Pros and cons

The use of a ventilated facade on wooden walls has many advantages. These include:

- improvement of thermal insulation parameters;

- long service life of the structure and structure;

- protection of wooden walls from moisture, direct sunlight or temperature changes;

- if necessary, worn out casing can be easily replaced;

- it is not required to regularly repair wooden walls or cover them with protective compounds;

- high quality ventilated facades do not impair the characteristics of wooden walls;

- after the construction of the object, there is no need to finish the wooden walls, so they are not even covered with paint or varnish;

- the ecological cleanliness of the building does not deteriorate;

- panels that have a beautiful appearance or imitate wood are easily selected.

Therefore, with the help of a ventilated facade, it is possible to improve the basic characteristics of a wooden structure. The disadvantages include only the need for additional costs, and during installation, mistakes must not be made that lead to a deterioration in the design parameters.

Attention! Ventilated facades are presented in a special way of finishing the walls of the building, which consists in the presence of a ventilation layer between the walls and the cladding.

Usually, insulation systems are used immediately, which make it possible to improve the thermal insulation parameters of the house. Thanks to ventilation, steam is removed from the walls of the building, so they do not rot or become moldy. A properly made structure is highly flexible, so it does not deform with changes in temperature and humidity. If mistakes are made, then this leads to cracks or other problems.

Why insulate a wooden house?

There is a way out of the situation if you use an expanded polystyrene layer as thermal insulation, but only if the homeowner does not mind that he has a "non-living" structure made of wood. The material from polymers, emitting chemical components due to moisture and heat, remains only a decorative design. It is customary to carry out work on the reconstruction of wooden houses, as well as the arrangement of the facade, with hinged systems - siding, PVC panels, block house, clinker tiles, etc.

An integrated approach to cladding

The installation of a wooden ventilated wooden facade makes it possible to solve:

- Warming issue.

- The problem of leveling noticeable wall defects.

- The task of decorating and creating extra strength.

- The problem with the soundproofing of wall structures. It also makes it easier to care for them, makes it possible to extend the period until the next repair work and the use of the house in general.

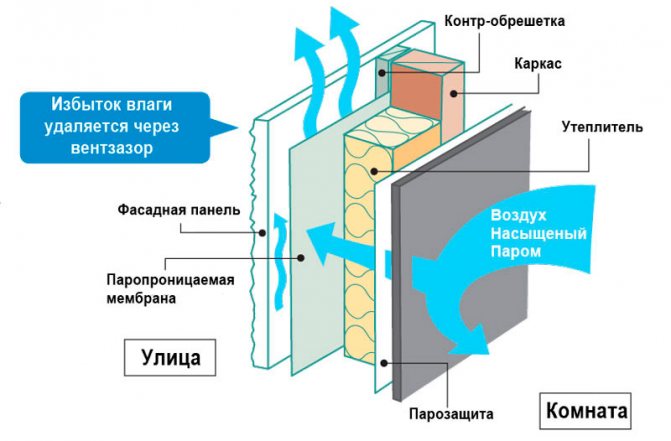

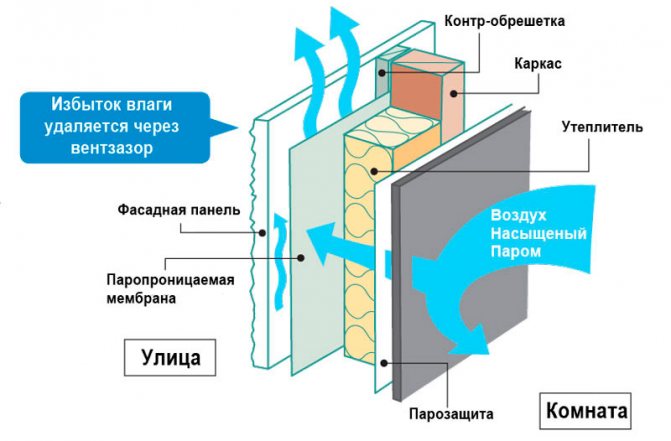

Wall cake with ventilation facade

Such a ventilated "pie" turns out to be multi-layered. It consists of a wooden wall surface, an insulation layer, a membrane to protect it from moisture, a ventilation gap and a finishing layer of decorative cladding. Each layer plays a specific role in a ventilated facade for a wooden house, so you cannot change such a "filling" for something else. The choice of insulation material will depend on the financial capabilities of the home owner, as well as the climatic conditions in the region. In the northern regions, special attention is paid to insulation.

