Rating of the best chimney manufacturers

| Photo | Name | Rating | Price | |

| #1 |

| CRAFT | ⭐ 100 / 100 4 - voices | Find out the price |

| #2 |

| Volcano | ⭐ 99 / 100 3 - voices | Find out the price |

| #3 |

| ROSST IN | ⭐ 97 / 100 | Find out the price |

| #4 |

| Jeremias | ⭐ 97 / 100 | Find out the price |

| #5 | Thermophore | ⭐ 96 / 100 | Find out the price | |

| #6 |

| Ferrum | ⭐ 96 / 100 1 - voice | Find out the price |

| #7 |

| Elits | ⭐ 95 / 100 1 - voice | Find out the price |

| #8 |

| Inzhkomtsentr VVD | ⭐ 93 / 100 3 - voices | Find out the price |

| #9 |

| Phoenix | ⭐ 92 / 100 1 - voice | Find out the price |

| #10 |

| Baltvent | ⭐ 91 / 100 | Find out the price |

| #11 |

| Rosinox | ⭐ 90 / 100 | Find out the price |

Which chimney manufacturer would you choose or would you advise to choose?

Take a survey

Chimney manufacturers rating: TOP-11 best

Before buying a chimney, a potential buyer should familiarize himself in advance with which brands offer the best quality products today.

Below we will tell you about the best manufacturers, as well as note their pros and cons. They have proven themselves well, which is also additionally confirmed in their reviews by the people who contacted them.

Rosinox

Rosinox

The brand, which has been operating since 2001, opens the rating of the best chimney manufacturers. Rosinox uses only high-quality stainless steel and other environmentally friendly materials, and all production is located in Klin. The best German technique is what helps a brand to have a good product.

The best German machines are used for manufacturing, so the products from Rosinox are quite competitive in relation to the products of other companies presented below.

The dealer network is well developed, which means that the products of this domestic company can be found in almost any city.

All employees work extremely well, which allows you not to worry about the good performance of the Rosinox chimney installed in your house.

The only drawback of this manufacturer is the problematic contact with the support service of this company.

pros

- Using fresh solutions and production technology from Germany.

- Dealerships can be found everywhere.

- The use of environmentally friendly material.

- High quality products.

Minuses

- It is quite difficult to contact the support team of this company.

chimney rosinox

Baltvent

Baltvent

This domestic company has existed for many years on the market of heating equipment and its components. The production is located in Kaliningrad, and this city, which is importantly located near Europe. It was the location that influenced the technical base of the enterprise from the very beginning.

The best equipment from Europe, excellent specialists, high-quality material - all this made it possible to become what we know it now - well-known and with great production.

Quite important in this company is that the pricing policy of this company is within the average value with high quality of the final product.

pros

- Modern European equipment with high production rates.

- Commitment to modern technological solutions that have improved the product itself.

- The price for the products of this company is within the normal range.

- Extremely high reliability of products from this company.

Minuses

- Few things can be found interesting in the assortment of this company.

Phoenix

Phoenix

Another domestic company with production in the Moscow region, whose products have high reliability and durability.The long warranty period will allow you not to worry about the state of the chimney, because for this "Phoenix" uses not only high-quality material, but also good equipment in combination with modern production technologies.

Before manufacturing the chimney, the company creates a 3D model on which everything is pre-checked, then plasma cutting and TIG welding. The result is obvious - a chimney from absolutely any shape and type with all the necessary certificates and documents confirming the high quality of the goods.

The clients who turned to them were generally satisfied with the quality of the service and product, noting only the average quality of the seam. Only a small number of people had a chimney corrosion problem.

pros

- The chimneys are manufactured using the latest technology.

- Quality equipment from Europe.

- Long warranty period - 15 years.

- It will be quite easy to install the chimney of this company.

Minuses

- The chimney of these products is easily corroded.

- Seam quality not very good.

Branch-sandwich 230x130

Inzhkomtsentr VVD

Inzhkomtsentr VVD

Another Russian company, founded in 1999 and known for the production and development of high-quality steel chimneys. Own production allows us to achieve high quality and low cost of products.

The versatility of the chimneys of this company allows them to be used in almost any heating system, which is extremely convenient.

It should be emphasized that people speak of this company only on the positive side, highlighting the reliability and ease of installation of their chimneys.

pros

- Anyone can buy the goods of this company due to the affordable cost.

- High quality products.

- The installation of such a chimney will take place quite quickly.

- Extremely reliable chimney.

Minuses

- After a while, the flue pipe may darken.

Elits

Elits

This company, judging by the name, makes only high quality chimneys. And this is so, because all the efforts of specialists and engineers are aimed at one thing - to create high-quality and at the same time inexpensive products.

The use of quality material in the form of stainless steel allows to achieve a long product life - more than ten years without a single complaint.

Elits chimneys can be found in many summer cottages, private homes, and even industrial warehouses. In addition, the versatility of the products of this company should be noted.

Ease of installation, high-quality welding and appearance - all this is available in Elits chimneys. And as the name implies, the pipes are really of the best quality.

The only thing that people notice is the presence of insignificant flaws in the design that are easily fixable.

pros

- Acceptable pricing policy.

- Easy installation.

- High quality seams.

- Wide area of use.

Minuses

- Design flaws.

Ferrum

Ferrum

In sixth place is the domestic manufacturer Ferrum, the range of which is quite large. Everyone can find the chimney that suits their home better.

All chimneys are manufactured in Voronezh, where the main workshop is located. Typically, the company uses high quality raw materials that go through a series of checks before entering production and becoming a chimney. High quality material is what gives this company's products the durability that the company has long been proud of.

Customers have repeatedly noted that the quality of Ferrum products is at the highest level, although the price, in their opinion, bites a lot.

pros

- The use of quality metal.

- The presence of a large assortment.

- The ability to purchase individual components in a large range.

- Simple and convenient installation.

- Nice appearance.

Minuses

- High price.

chimney ferrum

Thermophore

Thermophore

The top five of this rating of manufacturers is a relatively fresh company founded in 2003. The brand developed so rapidly at the beginning that a year later it already had an award.

The assortment of this company contains a variety of products, among which you can find the following products:

- tanks;

- boilers;

- ovens;

- chimneys.

