A warm house is the dream of every owner of suburban real estate. Only if the house has a comfortable and cozy atmosphere, the most favorable microclimate and good mood will reign in it, which is optimal for the whole family.

At the same time, it is possible to live comfortably in a private wooden house only if it is warm, and therefore you should definitely take care of high-quality insulation.

Photo of an insulated house with plastic lining

Currently, the most effective and inexpensive way to insulate a country house is to use special insulation materials and plastic siding.

Sheathing the house with siding with insulation makes it possible to isolate the building from the penetration of cold air, thereby providing an excellent level of thermal insulation, eliminating unnecessary financial costs for heating.

Types of heaters

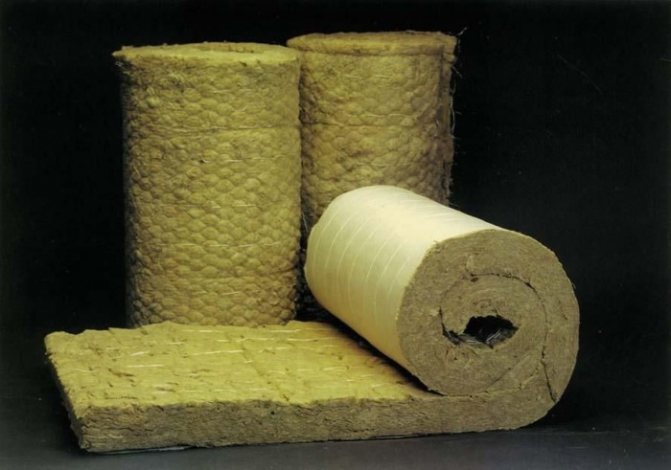

- Insulation materials for walls based on mineral wool are sold in roll and slab form with different densities, which affects their characteristics and, of course, the price of the material.

Photo: slab and roll mineral wool insulation.

- Glass wool. Such insulation for walls outside the house for siding is made on the basis of fiberglass. They are realized in slab and roll form. This type of insulation for walls outside the house is widely in demand in private housing construction as it has a low price, which makes the material available to all consumers.

Photo: glass wool in rolls and slabs.

- Styrofoam. This type of insulation for the walls outside the house is also very popular, although less than mineral wool and glass wool, but this does not mean that such insulation for the walls of the house is worse, it just loses to them in some respects, but in some respects vice versa is superior.

Photo: Styrofoam.

- Extruded expanded polystyrene. Such insulation for the walls of the house has good performance, which makes it widely in demand in modern construction. Insulation of a brick house from the outside with expanded polystyrene provides a high rate of heat saving.

Photo: expanded polystyrene.

It should be noted that insulation for walls outside the house, which would fully meet all the requirements, is not so easy to choose, because each of them is effective with its own set of characteristics, both good and bad.

And in order to choose the right insulation for walls for siding, which would be more suitable in your case, be sure to take into account the climatic conditions, the type of walls that will need to be insulated, and so on. Many make a big mistake when, when choosing insulation for walls for siding, they pay attention only to the price, while they do not even think about what degree of efficiency will be provided to a wooden house with such wall insulation.

That is why, in order to know exactly what kind of insulation is best for your home, carefully read the reviews of people who had to deal with the insulation of the facade of a wooden house.

Below is a video clip, after watching which you will have an idea of how the external insulation of a house under siding with your own hands is carried out:

Styrofoam. This is a very good, and most importantly, low-cost insulation for siding for a brick house, which has high thermal insulation characteristics.Among the advantages of such a heater for siding, one should especially highlight its excellent moisture resistance, low thermal conductivity, low price and ease of installation not only outside, but also inside, for example, a log house, its installation can be carried out on vertical and horizontal wall surfaces.

Now about the disadvantages. Polyfoam is a kind of insulation for siding that can disrupt natural air exchange inside a wooden house, since it has low vapor permeability. The walls of a wooden house when faced with foam plastic will not be able to "breathe", because of this, moisture begins to collect between the walls and the insulation under the siding, which then appears in the form of condensation.

Also, the disadvantages of such wall insulation outside a log house can be attributed to its fragility - the operating time of the foam is twelve to fifteen years. In addition, the foam burns, while releasing hazardous substances.

As for the sound insulation of such insulation of a log house outside under the siding, it cannot boast of this either, since it actually amplifies the sound even more, acting as a resonator. Therefore, before choosing such insulation for the facade of a wooden house, weigh the pros and cons well, read the discussions about the material and only then decide the issue with its choice.

