The importance of proper roof abutment work

One of the main functions of the roof is reliable weather protection. In order for precipitation not to penetrate inside, it is necessary to ensure its absolute tightness.

Such an irreplaceable metal roofing profile in the construction of houses.

All the subtleties of the process of building a hip roof with your own hands at the address.

On a flat surface, this is easy to achieve, but where the roof connects to walls and other structural elements can create serious problems. Snow, rainwater, debris accumulate in these areas, as a result, the load on the rafter system significantly increases and the risk of leaks and a violation of the sealing of the roof covering increases.

Competent arrangement of abutments is a guarantee of the reliability of roof sealing. This should be taken care of at the design stage.

If the building is brick, then a special visor is equipped during the laying. It is made from half a brick. The purpose of the canopy is to protect the junction of the roof and wall from rain and snow.

Some people choose another method: they leave a small recess when laying. Subsequently, a roof covering is put into it.

Regardless of the method chosen, even before the start of installation work, it is necessary to take into account all future joints and determine the way in which they will be sealed.

Seal for roof passages and its types ↑

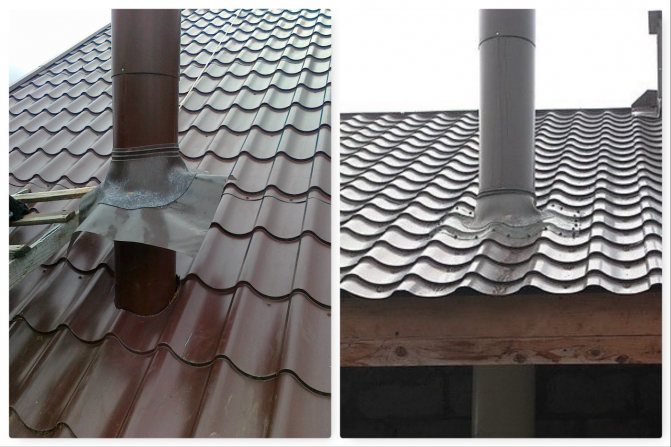

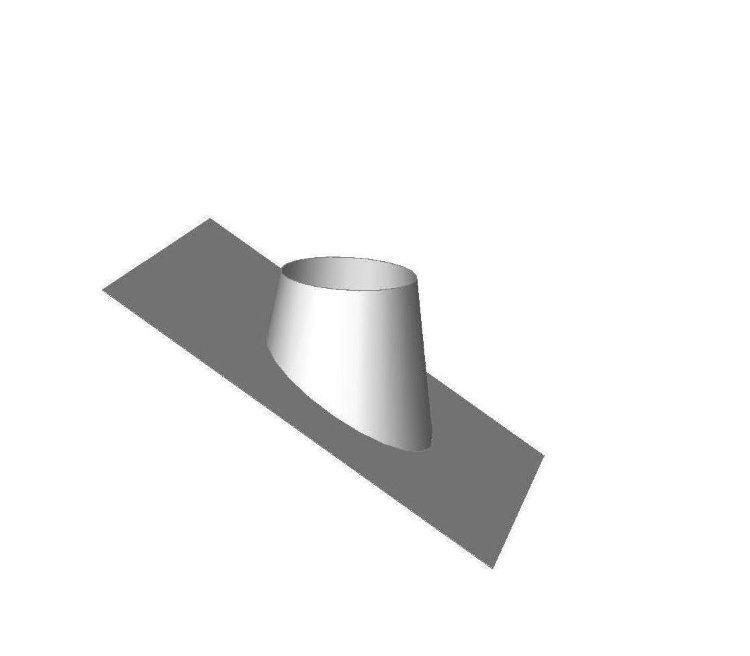

A special passage assembly used for the installation of ventilation shafts, antenna racks and pipes for various purposes in the places where they pass through the roof covering is called roof penetration. Various types of such assemblies are available, which make it possible to carry out tight connections on almost any type of roof with a variety of coatings.