It should be noted the qualifications of specialists, as well as powerful modern equipment that allows you to create a high-quality product.

However, it is important to be careful - "Termofor" has a lot of fakes, the quality of which is too far from that of the original products.

pros

- The equipment and technologies are all the most modern.

- Skilled workers, thanks to whom the products are of such high quality.

- A large assortment.

- High quality product.

Minuses

- Counterfeits are common.

- Finding products from Termofor is not always easy.

Jeremias

Jeremias

The fourth place is taken by this premium brand from Germany. The Bavarian company is the only foreign representative of this rating, so it will be quite interesting to take a look at Jeremias.

The company itself was founded quite a long time ago - in 1970, but the company appeared on the territory of the Russian Federation not so long ago - in 2008, when the company opened its own representative office.

In short, the products of this company are characterized by several characteristic features at once:

- fine chimney design;

- smooth seam;

- combination of modern developments and quality raw materials.

Judging by the reviews, the chimneys of this company are installed quite easily, which pleases. In addition, high reliability and high-quality work of specialists stands out.

pros

- Excellent quality in everything - material, workmanship and even seams.

- High-tech chimney production.

- Bright and attractive product design.

- High indicators of durability.

Minuses

- The price bites.

chimney Jeremias

ROSST IN

ROSST IN

"Bronze" in our rating is received by a company whose production is located in Moscow itself. It has long been known in the market for heating equipment and their components, and there is no doubt about the quality of the products.

The chimneys of this company are considered quite versatile, because they can be installed almost anywhere and without any problems.

Rosst In products are made according to the latest developments and using modern technologies.

High quality and reliability are what made this company one of the market leaders. A high price is a payment for the fact that the chimneys will serve for a long time and with high quality.

pros

- High indicators of the durability of the products of this company.

- From a design point of view, the chimneys of this company look pretty neat and fresh.

- Using modern technologies and only high quality materials.

Minuses

- High price.

Volcano

Volcano

The company that took the second place in this rating started the production of chimneys back in 1996. Therefore, we can say about a very rich assortment of chimneys from this brand.

Any potential buyer, whether he is a private owner or a representative of another company with his own production workshop, can find a suitable chimney model from this company.

Qualified specialists are constantly introducing new technologies. Having our own laboratory allows us to quickly test new possible options in search of the best solution.

High-quality materials and raw materials, as well as the most modern technology - what the company uses when creating its famous chimneys, which are quite capable of competing with their competitors, since such serious companies as Nissan and Toyota pay attention to them, which is extremely significant.

The products of the Vulcan company have all the necessary certificates and licenses, which confirm the high quality of the products, as well as a long warranty period, with which you can forget about the issue of replacing the chimney for a long time.

pros

- Advanced production with modern technology.

- Very long warranty period of fifty years.

- Use in the production of high quality raw materials.

- Availability of our own laboratory for testing.

Minuses

- High price.

chimney volcano

CRAFT

CRAFT

"Gold" is received by a fairly young domestic company, which, at the same time, has fairly high-quality products for the heating systems market.

It is interesting that the products of this company do not go outside the country, which means that they are sold only for the domestic market, which allows us to talk about an adequate price for most buyers.

The use of high quality materials, as well as an emphasis on modern equipment and technologies, allow us to achieve the best products that will delight you with reliability and durability.

pros

- The use of very high quality materials.

- Using the best technological base.

- Modern equipment.

- Reliability of goods.

Minuses

- Not detected.

chimney Craft

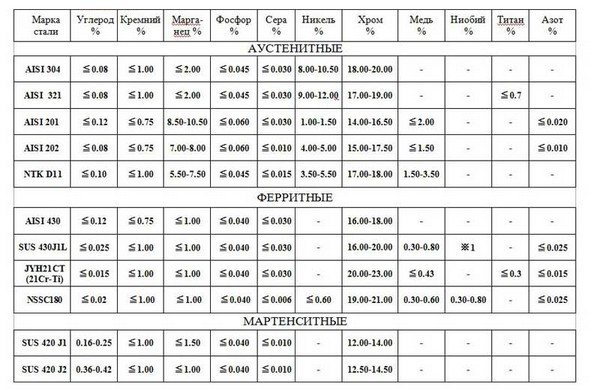

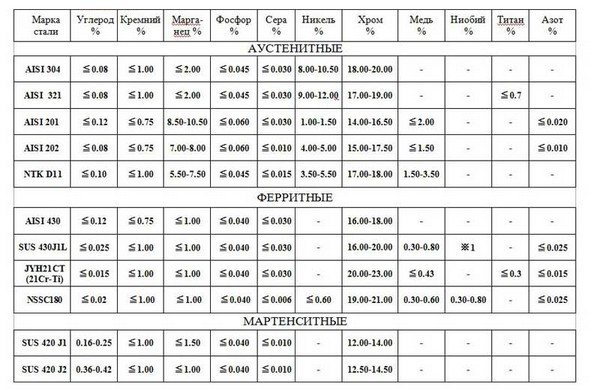

Stainless steel grade

Before you start making a chimney, you need to find the material. In this case, it will be stainless steel. She, interestingly, can be completely different, even if her types differ from each other will not be too much.

The main differences that they will have are in their composition, which will determine their resistance to high temperatures and acid. The higher it is, the longer the material will remain in its original state.

To date, manufacturers use only one series - the three hundredth, which is an example of quality. Here we will consider it below and consider the example of several representatives of this series.

A brand can decide a lot in the production of a chimney

AISI-304

- Austenitic stainless steel. It is an admixture of steel, chromium (18-20%), nickel (8-12%) and carbon (up to 0.08%).

- Steel with high resistance to acid and high temperatures (up to 400 ℃, taking into account the average level of acidity of the environment), therefore it is recommended for gas, solid fuel boilers.

Important! It is widely used in food production.

AISI-316

- The composition is the same as that of AISI-304, but in addition molybdenum is mixed (2-3%).

- Even greater resistance to negative external effects (up to 750 ℃ without deformation).

A chimney made of such a material can be used in almost any type of boiler, no matter what the heat source will be.

AISI-309, AISI-321

- Refractory stainless steel. It is an admixture of steel, chromium (19-21%), nickel (11-13%) and carbon (up to 0.2%).

