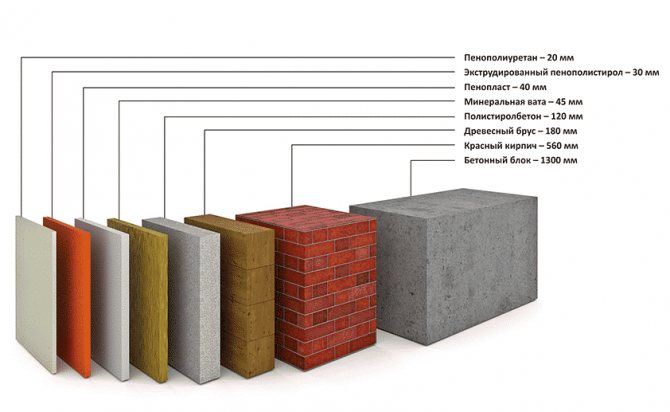

In technical literature, polyurethane foam is described as the material with the lowest thermal conductivity on the list of standard thermal insulation materials. Expanded polystyrene and rigid polyurethane foam with low density (from 20 to 50 kg / m3) have rightfully become the most used materials for industrial refrigerating and freezing chambers and other systems where increased thermal insulation is required. This is due to the low heat transfer. For comparison, the thermal conductivity of rigid polyurethane foam is several times lower than the thermal conductivity of mineral wool and all other popular heaters.

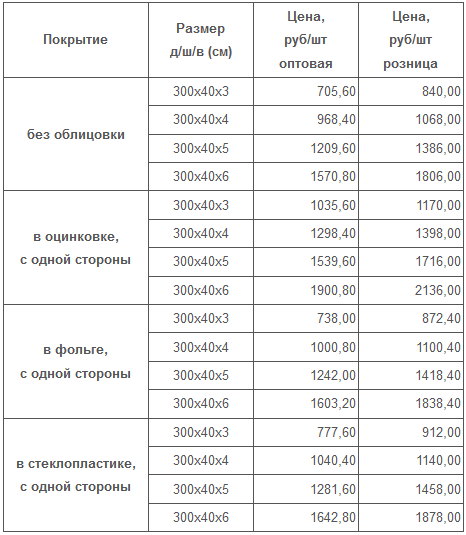

The cost of polyurethane foam (PPU) boards

The standard dimensions of the slabs are 300 * 40 cm, but other parameters are also possible. The ends of the material can be made in a quarter so that their joining is of the highest quality and reliability.

We are ready to provide discounts on PPU boards depending on the purchased volume.

As a thermotherapy, including a decorative function, we suggest that you consider decorative boards with imitation of wood texture. Facade decorative panels imitating wood can be used indoors and outdoors.

You can get acquainted with the prices for facade decorative thermal panels with wood imitation in the price list, with their outward appearance in the product catalog in the "Decorative boards" section.

The popularity of rigid polyurethane foam, which is the basis of polyurethane foam insulation boards, is due to its unique hydro-, sound- and heat-insulating qualities, as well as resistance to decay processes, fungus formation, aging and aggressive external climatic conditions. In addition, the advantages of PPU boards include simple material processing. These products are easy to saw, drill and cut. Another undoubted advantage is the ability to dismantle the PU foam boards and reuse them at another facility.

The standard dimensions of polyurethane foam insulation boards produced by the manufacturing enterprise are 40 cm in width, 300 cm in length and 25-100 mm in thickness.

It is possible to manufacture polyurethane foam boards with an additional coating of fiberglass or foil, as well as painted thermal insulation boards. Additional surface treatment of the insulating material makes it UV resistant.

Comparison of the characteristics of PU foam with other heat insulators

| Heat insulator | Average density (kg / cbm) | Thermal conductivity coefficient (W / m * K) | Porosity | Service life (years) | Working temperature (° С) |

| PPU rigid | 30-150 | 0,019-0,028 | Closed | 20 | -160..+150 |

| Cork plate | 220-400 | 0,5-0,6 | Closed | 3 | -30..+90 |

| Expanded polystyrene | 40-150 | 0,04-0,06 | Closed | 15 | -100..+80 |

| Min. cotton wool | 55-150 | 0,052-0,058 | Open | 5 | -40..+120 |

| Foam concrete | 250-400 | 0,145-0,160 | Open | 10 | -30..+120 |

Rigid PU foam has the lowest value of thermal conductivity of the medium of all known heat-insulating materials to date: from 0.019 W / m I. to 0.028 W / m I. Therefore, the heat-insulating ability of rigid PU foam is very high with a small thickness of the insulating layer. Due to these properties, rigid polyurethane foam is suitable for solving all professional thermal insulation tasks that, for technical and economic reasons, require optimal energy savings.