There are several types of special roof penetrations used to lead to the roof:

- ventilation of sewer pipes, which is necessary to avoid the destruction of the sewer system and the appearance of unpleasant odors;

- pipes, antennas and flagpoles;

- ventilation of internal premises;

- roof hatches intended for access to hard-to-reach areas of the roof, repair and maintenance of chimneys and other communications;

- ventilation of the under-roof space, which removes excess moisture from the roof space and attic spaces.

From the variety of roof penetrations, you need to choose the right option

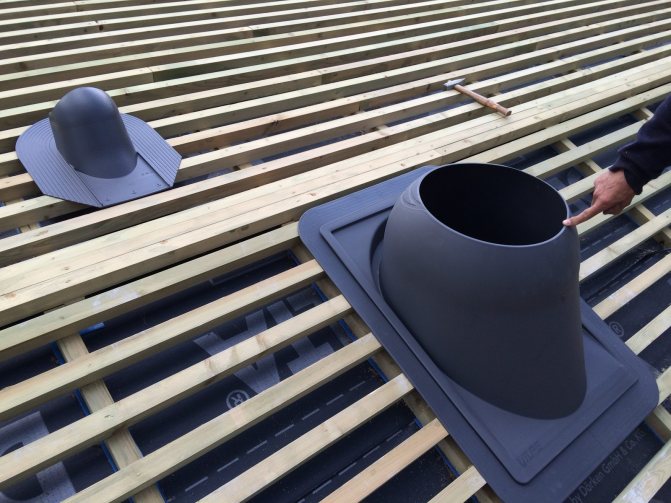

In addition to them, you can find on sale a universal seal for roofing passages, which is used to seal various joints when installing antennas, masts, lamps, ventilation, laying cables and electrical wires on roofs of any type. The structure is a multi-stage pyramid made of silicone or special rubber, fixed on a flexible square flange, the upper half of which is made of aluminum, and the lower half is made of silicone. Thus, the flexible base can be easily combined with any roofing material, eliminating vibration caused by various reasons: wind, snow, etc.

The universal tunnel is durable, UV resistant, and its aluminum alloy base is non-corrosive and extremely flexible. The design features make it easy to mount the unit on any roof and in different positions, adapting it to different diameters of ventilation and other pipes. On sale you can find a range of universal penetrations, differing in size.Each of them is designed to reliably seal sealed structures with a certain diameter value, which is indicated on the part body.

Important: Experts recommend choosing a larger universal roof penetration from two suitable adjacent sizes. Especially if the structure is installed on a pitched roof.

Universal roof penetration: the main thing is to choose the right size

Types of wall connections

Roof and wall docking is of two types: upper and lateral... When roofing work, one has to face the task of decorating other construction details: ventilation pipes, chimneys, canopies, awnings. It is in these places that rain and melt water accumulates, and in winter - snow.

Arrangement of abutments to the wall

During the installation of the roof, all joints should be carefully sealed. The sealing process is carried out using different technologies and depends on the specific type of roofing.

In the presence of a roof based on roll materials, several methods can be used.

- Flashing

This method consists in applying plastic mastic to the junction points in combination with a special reinforcing geotextile. When using this technique, you can get an absolutely tight, durable and elastic joint, which, moreover, does not lose its quality characteristics for a long time.

This method is so simple that the work can be carried out independently, without the help of professionals. Before applying the mastic, the surface must be carefully prepared.

When using roll materials, they are cleaned of dusting. Polyvinyl chloride should be degreased, the concrete should be coated with a primer, and the brickwork should be plastered and thoroughly dried.

All places of future joints must be cleaned of dust and any contamination. If there are large cracks and chips, they must be covered. Only after thorough preparation of the surface can a layer of mastic be applied to it.

Geotextile is laid on top, which is again covered with a layer of mastic. After applying one layer, you must wait at least 3 hours and no more than 24 - before applying the next layer. After waiting for the treated area to dry completely, you can apply mastic of the corresponding color on top.

- Fastening with a rail with self-tapping screws

When using this method, the place where the roof adjoins to the wall is arranged as follows: a silicone sealant is applied to the section of the rail-to-wall junction. The roll roofing must be raised on the wall by about 15-20 cm.

