The cross-section of the core is one of the main quantities that allow you to correctly perform electrical wiring, taking into account the total load on the network.

Knowing what wire cross-section is needed for 6 kW, you can easily choose the optimal cable product in terms of values.

Conductor material

A competent choice of material for electrical wiring is not only a matter of an affordable price, but also a guarantee of uninterrupted "delivery" of electricity, as well as safety, fire resistance and reliability during operation.

Currently, about three hundred brands and several thousand varieties of conductors are manufactured, differing in the type of material and other technical characteristics.

Aluminum

Aluminum is a soft and light, silvery-white metal widely used in the manufacture of cable products. The most significant advantages of aluminum wiring include:

- light weight of the material, which is especially important if it is necessary to install electrical transmission lines over several kilometers;

- the cost of a high-quality cable product available to a wide range of consumers;

- resistance to oxidation under the negative influence of open air and atmospheric phenomena;

- the presence of a protective layer that appears on aluminum during operation.

Aluminum is not devoid of some drawbacks that limit the scope of use of wires of this type. The disadvantages of the material include a high level of resistivity and a predisposition to heating with weakening of contact. The film formed on the surface of aluminum reduces the current conductivity, and the metal itself, as a result of frequent overheating, becomes excessively brittle.

As the practice of using aluminum electrical wiring shows, the standard service life is about a quarter of a century, after which it is imperative to replace such a network.

Copper

Wiring in residential or industrial buildings most often involves the installation of stranded copper wires.

VVG cable products with double PVC insulation have proven themselves very well.

Also, experts recommend paying attention to copper conductors in rubber KG insulation.

This option is characterized by good flexibility and ease of use.

Copper wires are much more expensive than aluminum cables, but such wiring is more reliable and much more durable. In addition, the advantages of copper wires include a high level of strength and softness, which minimizes the risk of breakage at bends and contact joints, resistance to harmful corrosive changes, and excellent current conductivity.

VBbShv copper armored cable products are characterized by double PVC insulation and fire resistance, due to which such wiring is in great demand in outdoor work.

What wire cross-section is needed for a 6 kW load?

In order to correctly determine the cross-section of the conductor, it is necessary to calculate the total power of all electrical devices in use.

The full performance of a significant part of household appliances will require the use of a wire that can withstand a load of 6 kW or more.

In this case, the best option would be to use a copper round wire with a cross section of at least 2.5 mm and double insulation.

Also, in conditions of such power indicators, it is allowed to perform work on the basis of a copper round wire in the form of twisted cores and double insulation.

The presence of aluminum wiring in the household, in order to ensure power indicators at the level of 6 kW, will require the installation of an aluminum flat wire with a cross section of 4.0 mm with single insulation.

A lot of outlets are required in the kitchen, as there can be a lot of equipment. Consider the options for placing outlets in the kitchen for ease of use.

You can see the wired switch connection diagram here.

You will find information on the purpose and importance of protective grounding in this article.

Selection of automatic switch by power

Power table of electrical appliances in the kitchen

Calculating the total power of household appliances will help you choose a protective switch. You will need to look at the value in the device passport. For example, in the kitchen, the outlet includes:

- coffee maker - 1000 W;

- electric oven - 2000 W;

- microwave oven - 2000 W;

- electric kettle - 1000 W;

- refrigerator - 500 W.

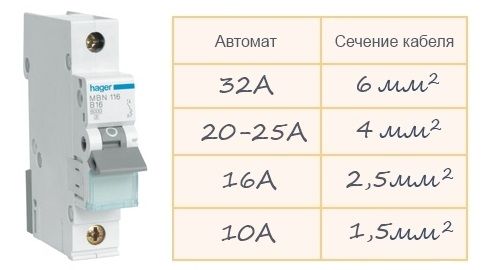

Summing up the indicators, we get 6500 W or 6.5 kilowatts. Next, you need to refer to the table of machines, depending on the connection power.

| Single-phase connection 220 V | Three-phase connection | Machine power | |

| Triangle circuit 380 V | Star circuit, 220 V | ||

| 3.5 kW | 18.2 kW | 10.6 kW | 16 A |

| 4.4 kW | 22.8 kW | 13.2 kW | 20 A |

| 5.5kw | 28.5 kW | 16.5 kW | 25 A |

| 7 kW | 36.5 kW | 21.1 kW | 32 A |

| 8.8 kW | 45.6 kW | 26.4 kW | 40 A |

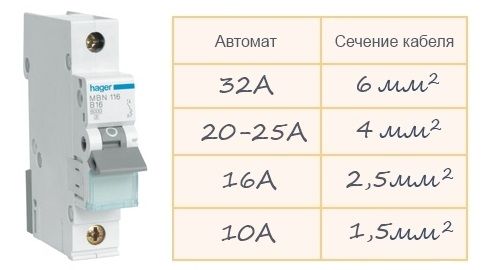

Based on the table for standard voltage wiring, you can select a 32 A device that is suitable for a total power of 7 kW.

