Advantages of facade panels

Building a house made of stone or brick is a very expensive undertaking. Facade panels for cladding a house, on the other hand, are a popular modern material, and also easy to install.

Benefits:

- Due to the fact that the panels are made from high quality, but inexpensive polymer, their cost is several times lower than bricks and stones for cladding.

- The material is durable, weather resistant and can be easily washed with a hose.

- Facade finishing is quick and uncomplicated, as only a few fasteners are required to install one panel. It can be carried out without the help of technology, independently. Fastening materials can always be found at any hardware store.

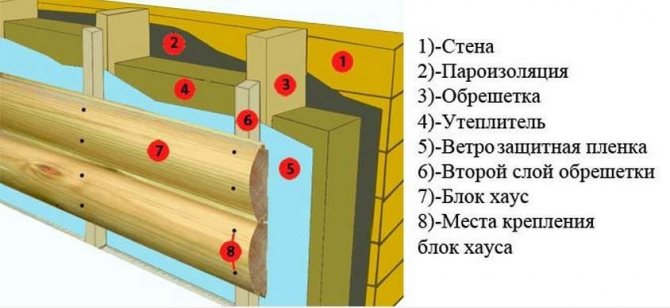

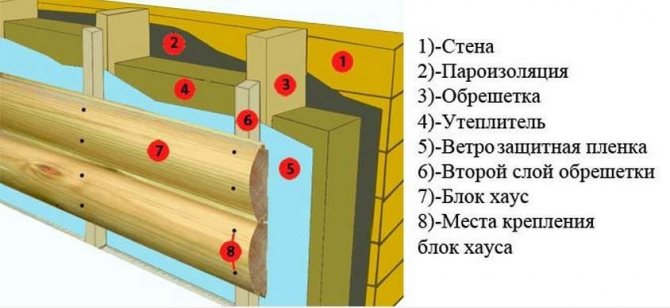

- Provided that front panels are used, it is possible to additionally insulate the house. The cladding is installed on a crate, under which various insulation materials can be laid. This is the second main purpose for facade panels after decorative.

- The cladding can have an appearance for absolutely any texture: wood, stone, brick. The palette of shades is varied.

The disadvantages include the fact that the panels are susceptible to mechanical damage. To safely solve this problem, you need to buy cladding material with a small margin, in case of damage and replacement.

In a short period of time, an ordinary house will turn into an exquisite, noble building.

Grouting

Facade tiles are sawn and sanded with a grinder angle grinder. In situations where the fastening plates had to be sawed off (near windows, doors, at corners, on gables), the facade tiles are drilled into the seam and fastened to a galvanized self-tapping screw, and the hat is rubbed. Colored grout is provided free of charge.

Installation of facade tiles

provides services for the installation and exterior decoration of house facades with tiles made of artificial facing stone own production

... We are engaged in the installation of ventilated facades

Full construction

since 1997 and have accumulated extensive experience in this segment of construction. Over the past 20 years, more than 1000 buildings in Moscow, the Moscow region and other regions of Russia have been tiled with our tiles.

Crews are staffed by qualified installers

who know the specifics and nuances of working with facade tiles.

Special offer:

Types of facade panels

There are many types, they differ in the material of manufacture, installation method, sizes, colors. About the most demanded further.

Metal siding

Models from aluminum, stainless steel, are reliable and durable construction. Metal siding is perfect for facing summer cottages, one-story houses. The panels repeat well the "effect" of wood and are easy to assemble. Maintenance is very simple - wash the contaminated part of the house.

Installation is as follows:

- A drainage is applied to the base.

- U-shaped profile is attached to p-shaped brackets.

- The initial bar is set in the joint to the drainage system.

- Metal siding is mounted.