It is necessary to ensure that a depression does not appear at the junction, which in the future may threaten a tear. To avoid this, a triangular bar should be installed between the wall and the roof surface and a layer of additional thermal insulation should be laid. The resulting roller is the prevention of a possible breakthrough of the material and additionally insulates the abutment areas.

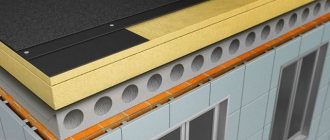

Roof from corrugated board

In the presence of a roof covering based on profiled sheets, the arrangement of abutments to the wall is carried out using special steel strips or aprons.

To install such a structure on a plaster or concrete base, it is necessary to make a recess in it with a depth of 20 to 30 mm. The recess must be parallel to the wall.

The apron is pre-treated with silicone sealant, after which it is inserted into the strobe and fixed from the bottom side with self-tapping screws.

You can also use a double apron. The top element must overlap with the bottom one. In this case, there is no need to groove the surface.

The upper part is attached to the base using dowels. The bottom element must be installed under it. It is snapped onto the top part using lock joints.The lower apron is equipped with clamps: they must be fixed to the roof with self-tapping screws. At the last stage of work, it is necessary to completely seal all sections of the connection.

When performing work, one must remember that a small gap must certainly remain at the points where the corrugated board adjoins the wall.

Soft roofing from shingles

The junction of the soft-type roof to the wall begins with a line on the wall. It is carried out at a height of 200 to 500 mm from the coating. Along the perimeter of the junction, a bar with a triangular cross-section, pre-impregnated with an antiseptic substance, should be fixed. It is necessary in order to smoothly fold the roofing cake and create a barrier for water leakage.

The joints must be cleaned of debris, accumulated dust, then primed. A soft roof covering must be applied to the timber, after which a special strip for the installation of the valley should be glued to the sealant or bitumen mastic. It is a 1 meter wide roll material reinforced by a special technology - a valley carpet.

The strip starts from the wall on the wall, its other end is located on the horizontal part of the roof, at least 200 mm wide. The roll materials to be glued are smoothed and pressed using a special rubber roller. It easily presses the material to the surface without damaging it. If there are large chips, it should be removed from the gluing site.

At the end, you need to fix the abutment unit using a clamping metal strip (100-120 mm) with a flanged edge, which, during installation, is included in the bar. It should be fixed on the wall plugs using rubber washers.

Causes of leaks

A roof covered with a profiled sheet must be equipped with several openings through which the chimney pipe and ventilation ducts will be led out. As a result, the integrity of the waterproofing can be compromised, which increases the risk of leaks. It is quite difficult to solve this problem if the chimney had to be led out through an already constructed roof.

For high-quality sealing of the pipe abutment sections to the corrugated board, you need to make a lot of effort.

If the work is performed poorly, many problems arise:

- Water begins to flow. This happens if the sealing of the joint between the chimney and the corrugated board is poorly equipped.

- The rafter system began to rot. After water gets inside the roofing cake, the wood from which most of the roof elements are made gets wet. As a result, the structure is deformed.

- The roofing material itself begins to rust. The corrugated board is not very well protected from corrosion from below.

- Aging of thermal insulation. When the insulation gets wet, its effectiveness is significantly reduced.

To increase the reliability of the roof, you need to choose the right place for the outlet of the chimney and ventilation ducts. This will make it much easier to seal the pipes.

On the roof, many holes are made from corrugated board through which the chimney and ventilation ducts are discharged, they violate the integrity of the waterproofing layer, leading to leaks. The most difficult thing is the waterproofing of the joint between the pipe and the roofing pie, if the installation is carried out after the end of the roofing work, in this case it is extremely problematic to ensure a tight fit of the corrugated board to the chimney wall. If the finish of the pipe passage on the roof is of poor quality, the following problems arise in the structure:

- Leaks. If the chimney is brought out on the roof, and the joint between it and the corrugated board is not properly sealed, leaks occur in the structure.

- Decay of the rafter frame. The flow of water through the joint between the corrugated board and the chimney leads to dampness of the wooden structural elements, and then to decay and deformation of the rafters.

