In modern construction, there are many types of foundations. Each of them has its own characteristics and basic functions. But the pile-screw type is considered the most universal foundation, suitable for almost any climatic conditions. This foundation is a metal, pile-and-beam structure. It protects the structure from groundwater, soil deformation and transfers the load to dense soil layers.

Why insulate a pile foundation

In areas with problem soil, where there are areas with floating layers of soil, the optimal solution for building a house would be a pile-screw foundation. It will provide reliability in places with a high level of groundwater, in contrast to strip monolithic or prefabricated foundations.

The pile-and-beam structure and dynamic loads are not terrible. It is very durable and resistant to the process of soil heaving. Also, he is not afraid of the destructive effect of groundwater, since the screw piles are made of anti-corrosion steel.

Another advantage of this type of foundation is the relatively low cost, as well as the speed and ease of construction. The installation of one pile foundation will take only one working day for a team of experienced specialists.

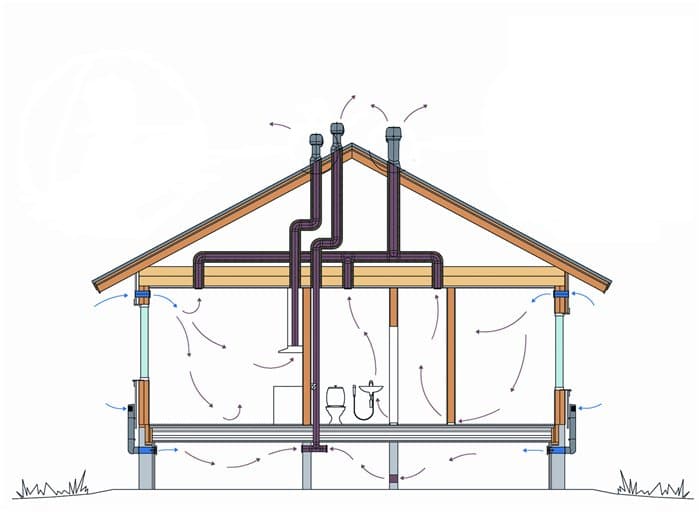

But, despite a number of positive qualities, the pile-screw foundation has a number of negative features. A house built on piles does not have a basement and also has poor thermal insulation parameters.

There is a space between the floor and the ground that can be easily blown through. It is because of what the precious warmth leaves the house very quickly. This is especially noticeable with the onset of cold weather. Radiators don't do their job as warm air always goes up and the floors stay cold.