If you plan to connect additional equipment, the increase factor is used. The average value of 1.5 is multiplied by the calculated power. The reduction factor is applied when it is impossible to operate several electrical appliances at the same time. It is equal to 1 or minus 1.

Criterias of choice

The main characteristics that you should pay attention to when choosing a conductor are represented by the material of the cores and their cross-section, design, thickness of the core insulation and sheath.

A quality cable product must be marked and certified.

The most important technical characteristics of the electric wire for a load of 6 kw:

- Durability. Single-insulated cable products have been in operation for about 15 years, and if double-insulated, they have been in operation for a quarter of a century.

- Oxidation stability. Aluminum belongs to metals that interact very actively with oxygen, which is accompanied by the formation of a thin film on the surface, which worsens the current conductivity. To isolate the contacts, special terminal blocks with a conductive paste are used.

- Strength indicators. Copper cable product is capable of reusable bend / unbend mode. Copper wires can withstand a little less than a hundred such modes, and aluminum ones - about ten.

- Resistivity level. This indicator for copper cable products is 0.018 Ohm * sq.mm / m, and aluminum wires have a resistance of 0.028 Ohm * sq.mm / m.

Equally important is the ease of self-assembly. In this regard, copper wires are more convenient, since they do not require the use of special elements in the form of an end piece, terminal block or bolted connection.

It should be remembered that copper cable products with a cross section of 2.5 mm2 are rated for 27 A, while the thickness of the aluminum wiring should not be less than 4.0 mm2.

Methods for selecting a difavtomat

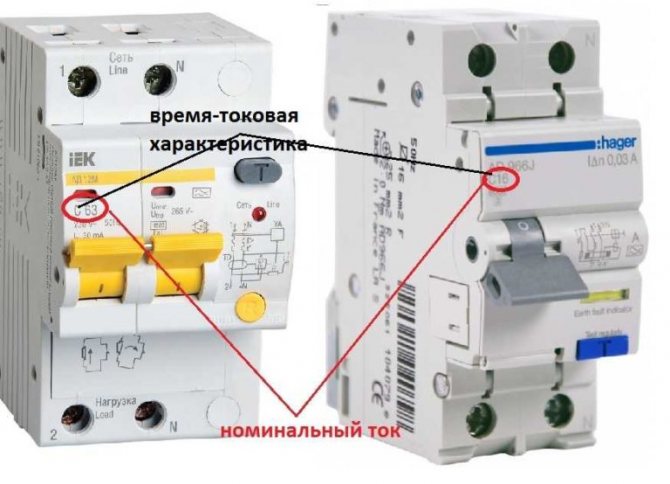

The nominal value of the difavtomat and its time-current characteristic

For example, consider a kitchen where a large amount of equipment is connected. First, you need to set the total power rating for a room with a refrigerator (500 W), a microwave oven (1000 W), a kettle (1500 W) and a cooker hood (100 W). The total power indicator is 3.1 kW. On its basis, various methods of choosing a machine for 3 phases are used.

Tabular method

Based on the table of devices, according to the connection power, a single-phase or three-phase device is selected. But the value in the calculations may not coincide with the tabular data. For a 3.1 kW network section, you will need a 16 A model - the closest in value is 3.5 kW.

Graphical method

The selection technology does not differ from the tabular one - you will need to find the schedule on the Internet. In the figure, as standard, there are switches horizontally with their current load, vertically - the power consumption in one section of the circuit.

To establish the power of the device, you will need to draw a line horizontally to the point with the rated current. The total network load of 3.1 kW corresponds to a 16 A switch.

Sectional area calculation

A competent choice of wire section allows you to ensure the reliability and safety of electrical wiring. The main indicator on which the standard calculation of the area of a conductor or its cross-section is based is the level of a long-term permissible current value.

The calculation of the wire cross-section in accordance with the load involves the summation of the power of all connected electrical appliances with the expression of power in the same units of measurement - W or kW.

