.

The power of the circulation pump is calculated using a formula of the form:

- Q = 0.86R / Dt, where

- Q - pump performance (measured in cubic meters per hour);

- R is the power of the heating boiler or circuit into which the circulation pump will be built;

- Dt is the temperature difference in the supply and return circuits (usually about 20 degrees).

When choosing a safety valve, you need to build on the maximum pressure that can occur in the system (as a rule, this value is 2.5 kgf / cm2). The volume of the expansion tank should be 1/10 of the volume of the coolant in the circuit. It is advisable to take a tank with a small margin. In standard heating systems, 1 kW of boiler power accounts for about 15 liters of coolant.

As a rule, the tank starts to operate at a pressure of 1.5 kgf / cm2 - i.e. when the operating pressure is exceeded in a balanced heating system. To increase the pressure, you need to use a tap connecting the heating and cold water supply, or simply pump up the expansion tank with air.

Radiator connection

The sectional radiator has four radiator plugs, to each of which a supply line can theoretically be connected. In practice, for the circulation of the coolant through the battery, two tie-ins are sufficient - supply and return. Heating devices are connected according to one of three schemes.

| Connection | Description | Features of the |

| Unilateral | Top and bottom plugs on one side are used to connect to the connections | The connection is convenient in terms of the compactness of the placement of connections. However, only the first 5-8 sections warm up effectively. The last sections are noticeably colder and silted up quickly, requiring periodic flushing |

| Diagonal | Uses an upper radiator plug on one side and a lower one on the other | All sections are heated evenly. Heat transfer is maximized. Only the bottom of the extreme sections is silted up from the side of the blind bottom plug |

| Lower | Both bottom plugs are used | Heat dissipation is 10-12% lower than with a diagonal connection. No flushing required; sections are not silted in principle |

Connection diagrams.

Strapping methods

To mount a battery harness in a private house or city apartment, you will need:

- shut-off valves, which are most often used the simplest ball valves;

- plugs to cover the remaining channels;

- Mayevsky taps, allowing to bleed air from the system during seasonal start-up of equipment;

A device for removing air from the heating system

sealing material.

Additionally, you can install on any heating radiator:

- a pressure gauge that determines the pressure in the system (most often used when installing equipment in autonomous country houses);

- thermostat operating in manual or automatic mode. With this equipment, you can set a specific temperature for any individual radiator.

Device for setting a specific mode of battery operation

If the strapping is carried out with polypropylene, then additional welding equipment is required.

Device for welding polypropylene pipes

So, depending on the factors presented above, the piping of the heating radiator can be performed according to the following schemes:

- for side connection;

- for diagonal connection;

- for bottom connection.

Side connection strapping

With a lateral connection method and a one-pipe system, the piping is installed as follows:

- ball valves are installed on the inlet and outlet nozzles, which make it possible to shut off the coolant supply for repair or maintenance work;

- taps are connected to tees;

- a piece of pipe is inserted into the remaining taps of the tees, which acts as a bypass.

A bypass is necessary for autonomous shut-off of a separate radiator, for example, for repairs, without shutting down the entire heating system.

With a lateral connection to a two-pipe system, work is carried out in a similar manner. However, a bypass is not required in this situation.

Strapping diagrams when choosing a side battery connection method

Diagonal connection strapping

The connection of the radiator to the pipes with a diagonal connection is as follows:

- the inlet pipe is connected to a pipe cut, no longer than 10 cm - 15 cm;

- then a ball valve and a tee are installed to connect the bypass;

- the outlet pipe is connected to the elbow and only after that it is connected to the pipeline that removes the coolant;

- a crane is installed before connecting to the central highway.

When connected to a two-pipe system, the operation is the same except for the bypass.

Battery strapping diagram when choosing a diagonal connection method

Bottom connection strapping

The strapping of the lower connection method is simpler than all the others:

- shut-off valves are connected to the inlet and outlet of the radiator;

- pipe bends are introduced into the central lines. If necessary, special adapters - angles or tees - are installed at the bend points.

Radiator piping diagram with bottom connection method

There is a separate nuance when tying the bottom connection when connected to a one-pipe system. In most cases, the connection is made as shown in the figure, that is, without a bypass that allows autonomous shutdown of the heater. But if you want to use the device, you can install it. For this, an additional piece of pipe is installed between the flanges of the inlet and outlet nozzles.