- High resistance to high temperatures (up to 1050 ℃), as well as to acids.

Chimneys are made from such material, which will work in places with the most difficult conditions.

- Bath.

- Sauna.

- Solid fuel boiler.

Each brand has its own properties, suitable for a particular task

Is it possible to install a sandwich chimney in a bath with your own hands?

There is a wide range of raw materials on the market for the production of smoke exhaust structures, we will briefly name each of them.

It has a low cost and ease of installation, however, due to its porous structure, it can accumulate condensate.

It conducts heat very well and heats up quickly, but there is no corrosion resistance. It has a large mass, which complicates the installation process and requires the construction of a foundation.

The model is quite expensive and difficult to install, although its appearance is very pleasant. If not cased inside, the structure becomes clogged with soot, lends itself to condensation, damp, and further crack and allow carbon monoxide to leak.

Due to its strength, ceramics withstand high temperatures, are durable and can be used with any type of boiler. Nevertheless, the installation of such a chimney is very expensive, and the design itself is poorly maintainable. Therefore, only a qualified technician should be engaged in the installation, and the owners will have to take good care of this ventilation system.

Most bath complexes - home or commercial - use this option. This is due to its excellent resistance to atmospheric agents, soot actually does not accumulate, and the installation will last for many years. The appearance is well suited to any exterior of the bath, the shiny surface is pleasing to the eye. Moreover, this design is quite easy to maintain.

Our production

Single wall chimneys

Double-walled chimneys

Mounting elements

A glass smoke duct is a good choice, as this material has minimal inertness and is resistant to moisture and corrosion. The constant increase in the cost of installing such a structure is due to the complexity of the process and the high cost of refractory glass in general. Therefore, such chimneys are the most expensive systems these days, although the cost is fully justified by the merits of this option.

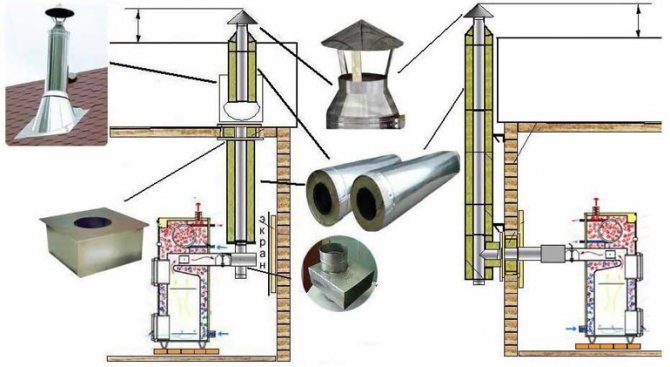

The use of such a design allows you to prevent and protect the premises from possible fires. Due to the insulation, the heating temperature of the pipe usually does not come out.

There is a certain sequence accompanying the correct self-assembly. Strict adherence to the rules and recommendations of the manufacturer, guarantee of uninterrupted operation of the chimney system.

Below are guidelines for what to focus on first.

The small size of the cross-section will impede the diversion of fuel products in the required amount. The volumetric section, on the other hand, contributes to the movement of smoke too quickly, which will not allow the bath room to be properly heated. This, in turn, will increase fuel costs. You should take a responsible attitude to this point, since the result will depend on it.

It is easy to decide on the form, given the basic principle of its work. Chimneys tend to heat up unevenly, as a result of which smoke escapes to the roof surface along the central axis. It follows that the correct shape is a circle. Cylindrical structures heat the room much faster and do not require unnecessary financial costs.

A chimney with a rectangular cross-section provokes turbulence that impedes the necessary draft. The rectangular configuration is only permissible when it comes to heaters that do not require powerful draft.

Pipe diameter

The scale is determined by the degree of power draft of the sauna stove and is located in the intermediate range from 115 to 270 (mm). Nevertheless, in order to accurately determine the diameter, you need to familiarize yourself with some of the instructions indicated by the manufacturer in the instructions. If you do not have a diagram for installing a chimney for a bath with your own hands, then it will be enough to know the ratio of cross-sectional diameters of different shapes. It looks like this:

- cylindrical - 1 in 10;

- rectangular - 1 to 1.5.

We offer you to familiarize yourself with the Arrangement of stretch ceilings using the harpoon method

For brick chimneys, the minimum cross-sectional diameter should be 140x140 mm.

The successful performance of the chimney system primarily depends on how accurately the chimney size is determined.

Chimney height

According to the standard, its height should be at least 5 meters. The calculation of the height of the chimney is carried out in accordance with the main technical characteristics of the materials.

The channel should be located at least half a meter above the roof ridge and in no way below its level. In this case, it is worth considering the thickness of the roofing and the angle of inclination of the roof slope. The height is selected without taking into account the chimney "umbrella".

- smoke assembly, not condensation. The most common and widespread mistake that very quickly destroys the pipe.

- location of wooden floors close to the pipe in the ceiling and walls. Savings on PPU.

- the use of materials strictly contraindicated for use as a chimney), since some of them can provoke a fire.

- insufficient chimney height;

- grouping several chimney structures at once into one;

- arbitrary calculation of the scale and diameter of materials.

Chimney installation is a very serious process that requires the necessary skills, care, patience, a responsible approach to the study of information about all kinds of installation methods. If you follow the manufacturers instructions or the advice given in this article exactly, then you will definitely not make mistakes in the process.

Remember that chimney repairs are often much more expensive than just installation services. It is for this reason that it is better to follow all the rules and recommendations at the design stage of the bath.

