Ventilated facades are very popular among private developers. The design under consideration allows you to simultaneously provide high-quality insulation and a beautiful appearance of a residential building. Anyone can handle the arrangement of a ventilated facade with their own hands. However, before starting work, you need to consider the main features of the system and select materials for assembling the battens, wall insulation and finishing cladding.

DIY ventilated facade

General information about ventilated facades

First of all, you need to study the features of hinged ventilated structures and understand their main purpose.

Ideally, the finishing decorative coating should have good vapor permeability. In the course of their life, people release a lot of moisture: cooking, bathing procedures and other household activities - all this leads to an increase in air humidity. Some of the moisture escapes through the ventilation system along with the exhaust air, while the remaining moisture must escape through the pores in the facing material.

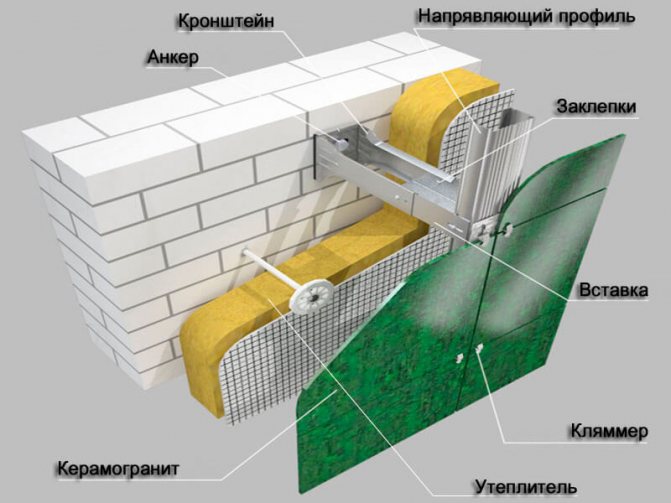

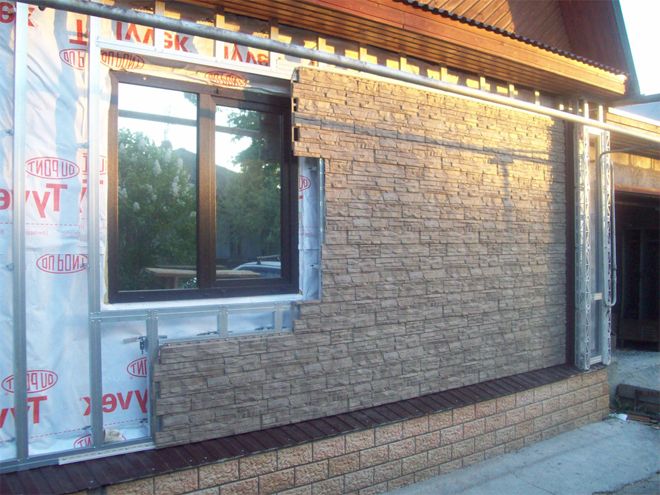

Ventilated facade made of porcelain stoneware

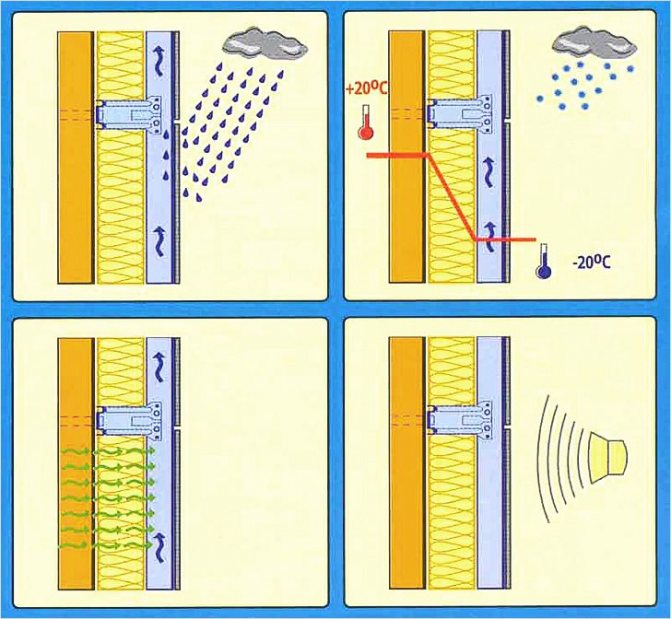

The vapor barrier should be equipped in such a way that the wall material is as vapor-permeable as possible inside the room and has minimum performance on the outside. This rule is relevant for all types of facades. Violation of this recommendation usually leads to a deterioration in the thermal insulation qualities of walls and a decrease in their durability.