- Roofing corrosion. When moisture appears under the corrugated board, it begins to corrode, since the protection on the inside of the material is not as reliable as on the outside, since the outside of the profiled sheet is covered with a polymer protective film, and the bottom is only varnished.

- Damp insulation. If you do not seal the joint on the roof, where the chimney is removed, moisture penetrates into the thermal insulation material, halving the effectiveness of insulation.

A roof covered with a profiled sheet must be equipped with several openings through which the chimney pipe and ventilation ducts will be led out. As a result, the integrity of the waterproofing can be compromised, which increases the risk of leaks. It is quite difficult to solve this problem if the chimney had to be led out through an already constructed roof.

Quite a lot of effort must be made to properly seal the areas where the pipe joins the corrugated board.

We suggest that you familiarize yourself with: A crack in a concrete floor how to repair

If the work is performed poorly, many problems arise:

- Water begins to flow. This happens if the sealing of the joint between the chimney and the corrugated board is poorly equipped.

- The rafter system began to rot. After water gets inside the roofing cake, the wood from which most of the roof elements are made gets wet. As a result, the structure is deformed.

- The roofing material itself begins to rust. The corrugated board is not very well protected from corrosion from below.

- Aging of thermal insulation. When the insulation gets wet, its effectiveness is significantly reduced.

To increase the reliability of the roof, you need to choose the right place for the outlet of the chimney and ventilation ducts. This will make it much easier to seal the pipes.

The main reason for the leakage of the pipe and roof joints is the violation of the tightness of the apron structures. To solve this problem, it is necessary to build an additional outer apron made of bitumen tape.

Before installing it, the roof should be cleaned of dust with a metal brush.

The tape is laid in several layers along the lower part of the pipe and along the adjoining sheet of corrugated board (or along the apron). Then it must be heated with a burner and pressed down with a wooden board.

Such a gasket can last for several years.

Serious leaks can only be repaired by replacing the apron.

Moisture can also get under the roof due to the excessive production of condensate from the pipe. To reduce its amount, an umbrella can be built on the chimney. Umbrellas are made from metals such as copper, galvanized steel and stainless steel. The hood not only reduces the volume of condensation, but also extinguishes the sparks coming out of the chimney, increasing the fire safety of the structure.

If the chimney is close to the edges of the slopes, then leaks can occur due to the accumulation of a large amount of snow masses. To eliminate this problem, the apron is complemented by a triangular convex design (with mandatory sealing), which will separate the snow and simplify its descent.

Arrangement of connections to chimneys and pipes

Arrangement of junctions to chimneys and chimneys is in many ways similar to the arrangement of junctions to walls. However, this work has some peculiarities associated with the high temperature of the pipes, their shape, and locations on the roof.

If the roofing material is metal or other cellular and profiled material, the abutment is made with an upper and lower metal apron around the chimney. To install it, it is recommended to release half a brick when laying the pipe. This technique protects the upper part of the outer apron from direct rainwater.

The chimney must be insulated from the roof structure with a layer of asbestos, the crate around is made continuous, but at the same time the 130-mm fire-prevention indent from the masonry must be preserved. The lower apron is installed on it.

It consists of 5 parts: top and bottom planks, two side pieces and a tie. It is necessary to cut the strips of the required length and join them to a seam, the upper flange is inserted into the groove to a depth of 20 mm, after which it is sealed.

On the sheathing, the apron is glued to the roofing sealant, and the tie that serves as drainage is directed to the nearest valley or brought to the cornice.

Why is the rafter system of a broken gable roof good in construction?

Instructions on how to properly make a ladder for the roof with your own hands.

If you have any difficulties with the correct fastening of the corrugated board on the roof, you will find answers to your questions in the article https://rooffs.ru/metallicheskaya/profnastil/ustrojstvo-krovli.html.

A roof covering is mounted on top, and the upper bypass of a pipe or chimney is installed on it. Planks can be prepared by yourself or you can buy ready-made ones. They must be connected to recumbent folds into a single structure. It is necessary to remember about the need to insert the upper flanging into the cut. The stem is treated with a heat-resistant sealant - for example, silicone.

