The knowledge of how to glue a sewer plastic pipe when the necessary equipment is not at hand will be useful to every home craftsman. Frequent leakage must be eliminated urgently when it is not possible to replace the damaged element. You can completely assemble the plastic piping system using special adhesives.

PVC pipes gluing

The composition and principle of action of adhesive materials

Plastic products are glued using specialized chemical compounds that dissolve the outer surface of the material. The active ingredient in most variants is methyl ethyl ketone, cyclohexane or tetrahydrofuran. Adhesive for sewer pipes made of PVC or polypropylene is made on the basis of the same substance as the parts of the pipeline themselves. In addition, various additives are mixed into the adhesive materials, which allow to influence the viscosity of the mixture and its setting time, as well as improve adhesion.

In the process of glue hardening, plastic pipes are rigidly connected due to the interweaving of molecular polymer chains on the outer surfaces of the parts to be joined. The solvent is then evaporated and a compound is obtained that has the same characteristics as a new one-piece product.

Causes of leaks

In free-flow systems, emergency situations arise due to improper operation, poor-quality installation and factory defects. A connection that is not made according to technology always causes a depressurization of the network.

I drilled a polypropylene pipe in the wall what to do

Polypropylene is not difficult to damage by mechanical stress. Most often, leaks in a free-flow system occur precisely due to external interference. Mechanical stress negatively affects the rubber sealing elements, with the help of which most of the connections are made in free-flow networks.

In systems under pressure, accidents occur for the following reasons:

- physical impact;

- incorrect installation;

- non-observance of recommendations during operation;

- increased pressure;

- erroneous assembly;

- use of substandard materials.

Often, a violation of the tightness of the PP system occurs during repair and construction work. Often, fitters or builders drill pipelines.

Factory defects can also be the cause of an emergency, because Chinese-made polymer pipes are present.

PP products have a durability of 50 years. This is the guarantee given by bona fide manufacturers of certified products.

How to choose a glue?

When choosing how to glue the sewer pipe, you need to pay attention to the following factors:

- bonding material;

- setting duration;

- technology of use;

- temperature conditions;

- time and storage conditions after opening the package.

All the necessary information is described in detail in the instructions, which should be carefully studied.

There are 2 main groups of adhesive materials for gluing plastic pipes:

- One-component formulations. Such products are sold ready-made and do not require preliminary mixing of the components. Adhesives are packaged in glass, plastic or metal containers and are used to join different types of plastic. They consist of dissolving, softening and joint-forming chemically active substances.But they do not have additives or additives that can change the duration of the course of a chemical reaction and enhance the strength of the abutting place. A typical example of such materials is sealant for PVC and polypropylene (Moment).

- Two-component formulations. They are produced in the form of 2 separate components, which are in different packages. They are mixed immediately before use. Chemically more complex compounds, since they include elements that improve adhesion and reduce the evaporation time of solvent components. The addition of additives promotes the acceleration of the formation of stable polymer chains, due to which bonds of the atomic level are obtained stronger. Higher quality of the joint is provided.

A convenient and effective way to quickly glue all types of pipelines is to use a special sealing tape.

How to glue a plastic sewer pipe

If fistulas are characteristic of cast iron, then no pipe, including plastic, is insured against cracks. If a hole has formed in the flat part, the same clamps come to the rescue.

Repair clamp

Just as in the case of a cast iron pipe, the clamp can be replaced with a piece of rubber (not for long!) And wire.

Silicone sealant ↑

A small crack can be repaired with silicone sealant. Act in stages:

- the crack is expanded (if possible) so that the composition penetrates as deeply as possible;

- the surface is thoroughly cleaned and degreased;

- dry the repaired area with a construction hairdryer;

- apply a sealant.

A two-component epoxy is used to repair the through hole. The procedure is slightly different:

- the surface is cleaned and degreased;

- the damaged area is wrapped with a bandage (it is prepared in advance from a flexible dense material) - along the entire length, with a margin, overlapping, at least 5 turns;

- epoxy glue is applied.

Sealing tape ↑

The method is very convenient and inexpensive. The tape is an impregnated adhesive fabric.

