07/11/2017 7253 Pechnik (Moscow) A metal fireplace with your own hands is a great opportunity to recreate an original heating structure, which will have a certain list of characteristics and an exclusive appearance. Despite the fact that it is quite difficult to create a metal hearth without assembly skills, it is quite possible to make the simplest option!

Do-it-yourself metal fireplaces will have the simplest design if classic solid fuel is needed for their work. Such foci, unlike electric and gas ones, do not require complex manipulations and lengthy assembly of the internal contents.

You can learn more about the preparatory work process, basic safety rules and a step-by-step assembly guide further or by watching the video in this article.

Design features

Iron wood fireplaces have an interesting design. The firebox, which looks like a chamber, stands on a special support or stand. There is no need to install an additional foundation for this heater, but due to the heavy weight of the unit, a reliable foundation must be provided.

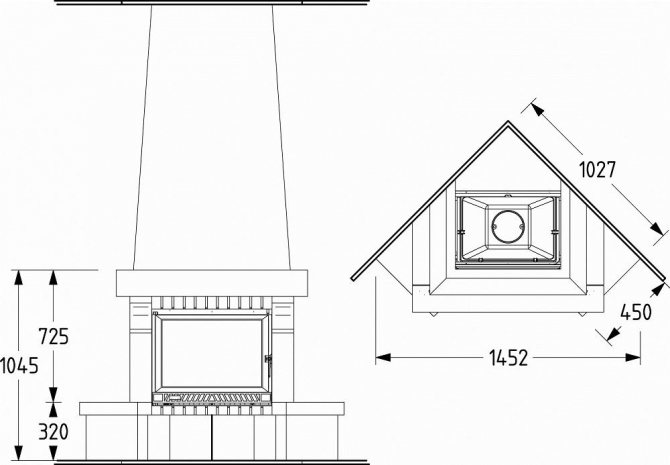

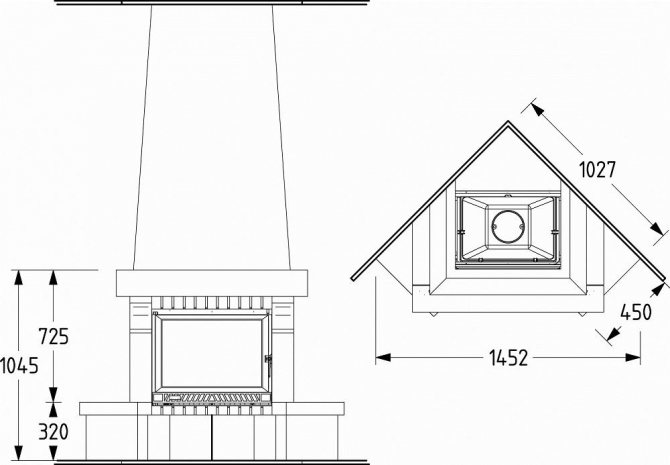

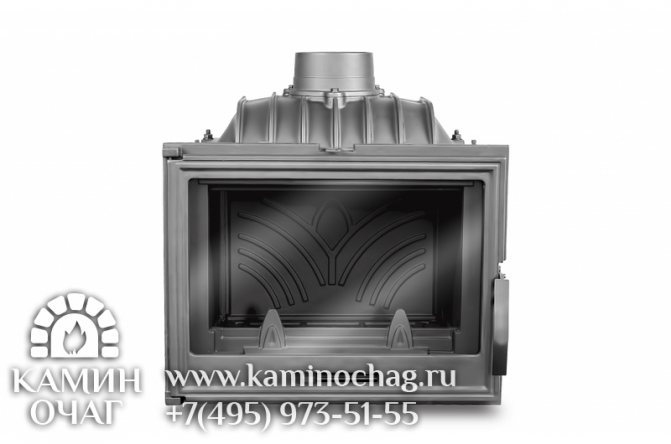

Metal fireplaces with side and top chimney connections

The firebox is connected to the chimney, which removes all combustion products from the heating system. To harmoniously fit the device into the interior of the house, its outer surface can be lined with refractory materials.

Finishing

In absolutely all cases, the resulting fireplace will have to be decorated outside. It can be simply painted over with a layer of glossy or matte paint. Here you need to remember the elementary laws from the physics course. Dark bodies emit more energy, and since our task is to remove energy, black colors will be a priority.

Good to know: How to choose a fireplace for a summer house on the wood, what types are there, how they work

The fireplace can be decorated with special refractory materials. These include ceramic, artificial and natural stone tiles. When gluing tiles, you should remember about the thermal expansion of the metal, so the joint gap should be slightly increased.

With the possibility of making a fireplace yourself, you have a lot of opportunities to realize your old dream exactly in the form in which it interprets itself. Desire and work in a certain sequence will serve to ensure an excellent result.

Varieties of aggregates

Depending on the method of placing the installation in a heated room, the following metal fireplaces are divided:

Built-in metal insert

- wall-mounted;

- corner;

- hinged;

- central;

- built-in.

In this case, there are different units depending on the shape and size of the firewood chamber. The firebox can be cylindrical, conical, parallelepiped or other geometric shape.

Types of fireplaces by location

- Built-in - their entire structure (firebox and chimney) is placed in the wall, which saves room space. Under and the portal of the fireplace is arranged above the floor level, and a brick floor is arranged in front and on the sides of the portal, while the bricks are placed on the edge.