As a result of the work carried out, the water that flows down the roofing above the pipe location will enter the inner lower apron and be diverted through the tie into the valley or directly to the cornice. Other streams of water will fall on the upper bypass of the chimney and from there drain towards the cornice.

As for the roofing based on soft materials, it is impossible to arrange two aprons on them. For this reason, the roof abutment is carried out along the outer contour into the shtraba.

To prevent possible leakage from the top of the pipe under the apron, the upper bar should be 300-400 mm longer than the pipe. It is wound under a soft coating, after which it is sealed from two planes. On each side of the chimney, the strip should have a projection of 150 to 200 mm. Other planks are placed on the cover. Such aprons can also be installed on metal folded roofs.

The areas where the roof adjoins the chimney can also be arranged using flash.

The surface is thoroughly cleaned of any dirt, dust and debris and is prepared for further work. Then a layer of waterproofing mastic should be applied to it and geotextile should be pulled on top. Another layer of mastic is applied to it.

The layers should dry for 3 to 24 hours. If necessary, several layers of mastic can be applied. An indispensable condition for laying the next layer is the complete drying of the previous one. The result is a very strong, flexible and durable connection.

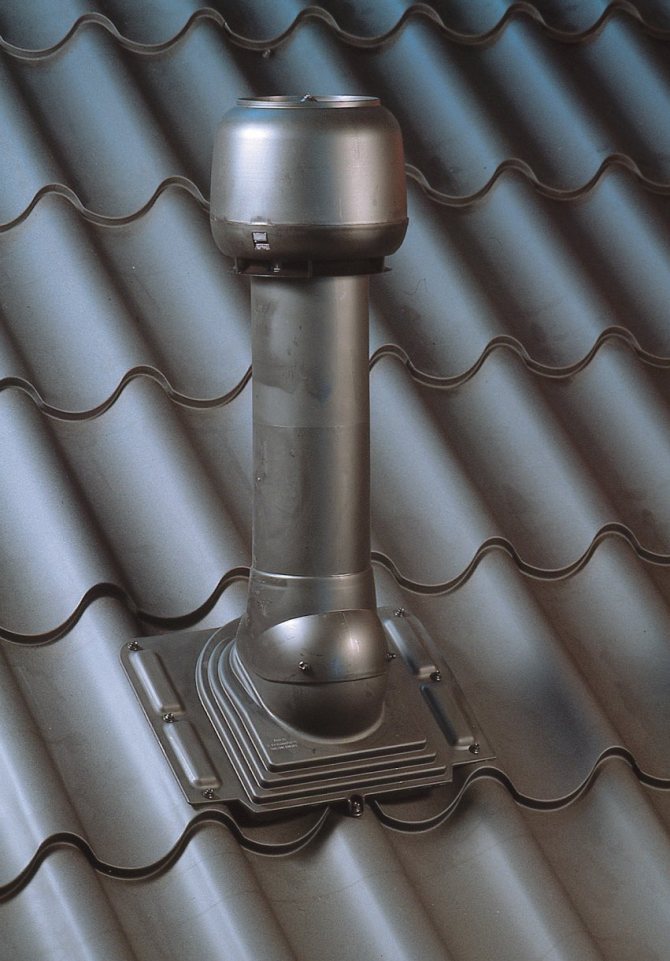

If there is a round pipe, sealing can also be done using an apron. The main elements of the joints of the roof to the pipes are a metal inclined plate with a hole and a large diameter pipe put on the chimney.

The most reliable option is in which the sheet and pipe forming the apron are pre-fitted and fixed to each other. At the same time, they do not make a striker: the pipe connection is sealed at the bottom with asbestos. From above, it is sealed with cement mortar.

Norms and requirements

High-quality installation of the chimney passage through the roof is so important for the safety of the building and residents that the state has officially enshrined the rules and regulations for its arrangement. The document that takes into account sanitary and hygienic, fire hazardous, corrosive and other loads on structures and materials is called SNiP 41-03-2003 "Thermal insulation of equipment and pipelines."