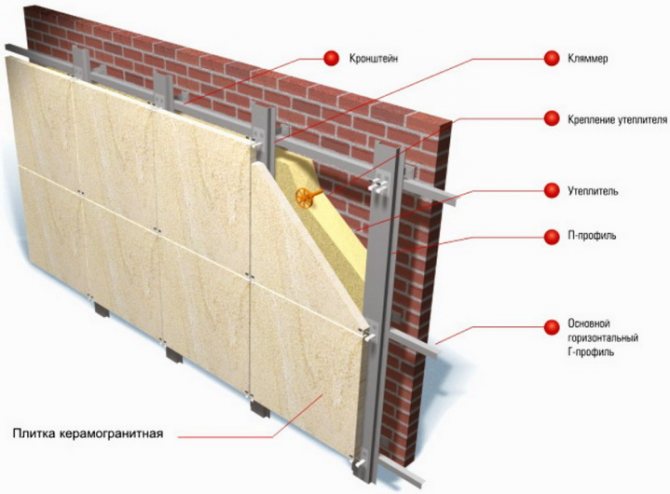

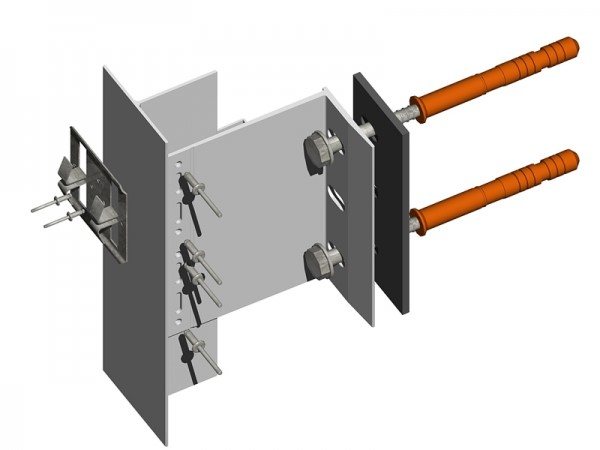

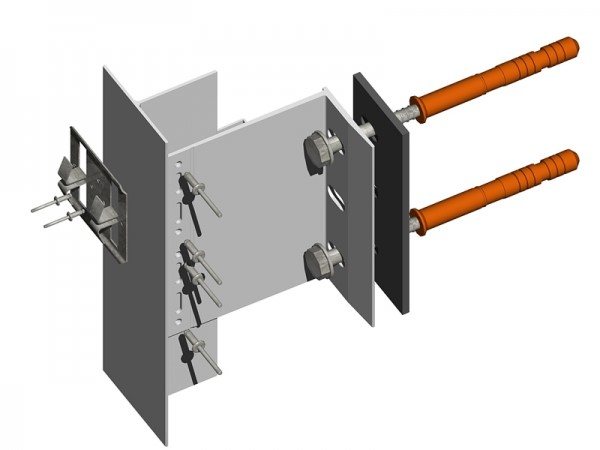

Types of fasteners and fasteners used for ventilation facades

A large number of different types of fasteners are intended for installation work, depending on the type of panels. To determine the required amount of fasteners, you need to be guided by the footage of the house, the number of fasteners for each coating. Among them are:

- facade screws;

- rivets;

- all kinds of dowels;

- concealed mounting bolts;

- fasteners duet facade and others.

Facade self-tapping screw

Fasteners for a ventilated facade - stainless steel screws (to avoid rust). Front screws are not used for galvanized systems, rivets are suitable for them. And for aluminum panels, they fit perfectly.