Only vacuum insulation (for example, a household thermos) is more effective than polyurethane foams, but it is incomparably more expensive and technologically difficult to implement.

To calculate the comparative heat-shielding efficiency of various building materials, it is enough to divide them. For example, for expanded polystyrene and polyurethane foam it is 0.04 / 0.028 = 1.43, i.e.10 cm of PU foam is equal to 14.3 cm of dry polystyrene.

For bricks and polyurethane foam, this is 0.80 / 0.028 = 28.57, i.e. 10cm PU foam is equivalent to 285.7cm brick.

For fibrous heat-insulating materials, such a calculation is not correct, since in the Russian construction realities they will certainly collect water, while the thermal conductivity increases several times.

Application of polyurethane foam boards

- Roof insulation.

- Wall insulation (applied before finishing cladding).

- Thermal insulation of internal and external enclosing structural elements.

- Insulation of basements and foundations.

- Insulation of the floor and interfloor floors.

- Construction of ventilation ducts.

PPU technical characteristics

| P / p No. | The name of indicators | Value for different grades of polyurethane foams |

| 1 | Apparent density kg / m3 | 18..300 |

| 2 | Thermal conductivity, W / m * K | Not more than 0.019..0.03 |

| 3 | Breaking stress, MPa, not less | Compression 0.15..1.0 Bending 0.35..1.9 |

| 4 | Water absorption,% volume | 1,2..2,1 |

| 5 | Closed pores | Not less than 85..95 |

| 6 | Flammability | GOST 12.1.044 (flame retardant) |

Advantages of PPU

- low coefficient of thermal conductivity (0.019 ... 0.028W / M * K);

- light weight 40-60kg / cbm;

- high adhesive strength;

- no need for fasteners;

- excellent anti-corrosion protection of metal structures;

- lack of cold bridges;

- the ability to isolate structures of any configuration and size;

- durability of coatings (not subject to decomposition and decay, not destroyed under the influence of seasonal temperature fluctuations, atmospheric precipitation, aggressive industrial atmosphere);

- high environmental friendliness of polyurethane foam (PPU) (according to hygienic standards, it is allowed to use it in refrigeration technology for food products);

- by pouring polyurethane foam into a mold, it is possible to obtain molded heat-insulating blocks ("shells" for pipelines, slabs, sandwich panels, etc.).

Polyurethane foam is sprayed on almost any material: wood, glass, metal, concrete, brick, paint, regardless of the surface configuration. As a result, there is no need for special insulation fasteners. In addition, the polyurethane foam coating is inert to acidic and alkaline environments, can work in the ground, used as a roofing material. The only thing that polyurethane foam requires is protection from direct sunlight.

PPU adhesion strength

The material has excellent adhesion properties, adhering perfectly to horizontal and vertical surfaces of any material and any shape. The applied polyurethane foam coating does not require renovation and repair during the entire service life of the building. Thermal insulation can be applied to floors, ceilings, and walls.

| Material | No less |

| Wood | 1.5 kg / sq. Cm. |

| Cast iron, galvanized iron | 2.0 kg / cm2 |

| Aluminum | 1.0 kg / sq. Cm. |

| Stainless steel | 1.5 kg / sq. Cm. |

| Concrete | 2.5 kg / sq. Cm. |

| Black steel | 3 kg / sq. Cm. |

Long-term behavior

The durability of PU foam is estimated at 25-30 years, but this is not the limit - In Germany, USA, Sweden, Japan, experts disassemble the structures of walls, roofs, foundations, cut samples of PU foam from pipes, poured in the 70s of the last century and correctly formulate - "Properties have not changed." There is no chemical reason for the destruction of a properly made PU foam. More than 90% of the polyurethane foam cells are closed, that is, they are plastic capsules filled with gas, with a thermal conductivity lower than that of air.

The results of industrial operation confirm the behavior of polyurethane foam in laboratory conditions.

The weather and climate resistance of rigid polyurethane foam is remarkable: rigid polyurethane foam has proven itself in practice in extreme climatic conditions in various parts of the world for decades. In pilot testing, rigid PU foam also shows excellent aging resistance in humid, changing climates without any significant deterioration in thermal insulation properties.

The results of field tests have again confirmed the high reputation of the PPU among the builders.Twenty years of experience in the successful industrial operation of rigid polyurethane foam made it possible to reveal not only the limits of possibilities, but also the "additional" advantages of this material, which include, first of all, the ability to maintain low thermal conductivity for a long time.