For the manufacture of stainless steel pipes for the chimney, various grades of steel are used. The service life of the product depends on the choice, its resistance to burnout when soot ignites in the pipe. The higher the quality of the steel, the more expensive it is. Be sure to take into account the frequency of operation of the chimney - for chimneys of boiler units operating around the clock during the heating season, the requirements are higher than for pipes of bath stoves, which are heated from time to time.

| steel grade | Characteristics |

| 439 | Titanium and aluminum were used as additives. The material is resistant to acid corrosion, withstands heating up to 850 ° C. |

| 430 | It is mainly used for the manufacture of casings and other elements that are not directly exposed to high temperatures and corrosive environments. |

| 409 | High heat resistance and acid resistance, can be used for chimneys of solid fuel stoves, fireplaces. |

| 304 | High strength, good weldability. Serves as a cheaper analogue of steel 316, somewhat inferior to its parameters due to the low amount of alloying additions. |

| 310S | Versatile material due to its ability to withstand heating up to 1000 ° C. |

| 316 | Thermal stability and chemical resistance are provided by the addition of molybdenum and nickel. The material is suitable for any type of boiler tube. |

| 316i, 321 | Pipes are versatile, flexible, corrosion resistant. Can be used for wood-burning stoves. |

Selection of stainless steel material

In private housing construction, stainless steel pipes of grades 409, 430, 439 are mainly used. With periodic operation (weekly heating of a sauna stove with wood), such a system will last about ten years. On boilers in load mode 24 hours a day, the average service life will be 2-3 years. In order to extend the life of the chimney system, it is recommended to install it in 3XX stainless steel.

Heating equipment type and chimney: what you need to know

When installing a stainless steel chimney, it is imperative to take into account not only the material itself and its brand, but also the thickness of the chimney wall. But, in addition to this, you need to consider what equipment is at home.

Below is an example of what heating equipment is available and what requirements it may have:

- stove or fireplace - AISI 321 (wall thickness - 0.5-1.0 mm);

- diesel boiler - AISI 316L (wall thickness - 0.5 mm);

- gas boiler - AISI 304 (L) and 321 (wall thickness - 0.5 mm);

- solid fuel boiler - AISI 309, 310 and 321 (wall thickness - 1.0 mm).

Conclusion number 1: solid fuel boilers need to have a chimney with a wall thickness of 1 mm. This chimney is made of heat-resistant steel, since the temperature inside the chimney can reach up to 500-700 ° C.

Conclusion number 2: oil and gas boilers emit acid, which means that you need to install a chimney with high resistance to temperature and acid, the wall thickness of which is 0.5 mm.

| Heating installation | Temperature inside the active installation, ° С | Stainless steel brand, AISI | Wall thickness of the inner pipe, mm | Insulation layer thickness, mm |

| Fireplace, stove | 350 — 650 | 321 | 0.5 – 1.0 | 50-100 |

| Sauna stove | 400 — 700 | 321 | 0.8 – 1.0 | 100 |

| A gas boiler | 120 — 200 | 304, 304L, 321 | 0.5 | 30-50 |

| Diesel boiler | 150 — 250 | 316L | 0.5 | 30-50 |

| Solid fuel boiler | 500 — 700 | 309, 310, 321 | 1.0 | 100 |

| Gas piston, gas turbine units | 450 — 600 | 316Ti, 321 | 1.0 – 1.5 | 100 |

| Diesel generators | 450 — 600 | 316Ti | 1.0 – 1.5 | 100 |

Pros and cons of stainless chimneys

The list of advantages of these alloys is headed by resistance to acid condensation, which appears when the hot air passing through the cold part of the chimney is cooled. This negative impact gradually destroys the metal, however, a stainless steel chimney is able to withstand the threat much better than all other metal structures. Often this property becomes the main criterion when choosing a material.

The list of advantages is not limited to this, it includes:

- Versatility of design, comparative ease of installation of a stainless steel chimney. These pipes can be combined with any heating equipment. Self-installation is possible in any season, and special skills are not needed for such work.

- Safety for people. The stainless steel channels heat up quickly, therefore they guarantee a sufficiently effective draft, which will not allow any force majeure circumstance to happen.

- Long service life of the chimney. It is not as outstanding as that of brick or stone structures, but if the installation of the chimney was carried out according to all the rules, then the pipes promise more than one decade of trouble-free work.

- Excellent cross-country ability. Plus - the complete absence of angles that can cause swirling of combustion products. The rounded shape avoids the accumulation of a large amount of soot, because there are no obstacles to the escape of smoke.

- Low weight of the flue duct, maintainability. The lightness of the design allows you to avoid arranging a serious foundation for the furnace. Replacing any module is simple; it does not require dismantling the entire system.

- High level of heat resistance. Such a chimney will be able to withstand temperatures up to 600 ° or more, but in this case the exact figure depends on the grade of stainless steel.

- Frost resistance, anti-corrosion properties, no fear of aggressive environments.

- Aesthetic appearance and a wide range of models.

- Reasonable price of the kit.

The list of advantages is quite impressive, but chimneys also have disadvantages. But are they serious?

In a large number of pluses, the only significant minus was "worn out". This is the need to take care of insulation. However, this disadvantage is often absent. Thermal insulation measures are needed only if the chimney is located outside the room, and when a model with single-layer modules is selected.

When planning the installation of a stainless steel chimney, you must first get acquainted with all the systems, since they are quite different in several characteristics.

There are several options here:

- Single-layer, single-wall models. They are made of single-sheet stainless steel, thickness - 0.5-1 mm. The pipes can have either oval or circular cross-section. Such chimneys are usually located indoors. Or outside, but then they are pre-insulated - with basalt, then fiberglass or heat-insulating foil material.

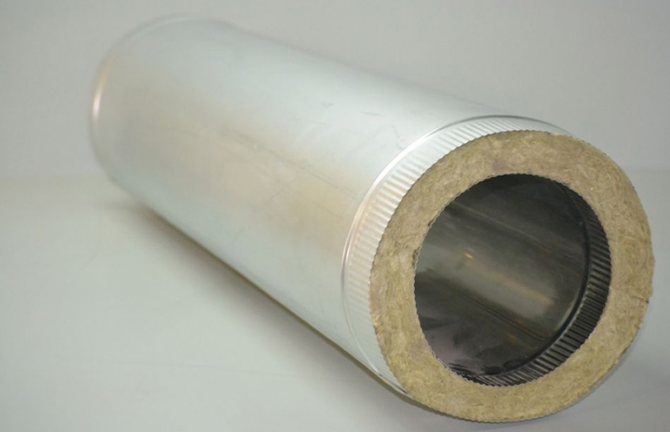

- Double-walled pipes - sandwich chimneys. They consist of three layers: outer and inner - stainless steel pipes, and between them - a layer of mineral insulation - from ordinary mineral wool or basalt variety. The sections are different: there are narrow materials (100 mm), the widest ones have a diameter of 1000 mm.