At the same time, the facade of the house must be reliably protected from atmospheric precipitation. In this case, it is best that the outer part of the walls does not get wet, because this will lead to a reduction in the service life of the structure.

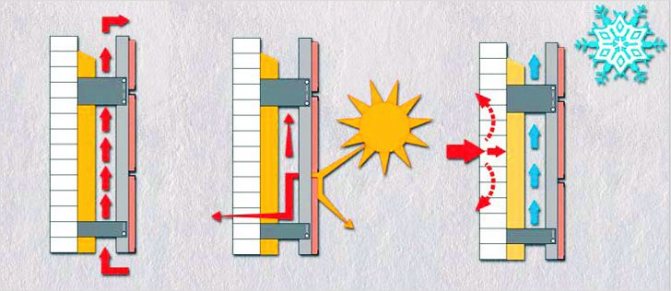

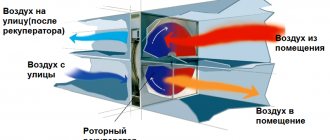

The most progressive façade system is a curtain-ventilated façade.

Some logical contradiction follows from the information given. But there is a completely understandable and simple solution: to ensure optimal waterproofing and vapor permeability, the protective facade coating must be fixed at a certain distance from the wall surface, while simultaneously providing high-quality ventilation of the gap. It is this structure that is commonly called a ventilated facade.

What is

Ventilated facade

What is a ventilated facade? This is a new technology for building exterior cladding. It is made in the form of a strong frame on which the facing materials are fixed.

The frame is made from the following materials:

- Cink Steel,

- aluminum,

- stainless steel.

Due to the design features of the facade, an empty space remains between it and the building in which air can freely circulate. A high level of ventilation prevents moisture, condensation and vapors from settling on the walls of the building. A ventilated facade is often used as additional insulation. In this case, the building is faced with thermal insulation materials. In most cases, it is customary to use mineral wool insulation or expanded polystyrene material.

Design advantages and disadvantages

Hinged ventilated structures have a number of advantages. But, like in principle all existing ones, such systems have some drawbacks.

Benefits

Among the main advantages of ventilated facades are the following provisions:

- insulation allows you to significantly save on heating the house;

- waterproofing in combination with a ventilation gap eliminates the risk of moisture retention on the walls, which significantly increases the service life of the materials used;

- ease of arrangement. You can handle the installation of all elements of the ventilated facade with your own hands;

- increasing the soundproofing properties of the walls.

disadvantages

Among the disadvantages, moreover, relative, can only be attributed to the high cost of the structure. However, at this point, it is imperative to pay attention to a significant reduction in heating costs after installing a ventilated facade. All expenses for insulation, cladding and other things pay off quickly enough.

Choosing a protective film for the ventilation facade

The film should cover the insulation.

The technology of installing a ventilated facade of a wooden house involves the use of a protective film. It must have two most important characteristics - it is to release steam from the thermal insulation and prevent the wind from blowing into the mineral wool.

According to these criteria, the following is suitable:

- wind protection;

- diffusion membrane.

Do not confuse a diffusion membrane (also called waterproofing) with a vapor barrier. The latter does not breathe at all, it cannot be used for a ventilation facade in any case. Membranes are more expensive than windscreens, but they will not let water into the insulation. Although this is a finishing task, additional measures are not superfluous. Before buying, check the strength of the film, if it disintegrates in your hands - do not buy. It is better to overpay for quality right away than to redo the work later.

Tips before you start

In order for the finished structure to retain its high performance characteristics for a long time, for its arrangement it is necessary, firstly, to use high-quality materials, and secondly, to follow the rules for installing all components. Follow the instructions and there will be no problems.

Do not skimp on the purchase of building and finishing materials. High-quality material cannot cost much less than its average market value. Buy all the necessary items in trusted places, giving preference to reputable manufacturers.

Facade siding

Pay due attention to the choice of facing material. For example, tiles in many of its varieties are very suitable for finishing the facade. However, the tile has a very big problem - tearing off at least one cladding element leads to the so-called. “Domino effect”, as a result of which the usual gust of wind can tear off nearby tiles.