According to the calculations obtained, the optimal cross-section indicators are determined according to tabular data for 6 kW:

- 27 A and 220 V - the diameter of the copper conductor is 2.26 mm with a cross section of 4.0 mm2;

- 15 A and 380 V - the diameter of the copper conductor is 1.38 mm with a cross section of 1.5 mm2;

- 26 A and 220 V - the diameter of the aluminum conductor is 2.76 mm with a cross section of 6.0 mm2;

- 16 A and 380 V - the diameter of the aluminum conductor is 1.78 mm with a cross section of 2.5 mm2.

When choosing a cross-section, it must be remembered that the inconsistency of the core area with current loads can provoke overheating, melting of the insulation, short circuit and a fire situation.

Vending machine calculation parameters

Each circuit breaker primarily protects the downstream wiring. The main calculations of these devices are carried out according to the rated load current. Power calculations are carried out when the entire length of the wire is designed for the load, in accordance with the rated current.

The final choice of the rated current for the machine depends on the wire cross-section. Only then can the load value be calculated. The maximum current allowed for a wire with a certain cross-section must be greater than the rated current indicated on the machine. Thus, when choosing a protective device, the smallest wire cross-section that is present in the electrical network is used.

When consumers have a question about which machine needs to be installed on 15 kW, the table also takes into account the three-phase electrical network. There is a methodology for such calculations. In these cases, the rated power of a three-phase machine is determined as the sum of the capacities of all electrical appliances planned to be connected through a circuit breaker.

For example, if the load of each of the three phases is 5 kW, then the operating current is determined by multiplying the sum of the powers of all phases by a factor of 1.52. Thus, it turns out 5x3x1.52 = 22.8 amperes. The rated current of the machine must exceed the operating current. In this regard, the most suitable will be a protective device with a rating of 25 A. The most common ratings of machines are 6, 10, 16, 20, 25, 32, 40, 50, 63, 80 and 100 amperes. At the same time, the correspondence of the cable cores to the declared loads is being specified.

This technique can be used only in cases where the load is the same for all three phases. If one of the phases consumes more power than all the others, then the rating of the circuit breaker is calculated according to the power of this particular phase. In this case, only the maximum power value is used, multiplied by a factor of 4.55. These calculations allow you to select an automaton not only from the table, but also from the most accurate data obtained.

The electrician said that for the water heater, you also need to buy a 25A machine. Wire 3 * 4. I bought a wire, but an automatic machine may be needed for 32A. The line to the heater will be individual (without additional consumers). If the power of the machine is exceeded, can it all burn out?

The average calculation is as follows: 1kW is 5A (ampere). 5.5kW x 5A = 27.5A (ampere). The closest denomination is 32 A. However, practice shows this: the machines are "sharpened" for shock loading, i.e. on short circuit (short circuit). With a relatively smooth increase in the load (turning on the heater at 25-29 amperes), the machine does not faint and lives quietly and does not interfere with the lives of others. Sometimes it reacts to an increase in the voltage in the network. This is for ABB machines. IEK automata, oddly enough, in this case live their own life. The cable must have a cross-section of 3x4kv.mm (PVA 3x4kv.mm, KG 3x4kv.mm are flexible cables. VVG-3x4kv.mm, NYM-3x4kv.mm are rigid cables).

The wire will not burn out, the useful life of the wire insulation will simply decrease. For water heaters, you will need to install an RCD better than a DIF automatic machine. I recommend looking at the passport for the heater, there is always the necessary information. Also, you must have a KUP (potential equalizer) installed. Best regards, Fedor

Ohm's law works here, the product of the voltage of the 220V network by the current consumption is equal to the power consumption. Those. Calculation of such a load with a power of 1 kW consumes a current equal to = 1000W / 220V = 4.6A. Your device is 5500W / 220V = 25A - it consumes a current of 25A. Therefore, if it is a water heater, then it is better to put a diff.automatic device for 32A (with a small margin). Above here they wrote that 25A does not fall with a smooth increase in the load, this is also true, but according to the standards, it is necessary to have some power reserve. The wire from the machine 3X4mm.kv is better flexible (stranded). And remember, according to the standard, when connecting the ground, the end of the "ground" wire should be shorter than the "zero" wire by at least 20 cm. This allows the internal resistance of the ground wire to be reduced as compared to zero.