In the photo above, you can see how the facade of a private house is insulated with foam.

Mineral wool. Such insulation for siding, as well as its varieties, which include basalt wool and glass wool, can be called the best heat insulator, which is successfully used for external insulation of a house under siding, and it does not matter at all whether it will be a wooden or brick house, and in that and in another case, it will provide high thermal insulation.

In terms of thermal insulation characteristics, mineral wool is not much inferior to foam plastic. The main advantage of mineral wool is that it does not burn, this makes the insulation of a wooden house outside with mineral wool for siding completely safe. In addition, all the modifications of mineral wool that exist today are vapor-permeable and, based on people's discussions, are considered the best sound insulator for the walls of a log house, and this speaks volumes. Below in the photo you can familiarize yourself with the scheme of wall insulation with mineral wool.

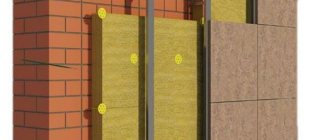

In the photo you can see the insulation of the walls of a wooden house with mineral wool.

In the photo you can see a diagram of the device of the "insulation cake" on the walls of a wooden house.

Despite the huge number of advantages of insulating a wooden house outside with mineral wool, the material has a big drawback, which is its hygroscopicity, it is seventy percent. Therefore, when insulating a wooden house outside with mineral wool, you will need to apply a waterproofing material. However, there is also a big problem here, that is, if an ordinary film is used for waterproofing, then the vapor permeability of the mineral wool will come to naught.

To provide better protection of the insulation against moisture penetration into the interior, it is necessary to use diffusion membranes for the waterproofing device, in which the vapor permeability index will be from four hundred to one thousand g / m2 per day or more.

The use of such waterproofing by fifteen to twenty-five percent will increase the estimate for wall insulation outside for the siding of a wooden house or cottage. Also, of the minuses, it should be noted that mineral wool when insulating a house can cause allergies as it is very "dusty", so it is better to use it only for insulating walls outside a brick house, and not inside.

Extruded styrofoam. The material is successfully used to insulate a wooden house. The main advantage of expanded polystyrene is its ease of installation and durability, it can last thirty years, and even more.Unlike foam, such insulation outside the house for wall siding has higher strength characteristics.

Air cells in the structure of extruded polystyrene foam improve its thermal insulation properties. The one and only big minus that is inherent in this insulation is a high degree of fire hazard, and it is not so much the fire itself that is terrible, but thick suffocating smoke that causes poisoning. That is why it is better not to use it to insulate a house or cottage whose walls are built of wood.

Extruded polystyrene foam compresses very badly, this makes it resistant to breakage, and if it happens that, for example, a log house begins to shrink, then the expanded polystyrene installed on the walls will not crack and crumble. In addition, the insulation has good resistance to moisture and temperature extremes. From the numerous reviews of people, one can understand one thing that such insulation of walls outside with foam plastic for siding for a house is one of the best options.

In the photo you can see the insulation with extruded polystyrene foam.

Photo: installation of extruded polystyrene foam on a brick wall.

Each material for insulating walls has its pros and cons, therefore, before choosing one or another type for insulating a wooden house for siding, you will need to compare their characteristics, read people's reviews and find out their opinion about this or that insulation. Below is a table of characteristics, looking at which you can understand the main advantages and disadvantages that are inherent in materials for insulating a house for siding with your own hands.

| Thermal insulation characteristics | Styrofoam | Mineral wool | Basalt wool |

| THEIR THERMAL CONDUCTIVITY COEFFICIENT | 0.037 W / MK | 0.052 W / MK | 0.035 W / MK |

| STEAM PERMEABILITY PROPERTIES | Minus. | A plus. | A plus. |

| WATER RESISTANCE PROPERTIES | A plus. | Minus. | Minus. |

| FIRE SAFETY PROPERTIES | Minus. | A plus. | A plus. |

| EASY TO INSTALL. | A plus. | Pole. | A plus. |

| ENVIRONMENTAL COMPONENT. | Minus. | Minus. | A plus. |

Looking at the table, you can see that all these materials for insulating a house for siding have a very similar thermal conductivity. The highest characteristics are inherent in basalt wool, which makes this material the best option for insulating the outside of the house with mineral wool for siding, and it can be used to insulate brick, lumber and wooden houses for siding.