- Attached - can be installed anywhere in the home. The only condition for installation is the presence of a fireproof wall or partition. Sometimes the chimney is attached to the chimney of an existing stove above the dampers. In this case, the stove and fireplace can be used both simultaneously and separately.

- Island - can be installed at some distance from the walls, for example, in the center of the room on a square or round area, towering 35-50 cm above the floor level. A square or round smoke collector is installed above the stove, made of sheet metal chimney. An example of island fireplaces is a metal hearth made by hand from a barrel or pipe 80-100 cm in diameter.

Metallic elements can be:

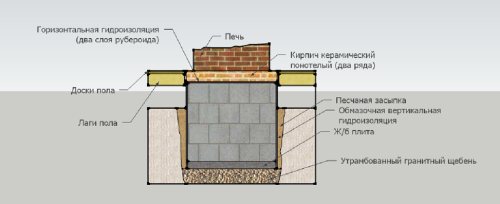

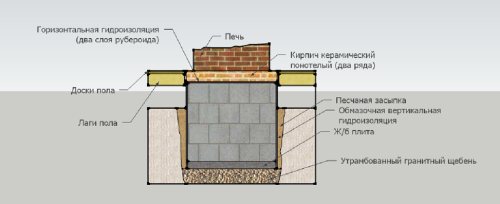

Diagram of the foundation for the fireplace.

- matte black;

- shiny black;

- completely smooth;

- with a corrugated pattern;

- decorated with a decorative stamp;

- with a minted design and other decorations.

A metal fireplace can work independently, or it can be combined with other materials, such as:

- natural stone;

- brick;

- tile.

Advantages and disadvantages of devices

A metal fireplace with wood has the following advantages over other types of heating devices for a private house or summer cottage:

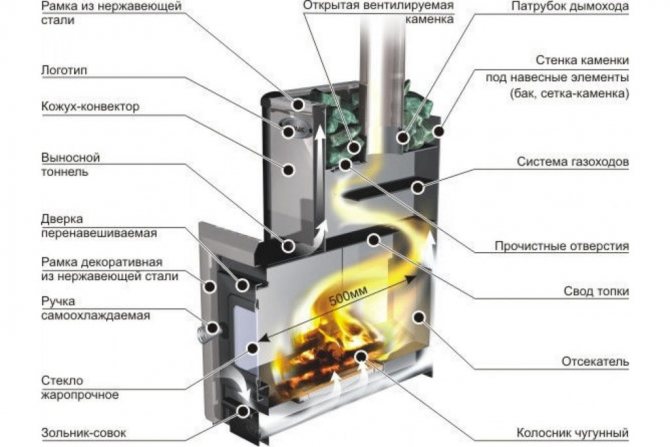

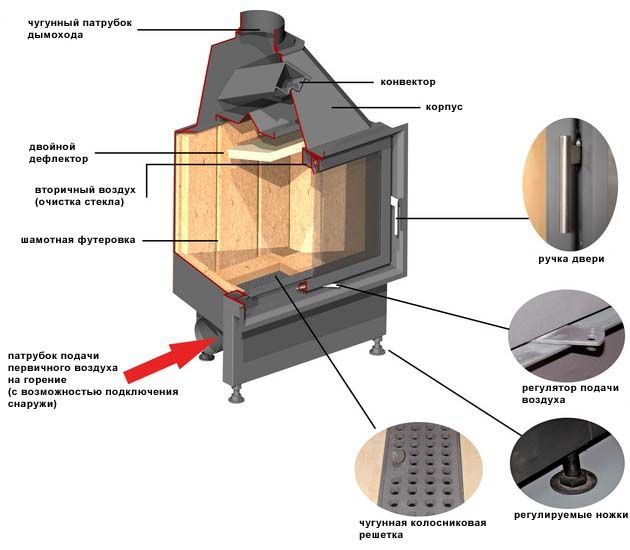

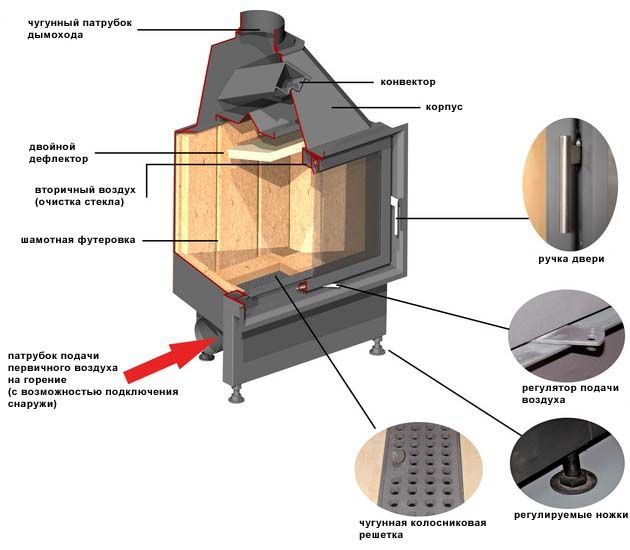

What does a metal firebox consist of?

- high efficiency;

- low weight of the unit;

- no specific maintenance required;

- ease of installation;

- lightning-fast heating of the room;

- can be installed anywhere.

