In this article, we will bring to your attention all the products that are positioned by manufacturing companies as environmentally friendly insulation and give their main parameters.

What is considered an environmentally friendly insulation

To understand what an environmentally friendly insulation should be, it is necessary to decide what qualities and properties it should have, what characteristics it should have. Here are the main criteria on the basis of which it is worth choosing the "environmental friendliness" of any insulation material:

- It should be natural insulation. It should be based only on natural fiber and natural ingredients. There can be no question that thermal insulation releases carcinogens or toxins into the air you breathe. Do not expect that the decorative layer covering the heat-shielding material will become a reliable sarcophagus for hazardous and harmful secretions and vapors. All paints and "protective" coatings are erased over time, and negative substances still enter the building and poison the residents.

- Moisture resistance. The material must be sufficiently dense and not absorb moisture, in addition, by itself, it must repel it. When wet, the fibers lose their thermal insulation, and instead, the heat transfer coefficient begins to grow. In addition, excess moisture favors mold growth, fungal growth and the growth of harmful microorganisms and viruses. Breathable insulation is able to absorb a significant amount of water and, with sufficient ventilation, dry out without losing its thermal insulation characteristics and other parameters.

- Thermal conductivity. The best indicators of thermal conductivity are shown by heaters made of natural fibers, which are based on plant fiber. The heat transfer coefficient should be in the range of 0.032 - 0.040 W / m ∙ K. This value is quite sufficient and even optimal to keep the house warm and comfortable.

- Flammability. One of the most important properties of insulation, of those that must be taken into account when insulating buildings and premises. Natural insulation does not support combustion. It can burn when exposed to an open flame and extinguish as soon as the fire source is localized. And even in the event of a fire, eco-friendly insulation does not emit toxic and hazardous substances into the environment, such as, for example, materials that use formaldehyde, when they burn, they emit phenols and other substances hazardous to human life and health.

Today on the market of thermal insulation materials there is a sufficient number of heaters that fully meet all the requirements to be considered environmentally friendly.

Natural heater for a bath

To insulate a bath, at least two different types of insulation are required. For the steam room - fiberglass insulation, for example.

And for the rest room, you can use eco-insulation, such as reed mats. Natural insulation for a bath will be able to provide natural air exchange, it is not subject to decay and contains bactericidal substances. The main disadvantage of many eco-heaters for a bath is the likelihood of damage by insects, rodents and birds.Reed is one of the few materials that does not have this drawback.

Requirements for insulation for a bath

Bath insulation should be:

- maximum moisture resistant;

- not susceptible to the appearance and spread of fungi and bacteria;

- able to keep its original shape for many years.

There is just a huge number of heaters suitable for a bath on the market: special mats, plates, amorphous fillings, light extrusion products, etc.

Often aluminum foil is used for the steam room. It has an insulating and heat-repelling function.

Attention! Roofing felt and roofing material release toxic components when heated. In this regard, it is strongly not recommended for the arrangement of interiors.

Thermal insulation of the ceiling of the bath. Protects against condensation, helps to extend the life of the entire building

Thermal insulation of walls with additional vapor barrier

Types of eco-friendly insulation

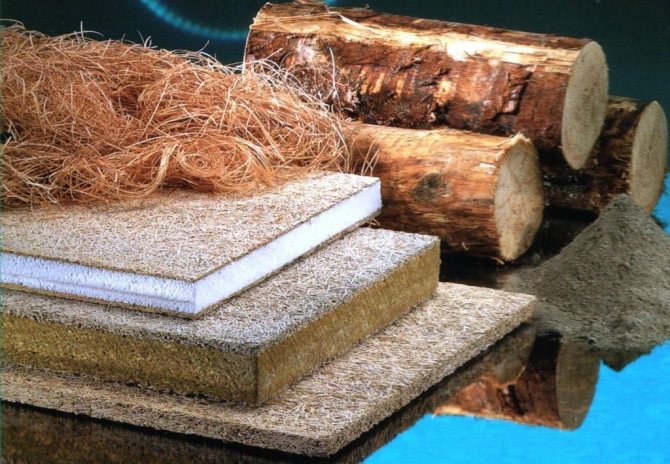

As mentioned above, ecological insulation is a natural insulation consisting of natural fibers. Of the entire abundance of heat-saving materials, the following can be distinguished:

- ecowool;

- ecotherm;

- eco-thermal;

- ecolen;

- damask;

- bung;

- hemp;

- peat blocks;

- cotton insulation.