Sealant tape

It is indispensable in the repair of hard-to-reach areas and is so convenient that it is used to seal cracks on straight sections of a sewer pipe. As with other materials, the surface is thoroughly cleaned and degreased, then the tape is stretched and wound around the pipe section (the tension of the tape must be constant to avoid wrinkling). They are wound with an overlap - the next layer should cover half of the previous one, so that in the end the material becomes two-layer.

How to prepare and glue plastic piping elements?

Since the pipe adhesive contains toxic volatile components, all work should be carried out in a well-ventilated area. The temperature should be within + 5 ... + 35 ° С. It is recommended to protect hands with rubber gloves to avoid causing an allergic reaction or irritation.

The sequence of actions is as follows:

- Cut pipe sections of the required length using special scissors (pipe cutter) or a fine-toothed saw. The edges of the cut are cleaned with a file and sandpaper to remove chips and burrs.

- Then the bonded area of the surface must be well cleaned of dirt and dried thoroughly.

- The preliminary assembly of the pipeline structure and the final adjustment of all elements are carried out.

- Before gluing the damage or gluing all the parts together, the gluing points must be degreased with a special solution or an alcohol-containing liquid.

- The adhesive is thoroughly mixed. When using the repair method with two-component glue, measure the required amount of material and knead it with your hands until it is ready (plasticine consistency).

- Using a brush or applicator, the glue is evenly distributed over the prepared surface.The parts are joined and fixed in a stationary state for several minutes (the exact time is indicated in the instructions). Reapplication is sometimes required. A thick mastic is applied to the repaired area and strongly pressed with a tourniquet.

- Excess glue protruding along the edges of the joint is removed with a paper towel or rag.

- The connected parts are left alone until the adhesive is completely dry.

The general tightness of the joints and the reliability of the entire structure are checked no earlier than after 24 hours. When sealing the leak, the repair mass hardens in an hour.

Using cold welding

An effective way to reliably seal a leak is to use cold welding to repair plastic pipes. This is a special repair compound that must be applied to the problem area. The material is sold in specialized stores.

The surface of the pipe to be repaired is preliminarily cleaned with sandpaper, thoroughly degreased and dried. After that, you need to take a sufficient amount of cold welding and knead it thoroughly. In this case, the hands should be moistened rubber gloves. The material is kneaded until it changes color to brown and acquires the consistency of plasticine. The prepared mass must be applied to the place to be repaired and pressed tightly with a tourniquet, leaving it for an hour. During this time, cold welding will harden and form an almost monolithic bond with the plastic.

Causes of defects when gluing PVC pipes

Sometimes, some time after sealing a crack in a PVC pipe or gluing the entire structure, fluid leakage is observed at the joints. Most often, the reasons are the following technological violations that were made during the work:

- Poor surface preparation on old pipe and severe irregularities. In case of poor processing of the cut edges, when roughness remains on the material, the adhesive dissolves and softens the material unevenly.

- Contamination remained on the treated areas. Unfatted surfaces also cannot be well impregnated with glue.

- Unevenness in the application of the adhesive leads to non-gluing in some places of the joint.

- The seam is not completely glued if a thin surface film has formed on the adhesive layer due to its overdrying. All work must be done quickly.

- A soft and loose glue layer instead of a good strong joint is formed at low ambient temperatures during work. In this case, the solvent does not completely evaporate and the composition does not harden.

- A porous adhesive layer may remain if the components are poorly mixed prior to application. Remaining air bubbles weaken the seam greatly.

- Insufficient compression force or lack of holding time, as a result of which there is a distortion and displacement of the parts to be glued during the curing of the composition.

- Incorrectly selected brand of glue.

In order not to have to take additional measures to eliminate the leakage due to poor-quality gluing, it is necessary to correctly select the adhesive composition and strictly observe the technology of the work.

