How to make a tie in a polypropylene pipe

Do you have plastic communication systems in your private house and do they need modernization or renovation? It is not difficult to install plastic on your own, thanks to the peculiarities of this material, right? But how do you bump into a plastic pipe when it's under pressure? And is it possible to do it yourself?

We will tell you the answers to your questions - the article discusses several ways of tapping into a pipe to organize a branch from an existing line. Starting from the simplest one - shut off the pipeline for a while and insert a tee in the right place, cutting out a section beforehand.

The tie-in options are provided with a detailed description of the process and are supplemented with visual photographic materials, which will allow you to understand the intricacies of the technology for installing cheap and durable plastic pipes.

By following the recommendations given in the videos, you can do most of the work on your own, without involving qualified specialists.

Features of inserting bends into pipes

Plastic pipelines are different. Some are used to supply water, others to drain it.

There are public highways, and there are personal intra-house and intra-apartment networks. And each option has its own nuances of work.

For tapping into a street pipe of a central water supply system or a village sewage system, permission is required from the owner of the networks; it is forbidden to unauthorizedly carry out such installation work

In order to crash into a common centralized system and not get yourself into problems with the law, you need to go through preliminary approvals.

It is best to delegate the signing of all the necessary papers and the insertion work itself to a specialized organization. This will make life much easier.

But no one bothers to crash into a plastic pipeline inside an apartment or a private house. This can be done almost anywhere. You just need to follow basic rules and not overload the system with an abundance of plumbing devices.

The water pressure in the water supply system must be sufficient for all devices and all users. And the sewer pipe is able to accept only the volume of waste for which it was originally designed.

There are several types of plastic pipes:

- "PP" - polypropylene;

- "PE" - polyethylene (most often it is HDPE);

- "PVC»- polyvinyl chloride;

- "PEX" - made of cross-linked polyethylene;

- "PEX-AL-PEX" - metal-plastic.

Some of them are recommended to be used for the distribution of hot water and heat supply systems, while others only for cold water supply or its removal. The tie-in technologies for all plastic pipes are similar in many ways.

The differences relate to the way they are connected to fittings and to each other in cases where an additional element is inserted into an existing pipeline.

The easiest way is to crash into a sewer pipe. Often it is enough to drill a hole of the required diameter and insert a pipe with a rubber cuff into it - there is no special pressure in the sewage system, such a connection is quite enough

All techniques for tapping a drain into a plastic water supply system can be divided into two groups:

- Cutting out a pipe section and inserting a tee in its place.

- Clamp (saddle) pipe lining with branch pipe.

The first method involves performing welding work with a special soldering iron for plastic or using pressure fittings.

In the second case, the presence of the superimposed part is sufficient.It is simply put on the pipe and mechanically tightened with bolts, or placed on a plastic surface and welded to it by means of built-in heating coils.

Sidebar Implementation Options

The most reliable technology for tapping into a plastic water pipe is a method with inserting a tee into it. In fact, this is a normal branch installation using standard fittings.

First, a section is cut out of the pipeline, and then a part with a bend is mounted in its place. However, it is not always possible to use this option.

If the pipe is located close to the wall, then it is problematic to cut out a part from it for inserting a tee, it will be even more difficult to perform plastic soldering using an iron in such a situation

The use of pads (clamps, saddles) simplifies the process of tapping into the water supply. And if he is under pressure, then this is the only possible option.

To install the tee, the water will have to be completely drained from the plastic pipeline, and this is not particularly necessary to do this with the help of special saddles.

Method # 1 - tee or manifold

The main problem with any method of making a tie-in into a water supply system is the water pressure. It is best when it is covered.

Then there will be no splashing during the work, which is simply dangerous, since you have to work with power tools. And the welding of plastic pipes according to the rules must be done dry.

If there is no experience in installing plastic pipelines with electric soldering or gluing, then it is better to refuse the option with inserting a tee - when installing the saddle pad yourself, there are much fewer risks to make a mistake

As an inserted element for organizing a branch, you can use:

- ordinary tee;

- collector for connecting several branch pipes.