To evaluate all the possibilities and advantages of each insulation, let us dwell on each of them in more detail.

Ecological insulation for the roof

- hydrophobicity;

- fire resistance;

- weight;

- shrinkage resistance.

The following materials are suitable for all these characteristics:

- expanded polystyrene (foam);

- mineral wool;

- cane;

A more detailed description of each can be found in the paragraph ecological insulation for a frame house.

Can't decide which natural insulation to choose? Order a free consultation with a specialist - find out all the necessary nuances and choose the best option for your roof!

Pay also attention to: turnkey construction of energy efficient houses

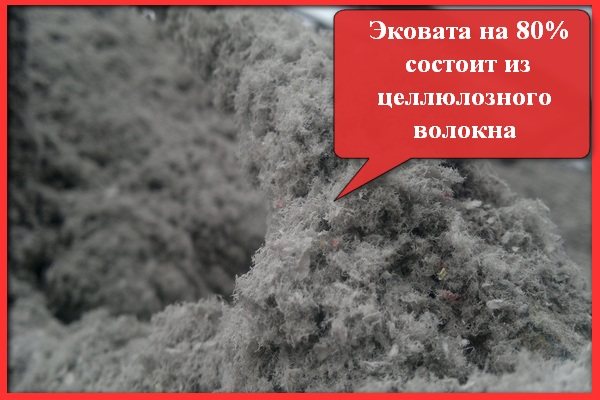

Ecowool

It is a breathable insulation made up of eighty percent cellulose fiber, which is simply waste paper. Twelve percent of the total composition is an antiseptic, represented by boric acid, and the last eight percent is borax, which acts as a fire retardant. Ecowool is also classified as environmentally friendly materials.

There are three ways to use insulation:

- Manual. The insulation is fluffed in a large container using a mixer nozzle on an electric drill or perforator. Specialists have a "gun" device for applying this insulation. Then they are stuffed by hand into the prepared cavities or niches in the quantities provided by the process technology.

- Mechanized or dry. Everything is exactly the same as with manual laying of insulation, only for large volumes of work, the cellulose fiber is blown using a compressor or the same pistol. This greatly simplifies and speeds up the work process.

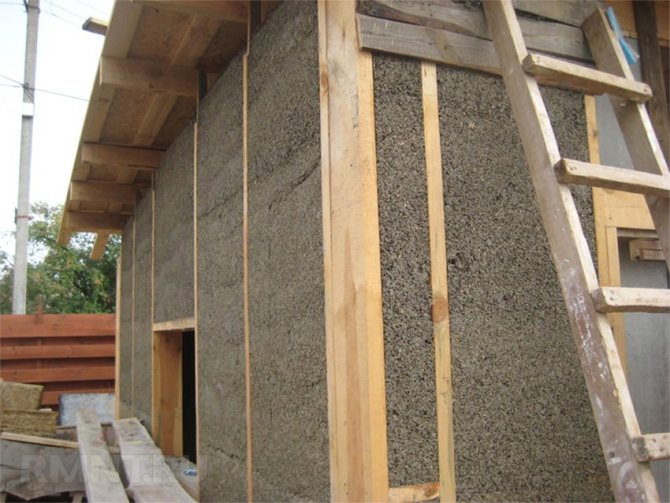

- Mechanized wet laying. Ecowool is fluffed up in a special bunker of a blowing machine, and blown out under pressure, moistened with an aqueous solution through special nozzles. If necessary, an adhesive composition can be added to the cotton wool.

Applying cellulose insulation

There are two methods of cellulose insulation: “dry” and “wet”. It is better to insulate inclined surfaces and floors according to the first option. A hole is cut in the closed cavities and, with the help of special equipment, the ecowool is blown into the structure. You can also carry out the process by hand, without the use of special equipment. To do this, it is enough to scatter the material over the surface to be treated, compacting it if necessary.

Wet installation of ecowool is suitable for walls equipped with a frame.The material is moistened with water and blown onto a plane to which it adheres very well and creates an insulating layer. The excess material must be cut off with a special roller.