CHOICE OF ELECTRIC BOILER FOR HOME

To choose the right electric boiler for heating a house, you need to take into account many factors, including the material and thickness of the walls, the glazing area, the air temperature outside in winter in your area, the height of the ceilings and many others.

Often, such calculations are entrusted to specialists who make a house heating project, taking into account all the necessary characteristics of the system, including the type and power of the electric boiler, often even a certain specific model or several to choose from is offered.

When independently choosing the required power of an electric boiler for heating, it is usually customary to use the following formula:

1 kW of power is required for heating 10 sq.m. at home.

The rule is relevant for single-circuit boilers used only for heating rooms, but if there are two circuits, one of which is used to heat water in the hot water supply system, the calculation must be changed, the same should be done with a ceiling height above the standard 2.5-2.7 m and in some other cases.

So, in our example, house area 120 sq.m. therefore, an electric boiler with a capacity of 12 kW was chosen, model ZOTA - 12 series "Econom".

After all the theoretical calculations, let's see if this boiler is suitable for the permitted (allocated) power for the house. We have this 15kW, with a three-phase input, respectively, in terms of power, a 12kW boiler suits us.

Of course, if the electric boiler operates at the maximum of its capabilities, only 3 kW of the allowed ones will remain for the rest of the consumers at home, which is not enough. But since the boiler will be a backup, and will only turn on when the main gas boiler is faulty, this decision was accepted as acceptable.

Automation design

All the internal equipment of automation for gas boilers, which is used when installing a heating system, can be divided into categories, there are only two of them:

- the first category is those devices that ensure the safe and correct operation of all boiler equipment;

- the second category is those devices that can significantly increase the comfort when using the boiler.

Safety automation for gas boilers consists of the following elements:

- the module that provides control over the flame. It consists of a thermocouple and a gas valve that acts as an electromagnetic valve and shuts off the fuel supply;

- also there is a device that protects the system from overheating and maintains the required temperature regime, the thermostat takes on this task. He independently, if necessary, turns on or off the boiler, at those moments when the temperature approaches the specified peak levels;

- the sensor that controls traction. This device works on the basis of vibrations, depending on how the position of the bimetallic plate changes. It, in turn, is connected to a gas valve, which cuts off the gas supply to the burner;

- there is also a safety valve that can be responsible for dumping excess coolant (for example, air or water) in the circuit. Some manufacturers immediately provide an element to help shed excess.

The devices that are included in the security system are divided into the following types:

- mechanical;

- and powered by a power source.

They work either under the influence of a drive and the controller that controls them, or they are electronically coordinated.

Automation provides the user with more comfortable functionality, which is additional:

- automatic ignition of the burner;

- modulation of flame intensity;

- self-diagnostic functions.

But this functionality is not limited to the internal design of the models.

Some design features of the models have such additions as sending data and processing them by an electronic system on equipment equipped with controllers and microprocessors. Then the following situation occurs: based on the data received, the controller itself begins to adjust the commands that activate the drives of the machine's system.

The mechanical automation of a gas boiler also requires detailed consideration.

- The gas valve is completely closed and the heating unit is inoperative.

- In order to start a mechanical gas boiler, a washer is squeezed out, which starts the fuel and opens the valve.

- The valve opened under the influence of the washer, and gas flowed to the igniter.

- Ignition is in progress.

- After that, gradual heating of the thermocouple begins.

- The electric shut-off magnet is energized to ensure its open position so that fuel access is not obstructed.

- The mechanical rotation of the washer regulates the required power of the gas heating device, and the fuel in the required volume and with the required pressure fits onto the burner itself. The fuel ignites, and the boiler plant begins to exist in operating mode.

- And then this process is controlled by a thermostat.

You will be interested >> The principle of operation of a floor-standing gas boiler

ELECTRIC WIRING FOR ELECTRIC BOILER

Now that the required boiler power for heating the house has been determined and a specific model has been selected, we make electrical wiring for it.

To do this, we will use the data from the article "Diagram of connecting an electric boiler to the mains", which shows in detail all the main schemes for connecting any electric boilers to electricity, and in addition, recommendations are given on the choice of the cable cross-section and the circuit breaker.

Our "ZOTA - 12" boiler is three-phase, designed to operate in a 380 V network, this information is reflected in the documentation for the boiler, in addition, the power consumption indirectly indicates this, 220 V boilers are rarely more than 8 kW.

In addition, you can look at the number of installed heating elements (Tubular electric heaters) and their connection diagram. For boilers for 380 V, at least three are usually installed.