- prepared in advance a piece of pipe with a soldered branch.

The end with a branch pipe can be threaded and soldered. The choice of the type of fitting depends on the type of plastic and the type of installation of the entire pipeline system.

If the water supply system was originally made in a collapsible version, then the insert into it should be done with a threaded connection. And if the entire pipeline was carried out by welding with an electric soldering iron, then it is better to insert into it in the same way.

The tee insertion technology is as follows:

- The water is shut off and completely drained from the system.

- The pipe cutter cuts a pipe section to size so that an additional fitting can be connected in its place.

- Installation of a tee using a soldering iron (for HDPE and polypropylene) or glue (for PVC).

- Installation of a shut-off valve on the outlet.

After installing the tap on the created branch, further work can already be performed with the water turned on. Welding plastic pipes when tapping in a branch can be end-to-end and into a socket. Both options are acceptable.

The method of connecting plastic pipelines is selected based on their material, and fittings and tees, according to their characteristics, must correspond to the installed pipes

If getting close to the water supply with a soldering iron is problematic due to its close location against the wall, then you can use collet clamps or press couplings.

To do this, first a section of the pipe with a welded bend is prepared, and only then it is inserted into the place of the cutout in the water supply system.

Method # 2 - electrowelded saddle

An overhead saddle on a pipe is understood as a part of the water supply system, which is designed to organize branches from the main line.

This element greatly simplifies the installation of branching units and does not imply a violation of the through integrity of the tubular product.To perform a branch in a plastic pipe, at the point of the tie-in, only a hole of the required size is drilled.

To install the saddle, you do not need a lot of space, it can be mounted even in narrow places and wells - with the help of such a fitting, you can cut into the water pipe at any part of it

A conventional saddle is fixed to the pipe with clamps and bolts. Its electrowelded counterpart has built-in heating coils in its design.

When voltage is applied to them from the mains, these elements melt the plastic, which, after cooling, forms a reliable connection between the fitting and the water supply.

Installation

Dismantling the old water supply

The installation of water pipes begins with the dismantling of the old pipeline. Traditionally, steel pipes are placed under the knife. The easiest and most convenient way to get rid of them is to cut with a impeller.

Very neatly installed polypropylene plumbing

This is much faster than disassembling all the threaded connections and then tearing out a bulky structure from the wall for a long time, fastened with a bracket welded to both pipes.

Under the root

Preparation of the work front

If a valve replacement is planned, it should be the first step.

- Disconnect and discard the water supply risers.

- We unscrew the old valves.

- We clean the eyeliner in the direction of the riser with a cable to ensure the normal permeability of the water supply system in all areas.

It is clearly visible here that the cold water pipe located at the bottom needs to be cleaned.

- We clean the thread with a metal brush.

- We wind up the thread with flax using paint or drying oil.

Advice: FUM tape and various synthetic threads are more convenient to use; however, it is enough to give the thread a slight reverse stroke - and it will begin to flow. The grandfather's method has no such problem.

- We turn on the valve and carefully tighten it with an adjustable, open-end or gas wrench. Tightening CAREFULLY! Brass is a fragile metal, and it is quite possible to tear off the thread on the liner with great effort.

- If the wiring is done on several rooms, make sure that the holes in the walls are of sufficient diameter. Expand them if necessary.

- If you plan to lay full or partial water pipes under the tiles (which is undesirable), make strobes.

Installing filters

This step is required. Ceramic faucets, automatic washing machines, and toilet cistern fittings live much longer if the water is free of sand and scale. Choose the simplest coarse filters.

Do not chase the filters to be disassembled manually - such designs use short-lived rubber seals, and after a few disassembly you will still have to rewind them with flax or other material.

Advice: mount the filters with the slag barrels downward. In this case, all the slag will accumulate in them, and not somewhere in an indefinite place in the water supply system.