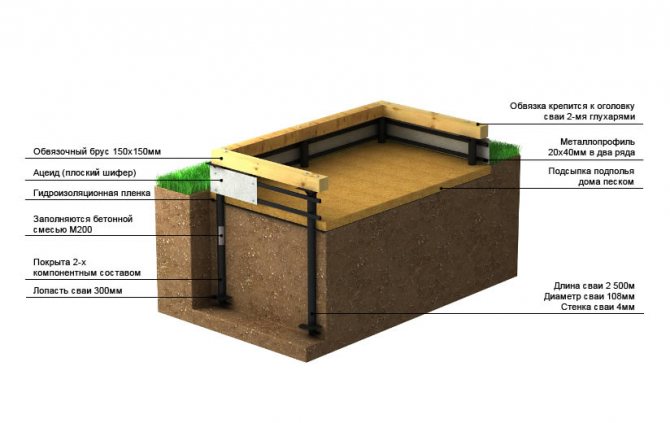

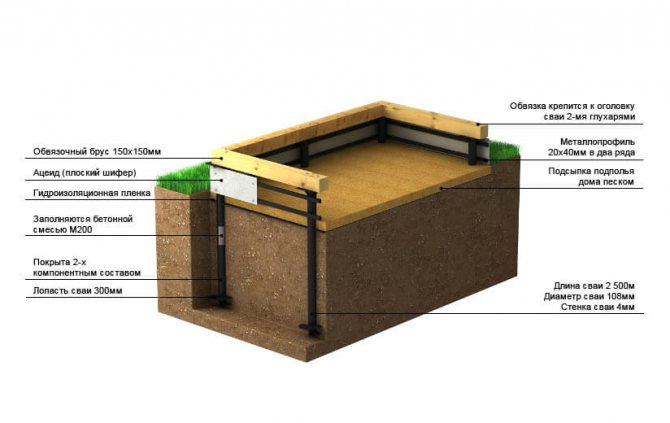

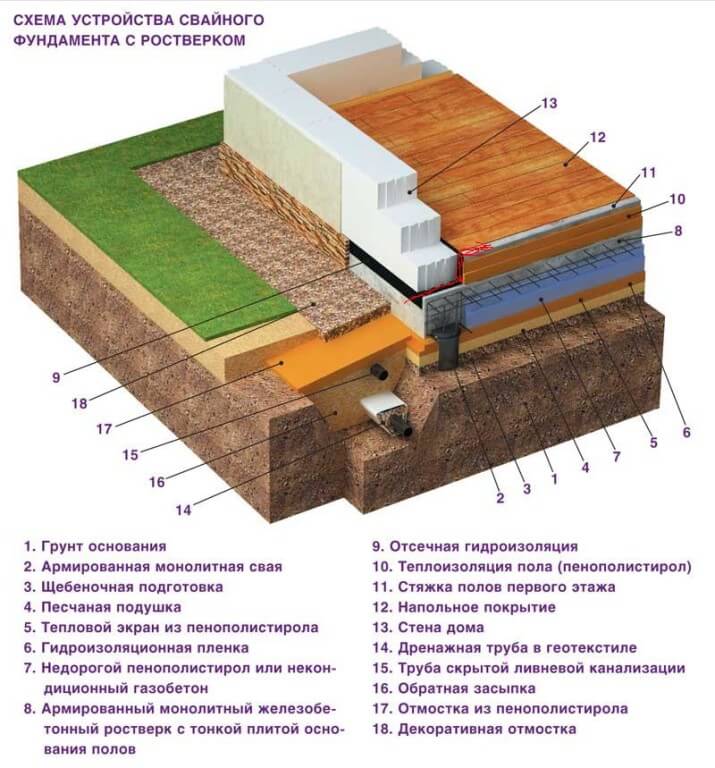

To solve this problem, you need to think about it even at the stage of designing a house - thermal insulation. Insulation of the pile-screw foundation occurs at the stage of working with the grillage in order to completely isolate it from external air flows. Finished houses can also be insulated, but this will not be as effective as thermal insulation during the construction phase.

Also, for high-quality and effective insulation of the pile-screw foundation, it is necessary to install a false base. It must exclude wind and precipitation from entering the free space between the soil and the house.

Our services

Our company is based exclusively on services: pile driving, leader drilling, sheet piling, as well as static and dynamic testing of piles. We have our own fleet of drilling and piling equipment at our disposal and we are ready to supply piles to the object with their further immersion at the construction site. Pile driving prices are presented on the page: pile driving prices. To order work on driving reinforced concrete piles, leave a request:

Dimensions of reinforced concrete piles for the foundation

SK "Bogatyr" is engaged in the supply of foundation piles of all demanded standard sizes. To order reinforced concrete products, contact the managers of our ...

More details

Foundation piles

Various types of piles are used for the construction of pile foundations. The use of one type or another depends on the planned load on the base, ...

More details

Pile-grillage foundation pros and cons

The design of the pile-grillage foundation is represented by pile supports, united at the top by slabs or beams, connecting the base and giving the necessary ...

More details

Useful materials

Country houses on screw piles

Screw flocks are a pretty good option for building a foundation for a cozy country house.

DIY installation of screw piles

Description of the process of driving screw piles: video, photo, detailed instructions. Pros and cons of doing the work yourself.

Materials for insulation of the foundation

When insulating the pile-screw foundation, it is necessary to pay attention to the false base and the grillage. These elements come into contact with the surface of the house and, when frozen, can transfer a low temperature to it. The screw piles themselves, immersed in the ground, do not need to be insulated.

When insulating a false base, it is necessary to choose a material that is not afraid of water and retains its thermal insulation properties even in a wet state. After all, a large amount of moisture emanates from the ground, which means that the insulation will be in a very humid environment. It must also be resistant to various salts and minerals in the soil. It is better to use high-density sheet materials or a liquid heat-insulating mixture when insulating a pile-screw foundation.

The most popular materials for insulating a pile-screw foundation are:

- Styrofoam;

- liquid penoizol;

- foamed glass blocks;

- extruded polystyrene foam or foam.