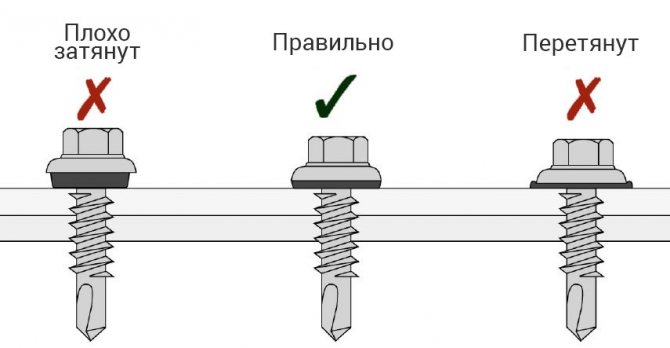

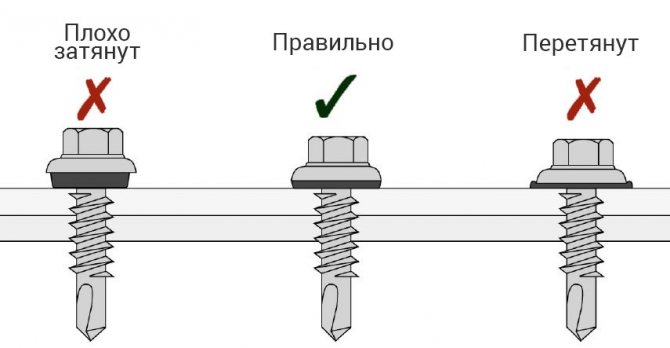

It is important to tighten the self-tapping screw correctly, you must not tighten and twist the fasteners.

How to work: the sheathing is evenly applied to the crate, then screwed one by one onto the self-tapping screws.

Rivets

Aluminum and stainless steel rivets are also used in the installation of ventilated facades made of aluminum profiles. They have sides that are enlarged and protruding. The diameter is the same as the side.

The rivet consists of a sleeve (stainless steel or aluminum) and a sleeve (stainless steel). A sleeve installed in the structure connects the bracket to the profile. The sleeve is stretched into the sleeve. The fasteners are reliable.

Front dowel for mounting brackets

In systems of ventilated facades, dowels of various configurations are used. When choosing them, you need to pay attention to the following nuances:

- the dowel should bend easily, not break;

- thickness from 12 to 16 mm;

- the dowel cover must be suitable for fastening the facade tiles;

- the diameter of the dowel depends on the load, the weight of the sheathing;

- Most often, dish-shaped dowels (umbrellas, fungi) are used to fix the thermal insulation: a hole is drilled slightly larger than the size of the fastener and the dowel is installed.

Concealed bolts

It is an anchor or a screw for hidden fasteners of a facade made of stone, plastic, fiber cement. It is installed in a pre-drilled hole, mechanically secured.

Wood siding

Wood siding

Such panels can only be used for finishing one-story buildings due to their impressive weight. Despite the special impregnations with which the products are processed, the first care will be required several seasons after installation. With proper handling, such siding will last for more than a decade.

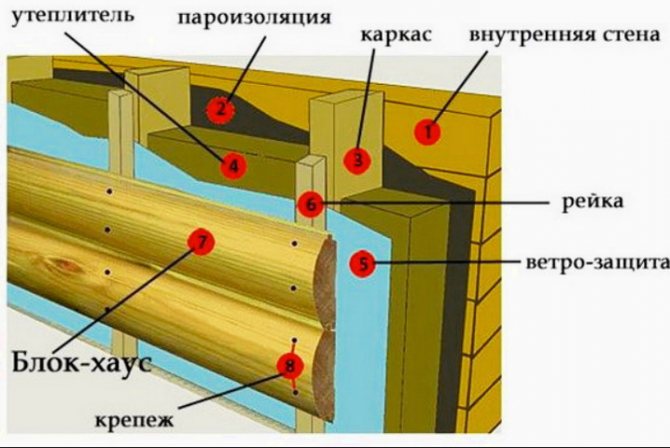

Installation technology

As in the case of metal siding, two options are possible here:

- install the panels yourself;

- buy a ready-made structure.

Self plating happens as follows.