Two in one: valve with filter in a single housing

Pipe preparation

It all depends on the type of pipes you have chosen. It is better to cut galvanized with a turbine or a hacksaw and cut (or weld) pipe threads. It is much more convenient to just cut off metal-plastic or polypropylene in place: here the slips in size are not so terrible due to the flexibility of the pipes.

Assembly

The connection of water pipes can be carried out in two ways: through a manifold, which is a wiring to individual devices using its own shut-off valves for each, or a simple tee.

This is what a collector might look like

Methods for connecting pipes to each other and with fittings are different for each material.

Steel tubes

If you have welding at your disposal, it can be used for joints between steel water pipes. She can also weld threads and bends bent on a pipe bender.

In other cases, the threads are cut on pre-prepared shafts and nozzles on a lathe or, in his absence, manually - with a die and a special holder. The assembly of threaded connections is the same as with valves, using flax and paint sealing.

Reinforced-plastic pipes

Here the connection method is fittings for metal-plastic pipes with union nuts. Having cut off the pipe, we remove the chamfer from its inner side with a knife. We put a union nut and a split ring on the pipe.

We insert the fitting of the fitting into the pipe (carefully so as not to displace the rubber sealing rings). Now, carefully, without jerking, tighten the nut. In this case, the split ring compresses the pipe on the fitting.

No harder than a child's constructor

Polypropylene pipes

In this case, we need an inexpensive soldering iron for all the work. Having chosen a suitable nozzle, we heat the inner surface of the fitting and the outer surface of the pipe end. And then we just insert one into the other and let it cool.

How to connect polypropylene water pipes to each other? Simply by taking the sleeve and making two welded joints on both sides.

Gasket

In the case of a steel pipe, it is willy-nilly combined with installation: the water supply is a rigid structure. Often steel pipes do not need to be attached additionally.

With a long length, when fasteners are still needed, the easiest way of fastening is several steel bars driven into the drilled holes of a slightly smaller diameter. The pipes are simply laid on them, after which the ends of the rods are bent upwards.

The laying of plumbing pipes made of flexible materials requires mandatory fixation along the entire length. For this, special plastic fasteners are sold in plumbing stores. You just need to choose the fasteners for the pipe diameter you need. The pipe after correct laying should not hang out and sag.

For any diameter

Laying plumbing pipes on the ceiling requires more frequent fastenings: gravity pulls a pipe full of water downward, trying to pull it out of the fasteners.

https://youtu.be/YmGF1CyqqZA

How to properly cut into a water supply plastic pipe

Do you have plastic communication systems in your private house and do they need modernization or renovation? It is not difficult to install plastic on your own, thanks to the peculiarities of this material, right? But how do you bump into a plastic pipe when it's under pressure? And is it possible to do it yourself?

We will tell you the answers to your questions - the article discusses several ways of tapping into a pipe to organize a branch from an existing line. Starting from the simplest one - shut off the pipeline for a while and insert a tee in the right place, cutting out a section beforehand.

The tie-in options are provided with a detailed description of the process and are supplemented with visual photographic materials, which will allow you to understand the intricacies of the technology for installing cheap and durable plastic pipes.

By following the recommendations given in the videos, you can do most of the work on your own, without involving qualified specialists.

Method # 3 - crimp clamp (pad)