Penoplex and polystyrene have the same thermal conductivity and are also vapor resistant. Penoizol also has a similar thermal conductivity, but allows moisture to pass through. It is better not to use mineral wool and basalt insulation, as they are not very convenient for installation.

What is the foundation

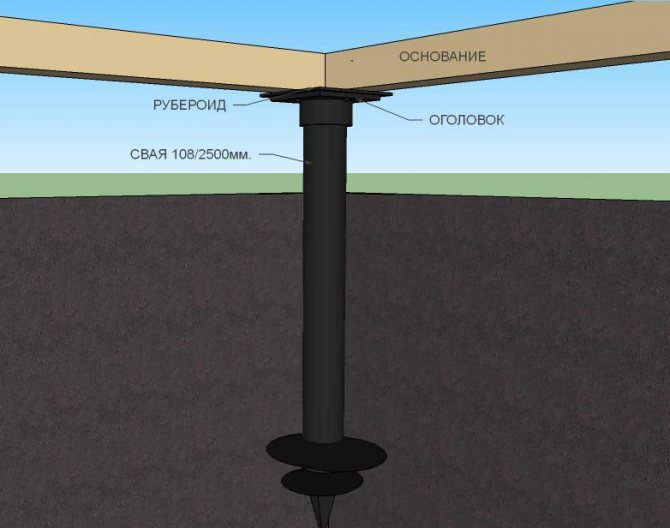

The main part of the base is a beam - a pile. The entire main load of the building falls on it. Therefore, rather high requirements are usually applied to piles.

The screw pile is made of strong, hardened metal. To evenly distribute the main load of the building, a basement grillage system is used.

- The screw pile diameter can vary from 10 to 35 cm

- The length of the beam is from 1.5 to 9 m

- The pile thickness is approximately 1 cm

At one end of the pile there is a sharp tip, at the other end there is a head for burying into the ground.

Do-it-yourself pile-screw foundation insulation

It is necessary to start warming the foundation only after the grillage of the house has been waterproofed. Waterproofing membranes are perfect for this. The most budgetary option may be roofing material or similar materials on a bitumen basis.

Attention! It is necessary to cover with waterproofing not only the upper surface of the grillage, on which the walls of the house will be erected, but also all its other parts, together with the pile heads.

For the self-made construction and insulation of the false base, the following tools are required:

- welding machine;

- trowel, spatula, hammer, tape measure, knife;

- low speed drill or screwdriver;

- concrete mixer.

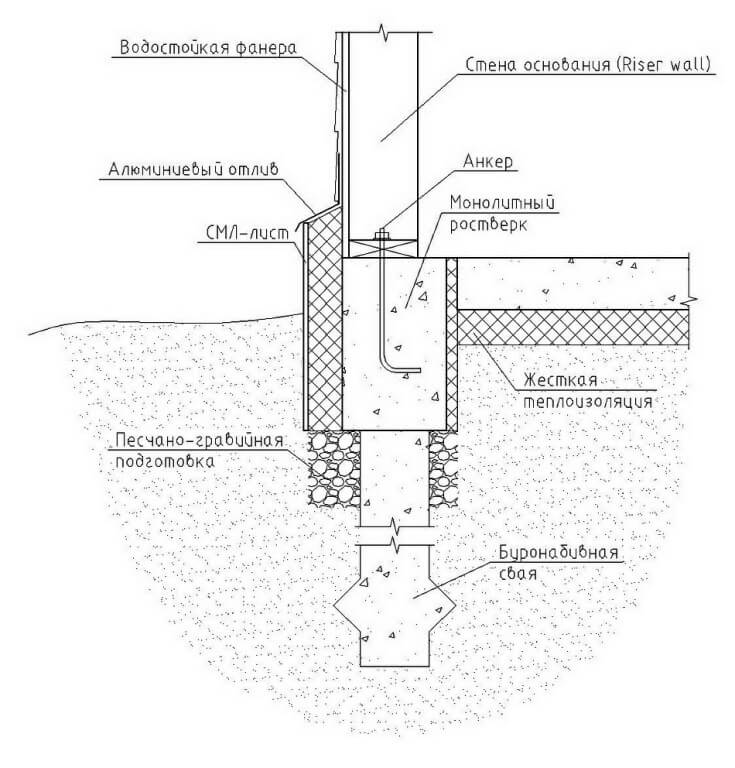

The false base of the pile-screw foundation does not bear any load, since its main task is to isolate the free space under the house from external factors. The first option is to build a brick wall under the grillage. Its thickness should be half a brick. The second option is to close the free space with decorative panels that are attached to the grillage.