Installation of mineral wool

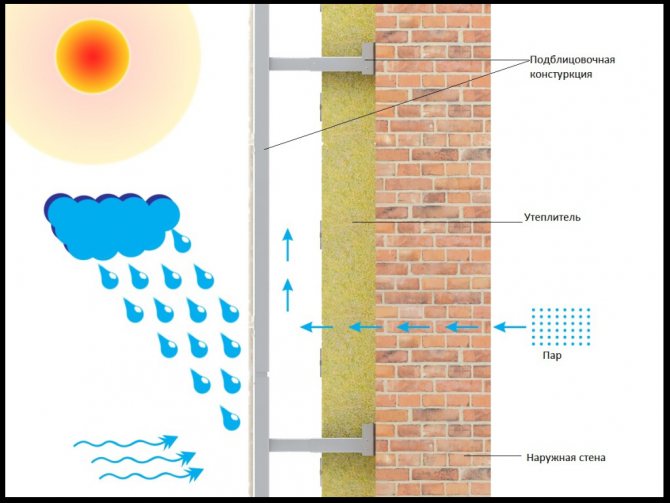

Insulation of a wooden house outside with mineral wool is carried out according to the ventilated facade scheme. So condensation will not accumulate under the facing material and the insulation will last longer. If decorative plaster is used for cladding, then wood-board finishing and reinforcement are performed on top.

Insulation in the ventilated facade system

To install mineral wool on the walls of a house in a ventilated facade system, it is necessary to perform a lathing with a step along the width of the insulation sheet, standard 60 cm. The thickness of the bars is taken depending on the number of layers of insulation. If the mineral wool needs to be laid in 2 layers, and the thickness of the mat is 20 mm, then 40 mm. The work is carried out in the following stages:

- A metal or wooden crate is sewn onto the wall. If you take wooden blocks, then they are pre-treated with antiseptics.

- Hydro-vapor barrier is mounted on the wall. It can be fixed with an ordinary construction stapler, with an overlap of 10-15 cm.

- A layer of mineral wool is laid out tightly between the crate. It is necessary to try not to leave uninsulated areas. The second layer of insulation is applied to the first so that the joints of the lower one do not coincide with the upper ones. If small empty areas remain, they must be covered with polyurethane foam. The mineral wool is fastened using special nails-fungi with a wide head. For added strength, you can stretch plastic straps.

- From above, mineral wool insulation must be protected from external influences: wind, moisture. To do this, it is covered with another layer of vapor barrier. It will not prevent the wooden walls from breathing, but it will not allow moisture to penetrate the mineral wool. You can fix the vapor barrier as in the first case.

- It is necessary to create a ventilated space for the facing material; for this, a counter lathing from a bar of a smaller section is mounted. It is attached to the first one with screws.

- A mesh with small cells is mounted below and above so that mice cannot get inside the structure.

- Panels are mounted on top of the counter crate: siding, block house, imitation of timber, lining. They choose according to their capabilities.

It is not always possible to do the work with your own hands. For those who do not have time and want to get high quality insulation, you should contact a specialist. The price of work depends on their volume and the qualifications of the team, and starts from 200 r / m2. Experienced specialists will take more. The cost of insulating the whole house will be cheaper for 1m2 than individual elements.

Doing work with your own hands means saving on the cost of work. In addition to saving, the owner will be sure of the quality of the finish. Since making insulation for their family, hardly anyone will be lazy and leave cold bridges.

House insulation technology under siding

Currently, there are several technologies that allow you to install insulation outside the house with mineral wool under siding with your own hands with little time. The first option for insulating a brick house with mineral wool can be considered really budgetary, this is when simple insulation materials in rolls are used for insulation, their installation is as follows: the insulation is glued to the surface of the wall and then fixed on it with the help of the crate made. Judging by the reviews of many people, this technology is currently simple and affordable.