- Corrugated products. These are flexible sleeves that can be up to 10 meters long. Corrugation is used to obtain curvilinear transitions, to assemble a chimney to heating systems, where the boiler efficiency is low, in old buildings, to organize chimneys with non-standard geometry.

The station wagons are sandwich pipes, they can be used both outside and inside the premises. Products made of corrugated stainless steel do not always have the required level of strength and heat resistance. Single-layer components are mono-systems that guarantee excessive consumption of heat carriers, abundant formation of condensate, if additional insulation is not provided outside.

The biggest threat to chimneys is sulfuric acid vapor deposited on the walls of the chimney. To minimize the impact on pipes, it is necessary to consider the steel grades that are used as raw materials for their production.

- 304 is a low carbon (maximum 0.08%) non-magnetic steel, ductile, but having a high density. It can withstand high temperatures, even damage to the outer layer is not able to destroy its structure. The alloy is well resistant to acids, corrosion, alkalis.

- 310 is a heat-resistant material with a high content of nickel and chromium. These components can successfully resist oxidation. Dross appears on metal only at temperatures around 1500 °. The brand is considered elite, so its price is appropriate.

- 316, 316L - steel enriched with inclusions of nickel, molybdenum. These additives increase resistance to high temperatures and acids. The alloy is considered an improved version of grade 304, so it is used to produce kits for almost all types of chimneys.

- 316Ti, 321. Titanium is added to both alloys for increased strength and resistance to aggressive environments. Another plus is better corrosion resistance. The temperature limit for them is about 850 °. These grades of stainless steel are even used for the manufacture of vessels and apparatus for working with acids.

We offer you to familiarize yourself with How to make a chimney from a steel pipe with your own hands?

The L stands for low carbon content. For three-layer sandwich chimneys, different grades of stainless steel are used. Internal modules are made from high quality raw materials, external ones, which do not experience such aggressive influences, from cheaper materials.

If you plan to purchase pipes and install a stainless steel chimney, then you need to focus on the type of autonomous heating system. Each of them requires "own" alloys, a certain wall thickness:

- gas boiler - 304, 321 (0.5 mm);

- diesel boiler - 316 L (0.5 mm);

- fireplace, stove - 321 (0.5 -1 mm);

- solid fuel boiler - 310, 321 (1 mm).

For gas and liquid fuel equipment, special acid-heat resistant alloys are required. For solid fuel boilers, the main threat is high temperature, so heat-resistant stainless steel grades are chosen for them.

You can use two options for joining elements:

- "Through the smoke." In this case, each next module is put on the previous one. The advantage of the method is reliable protection against smoke, since there are no obstacles to its passage. The downside is the lack of a solution to the problem of condensate drainage, which will cause the heat insulator to constantly get wet. If a condensate drain tee is installed in the system, then there is no problem.

- "By condensate". This is the “opposite way” - the upper tube is not put on the lower module, but inserted into it. The insulation is completely protected from moisture, as it flows into the condensate collector. But the smoke has a good chance to get into the room, if there is even the slightest loophole. This method is used if the systems do not include tees for condensate drainage.

There are two rules about these installation methods that must be taken into account. Horizontal or inclined sections require installation "through smoke" so that the combustion products can move further unhindered. On vertical sections, it is better to use a condensate connection so that the flowing liquid cannot spoil the insulation.

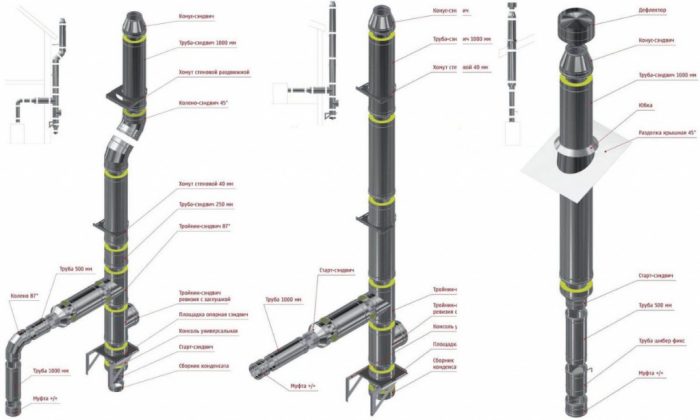

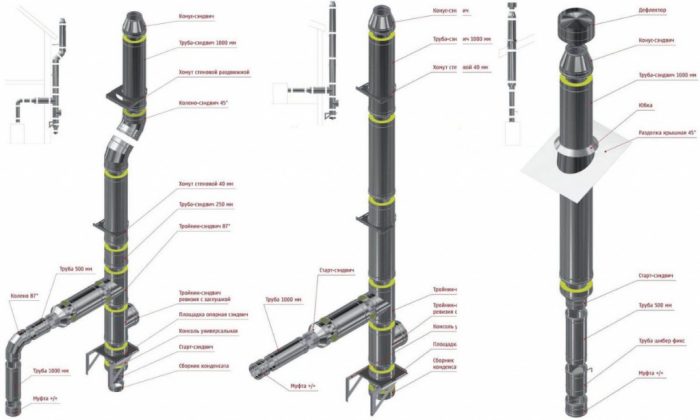

Modular chimneys are now in favorites, since with their help you can easily come up with and install a system of any configuration, without worrying about damage to the operation of heating equipment, for traction.

The preparatory stage includes calculations of the chimney, drawing up a sketch and marking the walls for fastenings. The last operation makes it possible to determine as accurately as possible the total length of the structure, the required number and type of parts for joining the sections.

Installation of a stainless steel chimney begins with a heat generator.

- An adapter adapter is put on it, the connection is coated with sealant, then fixed with a clamp. Then single-wall pipes are inserted, interspersed with component elements. The modules are pushed to a depth equal to half their outer diameter.

- After the channel for access to the roof has been formed, a ceiling-pass assembly is formed - homemade or (better) factory-made. A sandwich pipe is brought out through the roof, a corner passage, a cone, a skirt and a cap-head are put on it.

- After the final adjustment of the elements, the internal seams of the chimney are treated with a sealant. If they prefer to leave the structure collapsible, then use heat-resistant foam only at the joints of the modules.

Single-layer pipes are insulated, all joints are waterproofed using seals, as well as a sealant.