Creating a brick plinth

This option is more labor-intensive, but the efforts made will not be in vain. Since the brick base is as reliable as possible and has greater durability, while the decorative alternative is easily damaged.

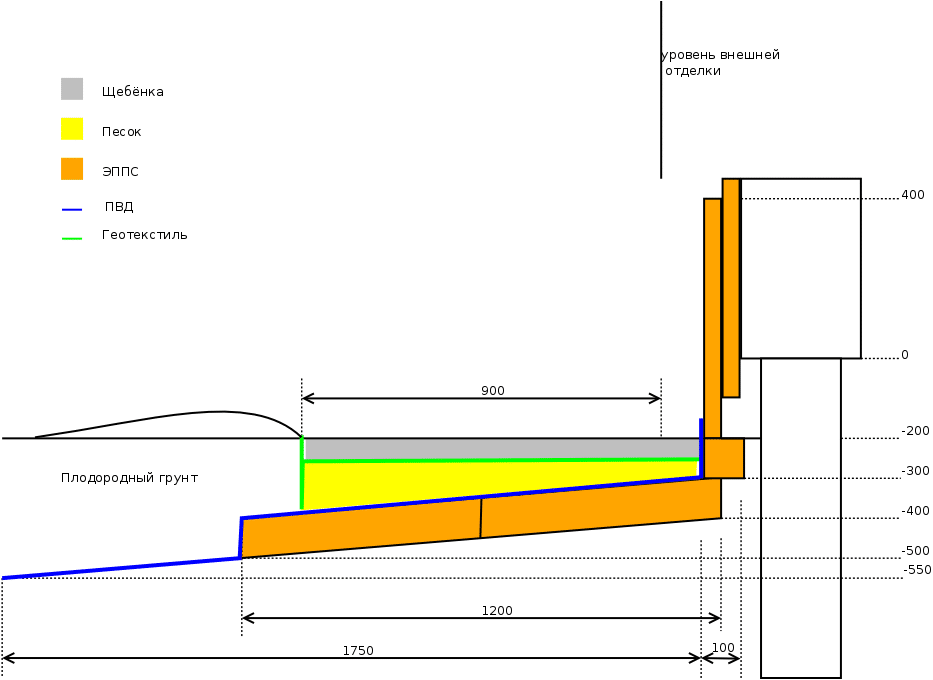

Before erecting and insulating the basement, it is necessary to dig a trench around the house under the grillage. The depth of the trench should be 20-30 centimeters, and the width should be slightly larger than the brick.

The trench should be filled with concrete and allowed to harden. This will be a kind of foundation on which the brick base will be laid. Due to the shallow depth of the concrete, reinforcement with a reinforcement diameter of 10-12 mm should be used.

After the concrete has completely set and hardened, you can start building the walls of the brick basement. It should be laid in small sections with a length of 1-2 meters. This is necessary in order to simplify the insulation on the surface of the base.

To fix the material selected for insulation, you will need specialized adhesives, which should not contain organic solvents.

Advice! Ceresit CT83 glue will be a good option for fixing the material to the base / plinth surface.

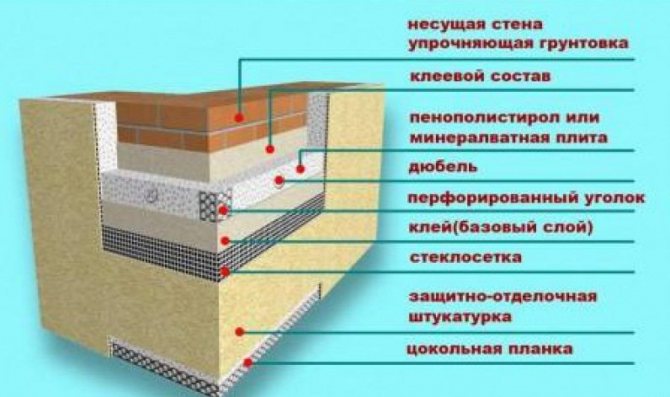

After insulating the basement, you need to close the brick wall with a decorative plug. The choice of materials is huge, suitable for everyone's preferences. You can also use plaster.