Bottom connection piping using bypass

The following video is devoted to a detailed description of the types of piping of batteries in the heating system.

Thus, with the correct choice of connection method and correct installation, the heating system will serve for a long time, evenly heating all rooms.

Output

The process of connecting the installation of a heating system using polypropylene pipes is not much different from other types of pipelines. The peculiarity is contained only in the method of connecting pipes with fittings, since this process is carried out using a special welding machine. In addition, a special adapter is used to connect the radiators themselves with the pipeline.

You can get acquainted with the additional necessary information on the indicated topic from the video in this article.

It will also come in handy for repairs:

- How to apply electric welding seam correctly

- Bison hand tool reviews

- Fishing on a bow what kind of tackle

Selection of the type of strapping

The piping scheme for heating system radiators is selected based on the following factors:

- the type of system that supplies heat to the room;

- method of connecting the radiator to the central highways.

Determining the type of system

Before proceeding with the selection of piping for heating equipment, it is necessary to determine the type of room heating system. The following types are currently used:

- one-pipe systems;

- two-pipe systems.

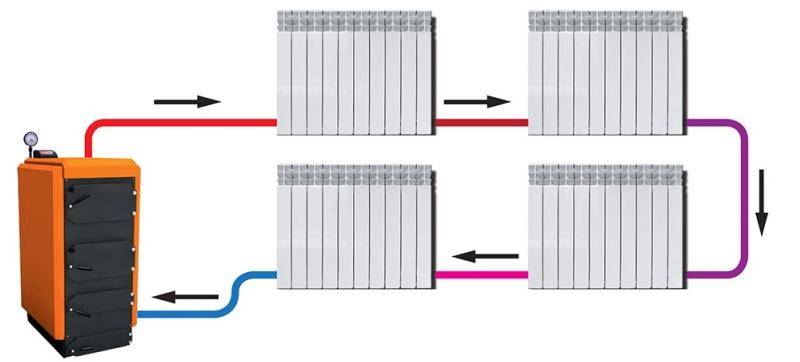

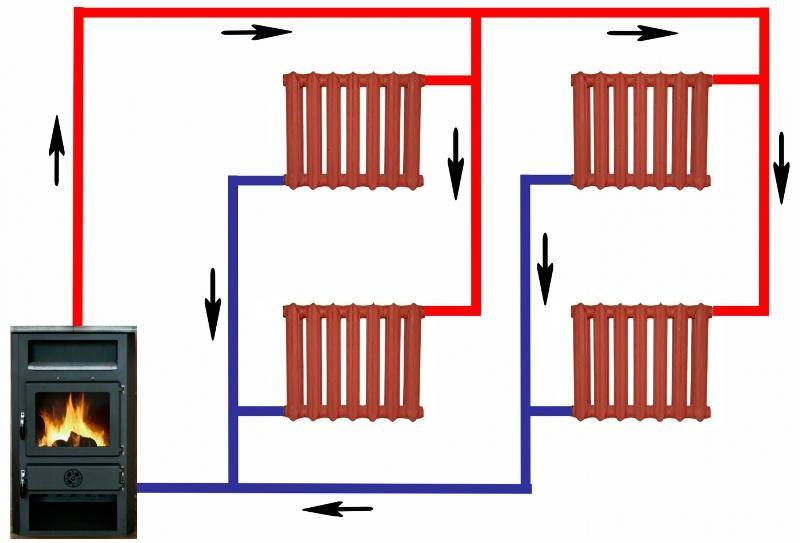

One-pipe heating is a system in which all heating equipment is connected by one pipe. The coolant sequentially enters each radiator and returns to the boiler in one closed loop.

Heating system with one closed circuit

The advantages of a one-pipe heating system are:

- balance of the system, which allows to achieve uniform heating of all connected radiators;

- increased heating rate;

- aesthetic appearance and minimal amount of occupied space;

- ease of installation;

- saving on materials.

The disadvantages include:

- the interconnectedness of all elements of the system, which leads to the impossibility of performing repair work on one of them without disconnecting the other;

- the complexity of regulating the temperature of the coolant;

- the need to install a pump with a high power rating.

Two-pipe heating includes two main pipelines. One delivers the coolant to the radiators, and the second returns to the heating equipment.

Heating network with two main pipelines

The advantages of such a system are:

- the same temperature of all radiators, since the coolant is supplied to a separate battery directly from the heater;

- the possibility of constructing a system with a lower internal pressure, which allows the installation of equipment of lower capacity.