It's so simple and effortless to insulate your home with safe and environmentally friendly materials, thereby maintaining a healthy indoor climate. The correct choice of insulation and proper installation will help solve the problem of energy saving for many years.

Ecoterm

Ecoterm is an eco-friendly insulation, which is 70% flax and 30% bicomponent polyester fiber. This fiber is the one that gives it sufficient strength and resilience. The ability to keep their shape well is an additional advantage during installation - the slabs can be installed between beams and joists without additional fasteners.

The main advantages of linen insulation:

- Durability - Expected service life of 60 years.

- Safe insulation. This means that it is absolutely hypoallergenic, leaving pleasant sensations from touching.

- Not subject to electrification.

- Antiseptic - parasites do not start in it, perfectly absorbs odors and purifies the air.

- Breathable - absorbs and releases moisture well, regulating heat exchange and humidity.

Natural antiseptic, absorbs excess moisture well and prevents the formation of mold and mildew. By its properties, the fiber is close to wood, and the use of linen thermal insulation in a frame house will help you easily get the effect of a “house made of logs” - the material allows the walls to breathe.

Flax is non-flammable, hardly flammable, and even when burning does not emit hazardous substances. In terms of fire safety, it is comparable to good quality basalt wool. Has excellent sound insulation. The use of plant fiber makes linen one of the safest insulation materials. It is produced in the form of plates with a thickness of 50 and 100 mm.

The qualities and properties of linen insulation allow you to work with it without fear, even when installing thermal insulation in children's rooms.

Ecolin

One of the safest materials for linen thermal insulation is eco-linen. The mass fraction of flax plant fibers in the insulation is 85%. The remaining 15 percent are thermo-bonding fibers, thanks to which the insulation perfectly keeps its shape and does not lose volume, which makes it possible to use it for insulating surfaces of complex shapes.

Material release form - mats 5 or 10 centimeters thick. The heat transfer coefficient is ekolna 0.034 W / m ∙ K. The insulation is breathable enough, therefore, with a packing density of 25-30 kg / m3, it provides sufficient breathing to the walls, without allowing moisture to pass through. The service life should be 75 years.

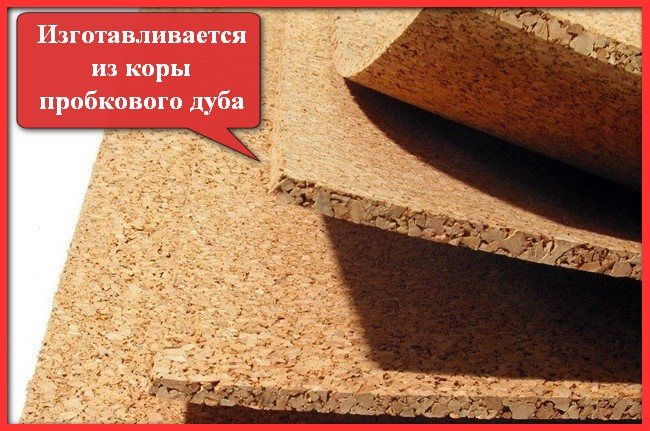

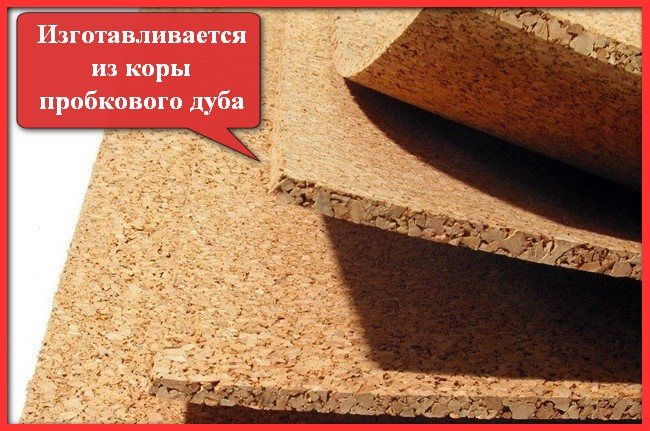

Bung

This environmentally friendly insulation for walls and floors is made from the bark of branches or trunks of cork oak, which is widespread in the Mediterranean. The material has a cellular structure - there are up to 40 million cells in a square centimeter, filled with a special gas that resembles air in composition, but does not contain carbon dioxide.