Despite all the advantages that the user of wood-burning fireplaces receives, these devices have a number of disadvantages. First of all, it is very easy to burn yourself on the stove, since the body heats up very much during the heating. Also, this device cools down quickly enough, which contributes to the uneven distribution of heat in the room.

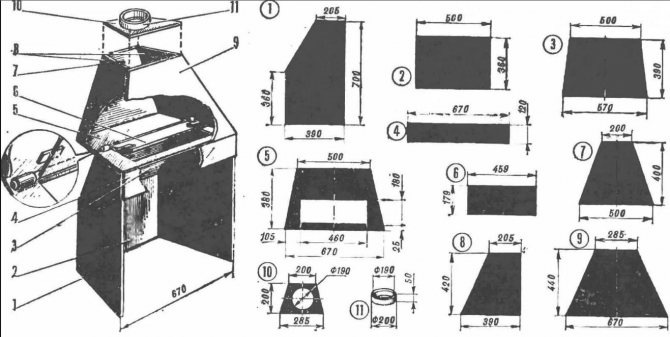

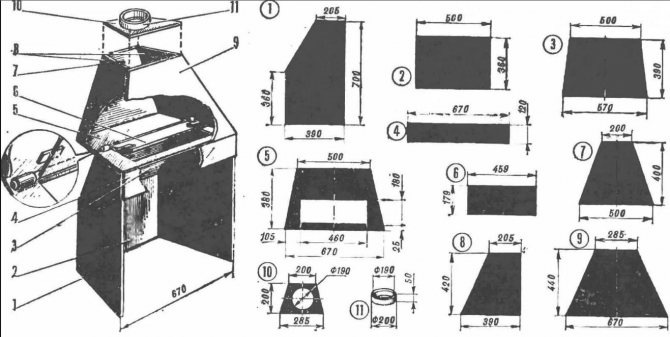

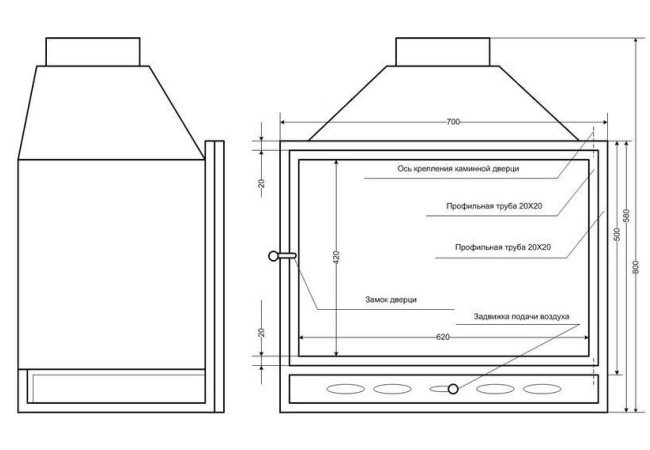

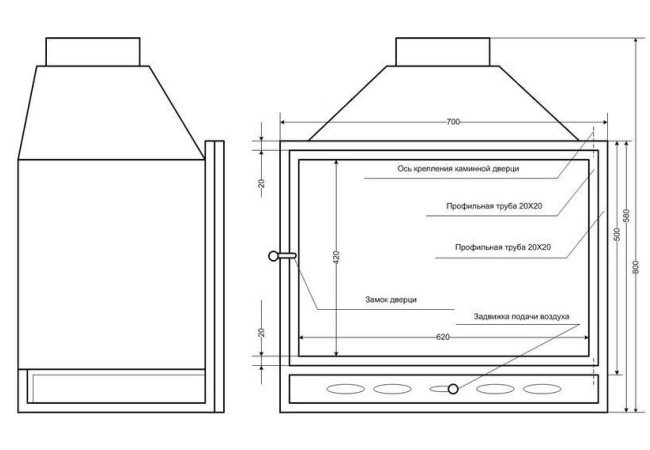

Do-it-yourself metal fireplace: drawings, as the main detail

It is very difficult to imagine a country house or dacha without a hearth. However, unfortunately, a brick fireplace, which is able to bring a note of attractiveness to the interior, puts forward a large number of conditions, which can be very difficult to fulfill. In order to make your dream come true, you can install a metal fireplace. But if you want to create it yourself, you will definitely need the corresponding drawings.

Before proceeding with the construction of a fireplace, it is worth completing its drawing on paper, indicating the dimensions of all elements

When planning and drawing up a drawing, be sure to keep in mind that a fireplace will require some free space, and of course a high-quality foundation of the house. All details are very important, because only if all the rules are followed, the fireplace will be able to please you with real, living fire.

Unlike brick structures, metal fireplaces do not require expensive foundations, since the structure does not have a large weight category.

Despite its low weight, the structure can easily heat a large room. And the crackling firewood and fire, which can be watched, will be able to create coziness and comfort for all residents. Another positive side is that in the case of a correctly drawn up drawing, you can get an increased efficiency than a brick-type fireplace.

What kind of fuel should you use?

For heating a summer cottage or a country house, it is best to use dry wood. In this case, give preference to aspen. A special type of metal aggregates is the stove, which uses pellets as an energy source. They are loaded into the firebox in the required volume, and the heating intensity is regulated automatically or using a manual control unit.