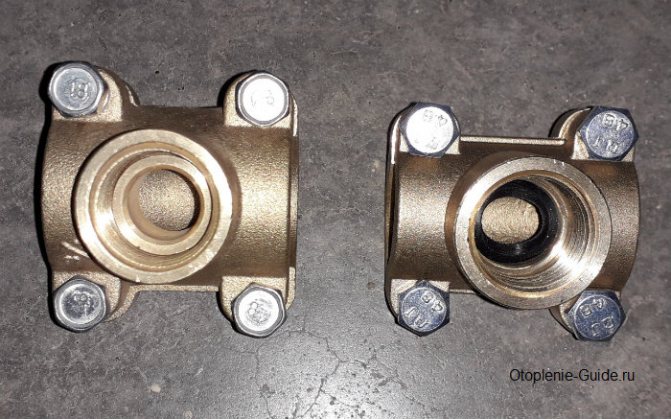

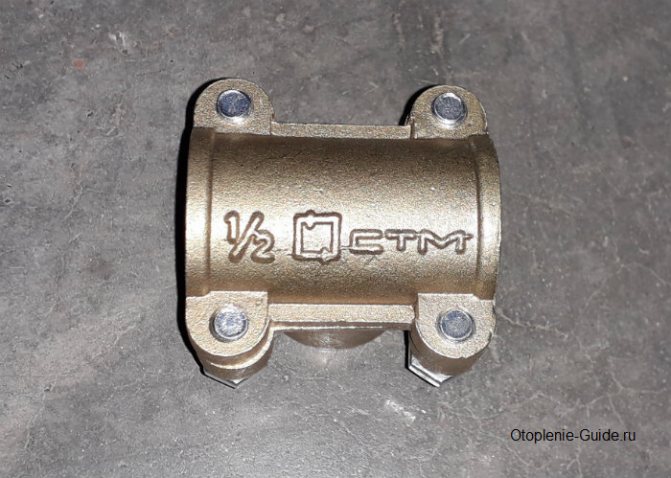

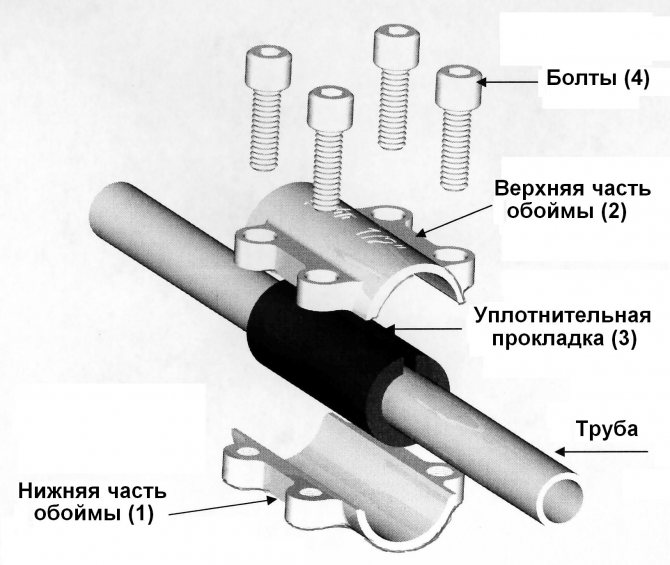

In addition to the electrowelded saddle, there is a simpler analogue of it - an overhead clamp. It consists of two separate bolted parts.

One for lining the top of the plastic pipe, and the second at the bottom for attracting the upper part. An additional sealing gasket is inserted between them to prevent leaks.

Tie-in scheme. The number of tightening bolts and the size of the clamp depends on the diameter of the pipeline into which the tie-in is made

Typically, the top and bottom overlays are exactly the same size as the pipe. But there are also universal clamps, in which the top is made small, and instead of the bottom there is a metal strip for the tie.

Outwardly, they resemble repair counterparts for connecting with a hose or closing fistulas.Only in the upper part do they have a branch pipe for connecting a branch.

Clamps for tapping into a plastic pipe are:

- with shut-off valve;

- with built-in cutter and safety valve;

- with a flanged or threaded metal end;

- with a plastic end for soldering or gluing.

To make a tie-in, the clamp is put on the pipe and fixed on it with nuts or bolts, depending on the design. Afterwards, drilling is performed through the existing branch pipe. And then the branch itself is connected from the main.

It is not recommended to drill the pipe without using a clamp or saddle. You can make a mistake with the drill diameter and drilling point. The best way to do this is through the nipple of the fitting already installed for the branch.