The routing of the pipe through the roof is planned during the construction phase. If the stove is reconstructed, changed or repaired during operation, then the chimney is usually left in the old place.A fundamental condition for a quality chimney is the location of the chimney in relation to the roof ridge.

To ensure optimal traction, the best place to lead the pipe to the roof is its highest point - the ridge. This allows the main part of the pipe to be guided through the attic space, which protects it from moisture and cold. The difficulty lies in the fact that it is necessary to violate the integrity of the horizontal beam by installing additional supports on both sides of the chimney. More often, the pipe is taken out at a short distance, which makes it possible to limit the street part of the pipe to a minimum of fifty centimeters.

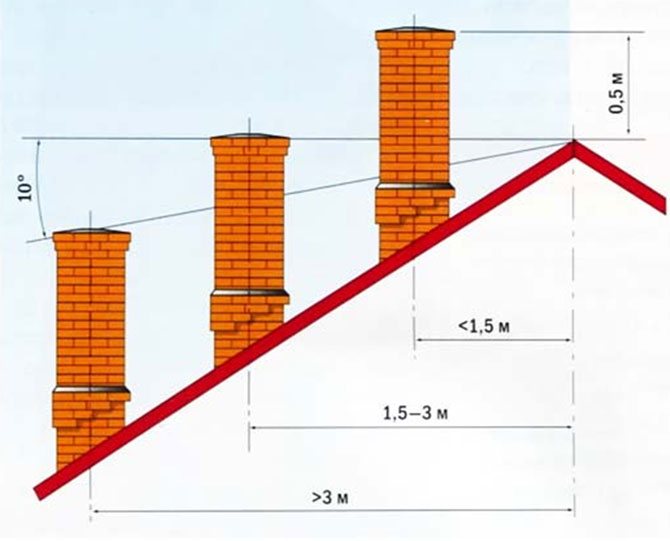

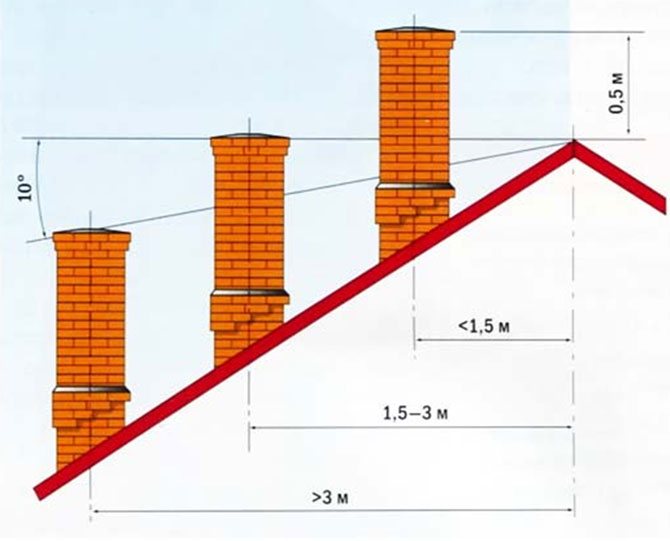

There is the following dependence of the height of the chimney on its distance from the ridge:

- the distance to the ridge does not exceed 1.5 m - the pipe rises 50 cm above it;

- distance from 1.5 to 3 m - it is enough to bring the chimney flush with the ridge;

- when the chimney outlet is more than 3 m away from the ridge, the chimney height may be lower than the top of the roof (the difference should be 10 degrees).

The optimal pipe height is from 0.5 m to 1.5 m. The outlet is located between the rafters so as not to violate their integrity and leave a distance of 15-25 cm to them.

Note! The worst location of the pipe outlet on the roof is in the recess between two slopes in a complex construction (in the valley).

If the straight vertical exit of the pipe falls on a similar merger of two roofs, then the roof penetration should be shifted by half a meter to the side, adding a horizontal section to the chimney (up to 1 m). Snow and ice accumulate in the deepening in winter, which creates an additional threat to the occurrence of leaks.

We recommend that you familiarize yourself with: How to clean a sewer with caustic soda?