Note: It is believed that it is possible to speak of efficiently saving energy only when the thickness of the insulating material is 7 to 10 cm. Foam can be used for this. It will not absorb moisture, which is an additional plus. Also, the material is characterized by a low level of vapor permeability, and this is a disadvantage.In contrast, mineral insulation is famous for the fact that it perfectly absorbs noise, but at the same time it is afraid of water.

At the same time, the windproof film will keep the structure from the destructive effect of gusts of wind or moisture. A ventilation layer that prevents the formation of condensation can be created by installing a lattice structure. The lathing has another useful function - trim parts are attached to it. The ventilated facade of the wooden house allows its residents not to freeze in the winter and not suffer from the summer heat.

Types of wooden facades

Curtain walls are made from different materials. Wood products are usually used for wooden buildings, as they allow you to maintain an attractive appearance of the house. To create such facades, different types of wood are used:

- Conifers such as spruce, pine or cedar. They have a reasonable price, are easily subjected to various types of processing, and they also contain a resin that does not allow the decay process to begin.

- Larch. From it, panels are obtained that easily cope with the effects of moisture, and also do not rot. The material is strong and durable.

- Heat-treated wood. It is represented by natural wood, which is dried at a temperature of 180 degrees. This allows you to get a durable, beautiful and moisture resistant material. Even with sharp and constant changes in temperature, it retains its shape and dimensions. Soft rocks are used to create thermowood.

- Decorative breeds. They come from the tropics and have an unbeatable look. They are distinguished by their high density, therefore, to fix them, a strong and reliable crate is required. The disadvantage of such wood is its high cost.

Attention! In the process of choosing a material, the climatic features of the area are taken into account.

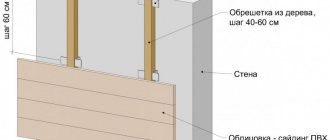

Facade system device

Wooden ventilation facades are suitable for houses made of different materials, but they are usually chosen for wooden buildings. Such a system consists of a frame, sheathing and an empty space between these parts. It can be filled with vapor barrier, waterproofing and thermal insulation materials.

The system is presented in two versions:

- Complex. Initially, the walls of the house are sheathed with heat-insulating materials and films, and then the cladding is fixed. A ventilation gap is left between the insulation and the casing. Thanks to this design, the house is insulated, and the walls are protected from various atmospheric factors.

- Simplified. It consists of a frame and cladding, so there are no additional materials between the walls of the house and the cladding. The system allows moisture to be removed from the walls of the house, and also protects the wood from the atmosphere. This option is suitable for warm regions of Russia.

For cold regions, a complex system is chosen. Thanks to it, the cost of heating the house is significantly reduced.

Appointment of cladding for a wooden house and the rules for the selection of material

| Insulation, brand | Density, kg / m3 |

| Styrofoam | 25-35 |

| Polyfoam GOST 15588 | 40 |

| Extruded foam | 32-38 |

| Polyurethane foam | 40-60 |

| Penoplex 35 | 35 |

| Penoplex 45 | 45 |

| Rolled fiberglass wool | 11 — 45 |

| Rockwool brand mineral wool | 37-160 |

| Mineral wool "Technonikol" | 30-127 |

| Mineral wool "Park Extra" | 37 |

The specific density factor depends on the specific grade of the given material. The table shows general values.

Vapor permeability

When insulating a log house outside with your own hands, it is necessary to take into account the vapor-permeable characteristics of the wall. The material used must have good characteristics to allow the vapor particles to escape to the outside.