So the size of the drill will definitely be slightly smaller than the internal section of the cut-in branch and will be installed exactly where it is needed.

The nuances of working on a water supply system under pressure

For tapping into the pressure pipeline, electrowelded saddles and clamps with a built-in cutter are used. It is located in a special sealed nozzle body.

For drilling plastic, it is often enough to turn it with a hex wrench. But there are also models for a drill.

The presence of a sealed branch with a cutter inside ensures that there is no splash of water when drilling a pipe under pressure

Some of these designs have a built-in valve. Then, after completing the drilling, the cutter rises, the tap closes, and the drill bit is removed. Instead, a branch pipe is mounted.

However, there are also commercially available products with a branch pipe that is directed sideways from the drill (parallel or at an angle to the connected water supply).

The use of linings with an internal cutter allows you to cut into any water supply... It doesn't matter if they are under pressure or not. But such attachments are much more expensive than conventional clamps and saddles.

They greatly simplify the tapping process, but they will have to be spent on them. At the same time, in terms of the tightness of the resulting joint, they do not exceed and are not inferior to standard solutions.

Conclusions and useful video on the topic

There are many nuances in connecting a branch to a plastic pipeline. There are different types of plastics, and fittings in terms of design, and methods of insertion.

In order to avoid gross mistakes, we recommend that you watch the videos below on this topic.

Tapping into HDPE pipe under pressure using a saddle with a cutter:

Features of mounting an electrowelded saddle:

The nuances of inserting into a polyethylene water supply system:

It is not often necessary to crash into existing plastic plumbing. But sometimes you need to change pipes, install water meters, or simply connect additional plumbing. There are several different types of fittings and tapping technologies for this.

For any case, there is the best option so that the installation can be carried out independently. It is mandatory to delegate these works to professional plumbers only in a situation of connection to a common water supply system, where preliminary approvals are required.

How to bump into a plastic water pipe: methods and necessary permissions

There are several ways to embed an individual outlet into the existing centralized communications. It all depends on how far away the collector well is, if we are talking about a tie-in outside an apartment or house. Such work requires permission. When it becomes necessary to connect an additional outlet inside the apartment, no approvals are needed.

What are the features of connecting a pipe to a centralized system

Work on inserting into a plastic water pipe, into a steel or cast iron pipeline is entrusted to the specialists of the water utility or a qualified contractor (with the knowledge of the water supply organization).

Self-tapping, even into a public plastic water pipe, is prohibited by law. An additional connection to the centralized water supply bypassing metering devices is illegal.

Note! You should start planning an individual tie-in to a centralized system with an official permit. Independent connection is punishable by material and administrative punishment.

Apply for the appropriate permit should be in the department to which the required pipeline belongs. In the case of a water supply system, this is a city water utility or an organization that maintains water supply systems in a village or settlement. To obtain a permit for tapping into a pipe, you should have documents for the land plot and house with you.

A permit for tapping into a centralized pipe will contain:

- accurate data on the place of the tie-in;

- indication of the diameter of the pipeline and branch;

- additional information depending on the purpose of the work.

After obtaining permission, you should contact the SES. After that, a tie-in project is prepared and registered, and an estimate of the work is drawn up.

Tie-in scheme into a centralized water supply system

If there is a collector well in the area where your house or plot is located, then the tie-in is carried out (if allowed) in this well. If it is located far away, then access to the pipe is carried out through an additional well.

For this:

- in the place indicated by the project, they dig a square pit measuring 1.5 \ 1.5 meters;

- from the pit, in the direction of the house, they dig a trench for future allotment;

- upon completion of all work on the tie-in point, an additional well with a cover is erected to access the connection point.

Connection to a centralized pipe, which is under pressure, is carried out in two stages:

- Fitting a branch flange with shut-off valve.

- Reaming the pipe body.

You can cut into a plastic water pipe with or without welding. Connection to steel communications is usually carried out using a welded flange.