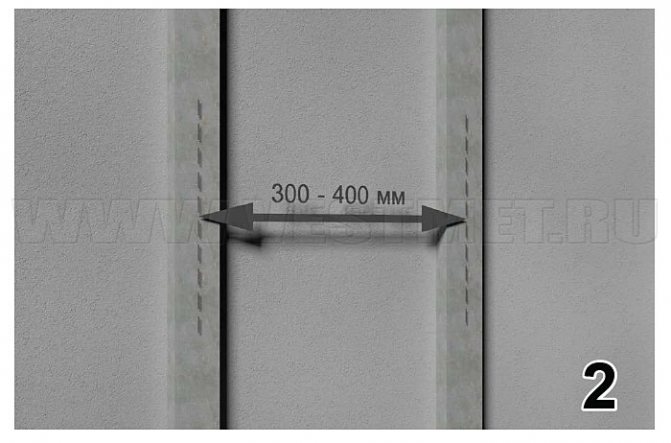

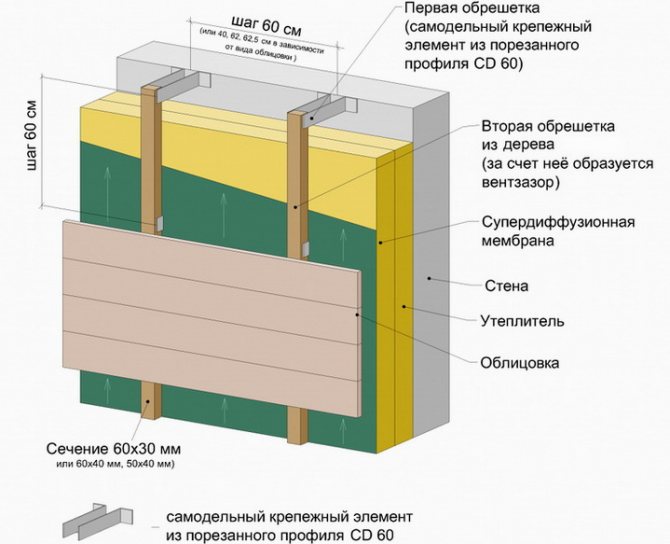

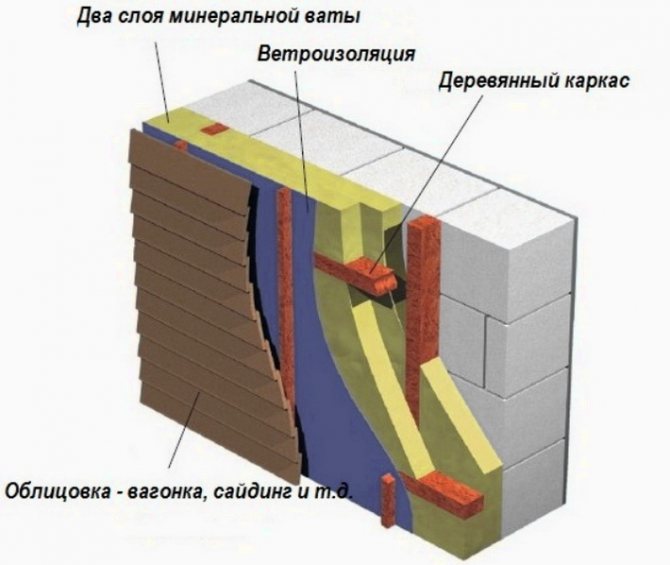

Stage 1. First, the frame is assembled from a wooden bar. The first post is fixed perpendicular to the ground, all subsequent ones are installed in the same way with a step of half a meter. After that, the transverse posts are installed. Instead of wood, the frame can be built from a metal profile.

Installation of lathing

Stage 2. The frame (if it is wooden) is treated with stain and antiseptics to protect it from insects, precipitation, wind, etc.

Important! Vertical racks cannot be placed directly on the ground - special linings need to be made, otherwise the tree will absorb moisture from the soil and will soon rot.

Stage 3. The space between the posts is filled with mineral wool.

Mineral wool insulation

Stage 4. The panels are attached to the frame with self-tapping screws.

The finished construction vaguely resembles a suspended ceiling. The installation procedure in this case is quite simple.

