Thermal insulation of a flat roof is an obligatory stage in construction, when the question of doing or not doing is not even worth it. According to the law of distribution of thermal energy (convection), heat tends to rise, therefore, its loss through the roofing should be minimized and the likelihood of condensation should be reduced.

Features of flat roof insulation

Since a structurally flat roof tends to retain moisture and snow on its plane, and is also sensitive to physical, mechanical and temperature effects, special requirements are imposed on its installation. A feature of the insulation of such roofs is the creation of a hydrophobic layer, which excludes the possibility of water penetration under the layers of the roofing cake.

The base of the load-bearing surface of a flat roof is a floor panel, which can be made of profiled metal sheet and reinforced concrete slab. Each type of base has its own characteristics of installation under a flat roof.

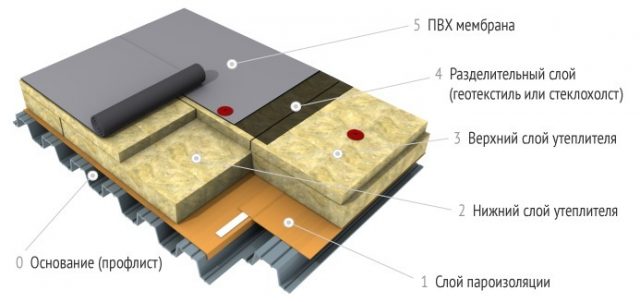

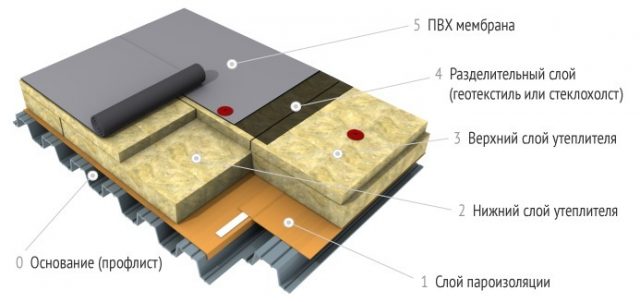

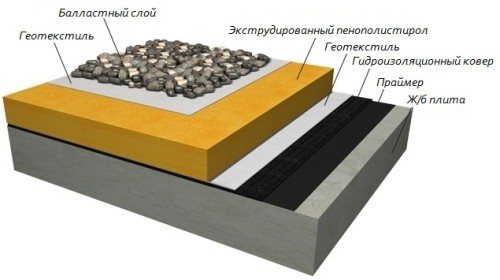

The diagrams below show options for layer-by-layer installation of a flat roof on reinforced concrete and metal profiles, as well as methods for their design.

The design of a flat roof can be of the classic (otherwise "soft roof") and inversion type.

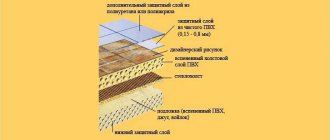

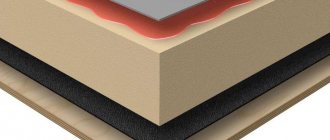

A flat roof in the classic version is a roofing cake consisting of a base plate, a vapor barrier, a thermal insulation pad, a waterproofing bitumen layer and an additional insulation layer. Such flat roofs are used in industrial or civil construction and can be unexploited and exploited.