The inner layers of the cork contain suberin, a natural glue, which is sufficient in the manufacture of cork insulation so that no additional synthetic adhesives are added during the agglomeration process. The wax protects against water penetration into the structure. Both of these components give the cork its firmness and elasticity.

The material does not burn without an open flame source. Poorly flammable. When smoldering, it does not emit toxic vapors and substances.

Cork insulation is produced in the form of rolls of 1000x100 millimeters in size, plates or plates with a thickness of 1 millimeter to 5 centimeters. It is used for insulation of floors and walls of residential premises and premises with high humidity, and thanks to excellent sound insulation - and music studios.

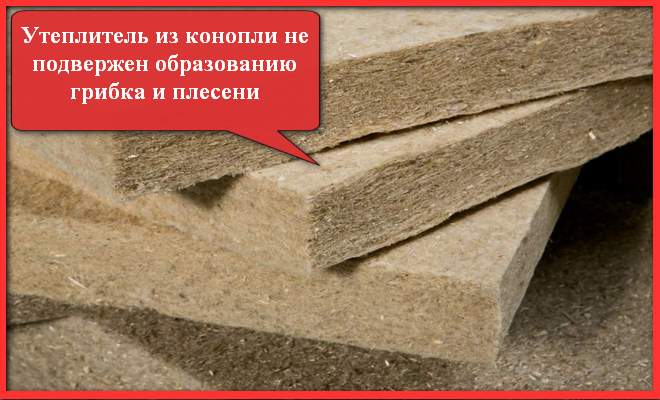

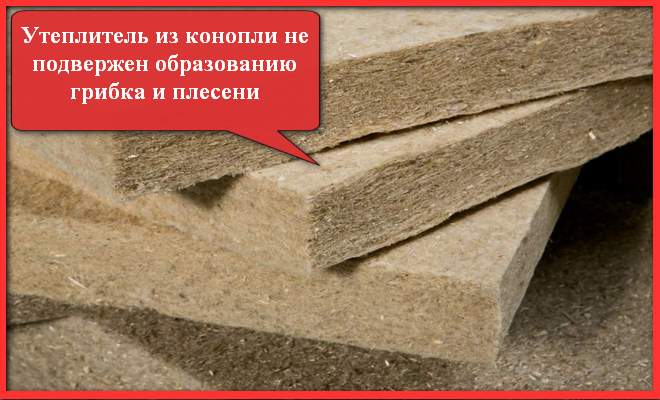

Hemp

As a heater for a wooden house, hemp has recently been widely used.Generously endowed with antiseptic properties by nature, it is not susceptible to the formation of fungus and mold itself and helps to protect the structures of the house from them.

It does not lose its qualities and properties under the influence of water - due to this, it is used when insulating rooms with a high level of humidity.

Natural home insulation

It is no longer possible to imagine modern residential buildings and apartments without insulation. With its use, the thermal insulation of pipes and walls rises at times. We bring to your attention the types of eco-heaters for the house and their application.

Ecological insulation for a wooden house

There is only one main requirement for the insulation of a residential wooden house: safety for human health. You can choose the rest of the characteristics as you wish: fire resistance, sound insulation, resistance to mechanical and chemical influences.

For many years we have been engaged in the construction of energy efficient houses and the production of insulation. For ourselves and our clients, we choose the best ecological insulation for a wooden house - reed. This is how it is prepared.

Fill out the consultation form - we will contact you ourselves, we will advise you on any issue about the insulation of wooden houses with reed and together we will select the best insulation option for your home.

Ecological insulation for a frame house:

Are you building a summer cottage or a country cottage using frame technology?

In any case, for a comfortable stay in such a house at any time of the year, an ecological insulation is necessary. The best ecological insulation for a frame house has an optimal heat transfer rate, has good sound insulation and is resistant to external factors.

For such a house, the value of the vapor permeability of the insulation material is of decisive importance; it should not be lower than that of the wood from which the frame is made. But as a safety net, you can use additional insulating material. For example, in the construction of frame houses, we use a vapor barrier film.