The most significant disadvantage is the cost of the system. It is generally accepted that the cost of purchasing materials increases by 2 times. In fact, this statement is incorrect, since with a one-pipe system, fewer pipes are required, but with a larger diameter, and for a two-pipe system, vice versa.

A single-pipe heating system is organized in almost all old apartment buildings. It is also advisable to install it in country houses with an area of up to 150 m². A two-pipe system is installed in new houses and country cottages.

Connection options

The methods for connecting radiators also depend on the location of the pipes in a private or apartment building. Allocate:

side connection, in which the inlet and outlet pipes are located on the same side of the radiator. This type is distinguished by minimal costs for the arrangement of the connection (serial connection), aesthetics and minimal losses of thermal energy. Typically used in most apartment buildings;

Radiator side connection

diagonal connection. Unlike the previous case, the input and output are located on opposite sides of the heating batteries. The main advantage is the possibility of uniform heating of radiators with a large number of sections (from 12 pieces);

Diagonal battery connection

bottom connection - inlet and outlet pipes are supplied from the bottom. The advantages of this method are aesthetics and the ability to mount highways to the floor or wall. The disadvantages include significant losses of thermal energy, which are at the level of 1% - 15%.

Bottom heater connection

Connection of polypropylene pipes

As you know, polypropylene pipes have certain operating restrictions. The working pressure in such a system should not exceed 20-25 kgf / cm2, at a temperature of no more than 95 degrees. When the pipe is heated by 50 degrees, the polypropylene product is capable of lengthening by 6.5 mm / 1 lm.

When the maximum possible heating of such a pipe is reached (95 degrees), the parameter of the permissible pressure decreases to 6-7 kgf / cm. If we translate the given digital indicators into the language of a simple layman, then the conclusion will be as follows: the connection of a radiator with a polypropylene pipe is possible only in autonomous heating systems.

Although the indicators of the standard parameters of the central heating (4 - 6 kgf / cm2, 50 - 95C) seem to be suitable for this material, however, the reality is usually completely different. As a rule, during the operation of central heating, one has to deal with violations of the conditions specified in GOSTs and SNiPs. For example, if outside the temperature drops very low, the elevator unit starts up without a nozzle, when the suction is muffled.

In addition, in the event of a water hammer, the internal pressure in the system can jump to 25 - 30 kgf / cm2. The reason for this phenomenon is usually too fast filling of the system with the coolant. In addition, polypropylene has several other specific features. Due to the too high elongation rate during heating, in the case of laying straight heating sections of impressive length, special expansion joints are used in the form of pipe bends. This significantly reduces the risk of accidental consequences during deformations.

Another way to avoid elongation is to use reinforced pipes, which are characterized by a reduced coefficient of thermal expansion:

- 3 mm / 1 lm / 50C. In the case of use as a reinforcement of chopped fiberglass (fiber).

- 1.5 mm / 1 lm / 50C. When polypropylene is reinforced with aluminum foil.

If a fitting is used, it is imperative to strip the foil at the joint, otherwise the pipe may delaminate. This is due to the electrochemical corrosion of aluminum during operation.

Let's take a closer look at the process of connecting a radiator to polypropylene pipes, which are most often used for heating today. We will understand the suitable types of connections and systems, as well as find out what is required for installation.

The coolant line is assembled at the place of installation of the radiators

In the case when water (coolant) enters at once throughout the building, while it flows down the pipes from top to bottom, they speak of a one-pipe system.

This system is very often used in apartment buildings and has significant disadvantages:

- there is no possibility of temperature control for heating equipment;

- it will be much warmer on the upper floors than on the lower ones; performing repair work, you will have to resort to disconnecting the whole riser;

- it is rather difficult to disconnect heating from the central heating system to transfer the apartment to autonomous heating.

- It differs in that the supply of water occurs through one pipe, and the return of cooled water occurs through the other (otherwise called "return").

- In this case, the radiators are connected in parallel, it is usually used to heat private houses and cottages.

- Allows you to adjust the temperature of the radiators for all available batteries on any floor.

Connecting a radiator with a polypropylene pipe using an "American"

To install a heating system, it is advisable to decide on a suitable type of radiator.