Possible schemes for connecting the boiler to a three-phase network, at least two, one is used when the heating elements are designed for 220 V and are connected "star", And the other is used in cases when the heating elements of the electric boiler are designed for a voltage of 380 V and are connected"triangle».

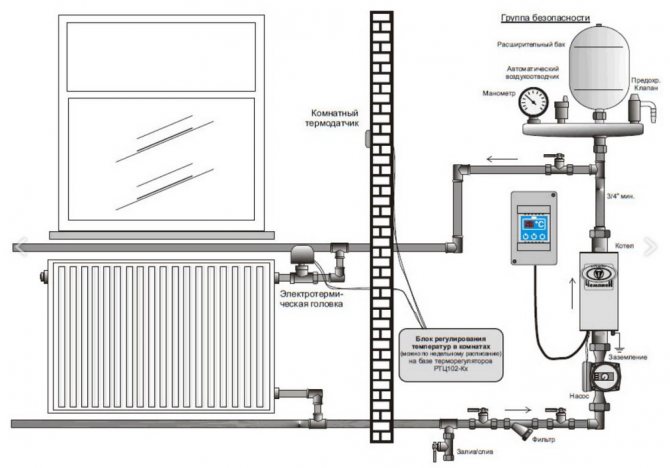

There are several ways to determine which connection diagram is suitable for your boiler, the simplest is to refer to the diagram in the documentation, for the ZOTA-12 boiler it is located on the back of the control panel and looks like this:

As you can see, this boiler has a Zvezda connection scheme, which means that the heating elements are designed for a voltage of 220 V. This is also confirmed by a direct examination of the contacts for connecting wires to the heating elements, they are also prepared for star connection. Their contacts for connecting the neutral conductor are connected with a jumper, phases will be connected to the free contacts in turn, each with its own.

Hence it follows that the scheme for connecting a three-phase electric boiler to electricity with heating elements for 220 V, a "star" connection is suitable for us.

It remains to choose the required cable cross-section for the electric boiler in terms of power and the rating of the circuit breaker... To do this, look at the table from the article:

Whence it follows that with a route length of up to 50 meters, we need to lay a 12 kW power up to a three-phase electric boiler, a VVGngLS five-core cable with a conductor cross-section of 4 sq. Mm. (VVGngLS 5 × 4kv.mm.) And supply a 25A differential circuit breaker, or a circuit breaker (AB) for 25 amperes - C25 and a residual current device (RCD) for 32A.

Now, having chosen an electric boiler and having decided on the connection diagram and wiring parameters, you can install it, after which we will continue to connect to electricity.

The connection of the ZOTA electric boiler to the mains is described in the next part of the article - HERE!

Diagram of connecting the electric boiler to the mains

An electric boiler installed in a heating system is often the most energy-consuming device in the whole house, moreover, its power consumption is often higher than that of all other electrical equipment in the premises combined.

And this is not surprising, because even the unspoken rule for choosing a boiler for a house says that 1 kW (kilowatt) of power is required to heat 10 square meters of a house. Following it, for heating a relatively small (by modern standards) house of 100sq.m. an electric boiler with a capacity of 10 kW is required.

Of course, this is a general rule, in real conditions, when choosing a boiler power, many factors are taken into account, but in general, the rule reflects the approximate average requirements for the boiler correctly.

Therefore, for such a "gluttonous" consumer of electricity as an electric boiler, on the stable operation of which a lot depends in winter, it is important to make the correct wiring, select reliable protective automation and make the connection correctly. In order to better understand the principle of connecting the boiler, you need to know what it usually consists of and how it works.

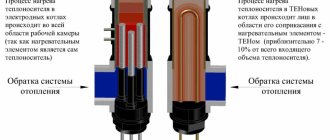

We will talk about the most common, heating elements boilers, the heart of which are Tubular Electric Heaters (heating elements)

In order to better understand the principle of connecting the boiler, you need to know what it usually consists of and how it works. We will talk about the most common, heating elements boilers, the heart of which are Tubular Electric Heaters (heating elements).

The electric current passing through the heating element heats it up, this process is controlled by an electronic unit that monitors important indicators of the boiler's operation using various sensors. Also, the electric boiler may include a circulation pump, a control panel, etc.

Depending on the power consumption, in everyday life, electric boilers are usually used designed for a supply voltage of 220 V - single-phase or 380 V - three-phase.