Stage 1. The extreme guides are attached.

Stage 2. Then, with a step equal to the length of the boards, the inner ones are installed.

Stage 3. Siding is inserted between the guides. The first lane, the second, the third, etc. is installed.

Step 4. After that, the top row is leveled and covered with a wooden frame for fixing.

Installation of wooden siding

This installation option has significant drawbacks, including the almost complete absence of thermal and noise insulation.

Important! There is another type of wood paneling - long-strip siding.It consists of sheets six meters long, which are attached with dowels or liquid nails not to the frame, but directly to the wall. Installation requires a minimum of two people.

Basic rules for installing panels

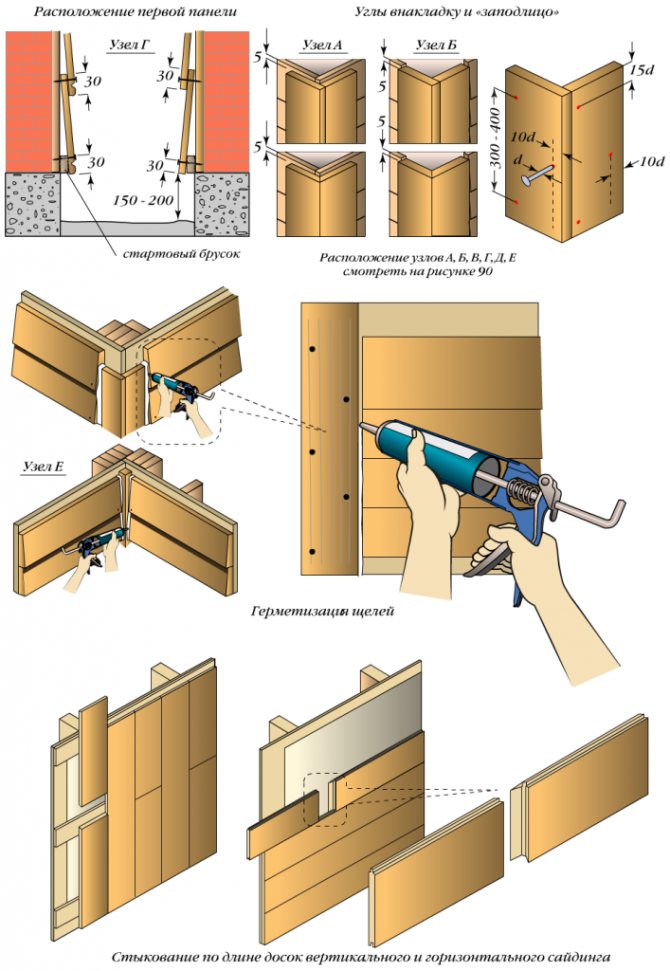

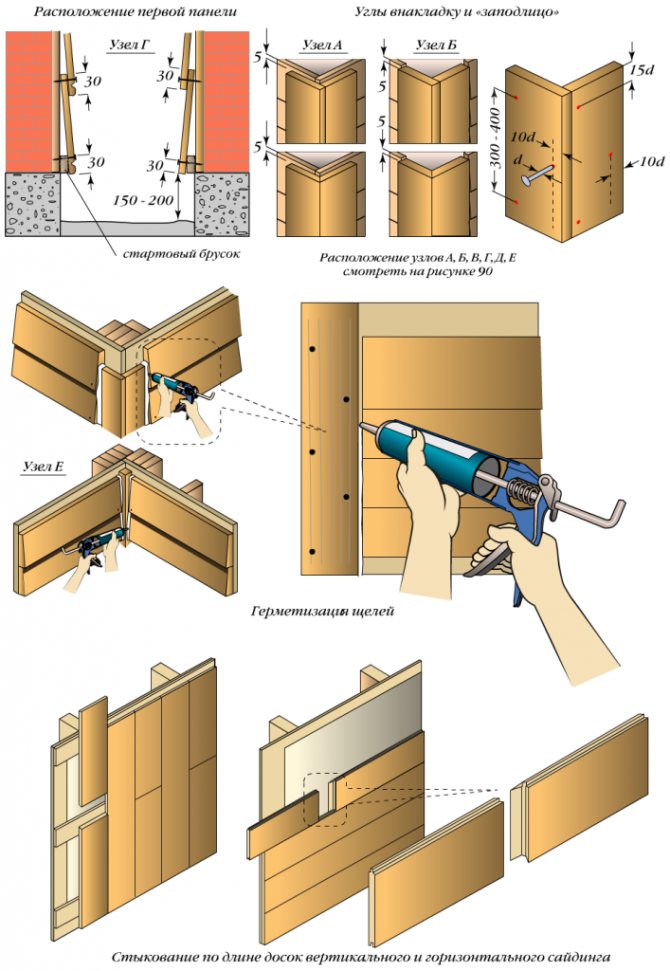

The cladding is installed in two ways: hidden and open.

Open-type installation involves reinforcing the panels on the purlins by simply drilling holes for fastening and attaching. All fasteners are visible in this case. But they can be matched to the color of the panels or decorative caps can be used, or simply painted in the color of the panels.

The hidden fastening method securely fixes the structure and remains invisible at the same time.

For facade panels for brick, stone, additional fastening strips are used. The hidden method is more difficult than the open one and more expensive. However, the exterior of the building is perfect. Often they use hidden installation, partly at the doors, the lower part of the house, and the upper part and the rear facades are strengthened in an open way.

When installing the coating, you must remember the basic rules:

- Installation should start from the bottom of the house and from the corners.

- Laying of rows should be checked with a level. With correct assembly, all seams are joined, and you get a one-piece facade sheet.

- Installation of cladding is an important component, it reduces the load on the walls, makes it possible to additionally insulate the house, hides defects and unevenness of old walls.

General recommendations

It is better to sheathe the house with panels at freezing temperatures. In this case, a distance of 5 mm is left between the planks and the cladding itself. If you have to work at temperatures below zero, the gap is increased to 10 mm to avoid deformation in summer. The material is stored in a warm room and taken out in parts during winter installation.