As a result, a hole will appear, due to which the characteristics of the entire structure will decrease. Therefore, if possible, it is recommended to refuse such a cladding.

Facade cladding with siding

The best finishing cladding for ventilated facades is siding. Subject to proper installation, the appearance, service life and other important characteristics of such a finish will not be inferior to other popular materials. You will receive more detailed information on the properties of siding below.

Life time

Although such structures have been used in our country not so long ago, it was created in Norway more than 50 years ago. Therefore, the Norwegians provide a lot of evidence for the durability of a ventilated façade. The service life depends on:

- Materials used for brackets and rails. Wooden beams will last up to 15 years, and metal ones - more than 50.

- The professionalism of the craftsmen who performed the work. A well-made construction lasts much longer.

- Facing material - the stronger and better the option, the longer it will delight the owner's eye. But with finishing, everything is much simpler, it can be replaced at any time, and the frame remains the same.

- Operating conditions.The harsher the environmental conditions, the faster even the highest quality material will become unusable.

Finishing

We have already mentioned the undisputed champion of this market segment - vinyl siding. The material has many advantages over existing alternatives, namely:

Vinyl siding

- siding is sold at an affordable cost. The difference becomes especially noticeable when comparing siding with porcelain stoneware or clinker tiles;

- the material is easy to process. You can use a simple hacksaw to cut the siding;

- siding is lightweight, so you don't have to worry about increasing the load on the foundation and walls of the house;

- a large selection of siding of a wide variety of colors and textures is available for sale, which allows you to choose the ideal finishing option for any site.

Vinyl siding

Cladding material

As a decorative finish, you can choose absolutely any option you like. The main thing is that the main structure, that is, the walls of the house and the foundation, can withstand such a load.

Often they choose as cladding:

- Siding panels.

- Fiber cement boards.

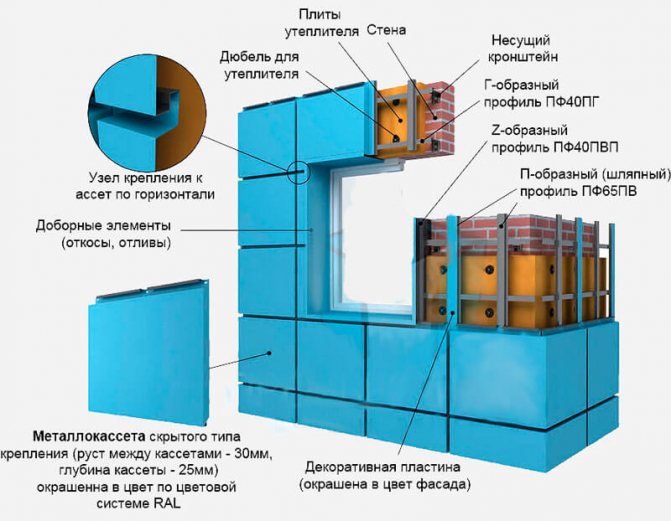

- Metal cassettes.

- Porcelain stoneware.

- Artificial or natural stone.

- Siding (vinyl, wood, metal).

Ventilated Facade Installation Guide

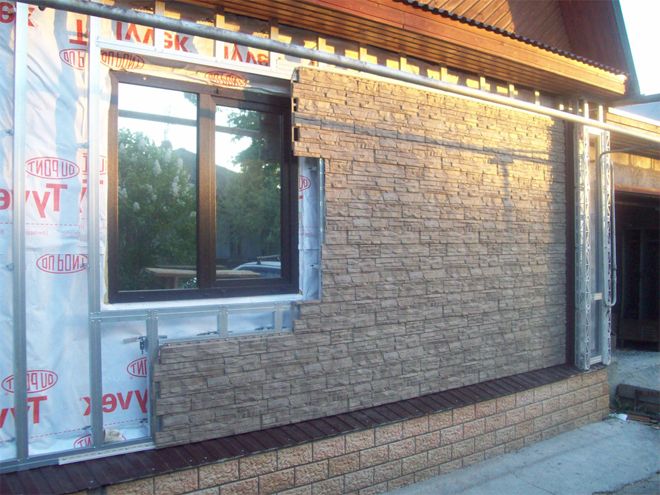

First step. Assemble the crate. Attach the bars to the wall vertically, in increments of a couple of centimeters less than the width of the insulation plates. It is more convenient to first fix the extreme slats, pull the string between them and, guided by the rope, fix the intermediate elements at the same level.