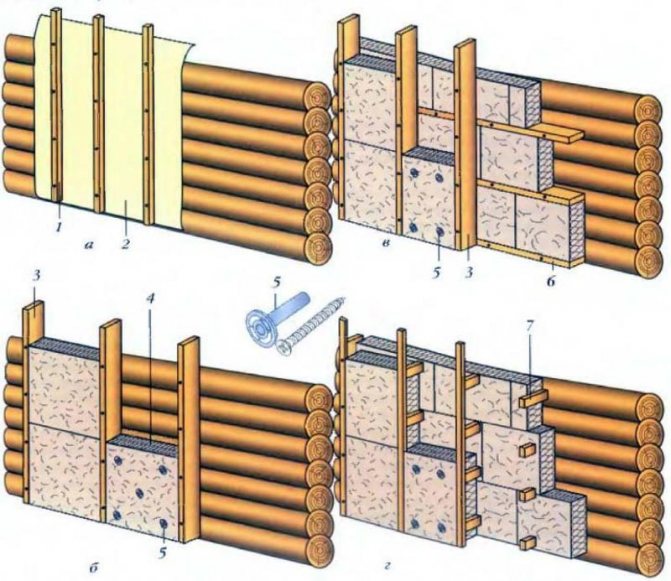

The next installation option is do-it-yourself interframe insulation of a log house under siding. Here, insulating plates of increased rigidity are used as insulation, the installation of which is carried out in the cells of the previously made lathing for siding and are fixed to the wall surface with screws or glue. The mineral wool installed in the cells of the crate will lie flat and adhere well to the brick wall.

The photo shows a diagram of the device of interframe two-layer wall insulation.

There is another technology for insulating a log house - installation on a cross frame. It must be said that it is precisely this technology of insulating a log house, according to experts, is the best, only the price of work and materials in this case will be rather big.

The fact is that with this technology, the installation of insulation takes place in several stages: first, a crate for siding is fixed to the surface, it is filled with insulation, then another crate is installed on it and also filled with insulation. Installation of the first lathing for siding with insulation is carried out vertically, and the second horizontally, so you can completely get rid of cold bridges.

Although such wall insulation outside for siding is expensive, it will always be warm in your wooden house. This technology is also well suited for the insulation of brick and concrete walls. Below you can watch a detailed video on how the installation of insulation under siding is carried out using a simple technology:

Video - Warming a house with mineral wool

Scheme and construction of facade insulation with mineral wool

- make a crate and place suspensions;

- for rigidity during the laying of the material, profiles are used;

- the plates are tightly inserted into the cells of the frame and fixed with dowels and glue;

- the joints are carefully processed;

- a layer of waterproofing is performed.

Then the surface is plastered or sheathed with clapboard.

Which insulation is better for siding: expert advice

Many who decided to insulate their wooden house very often ask themselves the question: what kind of insulation for the facade is better to choose for siding and why? It is impossible to unequivocally answer this question, since all heaters for siding differ in their pros and cons.

For example, polystyrene and all its varieties are distinguished by good resistance to the effects of moisture on them, because they have a small degree of vapor permeability, but because of this, the effect of stuffiness will always be present in a wooden house. But as for the mineral wool, when it gets wet, it loses about fifty percent of its inherent thermal insulation properties, therefore, during insulation with mineral wool outside the house, it will be necessary to equip additional protection for the insulation with the help of waterproofing materials.

Despite the weaknesses, mineral wool today, based on numerous reviews, is considered the best material for insulating walls outside for the siding of a wooden house or cottage. It must be said that such a facade insulation for siding in combination with a waterproof barrier will be able to provide a log house with excellent thermal insulation and sound insulation performance.

In addition, mineral wool is one hundred percent environmentally friendly, can last for many years, while the cost of mineral wool is low, which makes such insulation for the facade available to all buyers. As for the opinion of experts about mineral wool, they all unanimously assert that mineral wool insulation outside the house for siding is the most reasonable solution that can solve the issue of arranging the best facade insulation at home with your own hands.

Insulation of the foundation slab: is there a need for this

Another way to insulate a house is to use modern materials for finishing the foundation slab, which, like walls, often becomes a source of freezing of the building and can begin to collapse over time under the influence of external factors. further, spending 1.5-2 times less resources on heating the house.

Insulation of the foundation with foam

However, simply purchasing and attaching insulation will not be enough. It is necessary to ensure the full functioning of the system, having thought out a method for removing moisture and preventing the development of fungi, mold, as well as corrosive processes inside. This requires precise engineering calculations that will allow you to move the point outside the contour of the main part of the building.

In addition, one cannot but take into account such a phenomenon as soil heaving, which is characteristic of the winter period and can create significant pressure on the elements of the building located in the ground. Therefore, among the tasks that are set for the insulation material for the foundation slab, there is also protection against this kind of mechanical stress.