Creating a plinth with decorative panels

A much simpler way to erect and insulate a false base, as opposed to erecting a brick partition, is to install decorative panels. If you approach this issue seriously and competently, then this method will provide durable and reliable insulation of the pile-screw foundation.

To begin with, you should start choosing the supporting structure, on which the decorative panel of the false base and the material selected for insulation will actually be installed.

Advice! A good option when erecting a false base will be a frame made of a metal profile welded to the screw piles of the foundation.

The distance between the track profiles depends on the height of the free space between the floor of the house and the ground. Usually two or three longitudinal profile frames are enough.

A wooden beam will also cope well with the task of the frame, only it must be pre-treated with an antiseptic or mastic. The main thing is to protect the tree from rotting and insects.

Further, the cavity of the frame is filled with insulation. Styrofoam, penoplex or any other insulation. Do not forget about the thickness of the plates if penoplex is used for insulation. If it goes beyond the grillage, it will greatly complicate the installation of decorative panels.

After installing the thermal insulation material, a decorative fill should be installed on the grillage of the building using an adhesive mixture. The size of the decorative panels is also an important aspect. To ensure reliable fixation, it is necessary that the lower part goes into the ground to a depth of about 5 centimeters, and the upper part fits snugly against the grillage. In the place where the lower part of the panel is in contact with the ground, you need to dig a small ditch 10-15 centimeters deep and fill it with expanded clay.

Expanded clay filler has low thermal conductivity, which excludes the possibility of freezing of the structure at negative temperatures. Therefore, it will also help to reduce the heat loss of the building floor.

The choice of this version of a false base for a pile-screw foundation with vapor barrier materials (penoplex) implies the presence of natural ventilation. It is needed so that moisture does not accumulate in the internal space. Because of it, condensation will settle on the inside of the floor of the house, which can negatively affect the wooden structure. In order to allow air to circulate freely, special ventilation holes must be made. With the onset of cold weather, the holes should be closed with a plug or any heat-insulating material.

What materials will be required

Means for carrying out insulation on the construction market are presented in such an extensive range that many consumers have difficulties when choosing materials.

In fact, the most optimal options for insulation are the following:

- Styrofoam

- Foam glass

- Expanded polystyrene

- Penoplex

- Polyurethane foam

Sheets of insulation material are glued to the surface of the base. The seams between them are rubbed and sealed with polyurethane foam. Then, be sure to apply a layer of waterproofing material (for example, mastic or roofing material).

Ruberoid insulation of the foundation

How to close the basement of the house on screw piles?

The final stage in the construction of a house is the masking of the piles, which do not have a very presentable appearance. There are several options, and we offer each of them to our clients when they contact:

- Decking as a type of material is very popular.

- Plastic panels are used in various fields.

- Facing brick is one of the expensive ways to finish the basement of a house on a pile foundation, but beautiful.

- Ground siding is also in high demand. This type of material has many advantages, but there are practically no disadvantages.

In any case, the answer remains with the client, but we recommend that you approach the choice with a full sense of responsibility and, in no case, save money. For each of the listed types of work, our manager will name the exact price and guide you according to the deadline.

conclusions

The pile-screw foundation with a high grillage is popular due to its low cost and high practicality. Its minus is that it is a ventilated underground space.

To protect the house from the penetration of cold and just to give it beauty, the technology of creating a false base is used. It can be made using insulated brickwork, but it is better to use the technology of insulated panel basement. Compared to masonry, a panel plinth is much cheaper and more efficient.

How and how to insulate the base

You can insulate the base of the building with any waterproof heat-insulating material. The most traditional insulation for the basement of the house is expanded polystyrene, on top of which plastering is performed.

Also, an effective option is the use of mineral wool, the installation principle of which does not differ from insulation with polystyrene. Both materials are covered with a reinforcing mesh, on top of which a layer of plaster with a thickness of 2-5 cm is applied.

Advice! On top of the plaster, the plinth can be finished with artificial stone, tiles, or simply painted with paint.