Metal frame lathing

Second step. Place the insulation between the battens of the battens.

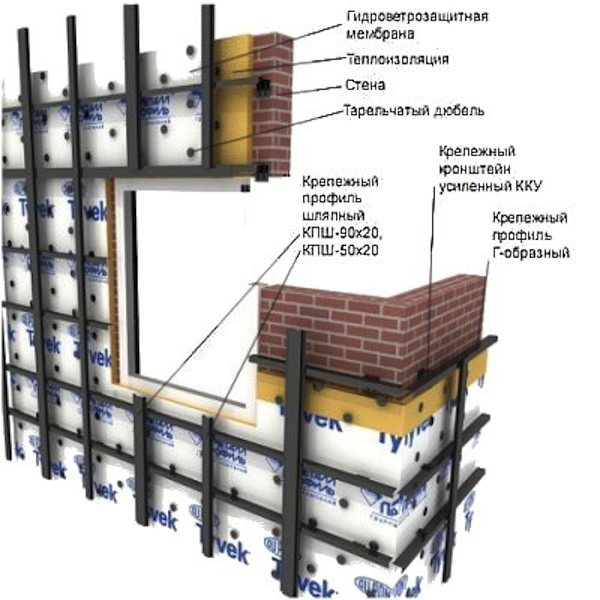

Step three. Cover the insulation with a vapor barrier membrane. Lay the vapor barrier strips horizontally with an overlap of about 10 cm.

Fourth step. Fill the perpendicular bars of the counter batten over the battens. This will create the required ventilation gap.