Insulation of foundation slabs using Swedish technology is one of the best foreign technologies that has become available in our area not so long ago. Let's consider what are the advantages of this method, and what are its main technologies:

- the method suggests the creation of a single solid structure, consisting of reinforced cast concrete, equipped with stiffening ribs. Installation is carried out on a special pillow, which is surrounded by polystyrene foam plates on all sides;

Construction of the insulated foundation using Swedish technology

- sand is poured under the bottom of the insulation, as well as on the sides of it;

- provision is made for the installation of a special system for collecting and draining water into the drain;

- in order to reduce the load on the drainage system, a blind area is provided;

- inside the house, a floor heating system will be provided, which is built into the foundation at the stage of its construction.

It is interesting that in Sweden this technology has been used for more than half a century, but in Russia it was used no more than 10 years ago. But even during this short period, some of the features of this technology became apparent:

- this method is great for building one-story and two-story houses. But if we are talking about the construction of tall buildings, then a large number of calculations will be required, as well as permission in all official instances;

- Even at the design stage, care must be taken to eliminate the risk of flooding the building. For this purpose, a sand bed of the required height is installed. It is possible to determine the necessary parameters by taking into account those statistics that are considered official for a particular region;

Insulated Swedish slabs for laying the foundation

- it is necessary to take into account the individual characteristics of the area on which the construction is carried out and, based on the available data, use standard or reinforced drainage and waterproofing systems;

- if construction is to be carried out on soils dominated by sand, then there is no need to install a water drainage system;

- as in all other cases, when it comes to working with concrete, it is recommended to carry out all work in the warm season, since the lowered temperature significantly increases the risk that the resulting structure will not end up being strong enough;

- even if a team of specialists is involved in the work, it takes time to implement this technology. This usually takes 3 to 4 weeks.

Ecowool application technology for wall insulation

When deciding to use Swedish technology, you need to understand that not all materials that we are used to using as insulation are suitable for its implementation. First of all, consider those that are categorically not suitable for this purpose:

- Mineral wool and all kinds of its analogues. Not having sufficient rigidity and strength, they also tend to absorb water, which is unacceptable in such operating conditions.

- Expanded clay and other granular materials. Their main problem is the inability to form a dense layer around the foundation, because of this, they allow moisture to pass through.

- Foam polymers, the creation of which is carried out directly on construction sites. And although in this case there is no unequivocal prohibition, such a technology requires vast experience and complex expensive equipment. Although even the presence of these factors still cannot guarantee success.

Based on the foregoing, it becomes obvious that the ideal option for insulating the foundation of a house from the outside is expanded polystyrene. Its characteristics are fully consistent with all the requirements that apply to the material to solve all the tasks.

Insulation of the foundation from the outside with foam plates

Among such properties, the following are worth noting:

- the standard dimensions of each slab greatly facilitate the process of their laying, allowing calculations to be made according to the available data, and ensuring high-quality and even joints;

- some manufacturers produce slabs equipped with special grooves on the sides, which additionally ensures the tightness of each joint;

- the material is very durable and absolutely does not allow moisture to pass through;

- high thermal insulation properties allow for high-quality insulation without laying many layers of material or one, but too thick. One layer of slabs of standard thickness will be enough.

You can also insulate the blind area with extruded polystyrene foam, which will further reduce the overall heat loss of the building through the foundation and provide additional savings.

Insulated foundation and blind area

The process of warming a foundation slab consists of several stages. Let's consider each of them, paying attention to the nuances of the work, as well as the difficulties that may arise during the installation process.

To carry out this type of work, it is considered quite sufficient to use 10 cm thick foam. The only requirement is that the material must be of high quality and purchased from a well-known manufacturer.

Site preparation consists in assessing the existing geological features of the site, as well as the type of soil that will have to be worked with. In the process of digging a hole under the foundation, you need to make sure that the bottom is as flat as possible. To do this, at the final stage, it is recommended to dig the groove by hand.

Extruded polystyrene foam is perfect for insulating the foundation of a wooden house

A layer of sand is poured at the bottom of the pit, which is compacted without fail. Then the temporary formwork is installed and the first layer of concrete is poured. At this stage, the use of any reinforcement elements is not yet envisaged.

After the first layer of concrete has hardened, polyurethane foam plates are laid on top, which are arranged in two layers in a checkerboard pattern. All joints and seams must be sealed to exclude the possibility of moisture getting into them. All this is covered from above with a layer of strong plastic film, laying it with an overlap and carefully gluing the joints with tape.

It remains only to fill the main part of the foundation, which provides for the mandatory presence of reinforcing elements and is carried out according to standard technology. After the concrete has completely solidified, foam polystyrene plates are attached to all end parts with the help of a special adhesive.