Fire resistance of PU foam

Refers to flammability classes G1-G4. Since fire retardants are included in the components for obtaining polyurethane foam, it burns only where the flame of an external fire source hits, and burns as long as this flame is present - If you remove the torch, the polyurethane foam goes out and does not smolder.

In addition, polyurethane foam has a unique property of preventing the spread of fire: it is charred and coked only where it is exposed to an open flame.

Biological stability of PU foam

Rigid PU foam is resistant to rodents, fungi and microbes, i.e. resistant to decay and microorganisms. In addition, it is resistant to root penetration.

New generation thermal insulation

PPU is an abbreviation for polyurethane foam. Heat-insulating material, in the form of a two-component composition, applied using special equipment to almost any surface. You can often hear the term "new generation isolation", but this is not entirely true. Polyurethane foam products have been known for a long time. But the application of polyurethane foam in a thin layer on the surface of walls and pipes is a relatively new business, and so far it cannot be said that it has become popular everywhere.

The fact is that the equipment for polyurethane foam allows you to apply it by thin spraying. By applying polyurethane foam, a certain chemical reaction is triggered - the sprayed composition swells up with a foam mass right before our eyes and fills all possible cavities and cracks with it. The composition hardens quickly, after 5-10 minutes. Thus, a layer of thermal insulation is formed, firmly adhered to the surface, while not having any seams or joints. This is the external picture of technology.

PU foam technologies are increasingly used for insulation of roofs and walls of commercial buildings.

We can say that thermal insulation in the form of polyurethane foam is produced directly at the facility, and as a result, a kind of monolithic porous "coat" is formed, which does not leave the heat with a chance of leakage.

Variants and scope

We figured out what the foamy polyurethane is and what it consists of. Now let's get acquainted with the options for its use, on which not only the scope of the insulation depends, but also some operational properties.

So, there are several options for using foamy polyurethane as insulation:

Options for using insulation

Below we will take a closer look at each application.

Application by spraying

This method of using PPU has recently been one of the most widespread. Its essence lies in applying liquid foam to the surface to be insulated, which quickly solidifies.

Moreover, the mixing of the initial components of the material occurs directly during the spraying process. As a result, a gas is released, which has a lower thermal conductivity than air.

Dignity:

- Good adhesion. Foam adheres perfectly to any surface, be it brick, concrete, wood or other material. Moreover, the insulation can be applied both to horizontal and vertical planes;

Polyurethane foam can be sprayed onto any surface

- It is applied in a continuous layer. This eliminates cold bridges. In addition, neither the shape nor the curvature of the surface affects the quality of insulation;

- Freezes quickly... Polyurethane foam begins to harden within a minute after application;

- Low thermal conductivity... The lowest thermal conductivity is possessed by foamy polyurethane, obtained precisely by the spraying method.

Not all home craftsmen know that polyurethane foam applied by spraying also includes polyurethane foam.

Polyurethane foam is the same sprayed polyurethane foam

Disadvantages:

- The need for special equipment. For this reason, it will not be possible to carry out the insulation of the home with your own hands. In addition, the process of warming itself is quite complex, requiring certain knowledge and skills;

Spraying foamy polyurethane requires expensive equipment

- Toxicity. In liquid form, polyurethane foam is highly toxic.

The scope of application of foamy polyurethane by spraying is practically unlimited - it can be used to insulate walls, floors, ceilings and roofs. Often, balconies and loggias in apartments are insulated in this way.

Cost. The price of the material, taking into account the work of specialists, starts from 400 rubles. for 1 m2.

Liquid fill

This technology differs from the previous one in that the components of the foam polyurethane are mixed and supplied without exposure to air. In this case, the outlet pressure is minimal.

By pouring foamy polyurethane, frame walls can be insulated

This technology is most often used to insulate the frame walls of a house. In this case, the walls are pre-sheathed, after which the polyurethane foam is fed through a hose into the hole in the wall.

Thus, the material is used as a filler for walls, which gives them strength and provides sound insulation, as well as insulation.

Dignity:

- The insulation lays down in a continuous layer. As in the previous case, such insulation excludes the formation of cold bridges;

- The ability to fill in forms. Liquid polyurethane foam can be poured not only into frame structures, but also forms. In particular, shells for pipes, as well as heat-insulating plates and other products are made in this way.