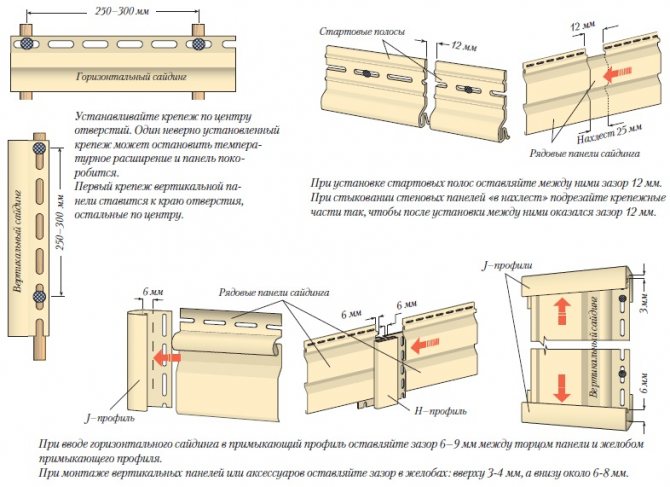

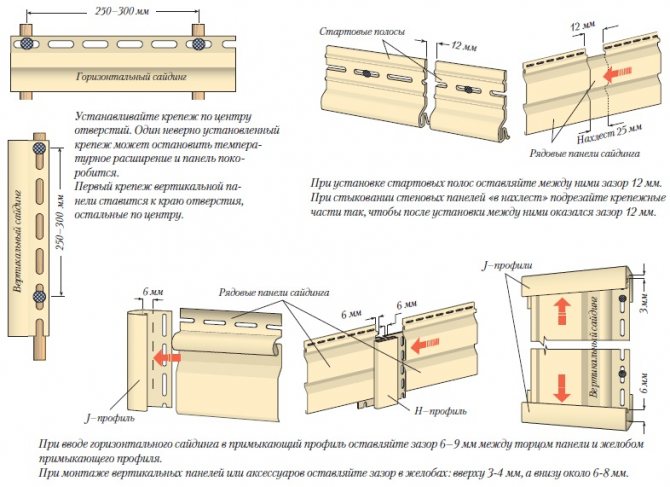

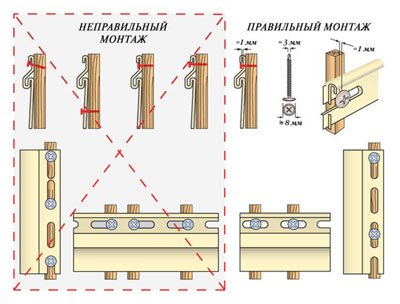

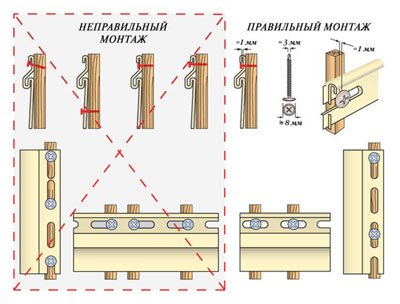

Fifth step. Attach the siding to the finished sheathing. The cladding is made of polyvinyl chloride. This material changes its size when the temperature changes, so rigid fastening of the planks is unacceptable. A small gap (3-5 mm) must be left between the panels. Hammer in the fasteners (screw in) not reaching the end by about 2 mm. Fasteners must be placed strictly in the center of the holes intended for them.