In this case, the first stage is no different:

- First, in the same way, an adapter is put on the pipe of the heating device, its tightness is ensured, then the clamp is attached. Then a horizontal section is mounted, which is taken out into the street through the passage node.

- Below the outlet of the horizontal section of the chimney structure, a bracket is fixed on the wall, which has a plate for installing an audit and a condensate drain, then these elements are installed.

- A vertical channel is assembled, which is attached with brackets to the wall every 1500-2000 mm. If the chimney is heavy, then additionally fixings are made at the points of articulation of taps, tees.

A cone and a cap-head are installed at the top.

Range

Installation of a stainless steel chimney is a rather difficult task, and therefore many people need to use a solution that is ready for installation. Many models come with various parts of the pipe, so it is quite possible to install the structure yourself.

Let's take a look at all these elements.

- Straight pipes. Their length, as a rule, is from 33 to 100 cm. Socket coupling is what firmly connects the elements of the pipes to each other.

The pipe does not need additional fasteners - Elbows at an angle of 45 °. They are best used when there is a need to deviate from the vertical.

- Elbows at an angle of 90 °. Due to them, it is possible to make transitions between the vertical and horizontal section of the place where the pipes are stretched.

Elbows 45 and 90 degrees - Condensate collector. It is placed at the lowest point of a vertically running pipe. It is used to collect water that appears when the smoke cools.

- Tee at 45 ° and 87 °. With it, you can collect pipes where condensate collection is planned. In addition, such a tee is useful when connecting two heating devices that are connected to a common chimney.

- Inspection element. The audit is installed where, most likely, soot accumulates. Its use is to check and clean the chimney.

Chimney inspection - Passages. This element provides insulation for the structure to protect against fire, sealing the roof and also guarantees improved pipe design.

- Additional accessories. To protect against precipitation inside the chimney structure, from reverse draft and from sparks, a number of accessories are installed on the roof at once, including a cap and a spark arrester.

Chimney cap

Installation of stainless steel chimney

Modular chimneys are now in favorites, since with their help you can easily come up with and install a system of any configuration, without worrying about damage to the operation of heating equipment, for traction.

The preparatory stage includes calculations of the chimney, drawing up a sketch and marking the walls for fastenings. The last operation makes it possible to determine as accurately as possible the total length of the structure, the required number and type of parts for joining the sections.

Internal chimney assembly

Installation of a stainless steel chimney begins with a heat generator.

- An adapter adapter is put on it, the connection is coated with sealant, then fixed with a clamp. Then single-wall pipes are inserted, interspersed with component elements. The modules are pushed to a depth equal to half their outer diameter.

- After the channel for access to the roof has been formed, a ceiling-pass assembly is formed - homemade or (better) factory-made. A sandwich pipe is brought out through the roof, a corner passage, a cone, a skirt and a cap-head are put on it.

- After the final adjustment of the elements, the internal seams of the chimney are treated with a sealant. If they prefer to leave the structure collapsible, then use heat-resistant foam only at the joints of the modules.

Single-layer pipes are insulated, all joints are waterproofed using seals, as well as a sealant.

Installation of external structure

In this case, the first stage is no different:

- First, in the same way, an adapter is put on the pipe of the heating device, its tightness is ensured, then the clamp is attached. Then a horizontal section is mounted, which is taken out into the street through the passage node.

- Below the outlet of the horizontal section of the chimney structure, a bracket is fixed on the wall, which has a plate for installing an audit and a condensate drain, then these elements are installed.

- A vertical channel is assembled, which is attached with brackets to the wall every 1500-2000 mm. If the chimney is heavy, then additionally fixings are made at the points of articulation of taps, tees.

A cone and a cap-head are installed at the top.

Stages of installation of the structure

To save money, you can install the chimney yourself - we'll figure out exactly how.

- At the exit point of the smoke collector, a metal pipe of a certain height is installed, since it determines what the heat transfer to the room from the heating equipment will be. It is necessary to put the construction "on the smoke". After installing the pipe, you need to put it on the branch pipe and install a gate that will block the channel. All joints are carefully coated with a special heat-resistant sealant.

- After installing the main part of the structure, you need to put on a starting sandwich chimney in the form of a double pipe, which is closed on one side. All the necessary products will then be put on this sandwich. And yes, the joints are again connected with a special sealant.

- Now you can collect all the items. Everything is installed so that the condensate drains to the desired point. All joints must be sealed with a sealant.

It is important not to forget to treat all joints with a sealant. - The installation of pipes on the roof involves the use of an unloading platform, and just below you can use special clamps. They should be used where parts of the pipes are connected, because this can increase the strength of the entire structure. Flammable materials are insulated with a layer of basalt wool in a box.

- All lines with twists and branches must have revisions so that pipes can be cleaned without problems.

- The last stage - the apron and the conical roof are installed together with a deflector or head.

Following the stage will allow you to install the pipes so that they function correctly in the future.

Homemade walk-through node

The internal installation of a stainless steel chimney is more demanding on the master: the main difficulty lies in one device - in the ceiling-through unit, which guarantees the necessary clearance, as well as high-quality waterproofing. You can make a similar detail yourself. This is a box that has a hole in the center for a pipe. The height of its walls is equal to the thickness of the floor (walls, roofs).

- First, the necessary hole is made in the structure, then the edges are additionally strengthened. Two blank plates are cut from a metal sheet (usually from the same stainless steel), the sides of which are 50 mm longer than that of the prepared hole, the height is equal to its height.

- These "extra" 500 mm are folded at a right angle. The elements are fixed on both sides of the hole made with self-tapping screws. In the same way, another pair is made, they are placed overlapping with the first. Then they make a bottom, in which they cut a hole for the chimney. It is laid on plates.

- The free space is filled with basalt wool or expanded clay. From below and from above, the box is closed with decorative plates.

The passage of the chimney through the roof is somewhat different. The difference is in the shape of the hole for it: it is made elliptical or rectangular. The chimney must be located between the rafters, ceiling beams, preferably in the center. After the pipe is withdrawn, it is imperative to restore steam, heat and waterproofing. Crimp skirt, cap (spark arrester) are attributes that are also required.

https://www.youtube.com/watch?v=L4j8Bi2Ns68

The installation of a stainless steel chimney is greatly simplified with the introduction of practical factory products. Even less work remains for those who decide to move the channel outside the home. The operation itself is not very demanding, but skills, the ability to read drawings, accuracy and sequence of actions are still necessary.