As you can see, the technology of warming the foundation with extruded polystyrene foam is not too complicated, if you familiarize yourself in advance with all the requirements for materials, as well as the procedure for carrying out the work.

Penoplex is another modern material for insulating walls and foundations of a wooden house

The fact that the external insulation of wooden houses significantly bypasses the internal one in terms of efficiency, has already been proven more than once in practice. Although much, of course, depends on the correct selection of heat-insulating material, and on compliance with all technology requirements. Fortunately, the modern market is rich enough to offer customers a wide range of materials for thermal insulation of wooden houses.

Do-it-yourself insulation of a house outside with mineral wool for siding: step-by-step instructions

To make it clear to you how the installation of insulation is carried out, below we will present instructions for installing insulation for siding. So, if the insulation outside the house for siding will be carried out with the help of mineral wool, then in this case it is better to purchase hard slabs and attach them to the surface of the walls with a wet method. The step-by-step instructions below will help you make facade insulation with mineral wool yourself.

- First of all, we need to fix a metal cornice at the bottom of the wall surface. This is necessary so that the insulation, in our case it is mineral wool, lays down evenly, in addition to this, in this way you will provide the insulation outside the house under siding with the best protection against rodents, which, judging by the discussion of people, for some reason prefer mineral wool more than other materials.

- The wall on which the mineral wool insulation will be carried out must be well primed.

- To make a reliable attachment to the wall of the mineral wool, we need polymer-cement glue, it is not difficult to make it, you just need to pour water into the dry mixture and mix well until you get a homogeneous mass. The finished glue must be applied to the back of the facade insulation.

- It will be necessary to fix the mineral wool starting from the bottom and moving to the top in such a way that a dressing of the seams is formed (as with brickwork). During the installation of mineral wool, you need to ensure that the plates fit well to each other. The mineral wool slabs glued to the wall surface should be additionally fixed with plastic dowels, which have large caps, although this should not be done immediately, but wait one day. When fixing the facade insulation under the siding, care must be taken to ensure that the slabs do not disperse to the sides.

That's all, mineral wool insulation of a wooden house is ready. And in order for you to better understand how such work is done, read people's reviews and watch the video instruction:

External thermal insulation of a wooden house

For external insulation, mineral wool is taken, made in the form of a slab or mat, its density is 80 kg / m³. The thickness of the slab on the outside should be at least 10 cm, this is quite enough to keep warm even in severe frosts.

The work is done in several stages:

- surface preparation;

- installation of the frame;

- installation of insulation;

- wind insulation device;

- installation of the second lathing;

- facing.

Preparation

Before starting the installation, a vapor barrier is applied with the rough side to the wall, which will ensure air exchange and waterproofing.

The material is overlapped and secured with stapling staples.

Lathing and installation of insulation

At the next stage, a metal crate is mounted. The metal profile is installed vertically and fixed with self-tapping screws. The distance between the elements depends on the width of the material.

The laying of mineral wool is done end-to-end on specially designed stops. To further strengthen the mats, dowels are used, on average 6 fasteners per square meter.

Wind protection and finishing

After laying the mineral wool, it is covered with a special membrane for effective wind protection. It is also attached with dowels. The result is an integral structure reinforced on a metal profile.

A profile is horizontally installed on top, which presses the insulation, and is also the basis for finishing the facade. In most cases, siding is attached to this frame, which provides good wall protection.

Insulation of the walls of a brick house with expanded polystyrene

If you decide to insulate the walls with expanded polystyrene, then such work is best done in the summer, when the weather is hot outside the window. By the way, mineral wool insulation is also best done in dry weather. The surface of the wall, which we will insulate with expanded polystyrene, must be dry, that is, moisture should not get on it for three to four days before the installation of the insulation begins.

- First, you need to well clean the surface of the wall from the dirt on it, if there are irregularities there, you also need to get rid of them.

- As soon as the walls are prepared, they will need to be leveled; a primer is used for this.

- We glue the insulation sheets to the wall surface.

- Next, you need to cover the insulated area with a primer, and only then you can proceed to installing siding on the walls of a wooden house.

The photo shows how to insulate brick walls with mineral wool.

Such wall insulation for siding will be very effective and will provide you with a comfortable existence even in the most severe frosts. The main thing is to competently carry out work on the walls insulation with expanded polystyrene from all sides of the wooden house, otherwise the wall insulation for siding will not be of high quality, therefore, there will be drafts and cold in the wooden house.