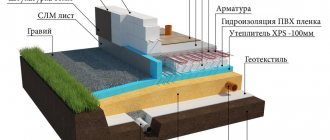

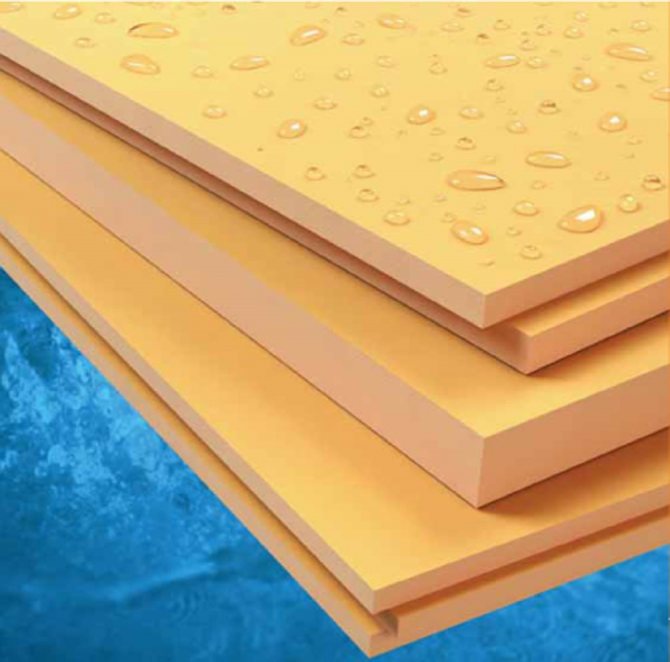

Extruded polystyrene foam

Thermal insulation with extruded polystyrene foam

One of the most effective materials is extruded polystyrene foam. It is characterized by low thermal conductivity and compressive strength. In addition, due to its homogeneous structure, it is well protected from moisture.

Accordingly, the base will also be protected from waterlogging. The low coefficient of water absorption is due to the good frost resistance of the material. According to the manufacturers, its service life is at least 50 years.

The thickness of the slabs varies from 30 to 120 mm.

To determine the optimal thickness of thermal insulation, it is necessary to perform calculations that take into account:

- The building material from which the basement is made and the thickness of its walls.

- The purpose of the basement.

- Features of the local climate.

Thermal insulation with extruded polystyrene foam

Expanded polystyrene is mounted on top of a waterproofing layer, which can be used as:

- Roofing material;

- Bitumen;

- Rubimast;

- Polyethylene.

The boards are glued with bitumen-polymer mastic or polyurethane glue. The adhesive is applied in a continuous layer or in dots. The joints should be covered with a special foam for insulation systems.

Advice! It is not recommended to fix the plates mechanically, as leaks may appear.

Cold bridges can be prevented by installing the slabs in two layers with overlapping joints. In this case, the lower slabs must rest on a rigid base, for example, on a ledge in the foundation or a blind area.

Penoplex

Penoplex insulation

Penoplex is another type of expanded polystyrene. This material also does not absorb moisture well and has a number of advantages over other materials. In particular, the thermal insulation coefficient of foam is 50 percent higher than that of conventional foam and mineral wool insulation.

The thicker the slab, the better the insulation. Moreover, the thickness of the slabs practically does not affect the weight of the insulation. In addition, the material perfectly tolerates large temperature changes, which is also an important indicator.

Installation instructions are as follows:

- First of all, the surface must be treated with a primer.

- Then the penoplex is glued with a special polymer glue. Plates must be laid end-to-end, trying to avoid gaps between them.

- Installation is reinforced with plastic dowels with wide caps, which are called "umbrellas" or "mushrooms". The holes are drilled with a hammer drill directly through the foam boards.

- Next, a fiberglass reinforcing mesh is applied over the insulation.

- A layer of plaster is applied to the reinforcing mesh, usually in two layers.

- Lastly, a topcoat is applied, which can be painted over. Instead of a topcoat, you can use artificial stone or other not heavy finishing materials.

Foam insulation scheme

Foam insulation

This option is the most budgetary type of insulation, since the price of polystyrene is the lowest.

However, it has some disadvantages:

- Styrofoam is not as strong as the materials described above;

- The stronger the frost in the region, the thicker the foam should be.

Advice! In the process of gluing the boards, irregularities may appear on the wall. In this case, all the protrusions can be rubbed with a special float to give the coating a perfectly flat surface, which can be checked with a building level.

If you opt for polystyrene, we insulate the basement of the house using the Ceresit system:

- First of all, the walls are cleaned of dirt.