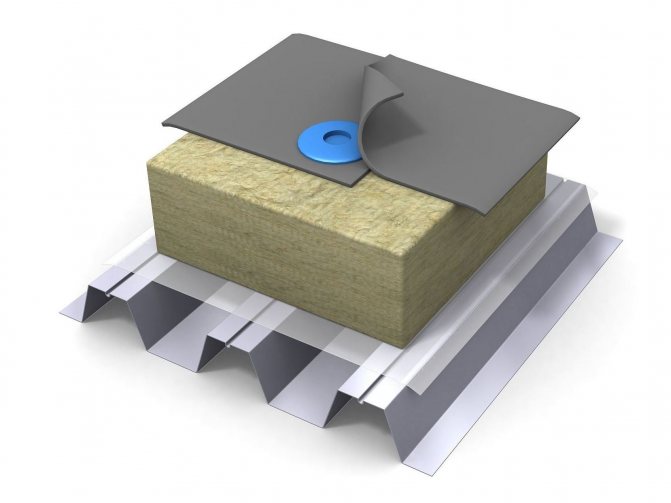

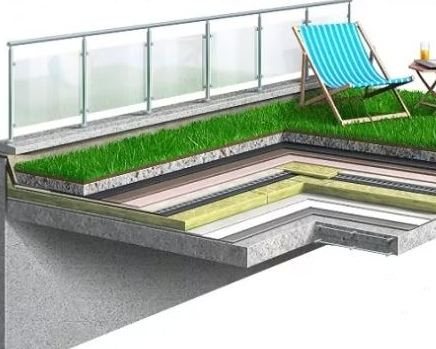

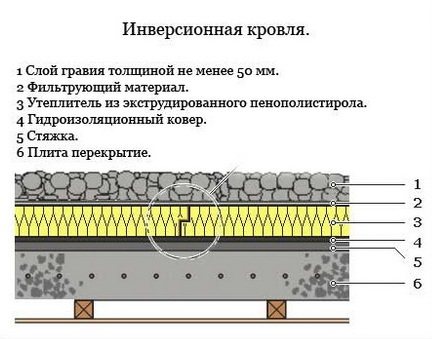

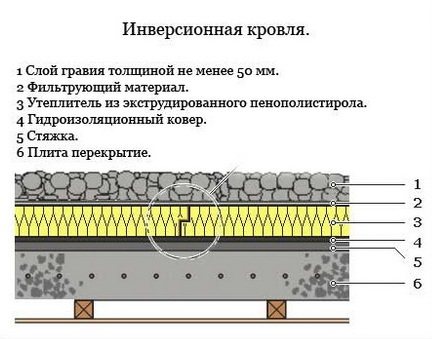

An inverted flat roof is the same flat roof in the classic, with improved construction and a change in the order of the coating layers. It is mounted in layers in the following order: gravel, filter material, thermal insulation layer, waterproofing, cement screed and reinforced concrete slab.

The fundamental difference between the classical roof structure and the inversion one is the sequence of the arrangement of the coating layers. In the first version, the thermal insulation layer is placed under the waterproofing layer, and in the second version, under it. This fact significantly improves the operational properties of the inverted roof and increases its service life.

Important! The design features of inverted flat coverings make it possible to use the roof area as additional economic objects. For example, on a flat roof, you can arrange a garden, resting place, cafe or parking lot.

Foam insulation

Before insulating a flat roof with foam, you will have to work hard and break the insulation into small parts. Styrofoam of any density, any type and any shape will do. The average size of the pieces is 3 * 3 centimeters. To insulate the roof, the foam is mixed with an ordinary concrete mixture and poured on the roof as a screed. The screed must be reinforced so that the concrete does not disperse later.

The main problem is that for a flat roof, you will need a lot of pieces of foam. Also, this type of insulation will not be very effective. Rather, it can be used as additional thermal insulation.

Types of insulation for a flat roof

Insulation for the roof is selected in accordance with the regulations for ensuring fire safety measures in buildings (protocol SP 02.13130 of 2009). Manufacturers of these products produce a wide range of insulation materials, different in terms of thickness, density and compressive and tensile strength.

Along with the basic types of thermal insulation materials, there are wedge-shaped slabs on the building materials market, with the help of which they provide the issue of drainage. Manufacturers offer a special type of insulation - fillets, used in construction as a component to ensure the conjugation of horizontal and vertical thermal insulation.

For insulation of a flat roof, any materials are used that are designed to protect walls, floor slabs and roofs. Concrete (lightweight concrete), gravel, synthetic or mineral material in a roll and a slab are used as insulation. Mineral wool and expanded polystyrene can be noted among the main insulation materials for flat roofs.

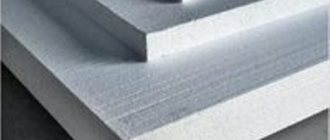

Thermal insulation of a flat roof with expanded polystyrene

The most popular and frequently used material for insulating a flat roof is expanded polystyrene. This building material is produced by baking styrene granules. Traditional expanded polystyrene is used as an insulating layer under a flat roof screed.

Along with the classic type of expanded polystyrene, manufacturers offer an extrusion type of insulation. It is a fairly tough and durable material with a porous structure. It is produced in an extruder by mixing styrene granules with a foaming material under high temperature and high pressure. This type of expanded polystyrene is used as a heater when installing a flat roof before the concrete screed process.

Thermal insulation of a flat roof with mineral wool

Mineral wool is still a popular material for roof insulation. Mineral wool is a rigid or semi-rigid thermal insulating material with a fibrous structure. It is obtained by melting silicate rocks in combination with metal production waste and its components. This material has the lowest level of thermal conductivity and flammability, light weight, excellent insulating properties and is very easy to install.