To prevent this from happening and you would not have to throw money down the drain, you need to approach the work of insulating walls with expanded polystyrene responsibly and strictly adhere to the video instructions:

and then the result will not disappoint you.

What is better to insulate?

Wall insulation

It is better to insulate the walls from the outside.This shifts the dew point towards the environment, which allows it to be removed much faster from the base. If you insulate the walls from the inside, then you can cause a completely opposite result. In this case, the walls will still freeze through.

For wall insulation we choose hard mineral wool mats. If you have the material resources, you can take the foil version. A layer of foil will bounce heat away from the walls. Before installing the insulation, it is imperative to close all the cracks.

In this case, we use a tourniquet, dry moss or tow. With this material we tightly seal the space between the crowns or cracks that may form on the logs.

Ceiling

There are two ways to insulate the ceiling:

- from the side of the room;

- from the attic.

Both the first and second methods are effective. More rigid materials are laid on the ceiling. If there is an attic under the roof, then it is better to resort to insulation from the side of the rooms. Then a structure is created from beams, between which sheet insulation is placed. Don't forget about vapor barrier membranes.

When there is an attic under the roof, you can use mineral wool and even foam. A tougher material must be laid on top of the insulation. It can be chipboard plates, which will protect the insulation from pushing through.

There is an option when bulk insulation is used, for example, sawdust, gravel. But a lot of such materials are needed, which can be even more expensive than using modern insulation.

The choice of technology for warming a dilapidated house depends on whether there is a basement or not. If there is a basement, then first they insulate it. You may not need to further isolate the floor after that.

But if such a need has already been determined, then the following options are chosen:

- Underfloor heating installation (electric heating). Not always suitable for old wooden structures, since it requires reliable electrical wiring.

- The use of thermal insulation materials. They choose only hard options, but they definitely make a plank floor or cover it with chipboard or OSB plates, and then decorate with the selected floor material.

We suggest that you familiarize yourself with the Ice screw with a screwdriver for winter fishing

It is in an old wooden house that large heat losses occur due to dilapidated floors. Therefore, do not neglect the possibility of insulating floors. More precisely, start insulating the house from the floors.

Installation of insulation under siding: step-by-step instructions

In order for the insulation with mineral wool or any other heat insulator to be done correctly, you need to follow the instructions and make the calculations correctly.

- To install wall insulation for siding, it is required to take insulation, the thickness of which must be at least four to five centimeters.

- With the help of glue, the siding insulation is fixed to the crate, which is installed on the surface of the outer wall of a wooden house.

- Installation of insulation for siding begins from bottom to top.

- As soon as the walls of the wooden house are fully lined with material, you can proceed with the installation of siding.

Photo: laying insulation on brick walls under siding.

Lathing for siding with insulation

The cladding of the facade of a wooden house must be started with the installation of the lathing. At the moment, the best and most inexpensive way is the use of bars or slats, such a crate will not only allow you to conveniently install the siding, but also install the insulation under the siding. The step of the wooden lathing should be between thirty-five and forty-five centimeters. All wooden elements of the lathing for the facade must be treated with a special antiseptic.

In the photo you can see the structure of the wooden lathing of the facade of a log house, as you can see here everything is very simple.

The need for lathing is due not only to the fact that it is necessary to align the walls, but also to arrange a place for laying insulation.

There is another type of lathing for facade insulation, it is made of metal. Such a crate for the facade will last for more than a dozen years. In order to be able to set the offset you need from the wall surface, you will need to use special suspensions.

In the photo you can see the lathing device for the facade of a brick house.

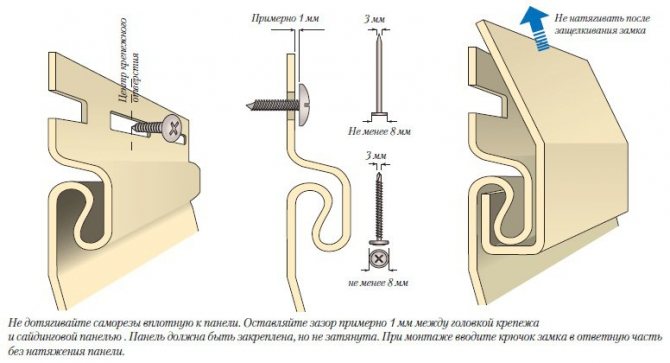

The photo shows a diagram of the installation of lathing and siding.