Polyurethane foam can be cast into molds

Disadvantages:

- Equipment requirement: As in the case of spraying, special equipment is required for mixing the components and feeding the foam;

- The complexity of insulation. When insulating frame structures, it is important to correctly calculate the volume of foam. In the case of its lack, cold bridges are formed. Excess can lead to deformation of the skin, since the polyurethane foam expands greatly;

- Limited use. In this way, only frame structures can be insulated. True, the ability to pour into molds and obtain solid insulation somewhat expands the scope.

Cost: The price of liquid polyurethane foam, taking into account the work, starts from 6500-7000 rubles. for 1m3.

Thermal panels combine finishing facade material and insulation

Application in the form of thermal panels

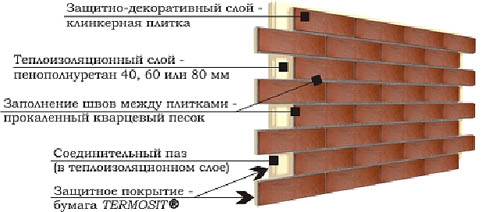

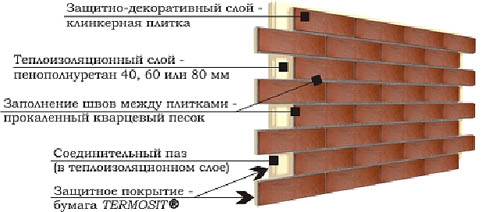

Thermal panels are a facade material consisting of two layers:

- Base... For these purposes, rigid polyurethane foam is used;

- Protective and decorative coating... Protects polyurethane foam from mechanical stress, as well as exposure to sunlight. In addition, the coating serves as a finishing finishing material for the facade.

The structure of the thermal panel consists of two or three layers

Most often, clinker tiles are used as a protective and decorative coating. However, other materials can also be used, for example, decorative stone, marble chips, etc.

Manufacturers of thermal panels use not only polyurethane foam as insulation, but also other thermal insulation materials, such as polystyrene foam. However, it is on the basis of polyurethane foam that the panels are the most durable and durable.

Dignity. Thermal panels combine a facing facade coating and insulation. This is the main advantage of this material.

In addition, they have other important positive qualities:

- Ease of installation. No special equipment is required to insulate the facade in this way. In addition, the instructions for installing the panels are extremely simple - they are attached to the walls using special fasteners-dowels, and are connected to each other in a tongue / groove lock;

Thermal panels are easy to install

- Efficiency. Due to the docking in the castle, cold bridges are excluded. Therefore, such wall insulation is also very effective;

- Aesthetics. The protective and decorative coating looks beautiful. It can imitate brickwork, decorative plaster, natural stone, etc.

Thermal panels can faithfully simulate brickwork and other finishes

Disadvantages. The main disadvantage of thermal panels is their high cost. The rest of the disadvantages are the same as in any polyurethane foam.

Cost:

| Brand | Cost of 1m2 |

| Regent | From 2700 |

| Classic CT-MIX | 2150 |

| Vostokstroy | 1250 |

Polyurethane foam sheet is an elastic insulation

Application as sheets

Polyurethane foam sheet is an elastic and at the same time quite hard material. As you might guess, it is made in the form of sheets. Moreover, the size and thickness of the latter can be very different.

Advantages:

- Wide range of applications. Sheet material can be used to insulate the floor, walls or even the roof. Thin ones are sometimes used as a substrate for various floor coverings.

- Possibility of self-styling. Working with sheets of foamy polyurethane is carried out in the same way as with other insulation materials, for example, mineral wool;

- Elasticity. Thanks to this quality, it is convenient to insulate curved surfaces with sheets.

The gaps between the foam polyurethane sheets must be foamed

Disadvantages:

- High price: Foam polyurethane foam sheets are more expensive than many other thermal insulation materials;

- Possibility of forming cold bridges... Therefore, during the installation process, it is necessary to ensure that there are no gaps between the insulation. If cracks do appear, they must be foamed.

Cost: The price depends on the thickness of the insulation. The cost of the thinnest sheets starts from 60 rubles. for 1 m2.

That's all the information I wanted to share with you regarding PU foam.

Features of the manufacture of polyurethane foam

Polyurethane foam is formed by combining the following components:

- polyester components;

- polyisocyanate.

Where the polyester component is a hydroxyl-containing compound, which, when combined with a polyisocyanate, forms a liquid polyurethane foam with a color from light yellow to brownish. They contain mixtures of polyester, catalyst, blowing agent, foam regulator and extinguishing additives.

When transporting by any type of transport, metal drums up to 200 liters are used.