The only drawback of mineral wool is the time and environment of use of the material. Installation of a flat roof using mineral wool should take place during the dry season, without rain and drizzle. Therefore, the main work on the installation and insulation of the roof is required to be done in one day. Otherwise, if the work is not completed before the rain and the thermal insulation gets wet, the material will lose its insulating properties, and the mineral wool will need to be changed.

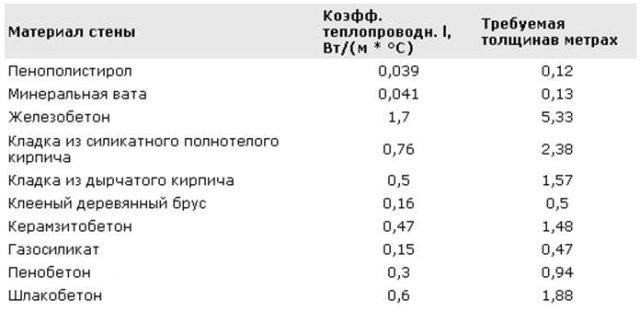

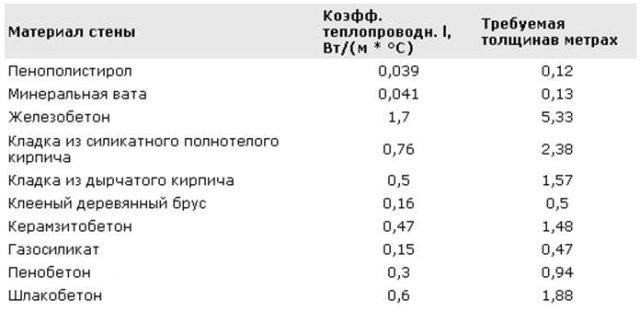

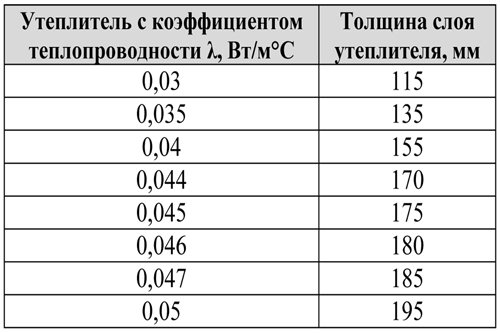

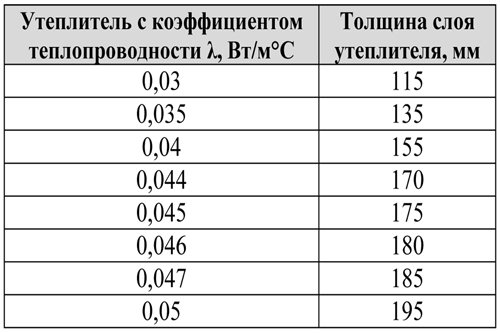

Insulation thickness for a flat roof

An extremely important parameter in the thermal insulation of a roof is the thickness of the insulation material. A roof insulated according to all the rules will help keep the house warm and "save" a significant amount of the family budget for heating.

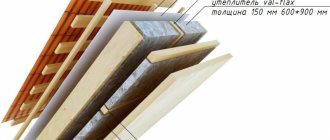

Sometimes the insulation is laid in 1 or 2 layers in order to maintain the required thickness in terms of thermal conductivity of a particular material. In this case, it is necessary to ensure that the joints of both layers are staggered, and the butt seams do not fall one above the other.

The thickness of the insulation depends on:

- region;

- material and method of wall mounting;

- the type and design of a flat roof;

- the type of insulation and the coefficient of its thermal conductivity.

A warning! When installing a flat roof, it is forbidden to use sheet polystyrene as insulation. This is due to the short service life of this material, the probable harm to human health and its relative fire safety.

The calculation of the thickness of the insulation should be made in accordance with the "Rules on thermal protection of structures" (SNiP 23-02-2003). The correct calculation will help not only to professionally approach the issue of home insulation, but also optimize the upcoming costs as accurately as possible.

First, you should find out the permissible coefficient of heat transfer resistance of roofing structures and compare these data with the regional parameters specified in SNiP. It is necessary to find the answer to the question, how much heat (W) can pass 1m² of a flat roof with the required thickness of insulation at a temperature difference of 1 ° C inside and outside the room for a certain time.