It should be remembered that even if the wet method is used, decorative plaster, as well as adhesives, must be vapor-permeable.

Thermal insulation must adhere to the facade, and between it and the wall it is strictly forbidden to install materials that prevent air from penetrating through the insulation plates. This can lead to accumulation of moisture and subsequent destruction of the wall.

useful in work

Insulation sheets, in the case of using ventilated facades technology, are strung on brackets pre-fixed on the wall.

There must be a distance of at least 4 cm between the insulation and the decorative material (ventilated gap). It is necessary to ensure the circulation of air inside the system and the removal of condensate to the outside. In this case, it will be correct to use a vapor-permeable moisture-proof membrane, it will prevent the insulation from getting wet and weathering and will extend the service life of it and the entire wall.

The table shows the average vapor permeability resistance coefficients of the most common heat insulators.

| Thermal insulation | Air humidity over 70% | Air humidity less than 70% |

| Styrofoam | 60 | 60 |

| Extruded polystyrene foam | 150 | 150 |

| Minvata | 1 | 1 |

| Polyurethane | 50 | 50 |

| Ecowool | 2 | 2 |

| Expanded clay | 2 | 2 |

A wooden house is one of the most environmentally friendly, comfortable and technologically advanced in construction. But wood is a relatively short-lived material if not protected from external influences. It rather actively absorbs moisture from the atmosphere and, when directly exposed to rain or snow, is prone to its accumulation. As a result of exposure to water, ultraviolet radiation and oxygen, the tree darkens, loses its density, begins to rot and collapse.

With an excessive amount of moisture in the tree, spores of mold, fungus, mosses settle, which have a negative effect. Also, the tree is susceptible to insects, rodents and other pests.

Protection of the facade of a wooden house consists in processing the material with various chemicals - impregnations, stains, paints, varnishes and covering the facade walls with other materials - clapboard, siding, plaster. The second option does not exclude the use of chemical protection (in many cases even provides for it) and is aimed more at enhancing the thermal and moisture-repellent characteristics of a wooden house and at improving the aesthetics of the building.

The main tasks of the cladding are:

- protection of walls from external influences;

- creating a barrier to heat loss;

- home decoration.

When choosing the option for finishing the facade of a wooden house, there are certain rules regarding the physical properties of the cladding, its cost and manufacturability of installation and maintenance of it.

First you need to consider such a property as vapor permeability. Wooden walls "breathe" - they are able to accumulate moisture from the atmosphere or the interior of the house and give it back when external conditions change. It is impossible to make the outer skin completely sealed - it must ensure free gas exchange with the external environment, that is, it must be vapor-permeable. In this case, the vapor permeability of the cladding should be greater than that of the solid wall. This will allow excess moisture to be removed to the outside and not to the inside of the house.

We invite you to read How to remove a felt-tip pen from wooden furniture?

If this rule is not followed, moisture will accumulate at the border of contact between two materials and form a zone of high humidity - an extremely favorable environment for the development of rot, mold and other phenomena unpleasant for the tree. At low temperatures, water, if it has accumulated enough, will freeze and turn into ice, which, expanding, can destroy the lining.

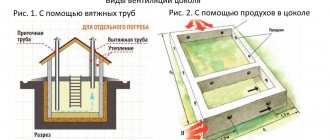

Ventilated facade construction.

If a wooden house is finished with a vapor-proof material, then a ventilated facade must be installed. The essence of the design is that the outer vapor-tight or relatively vapor-permeable layer is 60 - 150 mm from the wall surface.Holes are left in the lower and upper parts of the skin through which natural air circulation takes place and excess moisture is removed by convection currents.

Some difficulties with the installation of external cladding may give you an idea - is it needed at all? There is good reason to answer positively. Not just necessary, but necessary. Even if you like the look of a log house or a flat bar, sooner or later the house will have to be sheathed.