How to repair small damage

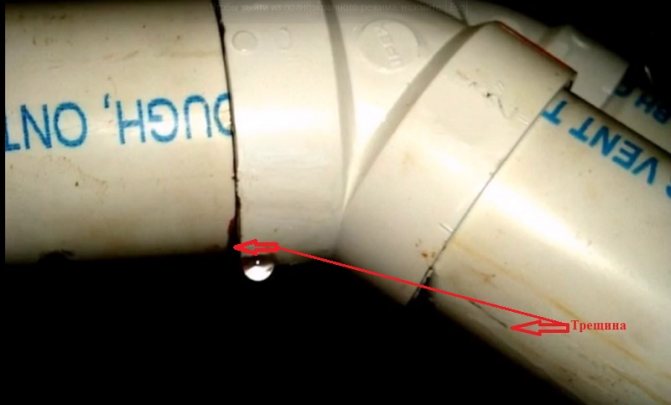

Sometimes cracks are so small that they are almost invisible visually. They can only be detected by smell. Most often, they appear from mechanical impact - a blow with a heavy object and the fall of something sharp.

Minor damage is difficult to identify. You need to carefully examine the pipe, perhaps even with a magnifying glass. There may be several chips. Even the smallest of them cannot be ignored. If the crack is not sealed, it will deteriorate further and may crack so that it will have to be replaced completely.

When all the points of damage are established, they begin to repair.For the restoration of small chips, it is enough to apply hot melt glue to the plastic. To get a positive effect, it is important to carry out the work correctly:

- Before starting the repair, dry the damaged areas with a hair dryer.

- Clean the crack with fine-grain sandpaper.

- Degrease the surface.

- Preheat the thermo gun to the required temperature. It should not be excessive, otherwise the pipe may melt. It is selected individually, depending on the material from which the pipe is made. Usually, after the installation of the drainage system, scraps remain. They can be pre-tested.

- Applying hot melt glue to the crack. If it is horizontal, the direction of movement of the gun nose does not matter. Most often it is carried out from left to right. When the crack is vertical, the nose of the device must be directed from the bottom up, as in welding.

Cracks on the pipe and at the junction are almost invisible. They can be identified by smell and droplet hanging.

- The glue is applied 2 cm further from the beginning of the crack on each side. If it spreads in width, it can be straightened with a spatula and pressed to the surface.

Hot melt glue dries very quickly, in just a few minutes. You don't have to wait long to start using the sewer again.

Conclusions and useful video on the topic

With the help of cold welding, really high-quality water and sewer pipelines are assembled. Moreover, the method can be equally effectively used when laying communications in a private and multi-storey building.

If you are not confident in your own abilities, it makes sense to hire professionals. But for home owners who know how to handle tools, it will not be difficult to do the work on their own. We offer useful videos to help craftsmen.

Why is it better to glue PVC pipes? An experienced master answers:

How and how you can cut polymer pipes is described in the following video:

The ideal choice is a multi-tool that cuts pipes straight and chamfers immediately:

The choice of glue directly depends on the type of pipes, so you should pay attention to them:

There is no simpler technology for joining polymer pipes than gluing. The method is cheap, convenient, and as effective as welding. Almost any person can handle the installation of the pipeline with the help of glue, because he doesn't need any special skills.

The main thing is to choose the right pipes, glue and tools, and be careful and neat when working.

Share with readers your experience in gluing PVC pipes, tell us what kind of glue you used in your work. Please leave comments on the article and ask questions of interest. The feedback form is located below.

In modern communications, plastic pipes are increasingly used, especially for domestic needs. Sewerage, water supply and heating systems for the most part consist of polypropylene pipes or PVC products. Such popularity is due to the long service life, ease of installation and reliability of polymer pipes. But even such products sometimes need repair. This article will discuss how to glue a plastic pipe.

What to do first if a leak occurs

If a leak appears in the high-pressure pipes, heating system or other communication in an apartment or house, then the first step is to close the shut-off valves. This truth is familiar to everyone. But what to do next?

The emerging leak can be "plugged" with clamps. Such structures are simply put on the desired area and tightened with bolts.

You can use the old way - use rubber. Using this method, I often repair a heating or water supply pipe. The problem area is wrapped with a piece of rubber (for example, from car tires) and clamped with a clamp or pulled over with a thin wire or strong cord.