The unfortunate location of the roof penetration for the chimney is the lower part of the roof. Here, the pipe can be damaged by the descent of masses of snow and ice. In addition, a large section of the pipe has to be taken out into the street to ensure normal traction, which contributes to its freezing and the formation of condensation on the inner walls.

Modern materials and technologies

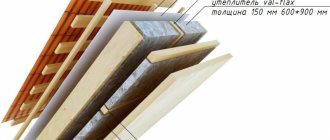

New generation materials greatly simplify the arrangement of points of abutment of pipes with an inclined roof. They reduce the labor intensity of the process and increase the reliability of the roof joints. The finished corrugated elastic cuff, made on the basis of a heat-resistant silicone material, retains its technical properties in temperatures ranging from minus 50 to plus 350 degrees. It can withstand heavy snow loads typical for most Russian regions.

The cuff has an adhesive base, its installation is not difficult. The result is a reliably sealed abutment. The service life of the cuff is approximately 15 years.

You can do without a cuff: arrange an abutment using self-adhesive strips of corrugated metal. Their width is 280–300 mm, and their length is 5 m. They are made of lead foil or aluminum with an applied layer of glue. In the upper part, the strips are fixed to the pipe with a metal clamp.

With their help, it is possible to seal very complex joints on the roof. Their service life is approximately 20 years.

Corrugations are produced in a wide range of colors. Expanding, they increase the surface by 60%.

The material can withstand temperatures from minus 50 to plus 100 degrees. The top edge must be additionally attached to the wall using a special strip called the Tank strip. In this case, it is not necessary to carry out the punishment.

With the help of materials of a new generation, it is possible to arrange abutments of roofs of different types and to other details: dormer and dormer windows, ventilation pipes of different sections, pediments.

Universal penetration

Units of this type are, in essence, insulating tubes that fit organically into the opening thanks to the silicone sheath. However, in this configuration, additional protection should be provided around the passage. The main task that such penetrations perform is to mechanically protect the pipeline or chimney from damage. In addition to the external silicone coating, the unit has a metal layer and thermal insulation. These are the optimal roof penetrations for circular ventilation pipes as they can adapt to any curve. What is also important, due to the stepped structure, such devices allow you to direct the channel in one direction or another as needed. Pipe orientation is possible with traditional penetrations, but changing direction in such cases requires a lot of effort.

Repair of abutments

If there is a need to repair the abutments of the roof to the elements of the roof structure, then the simplest way is to carry out it using the flash method.

In this case, a special one-component mastic is used, which consists of bitumen-polyurethane compounds. It can create reliable and durable waterproofing and is used on surfaces of a wide variety of shapes.

The application of mastic does not require special training and special knowledge or tools. In addition, the method is very economical compared to the traditional repair method using roll material and hot bitumen.

The junction points can be repaired in another way. It is suitable for applications where the roofing material has recently peeled off the wall and is in good condition. It should be pressed with a rail and fixed with self-tapping screws. The sections of the joints of the rail with the wall must be sealed with a polyurethane sealant.

Varieties of penetrations

There are several classifications of roof penetrations. First of all, you should focus on a specific purpose. Manufacturers produce special models for organizing the passage of antennas, pipes, ventilation ducts and chimneys. The belonging of the assembly to a certain group determines both the structural design and the material of manufacture. So, not all types of penetrations can be adjacent to a stone chimney. Also, plastic devices are not compatible with some types of metal pipes. The nodes also differ in shape. The most widespread are round and square sections, but in some cases only corner roof penetration can help, which has its drawbacks, but also advantages. Structures with such a cross-section, for example, are advisable to use in cramped conditions or when laying non-standard coverage.

CONCLUSIONS

- Abutments are areas of contact between the roof and the rest of the building.

- Competent arrangement of abutments ensures reliable protection of the building from precipitation.

- The arrangement of the connections must be taken care of already at the design stage.

- Wall joints are divided into top and side joints.

- Sealing of abutments to the wall is carried out in different ways, depending on the type of roofing.

- When installing connections to the chimney, it is necessary to take into account the high temperature of the pipes, their shape and location.

- Modern materials and technologies greatly simplify the work of sealing the joints.