Most often, the following ecological heaters are used for frame houses:

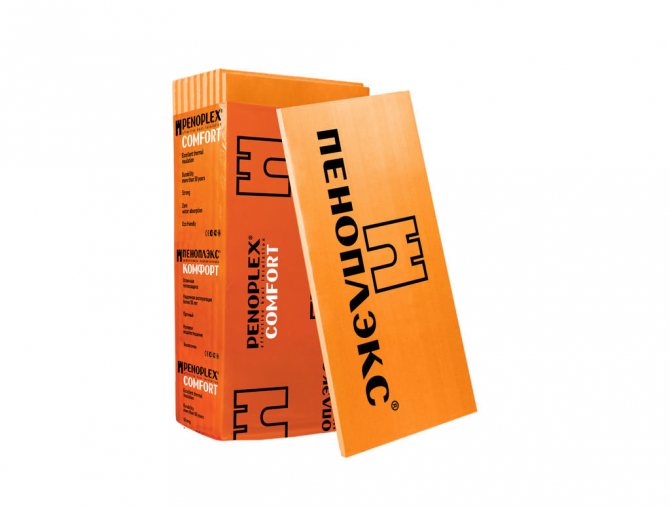

- polystyrene - in the last century, ranked first in demand as a heater for frame houses. However, it has serious drawbacks, which threw it off the pedestal: flammability, low noise insulation, fragility during installation, ideal as a house for rodents;

- Mineral wool is one of the most popular ecological insulation materials for frame houses. It has many advantages, but the main disadvantage is the possibility of small particles entering the body, which causes serious diseases;

- ecowool - is becoming more and more popular due to its harmlessness to health and its working properties. The only drawback is the need for special equipment and a specialist for its installation (the cost increases);

- natural insulation: reed, reed - in terms of ecological and thermophysical properties, natural material is not inferior to any of the above, and also does not require additional installation costs.

Peat blocks

Peat block is a natural, eco-friendly insulation for your home. Peat raw materials are ground with the addition of water, after which a filler is added to the resulting composition, which can be used as natural sawdust or shavings, straw, hemp or flax fire. The resulting mass is molded and dried until completely solidified.

The blocks are used to lay out walls, floors, and sometimes the ceiling of buildings. However, there are factors that can negatively affect the insulation - moisture. By accumulating water, the material changes its structure and quality characteristics.

The material is quite flammable and belongs to the G1 group.

The level of environmental and operational safety of expanded polystyrene materials

- Polystyrene foam insulation is represented by standard foam and extruded polystyrene foam, which is more advanced in many respects. Environmentalists have no particular complaints about these heaters. Even a relatively short-lived foam plastic does not create negative effects on the human body and the natural environment.

- The problem is in the low temperature resistance and fire hazard of both heaters. Styrofoam does not burn intensely, but at the same time emit a large amount of suffocating dense smoke.

- Most accidents, and this is more than 70%, are associated not with the thermal effects of fire, but with the poisoning of the body with combustion products.

An interesting pattern: the higher the ecological properties of the insulation, the higher its cost. An example is the range of environmentally friendly cellulosic insulation. The light, non-combustible, durable material, which was positively received by developers, is no longer in demand due to its high cost.

Cotton insulation

Probably the most environmentally friendly home insulation is cotton mats. The material can be rolled up. Cotton insulation is made from recycled cotton fabric, simply from jeans and polyester fibers. The percentage of the components is 85% cotton and 15% heat-bonding fibers.

It is produced in the form of mats with a size of 1000 x 600 millimeters, a thickness of 20 or 50 mm and a density of 45 kg / m3 or 80 kg / m3, respectively. The thermal insulation qualities of cotton insulation are not inferior to basalt wool, while it has excellent sound insulation.

Due to its properties, cotton as insulation is used for paneling and interior decoration of such specific premises as home theaters. Insulation work can be carried out independently. Environmental friendliness of the product allows you to do without the use of personal protective equipment.

The disadvantage of using this heat-saving composition is the difficulty of cutting it.