Care and maintenance of a stainless steel chimney

For more efficient operation of the stainless steel chimney, you need to follow the recommendations below.

- Before lighting a boiler or stove for the first time, you need to check in advance if there are any foreign objects or debris in the flue duct. If there is one, then you need to take some long tool and push it through until the revision. When the debris is there, you need to open the revision channel, pull it out of the pipe, and after getting rid of the debris, the chimney and the revision channels are cleaned of soot with a brush.

- Household waste should not be thrown into a working furnace or boiler for incineration, as it can worsen the condition of the chimney.

- In solid fuel heat generators, as a rule, logs from conifers are not thrown. The reason is the resin content, which will quickly build up. The only exception is aspen logs, which can create a high fire and burn soot in the chimney with it.

Several rules must be followed for the chimney to work properly.

From time to time it is necessary to inspect the roof on the roof if it is made of metal. This is done to detect any rust that may have appeared on the outside of the pipe. Yes, it can even hit a "stainless steel", which is quite unusual.

What should I do if I find this problem?

- Clear space around the pipe.

- Dismantle the problem piece of pipe.

- Clean, sand and degrease the work surface.

- Holes and cracks should be carefully repaired.

- Rinse with hot water and then dry thoroughly.

- Fill all the cracks found with a special sealant.

- Take a silicone nozzle, put it on the pipe, secure with self-tapping screws for greater strength.

Mistakes made in the arrangement of the chimney will lead to the reappearance of rust on the pipe or its transition to the roof.

The roof should not rust if done correctly

You may be interested to know which sauna stoves worth buying.

Stainless steel instead of ceramics: when is it better to choose steel?

Everyone knows that the chimney is an important part of the heater. And this means that his choice must be correct.And for this you need to know when and where it is better to use it. For a long time, the ceramic version was popular, and it could be found literally everywhere, but today it will be out of place, and therefore stainless steel, as an alternative, will look quite good.

Below, the experts of the Obzor-Expert.com website have identified three best cases when it is perfect.

- Boilers with a closed combustion chamber. It is better to use steel pipes for them. They are much more convenient than ceramic from the point of view of installation.

- Retrofitting a brick oven or fireplace. This is easier if stainless steel elements are added.

- Installation of an additional chimney. This is best done with double-layer sandwich pipes.

Important! It is quite difficult to choose the ideal option for heating equipment. Both options - both ceramic and stainless steel - have their own characteristics, pros and cons, and therefore you need to carefully study everything before choosing one.

Selection features

It may seem that stainless steel pipes for a chimney are very easy to choose, but before buying it is important to understand a few main parameters:

- Heater type. For reliable operation of the pipe, you will need to understand under which heating device the material will be placed. For example, boilers fueled by diesel or gas generate a lot of condensate, which is caustic. For such devices, it is recommended to use AISI 316L stainless steel with a thickness of 0.5 mm. The steel will withstand acidic and corrosive environments. For coal-fired furnaces, heat-resistant structures made of raw materials such as AISI 310, walls with a thickness of 0.8-1 mm should be used. For a wood-burning fireplace, it is enough to use AISI 321 steel.

- Chimney design features. Steel models are divided into several types. Single-wall devices are often used as an aid for a brick channel. They need to be insulated, but the double-circuit devices are already insulated, which allows you to partially get rid of condensation. Sandwich devices that require regular cleaning.

- Installation options. Modern systems are very simple, easy and convenient to maintain, and installation can be provided without outside help. During the purchase, you need to look at the evenness of all elements, connections, the quality of docking and pivot points.

- Reliability / durability. It is difficult to determine such parameters only visually, but based on the steel grade and pipe thickness, you can roughly determine the overall quality.

The article presents the best options and manufacturers today who make high-quality chimneys. Offers stainless steel chimneys Leroy Merlin - a chain of stores of the best building materials

Stainless steel pipe options

Today, you can find as many as three options for this kind of chimney.

- Single-walled (thickness - 0.6-20 millimeters).

- Corrugated.

- Three-layer sandwiches (two pipes + insulation).

Let's consider each of the options, taking into account their pros and cons in the form of a table.

| Pipe type | Dignity | disadvantages |

| Single layer | Low cost, smooth inner surface. | High heat transfer rates, condensation may form, the need to install thermal insulation. |

| Corrugated | Elasticity, some flexibility. | Low resistance to high temperatures, rapid wear, corrugated inner surface, on which condensation can accumulate, is not suitable for horizontal sections of the chimney duct, it is necessary to fix and install thermal insulation. |

| Three-layer | Low heat transfer rates, versatility, easy assembly, tight joints. | The rather high cost of this type of pipe compared to others. |

Each of the types of pipes has its own characteristics that hinder or help in choosing

Extremely important! The regulatory authorities, seeing the corrugated pipes, are likely to refuse to start the gas.

Video - About choosing and buying a stainless steel chimney

Features of operation

A stainless steel chimney is quite popular today, but, like other chimneys, it needs to be checked from time to time and generally looked after. Below we will show you how to do it correctly.

- The first thing to do when using a steel chimney is to thoroughly inspect the heater before each season. From time to time it may be necessary to clean it from soot and other dirt.

- Next, you need to check the draft when the time comes for the first ignition. If it is not there, then you need to find out what the matter is. As a rule, it is enough to simply warm up with improvised means and then check the traction with a match.

Important! The thrust is checked with the regulator damper or gate open.

- It is necessary to inspect the chimney, check if it is clogged with soot. You can get rid of it with a soft stainless steel brush and a plaque softener.

- At times, you can lay aspen wood, which can be used to remove the soot in the chimney.

- Proper use of the stove involves the use of deciduous wood that does not contain resin. It should also be noted that it is impossible to use cut plywood and chipboard for ignition.

It is necessary to take into account the presence of a number of operating features that determine the service life of the chimney

You may be interested to know which conditioners worth buying.

Features of sandwich chimney

Sandwich chimneys are made of modular pipes. This is a stainless steel base, wrapped in heat-insulating material, on top of which a protective stainless steel casing is worn. Stone wool is used as a heater. This material is non-flammable, does not emit harmful substances when heated.