The tree must be treated with protective agents at regular intervals. This entails significant costs that increase the cost of operation. By choosing the right material and finishing, the annualized operating costs will be significantly lower.

Natural wood materials used for the exterior cladding of a wooden house

When choosing the best way to finish the facade of a wooden house, natural wood materials inevitably come into view:

- lining;

- block house;

- imitation of a bar;

- planken.

All of them have obvious advantages as a natural material, but they also have the same disadvantages as any wooden product. This leads to the fact that, in addition to the cost of purchasing the material, it is necessary to incur certain costs for finishing with antiseptics and top varnishes and paints. It is worth noting that finishing the facade of the house with a block house is an excellent option.

Lining

The cheapest and most technologically advanced type of cladding made of natural wood is slats with profiled sides forming a groove / ridge connection. During installation, the lining is firmly and tightly connected and forms an almost monolithic surface.

For finishing, exclusively dry lining is used, with a moisture content not higher than 10 - 15%. If you use insufficiently dried lining, then it will inevitably dry out and gaps will appear along the mating lines.

There are several standards for lining, its average dimensions are as follows:

- thickness - 12 - 40 mm;

- width - 76 - 200 mm;

- thorn length - 4 - 5 mm;

- length - 2 - 6 m.

The installation of the lining is carried out in a horizontal position, starting from the bottom, with a spike up. If you set it up with a groove, then the water flowing down the wall will fall into the castle and eventually destroy it and the lining itself. With proper installation and proper care, the lining from the lining will last 10 - 15 years, and if it is saturated with modern antiseptics, then even longer.

Lining is essentially a thin board

The advantage of such cladding is its low cost and ease of installation. Anyone who can hold a hammer in their hands and use a building level can cope with the installation.

Imitation of a bar

It is the same prefabricated surface as the lining, but slightly different in appearance. It is also installed horizontally, only visible joints are practically invisible. After final installation it looks like a wall made of profiled timber. It is made from spruce, pine, cedar or larch, due to the resinous nature of these species, it is quite durable.

The material is produced in the form of boards 2 - 4 m long, 20 - 35 mm thick and 105 - 175 mm wide. You can buy a solid board, cut from one log, or spliced, glued under pressure from narrower slats. In terms of performance, both types are approximately the same.

Pros and cons are similar to clapboard. The imitation of timber wins only in appearance - the material is more modern and decorative.

Block house

An excellent finishing material that can be used to sheathe the facade of a wooden house, made in the form of planks with a semicircular outer side. When assembled, the material creates the appearance of a log cabin. Very decorative, durable and no more difficult to install than lining. Compared to clapboard and imitation timber, the block house is more durable, keeps heat better and is much more durable.

For the manufacture of lamellas, conifers are used, in most cases pine and spruce.Impregnation with various stains, glazes and glazing materials allows you to give the finish the look of any valuable wood species. When painting with oil or alkyd paints, most of the effect of using a block house disappears (in the case of imitation of a bar, this does not happen).

Planken

Comparatively new material in our latitudes. It is a facade board with beveled or rounded side edges. Made from pine, larch or wood-plastic materials. The width of the board is in the range of 70 - 140 mm with a thickness of 15 - 20 mm, the bevel angle of the edges is 45 - 700.

It is mounted on special fasteners in a spike or overlapping. It is very convenient for installing ventilated facades. As a rule, it is sold in a form treated with fire retardants and antiseptics, therefore it is resistant to biological pests and safe in a fire sense. In most cases, high-quality planken is impregnated with environmentally friendly means, but it will not be superfluous to check the certificate when buying. Cheap materials can be handled with toxic chemicals.

The choice of insulation

When creating a ventilated facade on a wooden house, the owners prefer not to save money, therefore they use an integrated system. It involves the installation of not only the frame and cladding, but also heat-insulating material. You can choose different heaters, but the types are usually bought:

- mineral wool, produced in the form of slabs;

- ecowool;

- penoizol.