Note! You can use regular paint. The place where a crack or leak appears is wrapped with a cloth and painted over with oil paint.

But all of the above methods can be considered a temporary solution. If such patches are left for a long time, then the leak will appear again. That is why many masters recommend replacing the problem area, especially since it is quite easy to do this using plastic pipes.

Damage types

The spillway system consists of an internal and external sewerage system. The operating conditions are different for both systems.

For the internal, characteristic:

- Periodic exposure to liquids up to 80–90 ° C. This causes an increased load due to the increased chemical aggressiveness of the effluent components.

- Volley discharge of water from all sources located in the living quarters. The consequence is the increased pressure of the liquid column on the structure of the internal sewage system. The material of the manifold and the docking units are subject to increased stress.

- Mechanical loading of system elements: using the collector as a stand or hanger, support when moving furniture. It is not uncommon for pipes to be used instead of a stepladder or a stand for a person, when he performs any actions.

Outdoor:

- Experiencing fluctuations from external temperatures. In winter - negative, in summer, reaching 50-60 ° C.

- In the cold season, the collector immersed in the ground can be influenced by the pressure force from the frozen groundwater.

- The line is subjected to a static load from the mass of the covering soil.

- Additional forces - weight from outdoor buildings or vehicles, if the highway is laid under the carriageway.

Due to the accounted and unaccounted impacts, defects may appear in the elements of the spillway system:

- cracking;

- the joint of the sewer pipe is damaged;

- complete destruction of part of the sewage system (burst collector).

How to close a hole in a polypropylene pipe

When repairing a polypropylene system, the safest way is to replace an unsealed section. For this, an emergency section with a hole is cut out of the communication.

Plumber examines a piece of pipe

Then a new unit is assembled on the ground, or a piece of pipe of the required length is simply prepared. It is already soldered in place using PP couplings.

In practice, it is not always possible to use a special welding machine to solder a part of a pipe or a whole assembly. In this case, other methods of filling holes in the system are used.

Clamp

One of the options for eliminating the leak would be the use of a clamp with screw clamps. This is a temporary way to stop the leak. The clamp is used in conjunction with a plastic waterproof sealing material. This option allows you to completely eliminate the leak.

The advantage of using a clamp is the free passage of water through the system. In this case, nothing will interfere with the movement of liquid. This method is implemented quickly without interrupting the operation of the system.

The disadvantage of this method is the inevitable loosening of the screw connection. Therefore, it is required to periodically check the site, and tighten the clamp.

Cold welding

Cold welding is often used to seal the hole. Its amount depends on the amount of repair work. At the beginning, the component is kneaded by hands or mixed in the required proportions. Then the substance is applied to the damaged area. Leakage is eliminated after solidification of cold welding.

Adhesive bandage

You can eliminate a hole in a polypropylene pipe using an adhesive bandage. The method is implemented using 2 clamps together with a material that is impregnated with a special glue - a 2-component composition.It is recommended to use rubber or bandage together with sewerage cement.

The advantage of this method is the ability not to turn off the water in the system. The disadvantage of the method is the impossibility of using an adhesive bandage in a network with high pressure.

Sealant and tapes

A good option is to use a sealing tape. The adhesive material allows you to quickly seal a leak through a small hole. It is necessary to apply the tape in several layers.

You can also apply a special sealant. It also allows you to quickly glue a crack that has formed at the junction of plastic pipes. However, this option is a temporary remedy for the leak.

For the high-quality implementation of any of the methods, you must first degrease and clean the surface with a defect.

In practice, the following main types of sealants are used:

- Neutral gun-applied substance suitable for use on all pipes;

- silicone universal compound designed for sealing bell-shaped sewer connections;

- an acidic sealant not suitable for brittle pipes and for the repair of acid transfer systems.

The most difficult thing is to eliminate leaks in heating networks. Thermal circuits are often laid in a closed way. Therefore, before gluing the hole in the pipe, you need to accurately determine the location of the damage. To do this, you have to open walls, floors and other building structures.