To better understand what a crate for a house for siding is, watch the video presented for you:

You can also read the discussions of people who made the crate for siding with their own hands.

Insulation

Then the insulation is attached to the wall. I would use basalt mats... This is the best breathable insulation. It can be soft (in the form of cotton wool), semi-rigid and rigid (in the form of separate blocks), and hard blocks can even be plastered. This insulation is very effective, environmentally friendly and non-flammable. I would strongly advise against using it in the insulation of a country house Styrofoam... It does not breathe at all and can eventually lead to the destruction of bricks and the appearance of mold, which, as you know, is almost impossible to fight. And we are not building for one day. So it's better to save up some money and buy quality materials. Moreover, it is quite possible to install siding on your own, saving on payment for construction work.

Another inexpensive, but very warm and absolutely environmentally friendly option for insulation is ecowool... It is a cellulose insulation, loose and light, consisting of 80% newsprint and 20% of non-volatile flame-extinguishing substances (borax and boric acid).

Ecowool can be applied with a spray or by hand, dry or wet.

But working with ecowool, especially when applied to vertical surfaces, is more difficult than with basalt mats, although it is cheaper. It's up to you to choose. In any case, on top of the insulation you need to lay and fix windscreen.

The price of work on the insulation of the facade for siding

Any of the existing methods of insulating walls outside a wooden house for siding is not difficult to do yourself, but if for some reason you cannot do this, then entrust such work to specialists. The cost of insulating a wooden house for siding will directly depend on how much work needs to be done. In the table below you can see the approximate price of insulation for siding the facade of a wooden house.

| Type of materials used | the cost of the material in rubles per square meter. | The cost of insulation without material in rubles per square meter. |

| Mineral wool (glass / min.) | From one hundred to one hundred and fifty rubles. | From two hundred fifty to three hundred rubles |

| Styrofoam | From seventy rubles. | From one hundred and twenty rubles. |

| Vapor barrier | From twenty five rubles | From fifty rubles. |

| Vinyl siding | From one hundred rubles. | From four hundred and fifty rubles. |

Price and manufacturers

When buying mineral wool for insulating a wooden house, you need to choose high-quality material from well-known manufacturers, for example: Ursa, Knauf, Rockwool, Isover, Technonikol. It costs an order of magnitude higher than little-known brands, but the quality is higher. In the construction markets, you can find goods without any labeling in simple PVC bags, its cost is lower, but the quality leaves much to be desired.

It is produced in clandestine conditions, and toxic low-quality adhesives are used for gluing. In a house insulated with such material, a headache will be felt, a chemical taste in the mouth will be felt, and an unpleasant odor appears during the rain. All these are signs of poisoning the body with poisonous vapors.

The price of quality mineral wool depends on several factors:

- Thickness and density of the material.

- Form (slab insulation is more expensive than rolled insulation).

- Manufacturer (Imported is more expensive than domestic).

- Composition (Stone and ecowool are 2 times more expensive than glass).

For the convenience of our readers, consider the cost of mineral wool of different types and manufacturers:

| Brand and name | Board density, kg / m2 | Size, mm | Price, rubles / pack | ||

| Thermolight: PM-35 | 35 | 50x150 | 1100 | ||

| PM-60 | 60 | 50x150 | 1450 | ||

| Linrock: Light Effect | 25 | 50x200 | 1050 | ||

| Light Optimal | 34 | 50x200 | 1160 | ||

| Light | 45 | 50x200 | 1450 | ||

| Standard | 64 | 50x200 | 2050 | ||

| Ecover: Light Universal | 28 | 50x200 | 1100 | ||

| Light 35 | 35 | 50x200 | 1300 | ||

| Standard 60 | 56 | 50x200 | 1950 | ||

| Eurotizol: EURO-LITE 25 | 25 | 50x200 | 1150 | ||

| EURO-LITE 30 | 30 | 50x200 | 1200 | ||

| EURO-LITE 35 | 35 | 50x200 | 1300 | ||

| Knauf: TeploKNAUF DACHA TR 044 | 44 | 100x610x1230 | 1350 | ||

| TeploKNAUF DOM TS 040 | 60 | 100x610x1230 | 1250 | ||

| Ursa: Eurolight | 60 | 100x600x1230 | 1350 | ||

| UrsaFacade | 60 | 100х610х1250 | 1400 | ||