The difference between them is simple, 220V boilers are rarely more powerful than 8 kW. most often in heating systems, devices are used no more than 2-5 kW, this is due to the limitations on the allocated power in single-phase supply lines of houses.

Accordingly, 380V electric boilers are more powerful and can effectively heat large houses. Connection diagrams, the rules for choosing a cable and protective automatics for boilers for 220V and 380V differ, so we will consider them separately, starting with single-phase ones.

Power of electric heating boilers

A relative advantage of an electric heating boiler is a wide power range of various boilers and a stepwise power regulator for each boiler separately.

There are two power ranges for electric boilers.

- Range from 4 to 18 kilowatts;

- From 22 to 60 kilowatts.

The indicated boiler ranges assumes:

- For boilers 4-8 kW, two switching stages;

- Boilers 8-18 kW three switching stages;

- For boilers 22-60 kW, there are four or three switching stages.

Stepwise switching of power allows you to quickly integrate power with the temperature "overboard", this saves electricity consumption and reduces the cost of heating. Also, we forget that an electric boiler does not require operating costs (purchase and delivery of fuel, preparation of a special room) and practically does not require maintenance costs. The form of use is very simple: connect it correctly and use it.

The principle of operation of an electric heating boiler

The general principle of an electric heating boiler is not complicated. In fact, this is a large electric kettle, where powerful heating elements heat the coolant in the heating system. Of course, electric boiler heating devices are much more complicated. It has both an automation system and a remote control system and a temperature control system and a circulation pump.

Despite the design, type and brand of the electric boiler, they have one unifying type of work, the electric boiler must be correctly connected to the power supply.

Correct connection of an electric heating boiler

By design, an electric heating boiler is a metal cabinet. Boiler mounting type is hinged. There is a special hole for entering the electric power cable into the boiler, and all the electrical equipment of the boiler is located in the electric cabinet of the boiler.

Choosing an electric cable for a heating boiler

There are no special calculations and "pitfalls" in connecting an electric heating boiler to the power supply. It must be connected like any other household appliance in terms of power consumption and according to the standards for laying electrical wiring in the house.

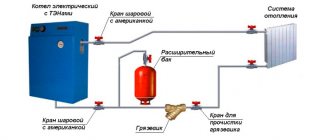

Rules for connecting an electric heating boiler

To connect an electric heating boiler, a separate wiring line (a separate group) is planned with its own automatic protection. A circuit breaker is used to protect the electrical cable of the boiler. The rating and type of the circuit breaker is selected according to the boiler power, or rather, according to the power of the heating elements included in the boiler design.

Heating boiler wiring

The power supply of the heating boiler depends on its design and the connection diagram of the heating elements. For the consumer, all the necessary data are indicated in the passport for the boiler.

Power circuit of an electric heating boiler with three heating elements

The heating boiler can be connected with a five-core or four-core cable. We look at the cross-sections of the cable cores in the passport for the boiler and in the table below.

As you can see in table 1, for the power supply of an average boiler, cables with a cross-section of conductors from 2.5 mm (4 kW) to 6 mm (18 kW) are needed.

Table 1

In table 2 we see cable cross-sections for more powerful heating boilers. As you can see, for powerful heating boilers with a thermal power of 60 kW, you need an electric cable with 25 mm cores and a safety circuit breaker in front of the boiler of 100 Amperes.

table 2

Let's orient ourselves and see a simple thermal calculation for the house. I will not show the calculation with heat losses, I will not even take into account the height of the ceiling. The simple calculation is very simple.

To heat one square meter of the house, you need 0.1 kW of the boiler's thermal power. That is, for a house with an area of 100 sq. meters you need a boiler of 10 kW of thermal power; for a house of 300 sq. meters you need a boiler of 30 kW. And this means that even for a house with an area larger than the average, an electric cable with a cross-section of no more than 10 mm will be needed.

Note: Speaking about the cross-sections of the cable cores we mean only copper cores, by the core cross-section we mean the cross-sectional area of the cable core cross-section specified in the cable passport.

Details

Boilers for heating - what they can be

There are many different types of boilers on the market. And you should deal with the fact that one type will be very different from the second consumer. So it will be easier to understand what exactly is worth choosing a floor-standing gas boiler for heating a house, or a hinged one, and with what options, so as not to be mistaken. Otherwise, you will need to either endure the inconvenience, or spend extra.