Isocyanate is a liquid with a specific odor and dark brown color. This component, reacting with moisture and water, precipitates, which has a solid structure, which is forbidden to use during processing. Given this fact, the component must be transported in sealed drums. In addition, it is necessary to provide protection against contact with atmospheric moisture or water.

Advantages and disadvantages

Insulation made of polyurethane foam plates has retained all the best that a rigid polyurethane foam has and removed those few of the existing disadvantages inherent in sprayed insulation. Among merits it is necessary to highlight:

- excellent thermal insulation properties - plates have the lowest thermal conductivity;

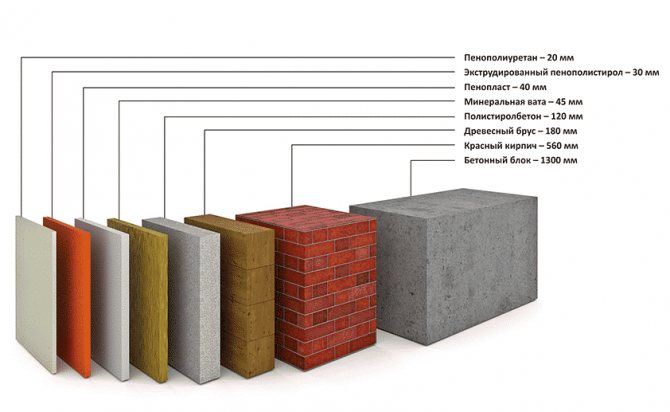

Comparison of the thermal insulation properties of different materials.

- durability - the service life of plates without surface protection is about 20 years, with surface cladding with foil, laminated paper or fiberglass is longer and is 50-60 years;

- affordable price for the bulk of consumers;

- simple installation - all work can be done by hand;

- environmental friendliness - the material is not an allergen, will not emit harmful substances during heating;

- high chemical and biological resistance - the insulation inertly transfers contact with alkalis, weak acids and gasoline, is not a base for the development of mold and mildew;

- low weight, which does not create mechanical loads on the foundation and rafter system;

- low water absorption - one of the leaders among all types of heat insulators;

- a wide range of temperatures, in which the operational characteristics are preserved - from -200oС to + 130oС, which allows you to fill the slabs with hot bitumen;

- versatility - you can insulate from inside and outside the house, on the roof, ceiling, walls, floor and foundation;

- low coefficient of thermal expansion, which allows the plates to maintain their linear dimensions (shape) during temperature drops;

- resistance to decay and corrosive processes;

- the possibility of mechanical processing and reuse;

- low fire hazard class - G1 (self-extinguishing).

There are several positive characteristics that are advertised by manufacturers, but in reality they are not.

1. Serves as a good noise isolator. The closed cell structure and low density cannot reflect or absorb sound waves. On the contrary, like polystyrene, PU foam plates begin to resonate, amplifying the sounds in the apartment. But thermal panels have the ability to absorb sound, and significant.

Firstly, metal and ceramics are dense materials that reflect sound vibrations, and secondly, metal connected to one piece with a heater loses its ability to resonate, amplifying sounds. For example, using metal tiles with an applied layer of insulation for roof insulation, the owners will no longer hear the drum roll of rain.

2. Not afraid of mice and rats. This conclusion is made by manufacturers on the basis that the polymer is not digested by rodents. But no one says that insulation is built into their food chain. The point is that rodents make moves in polyurethane foam with ease.

Minus, which is worth paying attention to, there is only one: intensive aging under ultraviolet rays (they began to fight the problem by revealing the plates with different materials).

The most terrible destroyer of polyurethane foam plates is ultraviolet.

The main indicators of polyurethane foam shells produced by LLC TK "AMARO"

For each batch of PPU Shells, a certificate of compliance with the Specifications is issued. The characteristics indicated below are determined according to the methods approved in GOST. The main GOSTs and TUs for our shells can be found in the section "GOSTs, OSTs, TUs for PPU shells".

Characteristics of PPU shells

| Indicator name | According to the norm | Actual in Amaro shells |

| Apparent density kg / m3 | 40-70 | 60 |

| Breaking stress in compression kPa, not less | 200 | 280 |

| Breaking stress in bending kPa, not less | 500 | 520 |

| The number of closed pores%, not less | 90 | 92 |

| Water absorption in 24 hours,% vol., No more | 8 | 3,5 |

| Thermal conductivity coefficient, W / m K | 0,019 -0,033 | 0,022 |

| Vicat softening temperature, load 10N, Сº, within | 108-186 | 130(150)* |

| * at short-term loads | ||