What kind of wood is better to heat

Also, some types of metal units can operate on gas. These devices are safer for heating, but it is impossible to make them yourself.

Metal furnace power

Despite the rapid heating of the walls and the same rapid extinction of the heat in the firebox, metal devices have a high efficiency - about 70-80%.How is it that a thin-walled furnace has such a high power? The thing is that each modern-made oven is supplemented with air supply adjustments. As soon as the air supply hole closes, a slow combustion mode begins inside the stove - the device works longer with less wood fuel consumption. The oven doors are closed very tightly, and fresh air does not penetrate through them. As a result, the burning time of one bookmark is 8-12 hours. The heat does not go out quickly, the stove gradually releases its energy. The gradual release of heat from a fired metal furnace is also caused by the presence of fireclay bricks inside, which is an additional heat accumulator.

Furnaces with a system of long (long) burning are also good in that they do not pollute the air - the exhaust gases are sent for recycling.

It is much easier to make a stove for a summer residence made of metal with your own hands than from a brick, and complex materials are not needed for such work - the most important thing is to equip with high-quality metal or cast iron and act in accordance with pre-drawn drawings.

.

Required materials for a homemade fireplace or stove

In order to make a stove with your own hands for heating a private house or summer cottage, you need to use the following materials:

- metal sheet 5 mm thick. This will be needed for the construction of a combustion chamber and a chimney;

- metal sheet 0.5 mm - for making an ash pan with your own hands;

- metal elbows for chimney;

- stainless steel pipes for the construction of a chimney;

- grate;

- solid door for the combustion chamber;

- various fasteners;

- stand for the case (corners and slats can be used).

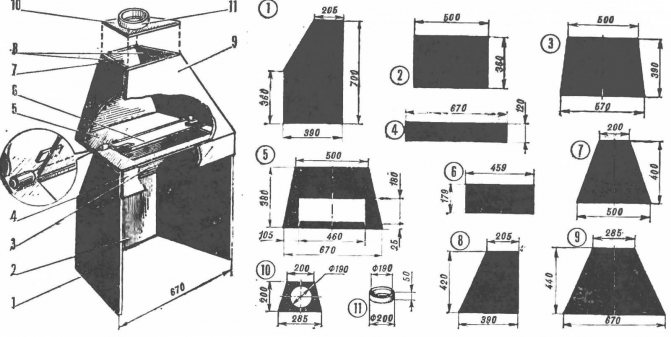

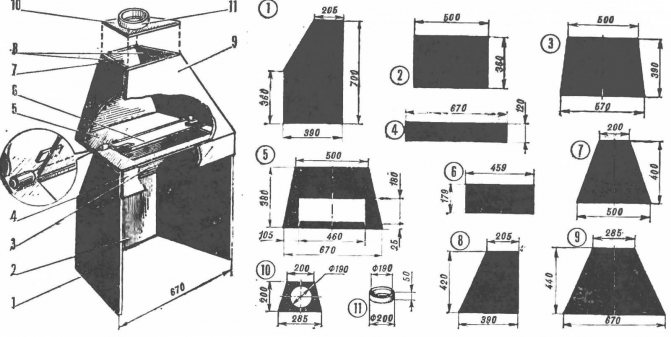

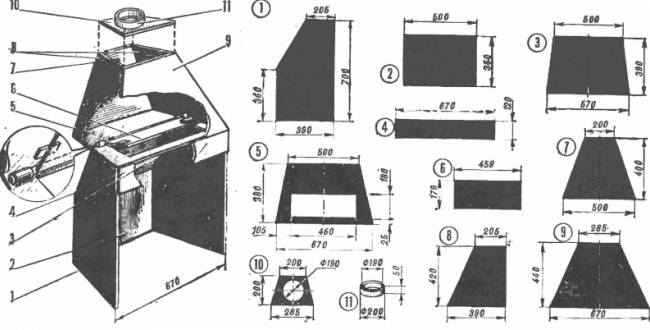

Scheme for making a homemade metal fireplace

Do-it-yourself fireplace with a cast-iron firebox

After preparing all the necessary materials, you need to start designing the stove. It is best to draw up drawings before the assembly process with your own hands, which will greatly simplify the installation of a heating device in a private house or summer cottage.