Vinyl siding

Installation instructions

Correct installation method

Device

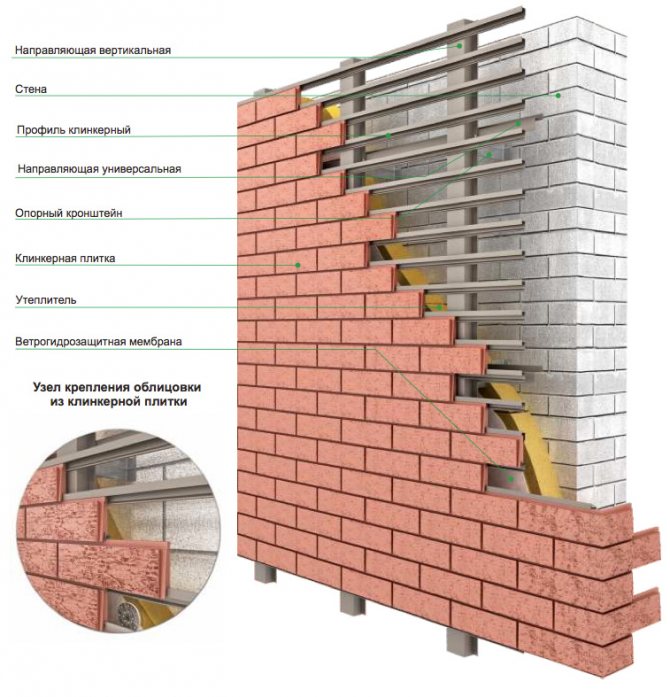

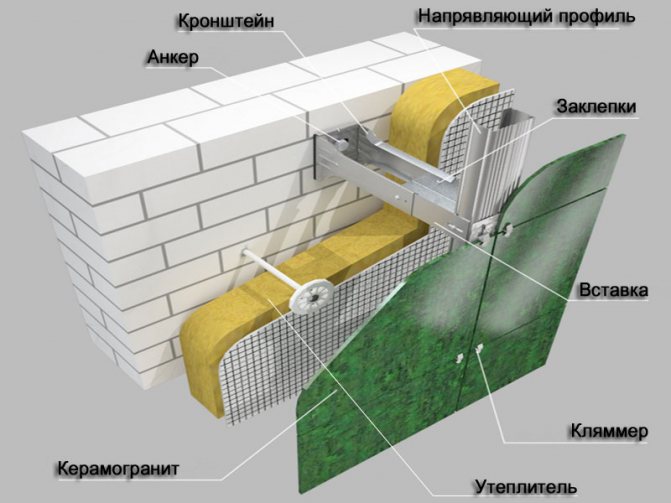

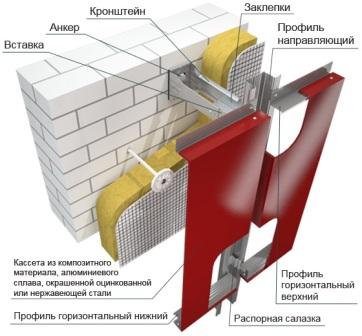

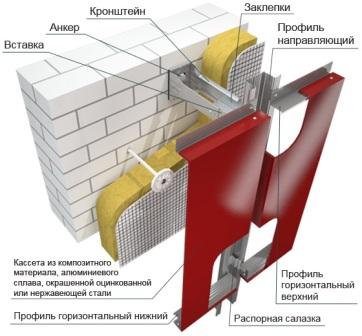

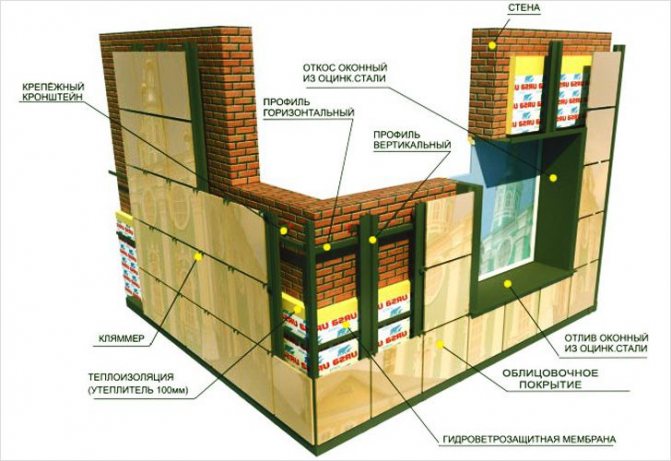

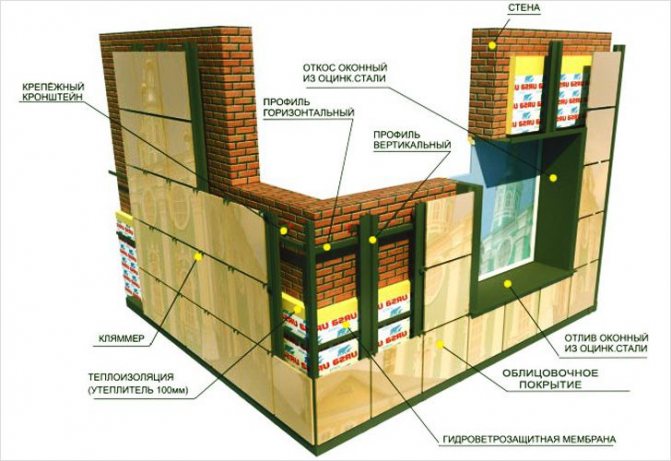

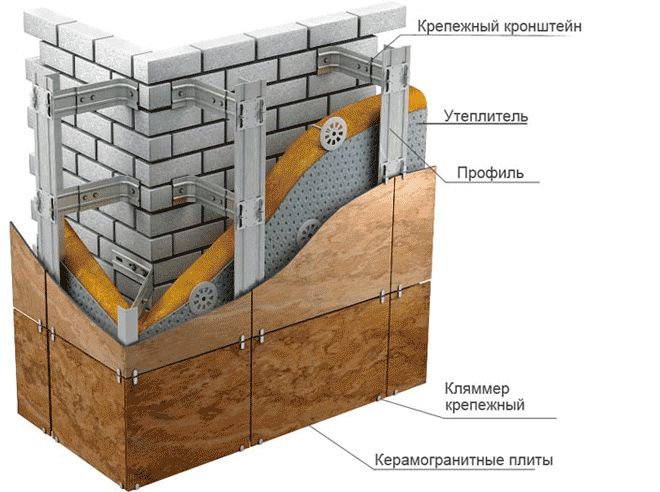

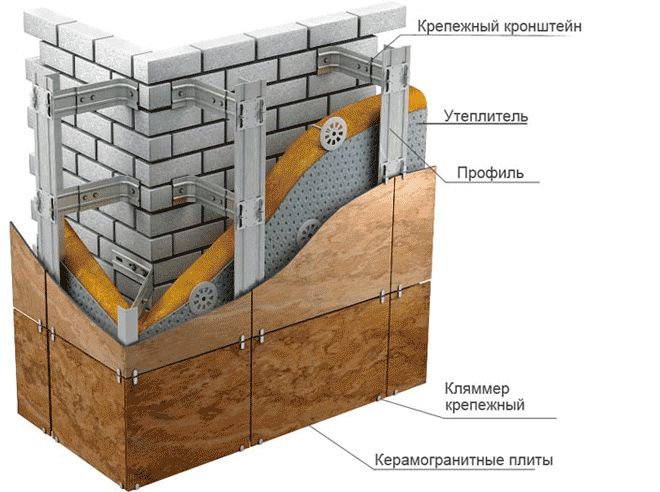

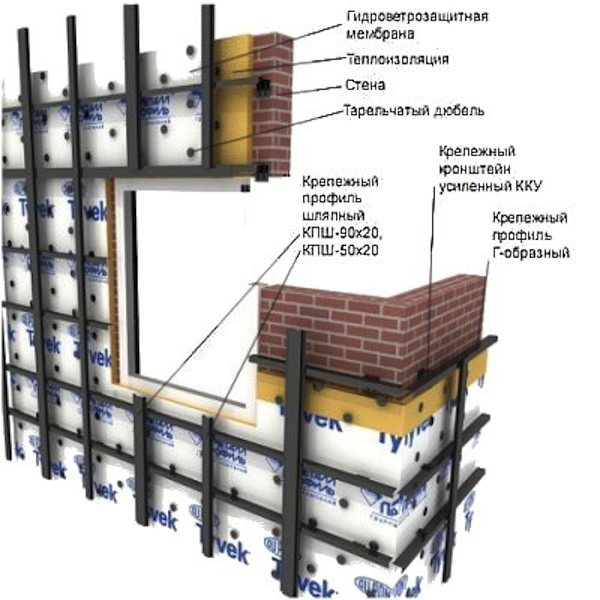

Ventilated facade systems are a multi-layer structure, the elements of which are:

- Frame subsystem, which is attached to the wall of the building and serves as a support for the entire structure. Most often it is made of galvanized or stainless steel or aluminum.

- Insulating layer. It is a multifunctional component that provides protection against moisture, steam, wind, cold, and also reduces the heat transfer of the building.

- Air circulation clearance. It is he who contributes to constant ventilation in the system.

- External decorative shell. Protects the lower layers of the ventilation façade and gives the building a presentable appearance.

Recommendations of professional builders

To make the work as easy as possible, and the finished ventilated facade retains its original characteristics for a long time, follow a few simple recommendations of professional builders.

Ventilated facade

- First of all, when installing a structure, you need to focus on an individual project developed specifically for your home. The project will allow you to competently plan the scope of work and calculate the required amount of materials.