Only mineral wool is an environmentally friendly and safe material that does not contain synthetic components. Therefore, it is ideal for timber construction. It is bought in the form of slabs, which are cut into separate elements that are fixed to the walls of the building between the frame elements.

Insulation layer size

The materials with which it is planned to insulate the facade of a wooden house are selected depending on the preferences of the owner or on which technology was chosen (wet method, ventilated facade or subsequent siding). But the thickness of the layer is determined based on the climatic conditions of the region in which the building is located. The table shows the average thickness of the insulators used.

| Region | The optimal size of the insulation layer, cm |

| Leningrad region | 10 |

| Moscow region | 10 |

| Novosibirsk region | 15 |

| Sverdlovsk region | 10 |

| The Republic of Mordovia | 10 |

| Samara Region | 10 |

| Republic of Tatarstan | 10 |

| Krasnodar region | 5 |

| Volgograd region | 10 |

Help from the "facade"

If your region is not in the table, ask in the comments, we will definitely answer you!

Choosing a protective film

The correct technology for mounting the structure is to use special films. They provide protection of the insulation from moisture and wind, and also allow steam to pass through easily.

Usually a windscreen or a universal diffusion membrane is chosen. The latter option is the most acceptable, since the material allows air to pass through, but protects the insulation from moisture. But the diffusion membrane is expensive, so it costs a lot to cover the whole house.

Ventilated facade installation

As soon as the necessary materials for the work are selected and purchased, the direct installation of the structure begins. For this, successive steps are performed:

- preparation of walls, which must be clean and strong, so all rotten areas are removed and mold is treated;

- a crate is formed, and for wooden buildings, slats are considered the ideal choice, and not metal profiles;

- insulation plates are laid between the parts of the frame;

- erection of the second level of the frame, which is installed perpendicular to the first layer;

- installation of a second thermal insulation layer, and the procedure is performed in such a way as to overlap the seams of the first layer;

- overlapping membrane or film installation with gluing of seams;

- the formation of a counter-lathing;

- installation of plates.

Attention! The structure of the ventilated facade should not contact the ground in any way, and if there is a base / plinth, then the installation is carried out on a special metal ebb.

Insulation laying rules

The insulation process depends on the material chosen. Usually, mineral wool slabs are used to insulate a wooden house. They are cut into separate elements, which must fit tightly into the gaps between the frame elements.

Sprayed thermal insulation is considered more simplified. It is applied with special equipment. It turns out a seamless and durable layer, but a lot of money is spent on its creation, and you will also have to use modern equipment.

Sometimes rolled thermal insulation is used, so the rolls are simply rolled along the wall between the parts of the frame, fixed with brackets or other fasteners.

The most common methods of insulation

There are some materials that are not often used for cladding the walls of a wooden house, but it is still worth considering them as a cladding material. First of all, this applies to materials such as corrugated board and facing bricks.

Facing brick

The brick facade of a wooden house is now a rarity. But it has the right to life, thanks to its extremely high strength, frost resistance, decorative effect. But when installing a brick facade, it is necessary that the house stands on a concrete foundation - the weight of a wall, even half a brick thick, is quite impressive.

Installation of a brick facade is carried out only after the complete shrinkage of the wooden house, otherwise damage is inevitable. A ventilation gap of at least 5 cm between the finish and the wall is absolutely essential. The attractiveness of a brick facade lies in the fact that it does not require any maintenance at all. The natural appearance has been preserved for many decades.

Professional list

In addition to special facade materials, the walls of a wooden house can be sheathed with an ordinary profiled sheet. The profiled sheet is made of galvanized steel covered with a polymer protective coating. Usually this material is used for finishing technical structures. But thanks to a wide range of design solutions, today corrugated board imitating wood, stone or brick is produced.

The main disadvantage of the material is its inability to pass steam. That is why it can only be used for cladding ventilated facades. In addition, when exposed to strong mechanical loads, the material can bend. At the same time, it is practically impossible to bring the material back to its original even state.