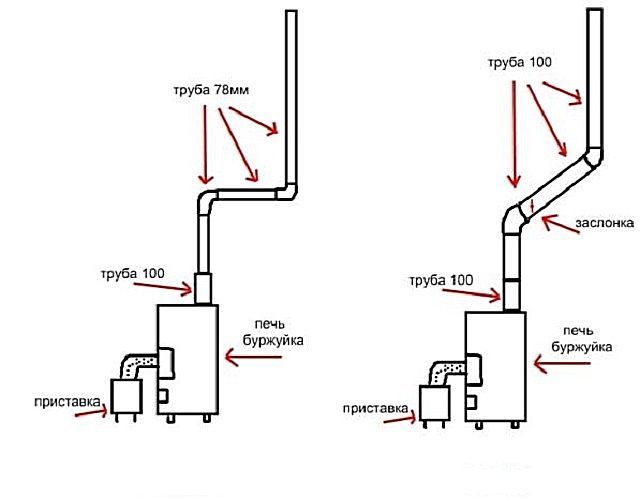

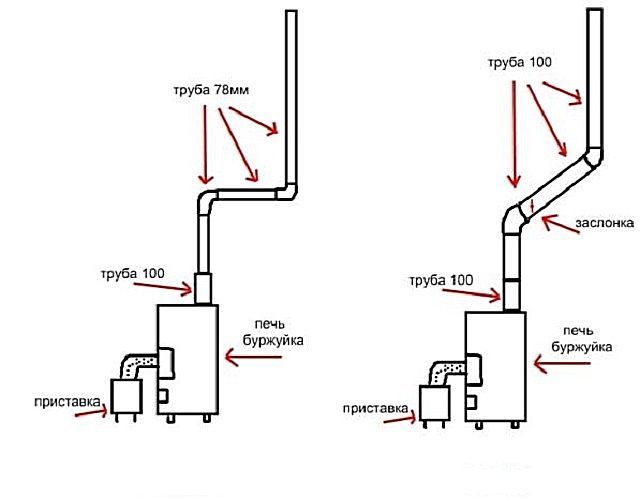

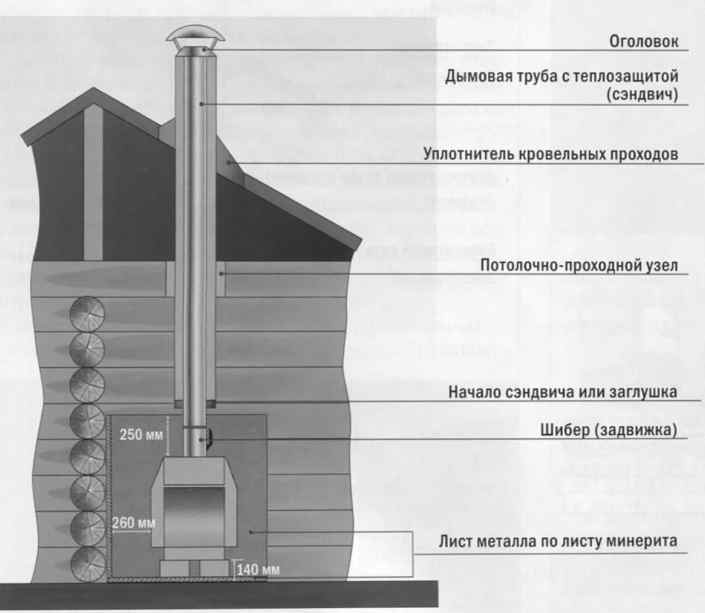

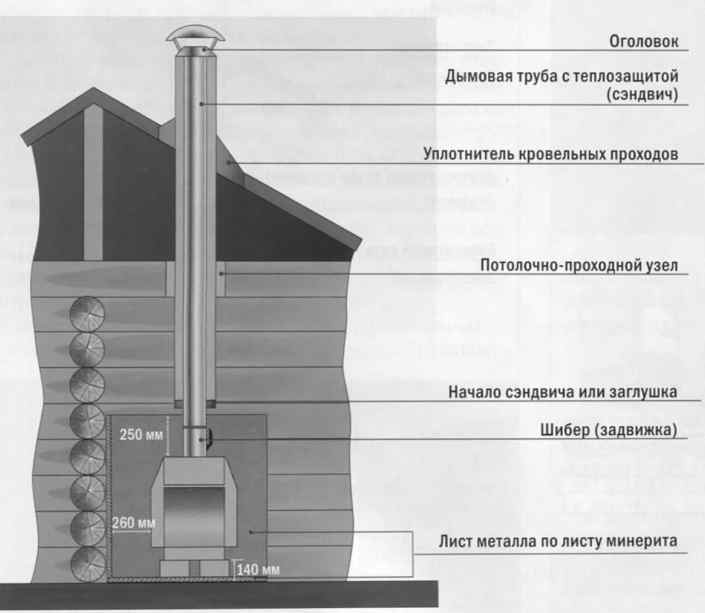

Chimney device for fireplaces

What is a chimney, what requirements are imposed on it, probably it is not necessary to say. The chimney is a long pipe, at least 5 meters, otherwise there will be problems with draft. The channel is led out into the street through the roof, in some cases it is allowed to lead out horizontally through the side walls. The main thing to remember is that it is better to do no more than three zigzags and turns, otherwise you are guaranteed problems with traction.

The pipe is installed in a specially cut hole in the lid, where it is fastened with a special fastening system. It is not recommended to weld "tightly". Do not forget that the joints, as well as all joints, must be treated with a heat-resistant sealant. By the way, the transition in the roof does not hurt to separate it with thermal insulation. The cap is brought out at a distance of 50 cm from the roof and it is recommended to install a flame arrester and a deflector on it.

How to make a heating stove yourself?

Step-by-step instructions for building a wood-burning stove for a summer cottage or a private house with your own hands: From metal corners, make a rectangular frame with legs, which will act as a base for the heating unit. Then attach it securely to the floor. Lay a sheet of metal on top of the frame.