However, it should be noted that it is very difficult to make such calculations on your own. Therefore, to select the thickness of the roof insulation, you can rely on SNiP, which gives verified data on heat loss for different regions.

Flat roof insulation methods

The choice of roof insulation method depends on several fundamental factors:

- type of flat roof base;

- basic (minimum required) insulation parameters;

- region of construction;

- financial capabilities of the building owner.

Insulation of a flat roof is carried out on a reinforced concrete floor slab or steel profiled sheet. Installation and sequence of work is carried out in full accordance with what kind of base the roof has.

Reinforced concrete roof base is slabs or concrete poured screeds. Insulation of such a roof is like a multi-layer cake, each layer of which has its own meaning and cannot be missed. Each stage of roof installation should go in turn and in this order:

- A slope is laid on the reinforced concrete base of a flat roof. This layer is responsible for the gutter system of the future roof.

- Next, a leveling layer is mounted on the roof, which smooths out irregularities, pits and bumps along the entire plane.

- Then a vapor barrier film is laid on the roof and fixed.

- Installation of thermal insulation boards is carried out in 2 layers. The first, lower layer is laid out from insulation plates with a thickness of 180-200 mm (data for each region are different) and a compression resistance of 30 kPa.

- The second, top layer of insulation is laid out on the first layer in a checkerboard pattern so that the butt seams do not fall one above the other. The thickness of the second layer is from 30 mm (also depends on regional parameters), and the compressive strength is 60 kPa.

- Further, the entire resulting roofing pie with insulation is fixed with special fasteners (2 units per 1 slab) to the concrete base of the roof.

- After that, the roof is covered with roll waterproofing. The seams of the tape insulation are mounted in series, overlapping each other, to avoid any penetration of moisture.

Insulation of a flat roof on a corrugated base has a two-layer structure and, in comparison with insulation of a roof on a reinforced concrete slab, has its own characteristics.

- Firstly, it concerns the strength characteristics of the lower layer of insulation, which must be at least 30 kPa to compression, and the same values of the upper layer of thermal insulation - 60 kPa. The degree of deformation of both layers of insulation should not be more than 10%.

- Secondly, the installation of thermal insulation plates on galvanized corrugated board can be carried out without a leveling layer from a flat sheet of central nervous system or slate, if the thickness of the insulation plate is 2 times greater than the value between the corrugations. It should be remembered that thermal insulation slabs must be supported on a flat base of corrugated board for at least 30% of the entire roof area.

- Thirdly, if the uppermost layer of the roofing cake is planned to be made of heated bitumen mastic, then the material can be laid directly on the insulation board.

- Fourthly, the mechanical fasteners of the insulation boards and waterproofing are made separately. When insulating the roof on a reinforced concrete basis, this stage of fastening was simultaneous.

How to choose insulation

The choice of insulation for a flat roof depends on the characteristics of the roof. So, it can be traditional or inversion.

A traditional roofing cake involves thermal insulation before waterproofing.Thus, the insulation will be protected from moisture, which expands the choice of material.

An inverted roofing pie is the other way around. The thermal insulation is placed above the waterproofing. Most often, this type of roof is used for an exploited roof. When choosing a heater, it is necessary to take into account that it should be as resistant to moisture as possible and at the same time have a high compressive strength.

In addition, it is possible that the sloping layer is created just from the insulation. This will require a special wedge-shaped thermal insulation. It is, of course, expensive, but it is convenient to work with it.

Thermal insulation can be installed in one or two layers. It depends on the floor slabs, which are often made of reinforced concrete slabs and profiled sheets.

In the first case, it is permissible to lay the insulation in one layer, while it must have a compressive strength of at least 40 kPa, after which a screed is poured over it. In the second case, a two-layer thermal insulation is required. The first layer must have a strength of at least 30 kPa, the second - at least 60 kPa. If desired, it is also possible to arrange the thermal insulation of the roof on a reinforced concrete base in the same way. This will improve its quality.

How to insulate a flat roof of a house with your own hands

Thermal insulation of flat roofs on their own is possible for everyone. If you understand the matter well, prepare correctly and follow all the instructions step by step, step by step, then this work can be done almost on a professional level.

Insulation of a flat roof from the outside

To insulate the roof with your own hands, use any of the classic installation methods described above. A feature of insulation can only be the type of the insulated roof base (reinforced concrete or steel profiled sheet) and the technique of fastening the insulating layer.