- Single-circuit and double-circuit boilers

One of the main classification methods will be the division into double-circuit and single-circuit boilers. By the way, the first ones heat water not just the heating system, but also for household needs. It turns out that there is no need to install an additional boiler. In a word, double-circuit gas-type boilers for heating a house are equipped in such a way that cold water from the central water supply system gets into them. Moreover, there is also a special valve that regulates where the hot water flows.

If you do not wash anything, do not take a bath, then the boiler will work to provide the heating system. But as soon as the tap is opened, the current valve will shut off the device, and water begins to flow to people. It is worth considering another important point when thinking about which gas boiler is better to choose - in order to have the happiness of taking a bath, and not just a contrast shower, you need a device with a power of at least 28 kW. The exact data will depend on the size of the space to be heated and the number of users. Roughly speaking, the more people wash, the higher the load will be. This means that the more powerful the device should be.

Can single-circuit boilers be used to heat water for domestic needs? Yes, most modern models provide this opportunity. But then you need to buy a boiler. It should be connected to the device, and the whole process, starting with the selection of the required model, is important to a specialist. In this case, most people only install a boiler that will operate on electricity. Which is the best option? Most often, they prefer to buy double-circuit boilers - they are much more convenient. But here it is worth considering that such models are much more expensive. The choice depends on the consumer.

- Wall and floor boilers

The devices may also differ in the way they are placed inside the space - there are wall and floor heating for a private house. The latter will take up much less space, and they are also more compact. In addition, you should install them almost anywhere, subject to certain requirements. Even for wall-mounted boilers, it is not necessary to organize a separate chimney - usually everything will be decided thanks to the branch pipe through which the combustion products will leave.

What is the difference between gas floor boilers for heating a house? they are usually noticeably heavier and even more powerful. For such models, much more space is needed - for the outline, and also for the chimney. And this is not to mention the kit, which consists of a boiler and a single-circuit boiler. Moreover, such specimens are quite noisy, and therefore they are usually installed in a separate room (that is, a boiler room).

The choice of the ideal solution will depend on what exactly you need in your particular case. That is, for a small dacha or apartment, the best option for a boiler would be a wall-mounted one, and for a country house, a floor-standing one.When purchasing, an additional factor should be taken into account, which is sometimes critical - dependence on electrical energy. In this case, floor-standing boilers operate stably. Even if there is no electrical energy in the house, the heat will still remain. True, now there are still models with automation that remove this advantage. And yet, options can be found.

Please note that all floor-standing models will depend on voltage - power surges can disable equipment. Naturally, no one can interfere with the stabilizer. But this will only increase costs, and there is still the issue of power outages.

In general, both wall and floor products have their own advantages and disadvantages. For this reason, it is necessary to figure out how to choose a gas boiler for a private house, depending on the characteristics of the room, the quality of the electrical network and financial capabilities.

- Closed / open chamber boilers

Devices can be with a closed or open combustion chamber. They will take air from the environment, and for this reason the issue of ventilation in this case will be critical. There is a risk that you will end up running out of air. Such models are obsolete because they are widely abandoned due to increased safety requirements. At the same time, boilers with an open chamber are distinguished by their simplicity of design. For this reason, they will fail less often (if we compare models in the lower price range), and cost less, and installation is much easier. Also, finding specialists who will deal with them will not be difficult.

Variants with a closed combustion chamber are considered modern. They are much safer, but will require the installation of a smoke outlet. This is just the case when you can spend money on the purchase of expensive furniture and installation once, and then not worry about the lack of oxygen in the room. And if someone suffers from the release of carbon dioxide, as can be the case with a problem with boilers of the first type.

Models with a closed camera have certain disadvantages. For example, you will need to install a ventilation system that needs a make-up from electrical energy. This makes such a structure dependent, and also increases the cost of providing a house. The easiest way to stop is on a boiler with a closed combustion chamber, and the pipe will be brought out. But for the installation of this model, there are far from always technical possibilities. If you think about which boiler to choose for the house, then you will need information about the object, is it possible to organize a separate room or bring the pipe out into the street.

How to choose a heating boiler for a private house

When choosing a gas-type boiler, one should take into account not only what they can be. There are many more different and important parameters, and we suggest you figure out what you should pay attention to.

- How to choose a gas boiler by power

It should be noted that it is extremely important to calculate the required power, namely, no more and no less. With the first it is still clear, because the building will not warm up to the required extent. But why is it undesirable for the boiler to become more powerful? In this case, the heating system will start to work unevenly, and this will lead to severe wear.