Note! The general rule of tapping in a branch is that the diameter of the cut-in communication is always less than the diameter of the central pipe.

Methods for inserting into a plastic water supply system inside an apartment

An additional outlet from the central water supply inside an apartment is easier to carry out than a tie-in into a common pipeline.

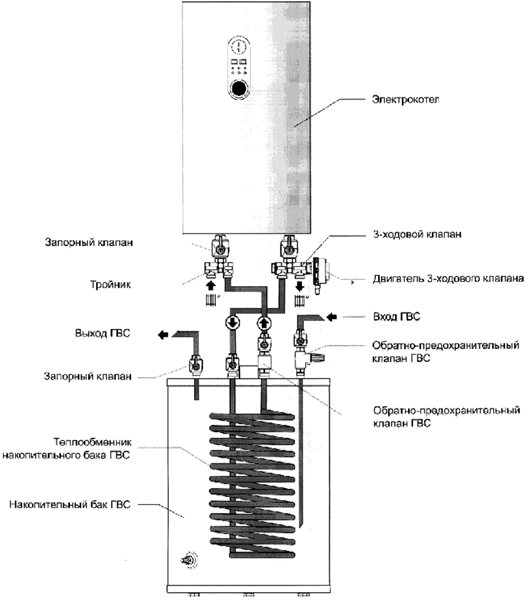

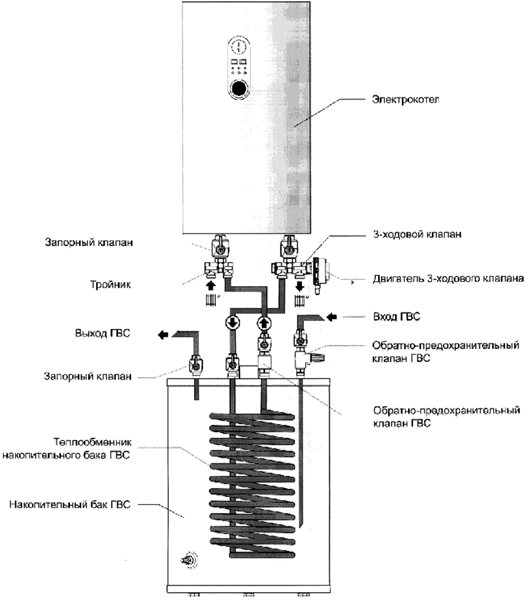

Insert of an electric boiler into the heating system

Diagram of inserting an electric boiler into the heating system

Before inserting an electric boiler into the heating system, you must read the installation instructions. Often, the scheme does not differ from the standard ones - the only exceptions are ion boilers, which are characterized by a small size.

It should be noted right away that illegal insertion of any boilers into the central heating system is prohibited. This cannot be done even if the level of water heating in the pipes is not appropriate. Otherwise, there is a high probability of a decrease in the efficiency of the system and failure of the boiler. To achieve the appropriate temperature mode of heating operation is possible only in the management company.

When inserting an electric boiler into an autonomous heating system, a piping should be made. It should consist of the following components:

- Pump. If it is already in the boiler, installation is not necessary;

- Control valve and balancing valve;

- Shut-off valves for the outlet and return pipes;

- Manometer and thermometer.

A new connection to the pipe of the existing heating should be carried out only after the main boiler has stopped. Otherwise, it may damage it.

If an electric boiler is installed as an additional source of water heating, you must first correctly calculate its power. The operation of the device should optimize the temperature regime without disturbing it.

Tapping into a plastic pipe without welding - several solutions

A private house or dacha is being rebuilt, improved, and equipped throughout the entire period of operation. Sometimes these manipulations are performed forcibly, due to wear and tear of any structure or system, and sometimes there is a desire to modernize them to increase comfort in the house.

But, whatever the reasons are at the heart of the process, sometimes such an operation as cutting into a pipe without welding becomes relevant.