To prevent moisture from getting into the space between the panels of the border of windows, doors and openings for communications, they are covered with a sealant.

For finishing the basement, it is better to choose special panels, since it is more affected by melt water and temperature differences. A border is installed at the junction of two different types of finishes. If you attach elements to wooden slats, be sure to treat them with a composition against fungus, moisture and fire. Also, you cannot use wood that is more than 15-20% moistened.

Wooden and metal battens have their pros and cons. Wood is more convenient for work, but it is difficult to find perfectly flat slats, you may have to modify them yourself. The iron frame is smoother and more durable, but it is not very convenient to screw the screws into it, and if it is not done at a right angle, then the wind can loosen them.

Do not forget about the ventilation gap between the wall and the cladding, this will extend the service life of the finishing materials and insulation.

The panels should be mounted on a clean wall without traces of mold or mildew. Irregularities can be corrected with a crate, only for this you need to check all surfaces.

External wall panels installation technology

Installation must be carried out in accordance with all requirements and instructions in a specific sequence. Before purchasing materials, it is imperative to make sure that the facade tiles are compatible with the fastening.

Surface, tool and material preparation

The walls of the house are prepared for work in advance:

- The walls are cleaned of dirt, drains and cornices are removed. Wooden facades are treated with antiseptics against mold.

- Potholes and irregularities in the walls are leveled and grounded.

- For each type of facade fastening, certain materials, fasteners and tools are prepared.

- If wall insulation, sealing is provided, then insulation materials are additionally prepared.

Lathing for panel mounting

For the installation of the cladding, a wooden or metal crate is installed. Metal is preferable - it is stronger and more durable. The lathing is installed using brackets, profiles, leveled with a level. Insulation is laid.With flat walls, installation of some panels (without insulation) can be carried out immediately.