- When choosing fasteners, be sure to check the quality of the dowels. Consider the parameters of the battens, insulation and cladding.

- The ventilated facade must not be built on walls made of hollow bricks, foam concrete and other materials with a density not exceeding 600 kg / m2.

- Thermal insulation materials are necessarily accompanied by the manufacturer's instructions, which describe in detail the procedure for fastening the material. Follow the recommendations. For example, a mandatory rule for all thermal insulation materials is some displacement of vertical seams.

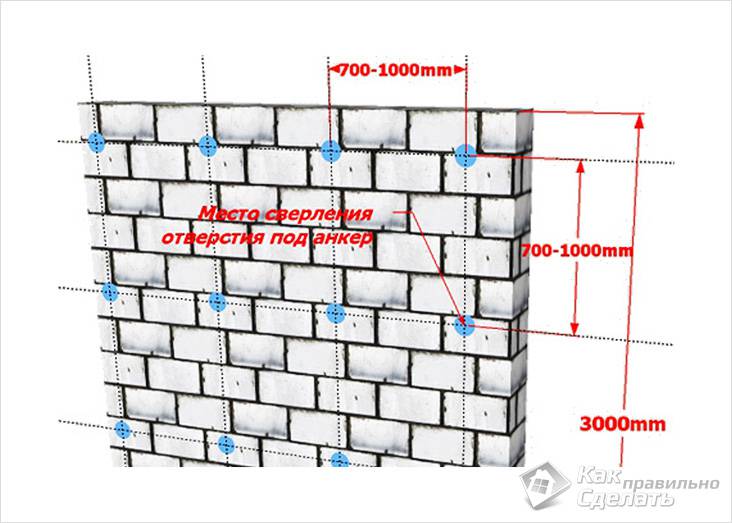

- Insulation and finishing material must be fixed strictly according to the level. Even a 5mm error for a 10m facade is an unacceptable deviation.

- The holes for the dowels are prepared exclusively with a drill. It is prohibited to use a perforator to accomplish these tasks.

- The design of a ventilated facade requires the presence of a counter-lattice. Thanks to this element, the gap necessary for ventilation of the space will be created.

Ceramic ventilated façade

Thus, there is nothing super complicated in the independent arrangement of a ventilated facade. It is enough to understand the basics of work, choose the most suitable materials and complete all planned activities in accordance with the instructions. Do not forget the recommendations received, and the ventilated facade of your house will serve as long as possible, while maintaining its original performance characteristics.

Happy work!