Frequent repairs and premature replacement of equipment can result. In addition, the gas consumption will increase. So how do you do the calculation?

To do this, ideally, you should turn to specialists, because the fact is that you need to calculate and take into account many factors:

- Number of floors.

- Ceiling height.

- The year the house was built.

- The presence / absence of thermal insulation, as well as its type.

- Selected method of heating water.

- Wall material.

- Climatic zone.

And that is not all! It will also matter whether the boiler is selected for a townhouse or an ordinary house (the former, as a rule, are warmer, although there are many nuances here). The calculation will still be influenced by the presence of other sources of heating in the building, for example, a warm floor. Moreover, experienced specialists will always clarify what the average room temperature should be, because the difference between +14 and +22 degrees is large. To make an approximate calculation, you should multiply the area of the house by the indicator of the climatic zone, and then divide the value by 10. This option is perfect for typical buildings with a ceiling height of up to three meters.

For example, the building will be located in the northern region of Russia, and there the climatic coefficient will be equal to 2 kW. Therefore, the boiler can have a capacity of 20 kW. But for a double-circuit boiler, this figure should be multiplied by 0.25. The result will be 25 kW, and remember that this is approximately.

Laying the electrical cable for the heating boiler

The laying of the electrical cable is done according to the wiring regulations in accordance with the design of the house. For a wooden house in pipes or open, for a stone house in boxes or hidden.

The electric boiler is not connected through the socket, the power cable is led into the boiler through the factory connection holes and connected to the circuit breaker or terminals installed on the boiler body in the electrical cabinet.

Important! Any twisting, soldering, welding and other connections not provided for by the boiler design are prohibited.

Connecting the heating boiler to the power supply

IN five-wire electrical network the phase power conductors of the cable are connected to the input terminals of the main circuit breaker of the boiler. The zero working conductor is connected to the connector marked with the letter "N". The protective conductor of the electrical supply cable is connected to the screw connector, which is indicated by the earth symbol.

Connecting an electric heating boiler in a five-wire system

If a the house has a four-wire network, then the phase conductors are connected in the same way, and the PEN conductor is connected to the screw connector with the earth symbol. In this case, the grounding clamp is connected to the neutral connector N with a PV-1 wire with a minimum cross-section of 2.5 mm2.

Connecting an electric heating boiler in a four-wire system

Note: Most often, the wiring diagram for an electric boiler assembled at the factory is adapted for a five-wire electrical network.

Output

The connection of an electric heating boiler is done in compliance with the rules of the PUE. If you read the instructions for any boiler designed for heating a house with electricity, you will see recommendations such as "only professionals with the appropriate skills should make the connection ...". This is true. However, the connection itself is not as difficult as, say, a gas boiler. If you follow the PUE (electrical installation rules) and safety precautions when working with electricity, then you can connect the boiler yourself.

© Ehto.ru

Related Articles

Varieties of automation for heating boilers

Automation works properly, accurately and reliably, increases the efficiency of heating equipment, contributes to the reasonable consumption of energy resources and makes the operation of the heating system simple, comfortable and absolutely safe.

The automatic system protects heating installations from overloads and activates an emergency shutdown of the gas supply in the event of sudden force majeure circumstances. Additionally, the technique regulates the level of combustion intensity and the current fuel consumption, allowing the owners to save money on heating the premises.

According to the basic principle of operation and design features, automation for equipment operating on gas is subdivided into:

- energy-dependent devices;

- energy independent appliances.

Systems of the first type are complex electronic units and for correct operation, which require an uninterrupted supply of electricity. The second types of devices are simplified mechanical structures that do not require power supply.

Type # 1 - volatile products

Volatile module Is a small electronic device that responds to the supply of a fuel resource. It turns on and off when the main gas valve is activated or closed. It features a complex design and a large number of elements and microcircuits.

Allows owners to solve the following tasks:

- activation or cessation of gas supply;

- starting the heating system in automatic mode;

- adjustment of the power level of the base burner (thanks to the presence of a thermostat);

- shutdown of the operating boiler both in emergency situations and within the framework of the mode specified by the user;

- output of current indicators to the display (general level of air temperature in the room, mark to which the working heat carrier is heated, etc.).

More "sophisticated" modules have additional functionality and offer users unlimited and most convenient conditions for monitoring the operation and control of the unit. Electronic panels provide full protection of the heating equipment against malfunction of the three-way valve and prevent the boiler from freezing.