Comparative table of environmentally friendly heaters

| Insulation | Thermal conductivity coefficient, W / m ∙ K | Density, kg / m3 | Price |

| Ecowool | 0,032-0,041 | 30-75 | 30-40 rubles / kg |

| Ecoterm | 0,038-0,04 | 20-34 | From 5.15 rubles / mp |

| Ecoteplin | 0,038-0,04 | 32-34 | From 1200 rubles / pack |

| Ecolin | 0.0366 | 15-20 | From 1250 rub / pack |

| Damask | 0.087 | 80-90 | 200 rub / m2 |

| Bung | 0.04 | 245 | From 1020 rub / pack |

| Hemp | 0.036 | 20-30 | From 2500 rubles / pack |

| Peat blocks | 0,047-0,08 | 200-380 | |

| Cotton insulation | 0,037-0,041 | 80 | From 2360 rub / pack |

Material prices are for comparison purposes only. Each category of thermal insulation materials is represented by product lines that differ in both physical characteristics and the size of the packaging of the material that fall into the retail chains. More detailed and accurate prices for the material you have chosen can always be found on the manufacturer's website.

Dangerous heaters

- the main

- Dangerous heaters

What the manufacturers of heaters are silent about.

We present to you one of the reports made at the all-Russian meeting "Construction of energy-efficient houses and improving the management of housing and communal services in order to create favorable living conditions for citizens." Tomsk, March 29-30, 2012

“... Saving fuel and energy resources, introducing energy efficient materials, increasing the efficiency of thermal protection of buildings and structures are priority areas in the development of both Russian and world economies.

It is known that each applied 1m³ of thermal insulation provides an average saving of 1.45 tons of standard fuel per year.

In the last decade, the design, construction, reconstruction and overhaul of buildings and structures in Russia have been carried out in accordance with new, increased requirements for their energy characteristics and thermal protection of enclosing structures, determined by SNiP 23-02-2003 "Thermal protection of buildings".

In the largest volumes in Russia, fibrous heat-insulating materials from mineral melts - stone, glass and slag - are used for thermal insulation of building envelopes. Of these, in turn, the largest volumes are produced and used materials from stone melts, the main raw material for which are rocks of the gabbro-basalt group. There is a huge amount of heaters of this group on the market and let the manufacturers themselves speak about the advantages. We will make a few comments about what they do not talk about ... "

All attempts to find out what is used as a binder in the production of these heaters have not been crowned with success (even on the Internet). All manufacturers have them the most environmentally friendly and energy efficient, which we will not discuss and leave it on their conscience. We found the truth in a textbook for universities: "Thermal insulation from stone wool" published by the Association of Construction Universities. Moscow. 2010 Authors: Rakhimov R.Z., Shelikhov N.S., Smirnova T.V .:

- “As the most common binders, synthetic composite binders are used and, less often, bituminous ones. Phenol alcohols (phenol-formaldehyde resin), urea resin, polyvinyl acetate dispersion are used as synthetic binders.

- Phenolic alcohols are not flammable, not explosive, but (!) Toxic. They are irritating to the skin and mucous membranes.

- Urea resin is non-flammable, non-explosive, but (!) Toxic due to the presence of free formaldehyde in it.

- Phenol-formaldehyde resin is less, but (!) Toxic in comparison with phenol alcohols ”(pp. 87-88).

Up to 150 types of compounds can be present in the air of an ordinary typical kopeck piece. These are the evaporation of varnish and paint, furniture glue and chipboard, anthropotoxins. Doctors are increasingly faced with cases of allergic, bronchopulmonary, hormonal and oncological diseases, in which it is impossible to determine the source that provoked the pathology. Often in such cases, in the course of a survey on living conditions, it turns out that a person has recently made repairs, moved to a new house.

The reason is that mineral building materials emit phenol formaldehyde, as well as respirable mineral wool and glass wool dust, which is a strong mechanical and allergic irritant.

The problem is aggravated by the fact that there are a lot of imitations of well-known manufacturers in the construction markets.

Dust contained in ordinary mineral and basalt wool is especially harmful to health. In Russia, these materials are used for thermal insulation in 2/3 of cases. Most of the particles of mineral dust of a dangerous size are less than 3-5 microns, and they forever settle in the lungs along with the vapors of free formaldehyde and phenol.