Insulation board fixing methods:

- mechanical method;

- ballast method;

- glue method.

Mechanics. Fixation of thermal insulation plates by mechanical method is carried out using special sliding fasteners. They are long, complex anchors, with self-tapping screws screwed into the base. The telescopic mount goes through the entire thickness of the building pie, and the plastic flat heads firmly hold the entire structure. For reinforced concrete slabs, a special anchorage is used, and for cement screeds, plastic sleeves are used.

Ballast. Thermal insulation boards are laid on a flat roof and covered with a layer of waterproofing, and then, on top of it, a layer of gravel (expanded clay) is poured. If the roof is operational, then instead of a loose layer after waterproofing, plastic supports are installed on the roof surface for laying tiles. All elements of the roofing cake are absolutely free (ballast). Fastening is carried out only along the perimeter of the roof, in the places where the chimney exits, ventilation and drainage systems.

Glue. Heated bitumen mastic is used as an adhesive in this method of roof insulation. Thermal insulation plates are glued to the base (reinforced concrete panel). It is necessary that the adhesive adhesion of both surfaces is at least 30% of the entire roof area. All other layers of the roofing cake are fixed in the same way. It should be remembered that all work must be carried out on a dry day, otherwise the insulation will absorb moisture and lose all its useful qualities.

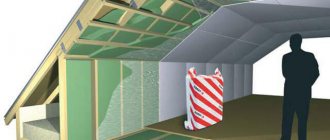

Insulation of a flat roof from the inside

Physically insulating the roof from the inside of the house is not very convenient, since most of the work needs to be done with your hands up. However, this process has its advantages - insulation is carried out regardless of weather conditions, there is no risk of the thermal insulation material getting wet.

The classic way to insulate the roof from the inside of the house is as follows:

- On the ceiling, a crate is made from a bar. The dimensions of the wooden beam should match the thickness of the insulation board, and the step width between the timber should match its width.It is good to cut the insulation board, if necessary, it can be cut to any size.

- Next, insulation plates (mineral wool or expanded polystyrene) are fixed to the finished crate. For this purpose, glue, bituminous mastic, and a stapler are used.

- After all the intermediate sections between the battens of the battens are filled with insulation, they proceed to the stage of waterproofing the ceiling. A vapor barrier film is fixed on the lathing bars with a construction stapler.

- Then the ceiling is sheathed with plasterboard, a stretch ceiling is made or combined with one another. Further finishing of the ceiling is carried out according to our own project.

Observing the rules of roof insulation from the inside, you can be absolutely sure that the house will be warm, dry and comfortable. A roof made with one's own hands "conscientiously" will become a reliable outpost and a subject of special pride for the owner.

Installation of extruded polystyrene foam

If we are talking about a traditional roofing cake (namely, it is used most often), then the preliminary stage of work will be as follows:

- Cleaning the base from dirt and dust.

- If corrugated board is used, its lower wave must be filled with insulation. If the thickness of the insulation is twice the width of the wave, this step can be skipped.

- Vapor barrier device. The film must be brought to the parapet to the height of the future heat-insulating layer. The longitudinal overlap is 10 centimeters, the transverse overlap is 15 centimeters. The joints must be glued with tape.

- Inspection of thermal insulation boards. The rigidity should be uniform over the entire area of the sheet. There should be no moisture.

Thermal insulation of a flat roof with mineral wool is performed as follows:

- Installation starts from the corner. It doesn't matter which one.

- Fastening of mineral wool can be done using mastic, or special dowels, at a minimum rate of 2 dowels per slab. In the corrugated board, the fasteners are screwed exclusively into the upper wave so as not to squeeze the insulation. It is permissible to glue the mineral wool to the concrete base with mastic.

- Next, the top layer of thermal insulation is laid. In this case, the joints should in no case fall on each other - this will lead to the formation of cold bridges. It is better if the upper plate overlaps the lower one by 1/4.

- The upper layer is fixed in the same way as the lower one, using special dowels. To ensure that the fasteners hit the upper wave of the profiled sheet, be guided by the parapet. There you can apply markings in advance. The minimum calculation of the fastening is 2 dowels per sheet. But it is better to make additional fixation in order to ensure a snug fit of the layers one to one. It is important not to squeeze the self-tapping screw inside the dowel - this will violate the integrity of the insulation, which will lead to the formation of cold bridges.