The choice of insulation

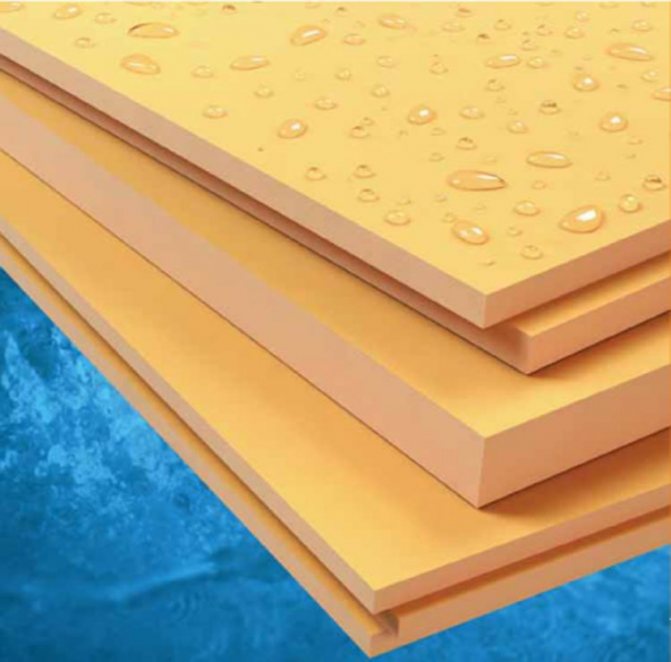

Insulation is an essential component of a good hinged ventilated system. As this element, it is worth using only mineral wool, since neither penoplex nor roll materials are able to provide the necessary technical parameters for the ventilation facade.

The standard thickness of mineral wool used for insulation is about 100 mm, although thicker types with additional insulation can be chosen.

Often the installation of cotton wool is carried out in two layers, the general principle of such a solution provides for density indicators of at least 50 kg / m3 and 80 kg / m3 for the lower and upper layers, respectively. More detailed advice on thermal insulation of ventilation facades with mineral wool will provide specific heat engineering calculations and recommendations from manufacturers of facade structures.

Installation process

How to make a ventilated facade yourself? Let's consider the main stages of work:

- Surface preparation. Cleaning the walls from dust and dirt. Impregnation of walls with a bactericidal solution.

- Marking the surface for installing the frame.

- Fastening the brackets in the marked places. They are necessary for holding and fixing the frame panels. To fix the brackets to the wall, you need to install them with anchors. Anchors must be coated with an anti-corrosion agent.

- Installation and fixing of insulation. It is necessary to make holes in the surface of the walls in which plastic anchors with a steel core are fixed. Insulation panels are fixed to the wall with an anchor cap.

- Installation and fixing of a layer of waterproofing film.

- Installation of the retaining frame. You need to install horizontal and vertical guides. They should be fixed with screws.

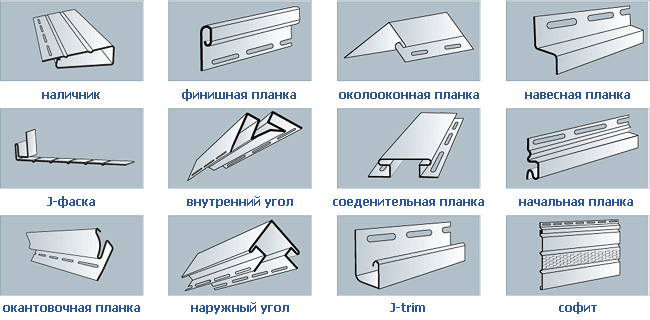

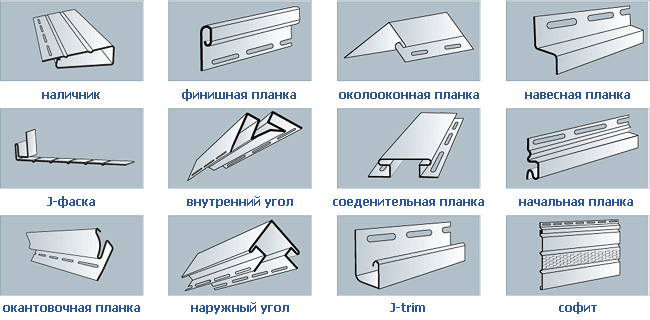

- Decorative plates are installed on the finished frame. Installation must be carried out horizontally, starting from the bottom row. The formation of gaps and gaps between the plates must not be allowed. Joints resulting from work can be closed with special panels.