The solution to all of the above problems when using heaters is the so-called organic heaters. At present, heaters of this kind have begun to appear on the Russian market, but this is either "exotic" in the form of slabs of straw, jute, or natural imported materials are very expensive.

In 2011, Siberia began to produce heat and sound insulation boards "Ecoteplin" from short flax fiber.

This is an absolutely environmentally friendly product from the moment of flax germination to the moment of delivery of the finished product. The production is based on the German technology worked out and modified for Siberian conditions.

According to its parameters and indicators, the insulation is not only not worse, but in most cases it is better than all heaters of the mineral basalt group.

Environmental friendliness.

The material consists of flax, natural starch binder (10%) and a safe flame retardant and bio-protection (10%) - natural boron salts. Flax has high antibacterial properties and is not electrostatic.

Water vapor permeability.

Linseed fiber is capable of absorbing and simultaneously releasing moisture without accumulating condensation. Therefore, an internal vapor barrier is not required, the insulated walls breathe freely, and a favorable microclimate is constantly maintained in the room.

Resistance to deformation and the absence of shrinkage without significant loads throughout the entire service life, which is at least 75 years. Most of the fibers in the structure of the plates are placed in different directions. That allows you to maintain the required thickness and insulating properties are not lost.

The heat-shielding properties of the Ecoteplin material are one of the best among heaters. The thermal conductivity coefficient is 0.038-0.04 W / mK.

Due to its structure and elasticity of linen fibers "Ecoteplin" has excellent sound insulation properties. Sound absorption coefficient - 0.98.

Fire safety.

The stoves do not support fire. Flammability group - G1 (not supporting combustion). Flammability group - B1 (hardly flammable). The most important thing in this part is that no harmful toxic substances and smoke are emitted during a fire.

A common problem, especially during reconstruction and major repairs, is the impossibility of insulation from the inside of the building. Due to its properties "Ecoteplin" is ideal for internal insulation and sound insulation.

"Ecoteplin" is used in residential, public buildings and structures, catering establishments, children's, medical and health institutions.

In low-rise and individual construction, this is perhaps the best material in its class.

Thanks to its ability to prevent energy loss in winter and to protect against heat gain in summer, proper insulation helps to conserve energy consumption and thus. Heating and air conditioning costs and improve energy efficiency.

P.S. Unfortunately, today Ecoteplin linen insulation is not produced. Apparently, this production could not cope with financial difficulties (we do not have reliable information). But the appearance of this material on the thermal insulation market in Russia gave impetus to the development of the natural insulation market. And for this we are very grateful to the manufacturer, who has invested a lot of funds and efforts in the development and popularization of natural, environmentally friendly heaters in our country! Now in Russia and Belarus there are several enterprises for the production of heaters from vegetable raw materials, in recent years builders and private developers have appreciated all the advantages of natural heaters and the demand for them is growing ...

Protect nature and be healthy)

Output

Natural insulation based on natural natural fiber was presented to your attention. Manufacturers of these products position them as safe for use and environmentally friendly. When choosing a material, you need to build on not only the cost of the insulation. Do not forget that your home should be comfortable, cozy, and most importantly, safe for your health and the health of your children, family and friends.

Insulating the outer walls and the facade of the house, it would seem, you can neglect the requirements for environmental friendliness and safety of thermal insulation. But the cracks and cracks that open to ventilate the window are all that open up direct access to all harmful and toxic substances in your home. Therefore, once saving on seemingly small things, you run the risk of having serious health problems.

Features of materials

The finest fibers of the material are held together by means of absolutely safe substances, which can be of synthetic (polyester) or natural (starch) origin. For more than ten years, such heaters have been produced all over the world, including Russia. In addition to being environmentally friendly, they have a number of significant advantages.For example, their thermal conductivity and acoustic properties are not inferior to those of mineral wool, and in some cases even surpass it.

In addition, when choosing one or another material that performs the function of insulation, it must be borne in mind that the effectiveness of insulation work depends not only on the degree of its thermal conductivity, but also on the quality of installation. And here an important role is played by the fact that the plant components at the plant are huddled into dense, elastic mats or slabs that adhere well to the wall, which means they exclude the appearance of "cold bridges" and reduce heat loss. To take a closer look at the most popular heat insulators for the home, consider their characteristics in more detail.