- Seams, more than half a centimeter wide, are filled with insulation.

- The next step is the waterproofing device.

For insulation of a residential building, mineral wool is laid, at least 20 centimeters thick. For outbuildings - at least 12 centimeters thick.

Thermal insulation of a flat roof using extruded polystyrene foam is performed as follows:

- Cleaning the base from dirt and dust.

- Installation starts from the corner.

- It is not necessary to lay a vapor barrier under the expanded polystyrene, it is completely moisture resistant, and condensation is not afraid of it. Therefore, this insulation is often glued to the base using cold mastic or special glue. As a last resort, use polyurethane foam. It is not necessary to apply glue or mastic all over the base of the slab, just smear a few points. It will not be superfluous to grease with glue and from the end, for a snug fit of the insulation to the parapet on one side, and for a reliable connection of the seams on the other.

- Possible cavities are sealed with polyurethane foam. Do not overdo it so that the foam does not squeeze out the insulation.

- The seams must be glued with tape in order to prevent the penetration of cement milk into them, due to which cold bridges are formed.

- If subsequently the waterproofing will be glued with a gas burner, a concrete tie is arranged on the expanded polystyrene, the minimum thickness of which is 3 centimeters.

- Then they wait several days for the screed to dry completely and arrange waterproofing.

We suggest that you familiarize yourself with the adjoining of the roof to the chimney

The thickness of the expanded polystyrene layer is the same as the thickness of the mineral wool.

Thermal insulation of a flat roof with foam glass is carried out using the following technology:

- Cleaning the base from dirt and dust.

- Installation starts from the corner.

- Foam glass also does not require a vapor barrier. The insulation is fixed with cold mastic or hot bitumen. There is no difference in the process.

Foam glass can be used both on reinforced concrete slabs and on corrugated board. In the first case, the mastic or bitumen is rolled over the base of the roof with a notched trowel to ensure a secure fixation of the thermal insulation layer. Insulation sheets are coated along the edges, for a snug fit to each other and to the wall.

In the second case, foam glass plates are soaked in an adhesive from all sides, except for the top. This is necessary to avoid overspending of bitumen or mastic. At the same time, hands should be protected with rubber gloves, but even so it is not worth lowering them in bitumen, and therefore it is better to hold the sheet in any convenient way, even wooden sticks are suitable for this.

- The upper layer is mounted according to the same principle as the lower one on reinforced concrete slabs. First, glue is rolled out on the base, and then the insulation is laid, not forgetting to coat the edges. Mastic or bitumen should protrude outward when the sheets are pressed tightly one to one.

- If there is a loose fit of the foam glass plates, and the formation of wide seams (more than 5 millimeters), they must be repaired. To do this, the edge of one of the sheets is cut off at an angle of 45 degrees and shifted towards the unsealed seam, having previously soaked it in bitumen.

Tips & Tricks

Experienced professional roofers know how, what and when to insulate a flat roof. For those who are going to do this work on their own, there are some useful tips to help you avoid mistakes. Here they are:

- All work on the insulation of a flat roof should be carried out exclusively in dry weather.

- It is better to use expanded polystyrene to insulate the roof from the outside, and mineral wool to insulate the roof from the inside.

- It is necessary to clarify the thickness of thermal insulation for the region of construction (use the data of SNiP 23-02-2003).

- Do not violate the order of laying the layers of the roofing cake (see the features of installing insulation on a reinforced concrete slab and corrugated board).

- Use only high-quality insulation of proven brands.

A warning! If over time the roof requires major repairs and insulation, then it is necessary to completely dismantle the top layer of waterproofing and old insulation boards. Installation of flat roof insulation must be done anew, the imposition of a new thermal insulating layer on the old one is unacceptable.

Warming with expanded clay

Expanded clay is rarely used as an independent thermal insulation for a flat roof. Rather, it is just an addition to the main insulation.

In addition, with the help of expanded clay, a slope-forming layer is often created. Therefore, the order of work is as follows:

- Installation of the main thermal insulation made of mineral wool or expanded polystyrene.

- Marking the angle of inclination of the roof, pulling the laces.

- Delivery of expanded clay to the roof and stretching it along a string, for this they use the rule.

- Excess material is pulled along the edges to ensure a good drainage of moisture from the parapet.

- A concrete screed is placed on top of the expanded clay.

The thickness of the expanded clay heat-insulating layer depends on the angle of inclination of the roof. Expanded clay should not affect the thickness of the main insulation layer.