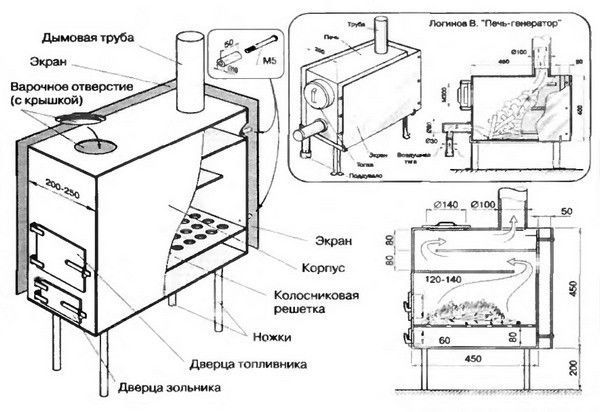

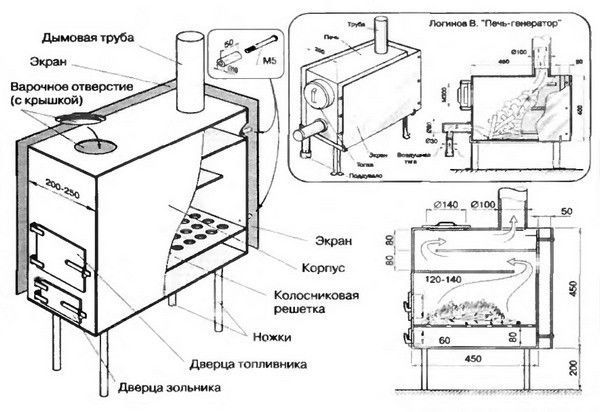

Drawing of a metal heating stove

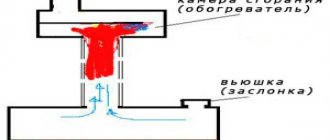

Build a box of sheets of metal that will act as a firewood chamber. The firebox should have double walls in order to increase the efficiency of the stove. Also divide its inner surface into two parts and install the damper. In the first compartment, the process of burning wood will take place, and in the second, the accumulation and removal of smoke.

Install the doors on the firebox, then install it on the prepared base.When the firebox is ready, proceed with the chimney arrangement. It can be made from pipes. They need to be joined together using sockets, and all seams must be lubricated with heat-resistant sealant. Use your knee to make the curved section.

Chimney for a homemade stove

Fix the chimney to the wall with clamps and brackets. So that the finished stove has a high fire safety, carefully insulate the nodes of the chimney transition through the ceiling. Do this with basalt cardboard and glass wool.

Cover the wall behind the fireplace with heat-resistant material. Perform the same operation for the floor near the heater.

In the bequesting stage, you can tile the stove. Homemade wood stoves should be placed in a place where a constant flow of air can be ensured.

Also, make sure that no flammable materials are placed near the heating unit.

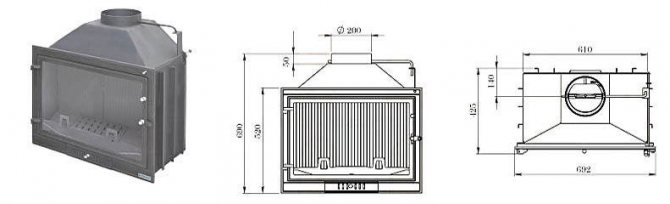

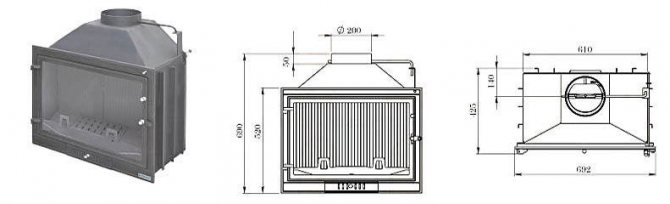

How to make a fireplace insert with your own hands made of metal

An integral part of a real fireplace is the firebox. It is made exclusively from iron sheet. It is divided into several parts. One will play the role of a firewood combustion chamber, and the second will play the role of a smoke chamber. Make sure that these chambers are separated by a special damper, which, if closed, will retain the generated heat. Such a firebox can be purchased at a specialized store, as well as it can be cooked by hand. This will require a welding machine and certain skills in this area in order to carry out the work.

If you do not have the skills to work with a welding machine, but you have no desire to purchase a ready-made one, contact the specialists who can help you in the organization.

To make a fireplace insert, you need to know how to use a welding machine

If you are engaged in the construction of a metal fireplace with your own hands, please note that it must have a double wall. Such an organization will be able to heat cold air from a metal firebox. Therefore, if you do your own welding, consider this detail.

Step-by-step installation instructions

The stages of the process of erecting and assembling a metal fireplace should go in a clear sequence and look like this:

- If the fireplace is installed on a wooden floor, it will be necessary to use heat-insulating material, the laying of which is done between the ceiling and the floor material.

- Since iron tends to get very hot, a heat-resistant base is required for installing the furnace. The pedestal is equipped with chipboard sheets, on top of which any heat-resistant coating is laid (tile, cement-bonded particle board, etc.).

Photo 7 Laying the base for the cast iron stove.

- For walls covered with wallpaper, which have a high degree of fire, you need to make a layer between the wall and the fireplace. Therefore, it is recommended to lay out tiles or any other facing material in this area.

Photo 8 The floor covering and walls are protected from the incandescence of the fireplace by means of a special material.