Benefits:

- Ease of installation. Anyone can do it without additional training.

- Light weight. This avoids the need to use many brackets.

- On sale there are all the components for the manufacture of a complete chimney.

- All parts are round. Advantages - no corners where smoke accumulates.

- Sandwich pipes for ovens are smooth inside. Condensation easily flows down them, soot builds up very slowly on them.

- Resistance to prolonged exposure to acids, water.

In addition to strengths, sandwich pipes have some disadvantages - short service life (about 15 years), high price.

Installation methods

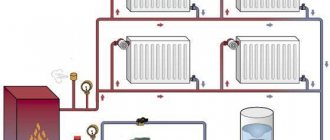

There are two ways to locate the chimney based on the location of the heater in the house.

- Outside the house... The simplest and therefore the most popular chimney installation technology. For the successful implementation of the venture, a double-circuit chimney with fastening in the form of clamps is used. To prevent heat loss, thermally insulated pipes are used.

- Indoors... A more complex and expensive option, which requires taking into account the design of the room, because the chimney will go through the floors and the roof to the outside, that is, to the street. The difficulty lies in the requirement to insulate the chimney, especially at the point of contact with the roof, where spark arresters are installed. However, the plus of such a system is to reduce waste on heating.

There are two different installation methods, each with its own pros

Installation Recommendations

The recommendations below will help you install the chimney correctly so that it functions without any difficulties.

- If you put a pipe with a height of five meters and more, then you can achieve good traction.

- The length of horizontal sections should be up to one meter, not more.

- Installation of a chimney on the street or in an unheated room involves the installation of thermal insulation material.

- If the chimney passes through a roof built with combustible materials, a spark arrester must be installed.

If you strictly follow the suggested recommendations, you can install the chimney without any problems

Important! Docking of uninsulated pipes in the wall is prohibited if the chimney ducts are not insulated.

Top entryway and top exit models

Such devices are suitable for connection to a boiler or fireplace, which have the ability to escape gases through the top. Due to this, the system is immediately installed on the roof, so it will be necessary to partially disassemble it, but a minimum amount of additional materials is needed to connect and transitions. The choice takes into account the length and distance above the ridge. Often a stainless steel chimney of 150, 200 or 115 mm.

Ferrum 115 mm, 0.8 mm

The best option for any fireplace in the house because of the direct connection and the good diameter for connection to the 115 mm outlet. Inside, everything is made of stainless steel with a high-quality seam that will not allow condensate to pass through, after which there is a dense layer of insulation using mineral wool with indicators of 120 kg / m3 and this excludes the fire of ceilings or roofing materials. The outer part is laser welded galvanized.

Pros:

- Complete kit with parts for overlap and complete installation.

- The insulation layer can withstand temperatures up to 700 degrees.

- The thickness of the insulating layer is 4-5 cm, therefore, objects from a pipe or hot smoke are excluded from ignition.

- It is recommended to buy for wood-fired heaters.

- There are screws for fasteners, a sealant that can withstand up to 1200 degrees. There are also 5 pipe clamps for fixing the pipes in height.

- The presence of a stainless steel head, which eliminates the clogging of the pipe with snow.

- Available with 7 sheets of basalt wool.

- Manufactured from AISI 439 steel on both sides.

Minuses:

- The thickness of the elements that are connected to the fireplace 0.8 mm, and outside (outdoors) 0.5 mm.

- The part of the pipe that extends from the fireplace does not have insulation, it starts only from the ceiling, due to which there are risks of causing a burn.

- For the entire set, you have to pay about 27,000 rubles.

Smoke 115mm, 0.5mm

This kit is the most optimal and affordable for people, and it has everything you need for installation. Inside the product there is stainless steel with walls of 0.5 mm, and due to the use of insulation, the pipe is not subject to deformation. The outer part is made of galvanized steel sheet. TIG welding is used for the connection, which helps to make strong seams, so soot is almost not collected in them.

Pros:

- Attractive cost per set, namely 11 thousand rubles.

- It is sold together with an umbrella, which is already insulated and excludes rainfall.

- Supplied with 4 clamps for assembling the structure.

- There is an adapter for pipes of different types.

- The presence of a master flash.

- 1 meter starting pipe and 3 meters double layer pipe for large roof.

- 4 cm sandwich.

- The use of steel grade AISI 439.

Minuses:

- There is no insulation for the floors, so you will need to purchase parts separately.

- There is only 1 bracket for vertical installation.

- Weak pipe thickness, only 0.5 mm.

- Recommended only for gas or coal-fired systems, not suitable for wood-burning stoves due to thin walls.

Ferrum 200 mm, 0.8mm

An excellent choice for heating systems in the home, office, because the inside diameter of the pipe is 20 cm, and this is suitable for a powerful boiler. Steel thickness 0.8 mm, optimal rigidity.

Pros:

- High quality insulating materials with a density of 120 kg / m3.

- The metal does not corrode and has increased strength.

- It can withstand up to 700 degrees.

- The assembly is simplified, it is carried out on its own without the involvement of masters.

- The inner seam is sealed.

- Insulation 5 cm thick.

- The total length of the pipe is 7 meters, so the overhang is high.

- There is a flange for the ceiling.

- The cap is large, reliably protects the pipe from snow and other precipitation.

- It is sold with 2 fasteners, 9 clamps and 8 insulation plates for the attic space, there is also a 1x1 meter stainless steel screen.

Minuses:

- Outside, the diameter is very large, as much as 28 cm, so you need to make a corresponding hole.

- The cost of the set is overstated - 42 thousand rubles.

Voting: the best chimney manufacturers

Which chimney manufacturer would you choose or would you advise to choose?

CRAFT

30.77 % ( 4 )

Volcano

23.08 % ( 3 )

ROSST IN

0.00 % ( 0 )

Jeremias

0.00 % ( 0 )

Thermophore

0.00 % ( 0 )

Ferrum

7.69 % ( 1 )

Elits

7.69 % ( 1 )

Inzhkomtsentr VVD

23.08 % ( 3 )

Phoenix

7.69 % ( 1 )

Baltvent

0.00 % ( 0 )