For example, without this procedure, it is impossible to organize an additional sewer drain when installing a washing machine, or vice versa, creating an additional point of water intake for connecting a household appliance to the water supply system.

Outlining the range of tasks

If you need an insert into a water pipe, for example, then the most logical at first glance would be a very simple way:

- The pipe is cut.

- A tee is welded or inserted.

- The connection to the tee is in progress.

If you have to deal with a plumbing or heating pipeline that is still "Soviet-style", that is, metal, then such a head-to-head manipulation is a very effective way to solve the problem.

But in practice, such pipes are found less and less, they are ruthlessly and everywhere replaced by systems made of plastic and its derivatives.

Therefore, today the question of how to cut into a plastic pipe will be more relevant.

Naturally, this work is not as simple as it seems at first glance, although on the other hand a non-professional can cope with it, if he is armed with our advice, and also shows diligence and will. And first, you need to understand the amount of work that you will have to face.

Possible problems with sidebar:

- The pipe is sawn and in the right place a piece for the tee is cut very precisely in size. It should be borne in mind that the pipe can be very close to the wall surface, and it can still be walled up halfway into the wall.

- Possibly dad-mom docking is required. The end of each pipe is equipped with an extension - a bell, in which there is a rubber seal. It is in this socket that another pipe will have to be inserted.

- Also, most likely, you will have to replace one whole pipe with two smaller ones. And between them, you will need to install a piece of pipe with a pipe through which the connection will be made.

Tapping into the water supply using a pipe

In fact, the answer to the question of how to bump into a water pipe can be very simple. One way of doing this does not require cutting the pipeline element at all. To begin with, a piece of pipe with a branch pipe, of course, the same diameter as the water pipe, is purchased in any specialized store.

Inserting without cutting - a few easy steps

A branch pipe must be cut out of the acquired pipe segment, but in such a way that an element of the "half-pipe" type is obtained at its end. It is he who must ensure reliable overlap of the place of the future tie-in. Simply put, a second pipe wall should form. In a predetermined place, a hole is drilled, the diameter of which must correspond to the diameter of the nozzle.

Any non-drying sealant, for example, "Body 940", is evenly applied to the entire inner surface of the flange. It is worth looking for in car dealerships, in auto cosmetics departments. The area around the hole is lubricated with the same composition, but you do not need to reach about 1 cm to the hole itself.

Further, when installing such a curved flange on a pipe, I will have to use such a fastening element as a clamp for tapping into a pipe. Rather, you need two of them to pull the edges on both sides. The clamps must be tightened very carefully, but so that the sealant begins to squeeze out from under the flange. Residual grease is removed.

Attention! If a tie-in is made into a polyethylene pipe of a water supply (sewage), where a small pressure is recorded, then the use of clamps is an optional condition. It is possible to simply "fasten" the flange using a wide electrical tape.

Standard frame

The standard method is to install a standard tee fitting onto a plastic pipe. For this purpose, the supply to the pipeline is shut off and all the water is drained from it. Then a section of the pipe is cut to the required length, and a fitting is installed in its place. Installation on the PPR pipe is carried out by soldering the fitting. On the HDPE sewer pipe, it can be installed by the assembly method on seals or by means of butt welding. A standard crimp or press fitting is put on a metal-plastic pipe.

This method is the most reliable, but it is not always applicable. For example, it is difficult to install on a pipe located directly next to a wall. Also, it is not always possible to drain the water from the pipeline. Therefore, you often have to look for additional options. It is easy and quick to perform the tapping even in difficult conditions with a special part - the overhead saddle.

Instructions on how to make a tie in a plastic pipe

In everyday life, plastic pipes are even more common today than metal ones. The lightness of the material, its insensitivity to corrosion, ease of installation - all this makes plastic products the best option.

Insert into a metal pipe

Therefore, the question of how to make an insert into a plastic pipe is relevant for many home craftsmen.