- Then glue is prepared from a dry mixture, which can be purchased at every hardware store.

- Next, the glue solution is applied with a comb to ensure better adhesion of the foam to the wall. For a quality installation, it is enough to cover 75 percent of the material area with glue.

- As with the previous insulation, additional reinforcement with dowels is required. Each slab should be fixed at five points. It is allowed to hammer in dowels at the joints of the slabs, thus, one "umbrella" will fix several slabs at once.

- Next, you need to cover the surface of the foam with a primer and lay the mesh, which is glued with the same mixture as the foam. In this case, the surface should be leveled with a spatula.

- After the glue hardens, it is rubbed and primed again.

Pasting walls with foam

This completes the warming of the basement part of the house, the finish remains - and the basement is ready. For finishing, you can use textured plaster or artificial stone.

Advice! Using the above technology, you can insulate not only the basement, but all the walls of the house.

Insulation of pile foundations

As a rule, the most questionable for developers is the insulation of the lower part of the house on screw piles. This is due to the fact that such a foundation does not have a base, so there is just free space under the building.

In fact, the solution is very simple - if the house does not have a basement, then it must be done by hand.A hinged structure in this case will not work, so you will have to build a capital shallow strip foundation, on top of which you should lay the masonry to the level of the overlap.

The work is done as follows:

- A trench about 40 cm deep is dug around the perimeter of the structure.

- Then the formwork is laid, reinforcement is performed and the pit is concreted.

- When the concrete hardens, you need to build a masonry of bricks or some other material.

At this, the first stage of the work is completed, it remains to carry out the insulation of the basement using one of the above methods.

In the photo - insulation of the blind area

Insulation of the blind area

For maximum efficiency, the blind area should also be insulated.

This can be done with the same foam as follows:

- Plates are laid on crushed stone or roofing material.

- The joints are filled with polyurethane foam to prevent water from entering them.

- A layer of sand is poured onto the slabs and then compacted.

- From above, the sand is poured with concrete. You can decorate the blind area with stones.

Note! The width of the blind area should be at least 60 cm, while it should be 20-30 cm wider than the overhang.

Self-conduct of the insulation procedure

Consider how to insulate a foundation on piles with your own hands:

- Carrying out waterproofing works.

Work is carried out on the surface of the grillage. Roofing material is used as a waterproofing material. It is laid in the gaps between the grillage and the building itself.

The surface of the piles and grillage must also be treated with a mastic that does not allow moisture to pass through.

- Installation of thermal insulation means. After choosing the material for work and calculating its parameters, you can proceed directly to the installation of the thermal insulation layer.

Using an adhesive, sheets of heat-insulating material are applied along the entire perimeter of the grillage and along the surface of the piles.

It is necessary to firmly fix the waterproofing materials. For this, polyurethane foam is used, laid in the seams between the plates of the material.

- Carrying out external cladding. Various types of decorative tiles are used as materials. So, you can use materials that imitate brick, natural stone. For cladding, you can use marble, granite, porcelain stoneware. Profiled sheet or siding panels are used as a budget option.

The cladding of the base is necessary to protect it from external influences of the environment and damage to the surface of the thermal insulation.

Insulation of the floor from below under the house

To keep the house warm, you need to insulate the floor of the first floor. The floors take a very long time to warm up. Only when the entire volume of the house warms up, the floors begin to warm up.

If the floor of the first floor is not insulated, it will remain cold and this will create discomfort.

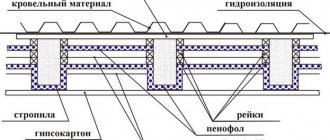

Insulation of the floor of the first floor with TM15 polystyrene

The overlap of the first floor of a house on stilts can be insulated with polystyrene plates. The technology of such insulation is very simple.

Polystyrene plates with a size of 1m * 1.2m from the bottom are attached along the log and across the log with a board-inch self-tapping screws 5 * 12 cm. All joints between the plates are foamed.

In total, the overlap of the first floor will consist of the following elements:

- Expanded polystyrene.

- Lags.

- Insulation 200 mm.

- Vapor barrier.

- Inch board.

The dew point is obtained in the house, that is, the insulation will be dry, and the house will be warm.

Insulation of the floor of the first floor with TM15 polystyrene.