When choosing a heater for the walls of a house, first of all, it is necessary to take into account its thermal insulation characteristics. In addition, an important factor is the tendency of the material to "slip". Different installation technology implies special requirements for thermal insulation.

The structure of wall insulation is similar to a layer cake. The design consists of several layers:

- Heat insulating material;

- lathing (not required in case of wet facade installation);

- vapor-permeable moisture-proof membrane or reinforcing mesh (depending on the selected technology);

- finishing layer of facing material.

useful in work

Professionals call the technology of wall insulation with a wet method - a pie. The thermal insulation material is glued to the facade using adhesives, then treated with decorative plaster.

Wet facade

The construction called a wet facade (cake) requires the use of only dense materials, since the subsequent plastering of the surface will be impossible when using rolled Ursa fiberglass wool, which has a low density of 11 kg / m3.

Ventilated facade

The technology of wall insulation with a ventilated method is usually used in the construction of shopping centers or high-rise residential buildings; in private construction, an analogue of this technology is siding, but more on that later. The ventilation façade is usually installed with mineral wool insulation. A special frame (lathing) is organized, cladding is attached to it. It should be noted that the choice of cladding is very large. From heavy stone to light modern aluminum composite material.

The basic principle is the circulation of air between the insulation and the facing layer. Thus, the dew point from the insulation leaves with updrafts.

It's important to know

Failure to comply with technical requirements when installing a ventilated facade leads to dire consequences. For example, if there are no special gaps between the vertical struts of the profile, which are necessary to compensate for the thermal deformation, the system will “bend”, the facing layer will be broken, and the money will be spent “on the wind”.

Siding decoration

This method of wall insulation can be called the most common, since it is inexpensive, and all the work can be done by hand. In fact, it is very similar to the ventilated method, the difference is that there are no lugs for air inflow and outflow. Ventilation is provided through special holes located in each panel. Materials can be used of any density; you can firmly fix the insulation on the wall using the lathing.

The only reason why it is necessary to insulate a wooden house is insufficient thermal protection. This term from the normative documentation really reflects the situation after the introduction of a new standard - SNiP 23-02-2003.

The standards for thermal protection of residential buildings in force until 2003 were “soft”. The latest revision was put into effect back in 1979.

when they did not think about energy saving at all.

The walls of a wooden house made of timber 20 cm thick in central Russia fully complied with these standards.

If we take into account that the thermal conductivity of dry pine is 5-6 times lower than a full-bodied ordinary brick and 4 times lower than a slotted facing, then 20 cm of a beam is equivalent to a brick wall with a thickness of 1 m.

The new standards are very “tough”. The estimated thickness of the walls of wooden houses according to the new standard should be slightly more than 50 cm, and brick - two meters.

You can do nothing and pay the growing bills further. But it is better to invest once in insulating a house, even a wooden house, and save money in the future.

How to insulate?

Before insulating a wooden house, it is necessary to choose technology and materials.

According to the current Russian code of rules SP 23-101-2004 (clause 8.11), there are three types of external walls according to the number of main layers of the structure:

- single-layer;

- two-layer;

- three-layer.

Single layer. These are timber frame houses in which the walls at the structure level combine bearing and thermal insulation properties. They are not insulated.

We invite you to familiarize yourself with an unpleasant smell in a wooden house

Three-layer. These are walls with external railing on point links with a minimum thickness of the external layer of 50 mm. But such technologies for a wooden house are laid at the construction level. But the brick facade can be insulated with flexible connections during repair and reconstruction.

Therefore, the insulation of the walls of an already built wooden house is a typical two-layer construction.

There are recommendations in the regulations and how to properly insulate a wooden house in order to ensure the durability of the structure.

SP3-2000 (clause 7.2.2) and SP 23-101-2004 (clause 8.11) indicate that this must be done outside. In exceptional cases, wall insulation is allowed from the inside. For example, if it is an architectural monument or a facade of historical value.

Insulation from the inside is allowed only if a continuous layer of durable vapor barrier materials is created.