Technology features

The mechanism of the process is quite simple. To cut into the pipeline, you need to drill a hole in the required area. If we are talking about any main option - a water supply system, a sewerage system, where there is no way to turn off the water, it is necessary to immediately solve the problem and shut off the water exactly at the working area.

Technology features

That is, you need to achieve 2 goals at once: to make a hole and shut off the water under pressure using some kind of locking mechanism. Moreover, the fittings should also provide for the possibility of installing the next branch.

Drilling a pipe

An insert into a plastic sewer pipe or, conversely, fastening a branch to a cast-iron main pipe, requires compliance with 2 main rules:

- the diameter of the pipe into which they are cut is larger than the pipe that is being mounted;

- the diameter of the drill must be exactly the same as the diameter of the cut-in section.

The design of such a device depends on the type of pipeline. In addition, the scale of the work itself must be taken into account.

Main pipeline

The main pipeline implies the supply of liquid under pressure, and it is very tangible, which means the use of special equipment and special locking mechanisms.

To get to the highway, you need to dig a trench, for which, as a rule, shovels are not enough, but the services of an excavator will be needed. It is possible to carry out any work on connecting to the backbone systems only upon receipt of a special permit confirming the qualifications of the master.

All this makes the possibility of self-tapping into the highway an extremely costly and unprofitable occupation.

Sewage pipe

In household sewer and water supply systems, you can actually make a cut-in of a plastic pipe yourself, both into a plastic and a steel pipeline.

Installation technology in a metal pipeline

Today, private houses and apartments are serviced by cast iron and steel pipes. To install a new section in them, special devices are used - clamps. The design of the latter can be different, and the rules for working with metal alloys are different.

Do-it-yourself insertion into a steel pipeline requires the following recommendations:

- the best way to work is to use a saddle clamp.They use different types depending on the system - sewer, plumbing, heating. In addition to the seat itself - the part adjacent to the pipe, the device includes a drill and a shut-off valve;

- before installation, the surface of the pipeline is cleaned from rust and dirt;

- the device is fixed with bolts, gaskets are used;

- a hole is drilled and a shut-off valve is immediately installed;

- turn the valve, shutting off the water supply. Install special equipment for drilling a hole for the pipe. The guide sleeve allows you to drill in the required direction;

- after that, the fitting or adapter is fixed and a new branch is connected. The photo shows the moment of installation.

Cast iron is more brittle than steel. The insertion of a plastic pipe into a cast iron pipe is carried out according to the same scheme, but subject to additional requirements: bimetallic crowns and special devices are used for drilling. It is important not to let the bit overheat and only run at low speeds. It is practically unrealistic to install a cast-iron pipeline on your own.

Flanged and electrowelded saddle for tapping into HDPE pipes

An insert into HDPE pipelines operating under a pressure of no more than 16 atmospheres, as well as having a diameter of 8-60 cm and an outlet flange of 4-15 cm, is performed using a flange saddle. This part allows for the simultaneous fastening of shut-off valves, flanged valves and valves of secondary channels with a welded flange. For the manufacture of a nurse on a HDPE pipe, ductile iron with an epoxy powder coating is used, which protects metal elements from the formation of corrosive processes and various aggressive environments.

The part is fastened by means of two clamps in a movable rubber casing, which simplify the installation of the part. The rubber sealing part of the saddle provides a strong and tight connection.

Installation of an electrowelded saddle is performed as follows:

- The upper part of the part is applied to the pipe surface and its contour is drawn.

- The polyethylene channel is cleaned from the epoxy layer to a depth of 0.15 mm.

- Degrease the surfaces to be joined.

- Install the saddle on the pipe.

- Welding is carried out by means of an electrofusion welding device.

- Using a cutter that allows you to work on the pipeline under pressure, a hole is cut in the pipe.

- Remove the outlet plug, screw in the cutter to the lower stop, turn the cutter back out and put the plug in place.

Tie-in without welding into pipelines made of low-pressure polyethylene is especially relevant when connecting household appliances to the water supply system or when creating an additional sewer drain.