- Having prepared the location, the next step is to assemble the furnace structure. Initially, the sides of the fireplace are completed with the help of a welding machine. After that, the back and front walls are attached to them with a welding seam. Previously, in the front wall, in the center, you need to cut out a backlash through which the firewood will be loaded. In the ash pan, a similar procedure is carried out for the convenience of ash removal.

Photo 9 Components of the iron fireplace.

- The legs must be welded to the iron sheet, their optimal height is 8-10 cm, and the thickness is at least 6 cm. The bottom with the legs is welded last. Depending on the dimensions of the fireplace, it is necessary to calculate the required number and width of the supports, because the appliance must be stable.

- Next, install a partition for the ash compartment and combustion chamber.

- A grate is installed between the niche of the firebox and the ash collection chamber.This part is either purchased ready-made, or by welding it is produced independently from reinforcing bars.

Photo 10 Ready grate for the fireplace.

- The hinges need to be welded to the front of the fireplace. Doors will be hung on them. Having stepped back from the furnace door about 10 cm, the corners are welded, by means of which the grate will be fixed.

- A hole for the chimney is cut in the upper wall and the fireplace is closed with this "cover".

- A chimney is installed at the finish line.

It's important to know! A building level control check should be carried out after each assembly stage. If there are cracks in the assembled fireplace, the structure will need to be reassembled.

We equip the chimney

One of the important elements of the device of any fireplace is the chimney system. All combustible materials emit smoke during combustion, which should not enter the room. This mechanism is represented by a one-piece pipe facing the street. A variant of the assembled device is also possible from several branch pipes connected by an elbow.

Photo 11 Chimney device.

The pipe that removes the combustion products is mounted in a prepared hole in the upper part of the furnace. Wall mounting is done with brackets. If contact or bending is required, this is done using the knee. Docking areas are treated with a heat-resistant hermetic compound.

As a result, the chimney is brought out to the roof, where it should rise not less than 5 cm. The top of the chimney is formed with a head and a fungus, protecting it from water and debris.

Photo 12 Initially, the chimney is directed to the ceiling, and then it is brought out to the roof.

At the finish, we get a finished oven device. If there are technical or financial possibilities, the fireplace is additionally decorated with decorative details. You can choose forged cast iron products, figurines, etc. Details can be painted with a special paint, giving them even more sophistication and luxury.

Fireplace insert MCZ Forma 75

201 000 ₽

More details

Fireplace insert Kaw-Met W 7 CO

119 120 ₽

More details

Fireplace insert Kaw-Met W 13

43 120 ₽

More details

Fireplace insert Hajduk Volcano 2Ph one part glass

199 600 ₽

More details

Fireplace insert MCZ Forma 115

240 500 ₽

More details

How can you replace a brick oven

A metal device can become an equivalent replacement for a brick fireplace. For such a furnace, a foundation is not needed at all. Its weight is small. For such a stove device, the task is not set to heat the whole house. It is enough that he will create a special atmosphere. But real warmth also comes from him. Do not freeze on cold evenings. They say that the tradition of using such fireplaces came to us from the Land of the Rising Sun - Japan.

Such devices are made of various metals: copper, steel, tin. It turns out there are many styles of metal stoves. Different shapes of hoods, different fixings for chimneys provide a huge variety of shapes for metal devices. This type of stove can be used on its own or can be clad with brick, stone, ceramic or tile.

Maintenance and cleaning of metal fireplaces

Alas, like everything in our life, even the most beautiful, warm and light has the ability to get dirty and lose its gloss, to lose fire in the truest sense of the word. Having bought and installed a fireplace for yourself, even if it is as comfortable as all metal models, you automatically become Cinderella, and there is absolutely no difference whether you are a man or a woman. Nothing bad will happen. It's just that from time to time the grate on the fireplace will rise, and ... the era of cleaning will begin. Yes, the activity is not particularly pleasant for everyone, but soot and wood decay products that collect in the chimney after the fire dance in the stove do not go anywhere, but only accumulate and interfere with the normal operation of the fireplace.

With complete disregard for the cleaning procedures, careless owners risk their property and even their lives. Those decomposition products that accumulate in the chimney and are not eliminated can cause overheating and fire in the chimney. (See also: Do-it-yourself electric fireplaces)

The fireplace can be cleaned in different ways. This may be the simplest method, which is based on mechanical manual chimney cleaning. It is recommended to hold such an event at least once per heating season. But there are other, more effective, efficient ways. The world of modern innovative technologies is constantly moving and opens up new opportunities. Already, there are products on sale that themselves, without the participation of your hands, will clean the fireplace. You will not need to order services from a team of specialists, you just need to add such products to the wood during combustion in order to constantly keep the chimney relatively clean.

The tool works simply, but incredibly effective: it simply prevents soot deposits from forming. This kind of prevention, which, as you know, is the best cure for any disease. Chimney cleaning products are sold in convenient 500 grams or 1 kilogram packs. They can be safely used for cleaning various upper pipes, stoves, fireplaces of different types and materials.

Manufacturing

It just so happens that even with any degree of availability of different models of fireplaces in the store, we are interested in the question of how to make a fireplace out of metal with our own hands. Moreover, this interest is motivated not only by the desire to save money. Here you can embody all your ideas about the location, shape and decoration of a living hearth. After all the work done, plunge into an easy chair and listen to the crackling of firewood in the firebox with a sense of satisfaction.