We invite you to familiarize yourself with the video on the design of the abutment of the roof to the wall of the building

How to install a passage for chimneys through roof ceilings

In the event that the diameter of the hole does not correspond to the integrity of the ribbed or hollow slab, sections of monolithic concrete are made in the place of the penetration device. The roof penetration with a metal light frame will be the same, but the glasses must be metal.If the building has a large area and has a civil, industrial and residential purpose, then the location of the nodes is calculated at the design stage.

When installing a chimney on the roof of a building, the tightness of the waterproofing is broken and the risk of moisture passing through during precipitation increases. It is necessary to know how the sealing of the chimney on the roof made of corrugated board is ensured. There are standard requirements for waterproofing pipes on a roof made of corrugated board:

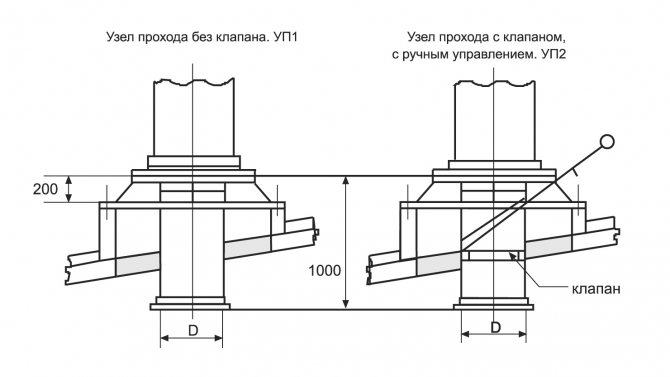

There are several types of ventilation systems: Systems with a manual type of adjustment are used in cases where the system does not need constant monitoring of operating modes. This ventilation system control method consists of: An electric one-turn mechanism controls the operation of the valve - it closes and opens it. The valve itself is made of 0.8 mm thick stainless steel.

Units through a soft roof are mounted on a galvanized steel base, which is installed together with a layer of thermal insulation. Warm material should be no thinner than 5 cm, mineral wool is best suited for this. Later, it will be possible to place special deflectors in a heat insulator - an aerodynamic device that is attached to the top of a ventilation or chimney pipe.

Designed to disperse the flow of outgoing processed air. At the end of the installation of the ventilation blades, plastic pipes made of plastic are held inside, through which the electrical wiring runs. The passage of the chimney through the roof must simultaneously solve two not the simplest tasks: to ensure fire safety and tightness. According to the fire safety rules, the temperature of the walls of the chimney should not be higher than 50 ° C at the points of contact of the chimney with combustible materials.

For brick chimneys, this is solved by increasing the wall thickness. For this, stove-makers lay out a special penetration. There is no single solution here, since a lot depends on the angle of inclination of the roof. Therefore, this option is not very popular today - it is difficult to find a person who can competently and safely make such a penetration through the roof.

When a brick pipe passes through the roof, it is surrounded on all sides by a box of additional rafters and cross beams. How is the issue resolved then? They simply make a square or rectangular pipe, which is led out between the rafter legs, and transverse beams are installed above and below the pipe. The distance between the pipe and the wooden structural elements - see. If the distance between the rafters is greater, additional ones are installed. This minimizes the harm that we will definitely inflict on the waterproofing and vapor barrier of the roof: in order to remove the pipe, we will have to break the integrity of the films and membranes.

When installing the chimney, it ends up in a separate box. Films and membranes inside this box are carefully cut. The geometry of the cut is similar to that of a pipe or duct, but smaller than the dimensions of a trunking made of rafters. In the corners, the films are cut at an angle with an envelope, the edges of the films are folded and fixed with staples or clamping strips to the elements of the rafter system.

The edges and entry points of the fasteners are sealed with adhesive tapes or sealants. This operation should be carried out carefully - the durability and reliability of the roof depends on it. There is another option. It is possible if the temperature of the pipe in the area of the roof is not higher than 50 ° C. In this case, the edges of the films can be glued to the pipe with sealants or the same adhesive tapes, trying to seal everything as best as possible.

Now there is a free space between the rafters and the brick pipe. It is laid with a heat-resistant heat insulator.