There are two types of double layer wood exterior walls:

- no gap between the structural material of the wall and the insulation;

- with a ventilated air gap between the cladding and the insulation.

Air spaces in insulation systems can also be non-ventilated. But according to SP 23-101-2004 (table 4), this option is not provided for wooden walls.

If we translate the normative formulations of the species into the usual ones, then we can talk about three ways of warming:

- "Wet" facade;

- sprayed thermal insulation;

- ventilated facades.

Usually they choose among two types of insulation - mineral wool and expanded polystyrene (conventional or extruded).

The regulations do not prohibit the use of expanded polystyrene as insulation for the walls of a wooden house. In the same table 4 of SP 23-101-2004, it is recommended as a type of material for various technical solutions and it has the best thermal insulation properties.

But below in clause 8.5 there is a requirement that the location of the layers should exclude the creation of conditions for the accumulation of moisture in the enclosing structure and contribute to its drying - the weathering of water vapor. And in this case, the vapor permeability of each layer is important.

To prevent the structure from getting wet, the vapor permeability of the materials of multilayer walls must increase (or be equal) in the direction "from the inside out".

Wood is a unique building material with non-uniform breathability, and this must be taken into account. Pine has the lowest vapor permeability coefficient along the grain, and across it is the lowest.

But rounded logs and beams, like any lumber, have a surface of cut fibers, so their vapor permeability across the fibers is higher than that of a log.

And the condition for the correct arrangement of layers according to this indicator corresponds to the only insulation - mineral wool. Neither expanded polystyrene nor polyurethane foam (sprayed insulation) In some articles, you can find references to PVC foam.

In terms of vapor permeability, it is the best thermal insulation material in its class, and in terms of strength it belongs to structural ones, but it is very expensive. For reference: PVC foam elements are used as insulation for hulls of small ships (yachts and boats).

https://www.youtube.com/watch?v=WePqwTequSg

Therefore, to the question of what is better to insulate a wooden house, the answer is unequivocal - with mineral stone wool.

Regardless of the technology chosen, work begins with the preparation of the facade.

All hinged elements must be dismantled from the surface of the walls: gutters, ebbs, plates, visors, lighting fixtures and elements of engineering networks that can be removed.

At log cabins and houses made of ordinary timber, the condition of the inter-row seals is checked, if necessary, caulking is carried out.

The entire surface is treated with an antiseptic at least two times. Work should take place in stable "dry" weather.

Antiseptic treatment by the "staining" method does not provide such a deep penetration of the solution into the structure of the tree as soaking or impregnation. Therefore, in this case, it is especially important that the wood is dry.

When insulating a new wooden house, of all types of work, an obligatory step is to treat the walls with an antiseptic.

This is a standard insulation technology, but its peculiarity is that mineral wool is loaded with a layer of plaster, so it must be fixed with an adhesive mixture and mechanical fasteners. And in order for the insulation plates to be glued to the wall, they must be even or with small differences in the height of the surface relief, which can be compensated for with a layer of glue.

Installation of cladding

This process is the final step in creating a ventilated façade. The rules for its implementation include:

- cladding slabs can be placed vertically or horizontally;

- they are fixed with self-tapping screws through special holes made at the factory;

- only zinc fasteners are used, which are protected from the corrosion process;

- slabs are equipped with special grooves and spikes, with the help of which they are firmly connected to each other, forming an even coating;

- the styling procedure is performed from the bottom up;

- from below, the elements are fixed and closed with a special mesh, which prevents insects or rodents from penetrating under the sheathing;

- a drain is provided for water flowing from the roof;

- in the corners, you will have to cut the panels, for which a grinder is used, equipped with the necessary nozzle.

Attention! The indisputable advantage of the ventilation facade is considered to be a small mass that does not exert a significant load on the foundation of the building.

During installation, only high-quality and certified materials with positive parameters are used. It is recommended to abandon Chinese or fake items that quickly fail, deteriorate under the influence of atmospheric factors and quickly lose their attractiveness.