Before you start designing a metal fireplace with your own hands, you need to familiarize yourself with a number of aspects that will not only help to increase the efficiency of its work, but are also necessary to ensure the required level of fire safety.

- The walls of the fireplace body get very hot when the wood is burning. By the way, this fact should be taken into account when choosing a room for installation. In no case should this be done in children's bedrooms. Closely spaced surfaces on all sides must be insulated, this applies to walls and floors.

- The chimney, which ensures the removal of combustion products, must be brought out through the roof to the street, therefore, despite the mobility of the fireplace, you should carefully consider the place of its deployment.

A homemade fireplace can be made from any material: copper, iron, steel, cast iron. As a rule, iron fireplaces are cheaper in terms of cost, but they are inferior in performance to copper or cast iron. The metal for the main firebox in its thickness should have indicators of 3-5 mm. Having prepared the required number of sheets, as well as the corners for making the frame, you can proceed to action.

To make it easier to start designing a metal fireplace with your own hands, you need to prepare the necessary drawings, according to which the sheets will be cut and assembled. There are ready-made projects for different types of fireplaces, but you can apply your own artistic abilities on your own. Moreover, there are no special requirements for the design, so modeling and drawings are made taking into account the required geometric shapes and sizes.

It is necessary to start the assembly from the fireplace stand. It performs a double function, on the one hand, the stand insulates the firebox from the floor with a decent distance, and on the other hand, it provides access to cold air, which is necessary for combustion and is a heat carrier. The stand will be a rectangular frame that needs to be welded from the corners and legs that provide an elevation of 15-20 cm above the floor. The resulting frame is sewn up with a sheet of iron.

The body of the fireplace will frame the firebox, and not be it (as in the "potbelly stove"). Double walls will heat the room more efficiently. The air will pass in the space between the firebox and the body and, when heated, enter the room.

The body is made of metal sheets in the shape of a parallelepiped. A chimney hole is made in the upper part. On the front side, the hinges are welded to the wall, and the door is installed. All these manipulations require skills in working with a welding machine. If the initial appearance does not have aesthetics, then you should not forget about the surface finish, with which you can disguise all the flaws.

The firebox should be divided into two parts, but not a blank wall is used as a partition, but a valve capable of adjusting the gap between the sections.

- One part will be used for direct combustion of firewood.

- The second is used as a smoke collector before it enters the chimney.

Such a furnace device will allow for some time to retain heat in order to remove it through the walls of the body. In the lower part of the combustion chamber, a grate is installed and an ash pan is made. It must be of sufficient size to allow the accumulation of ash during at least one fireplace cycle.

Stove models for home

Buleryan

This is a Canadian design and build oven. It is quite simple to operate and has a simple design. The main part of the furnace (firebox) is made in the form of a steel cylinder, the thickness of which is 5-6 mm. The hole for the coal supply (door) is made at the end of the furnace. The main part is adjoined by round (or rectangular) pipes, hollow inside. After warming up, these pipes create the necessary transfer of warm air in the right direction.

The grate for supporting coal (grate) is made at the bottom of the furnace. There is a fence at the top of the furnace that divides the main part of the furnace into two halves. This is done in order to be able to heat both coal and gas. The smoke outlet is located on the back side of the door and is aligned with the firebox, which allows smoke to escape safely outside.

Butakov's stove

Tested in extreme cold climates, failing to meet patent holders' expectations. This brand has several varieties. The models, which are planned to operate around the clock, have been improved with glass barriers. The stove consumes 12 times less fuel than a potbelly stove, and two times less than ordinary brickwork.

Model "Student"

This is due to the fact that in such a furnace the fuel does not burn, but smolders (pyrolysis process). The only drawback is that the chimney pipe is not tight enough and during the transition of steam into liquid, water can drip from there. There are 6 types of such ovens. "Gymnaz student" is the most comfortable in size.

Breneran

Russian model of the Buleryan furnace. The oven is lightweight and compact. It is suitable for both living quarters and garage. Testing of such a furnace was carried out in the mountainous area of Tajikistan, where the border service premises are equipped with furnaces of a similar type. Breneran stoves come in 5 sizes, with a capacity of up to 35 kilowatts.

Teplodar-Matrix

It is a successful combination of design and functionality. In furnaces of this type, there is the possibility of continuous 8-hour combustion (with one fuel supply). The convector compartment casing creates uniform heating and protects against negative radiation. The depth of the smoke outlet and the compactness of the oven save space and create additional advantages during installation - the chimney can be made in the direction in which it is necessary or convenient. This manufacturer has a fairly large selection of models, so you can choose the best option based on your needs and preferences.

Teplodar-Matrix 100

Teplodar-Matrix 200

Suitable if you need to heat a room with an area of up to 200 sq. For garage premises, the best option is the Teplodar T series. For kitchen areas, a vertical fireplace stove is ideal.

If uniform heating of the living space is of paramount importance, it is better to choose the Vesuvius model.

Thermophore

High-quality domestic stoves for heating areas with an air volume of 50 to 250 cubic meters. The power of such furnaces reaches 13 kilowatts. Suitable for heating both residential and non-residential premises. On some models, fans have been added for better overclocking of warm air. A large number of different models are presented - Ermak, Normal, Indigirka, Cinderella, etc. These furnaces are compact and have an efficiency of up to 90%. Some models have glass flaps.