There are batteries that are designed for various pipe connections, fasteners, equipment material:

- panel radiators made of steel. which are connected from the side or bottom;

- aluminum lightweight batteries in the form of sections and bimetallic models. They are connected at once in one or more sections using the side connection method.

How to connect a heating radiator with a polypropylene pipe built into the wall

Tip: The ideal option would be to use polypropylene pipes as they are most suitable for this purpose.

- In apartments equipped with central heating, bimetallic radiators are used instead of heavy and large cast iron batteries. However, this replacement is largely due to the fact that alkali, which damages cast iron, is often added to the heating system.

- In private construction - it is optimal to opt for radiators made of aluminum or steel.

- For an ordinary apartment, we recommend aluminum models (individual) and bimetallic.

In this case, the specified procedure will be carried out using polypropylene pipes. Ball valves should be straight or angled, which are also made of polypropylene.

Installation is not difficult if you already have some skill in working with such materials. The price of elements for the heating system is very low.

How to connect a heating radiator to a polypropylene pipe from a riser

To complete the strapping, adhere to the following sequence of work:

- the sleeve with the union nut should be inserted into the multiflex;

- specially made brackets will help fix the pipes to the walls, it is important to choose a comfortable height, only so that the pipes do not touch the surface, you can fix the elements on the walls with nails or self-tapping screws.

Pipes are easy to hide behind plasterboard structures

Tip: when laying pipes in walls, use polypropylene pipes for heating. which will come out of them only at the connection points.

A wide variety of fasteners can be used to secure the batteries, but a pin connection is usually preferred. To hang the heating equipment at the required height, you can use corner brackets.

When it comes to the battery-panel, usually the fasteners can be found in the kit itself. If using sectional batteries, think about purchasing it in advance.

Tip: two brackets or two pins will be enough to secure one conventional radiator.

The procedure for connecting the battery taps:

- disassemble the tap, screw the fitting and the union nut into the radiator;

- take a special wrench to screw it tightly.

This work does not cause any particular difficulties, but for correct execution you will need to have a key for "American women".

To mount the batteries and perform their strapping, prepare:

- thread for carving;

- seals for its connection;

- a set of keys;

- tow, thread paste.

In the photo - options for the inclusion of a heater in the system

When installing the equipment, it is important to take into account certain features:

- from 100 mm - the minimum distance from the battery to the window sill, otherwise the heat flow will follow a different trajectory, reducing the heating effect;

- from 120-150 mm - from the radiator to the floor, otherwise sharp temperature fluctuations are possible;

- 20 mm is the distance from the heating equipment to the wall.

It is advisable to install the battery under the window so that the cold air from the street is replaced as much as possible with the warm air from the device. It is also important that the equipment is always open, only in this case and subject to all dimensions, it is possible to achieve 96 - 97%

The efficiency of the system, if an open battery is in a niche, is 93%, an indicator of 88 - 93% will be with a partially obscured form, and if it is completely closed, it will be 75 - 80% or less.

The use of polypropylene pipes instead of metal pipes fully justifies itself. In fact, you can independently make not only repairs, but also further maintenance of the heating system without the involvement of specialists. The video in this article will provide an opportunity to find additional information on the above topic.

Nowadays, polypropylene pipes are more popular when installing heat supply systems. However, their connection to heating devices, including radiators, has some nuances, so this task raises a number of questions for novice home craftsmen.

Below we will take a closer look at how to install heating radiators with polypropylene pipes.

Radiator connected to a polypropylene pipeline

Types of radiators for strapping

To install a heating system, you must select the type of radiator. Different types of heating equipment differ in their fastening to the wall, materials of manufacture, and connecting pipes. Manufacturers today offer the following options:

Sectional radiators device.

- Panel steel batteries in the form of relatively thin solid panels. The connection of such radiators can be side or bottom.

- Lightweight sectional made of aluminum. Bimetallic ones are also often used. Such batteries can be connected in one or more sections, the connection with the common system is lateral, polypropylene pipes are ideal.

For apartments with central heating, bimetallic radiators are used (cast-iron radiators are used less and less, this is due to their heavy weight, bulkiness, fragility). This is due to the fact that in the water supplied to the heating system, there is often alkali, sand, which can damage other types of radiators.

For a private house, aluminum, steel panel radiators are perfect, while all the conditions for connection must be observed (for a copper pipeline, steel and aluminum radiators are used, for a conventional one, only aluminum is possible).