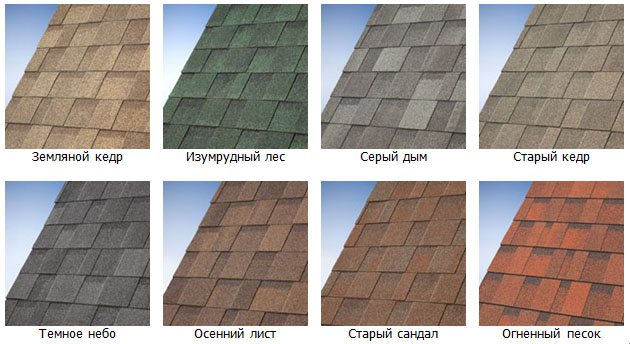

Soft roof (bituminous shingles)

Shingles can be called differently. These are bituminous, soft and composite shingles. It is also called roofing tiles or shingles. Outwardly, it is represented by flat sheets, the size of which is mainly 100 cm by 34 cm. Shingles have curly cutouts dividing the sheets into petals. The roof resembles a tiled roof as a result of the fact that the sheets are stacked by displacing two adjacent rows relative to each other.

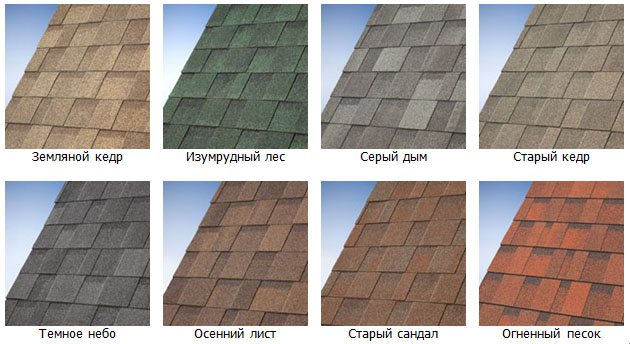

Today, soft roofing can have different petal shapes: rectangular, triangular, oval, wavy, etc. In addition, there is a large selection of colors. But, regardless of the large selection of shades and shapes, each version of the soft roof has an identical composition and structure.

- The top layer is decorative, it creates the desired color of the roof. Consists of mineral chips. Its main task is to protect the rest of the layers from the negative influence of external factors.

- Bituminous polymer material. Provides flexibility to the shingles and protects them from deformation.

- Substrate impregnated with bituminous fiberglass or organic cellulose.

- A layer of bitumen-polymer resin.

- Self-adhesive composition of bitumen-polymer mass.

- Siliconized film that protects the adhesive layer.

If we compare shingles with other types of roofing, then the first has many advantages. They are due to the optimal size of the material and modern manufacturing technology:

- easy to install;

- profitability - little waste during installation;

- weighs little;

- absorbs sound well;

- low and high temperatures, its sharp drops are not terrible;

- condensation does not form on the inside of the OSB;

- can be installed on any roof, even with the most complex structure;

- resistance to sunlight;

- bacteria and corrosion are not terrible;

- the material has a dielectric capacity;

- a large selection of shades;

- long service life (20-50 years, depending on the manufacturer);

- high level of water resistance, minimum water absorption.

Expert opinion

Konstantin Alexandrovich

But it is important to remember that using shingles involves spending money on creating a solid foundation. It cannot be installed if the outside temperature is freezing. But these disadvantages are insignificant in comparison with the huge number of positive aspects.

Features of ventilation of a cold roof from a soft roof

When installing a cold roof, additional measures are taken to ventilate the attic:

- in wooden houses with gable roofs, boards are loosely fitted on all gables, air penetrates through the cracks. This method is simple to perform, but it is not suitable for houses with stone / brick gables, as well as for hip roofs that do not have gables at all. Another disadvantage is that rainwater penetrates into the cracks along with the wind;

- ventilation holes are made in stone and brick pediments. Their total area is 0.2 percent of the area of the attic itself, otherwise it will not be enough for full ventilation. Ventilation grilles are placed with holes downward so that rainwater does not flow into the attic;

- for hip roofs, one ventilation hole is located in the cornice lining, the second at the ridge. Loosely fitted boards or perforated plastic soffits can be used as filing;

- hip and round roofs do not have a ridge. Here you will need to install point aerators.

I already wrote in more detail about ventilation of a soft roof in one of the articles. You can get acquainted with her here.

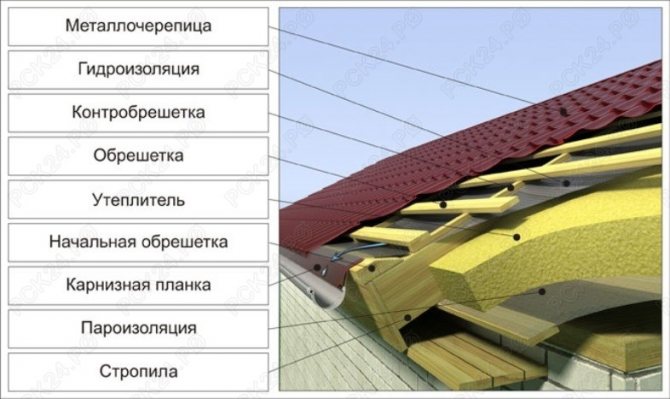

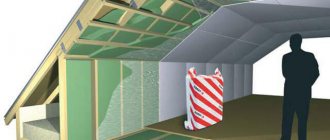

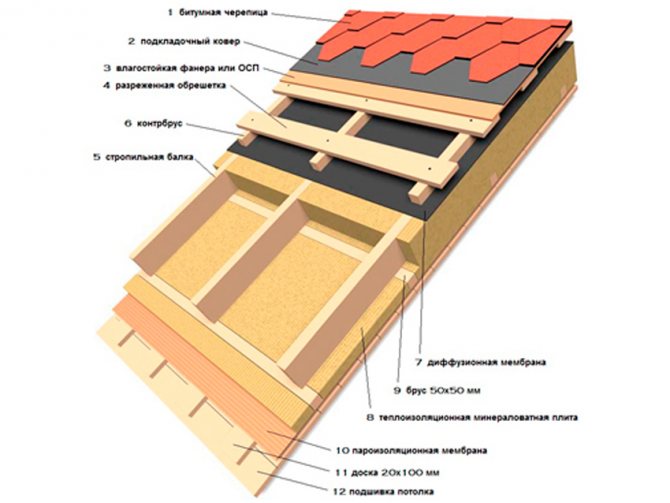

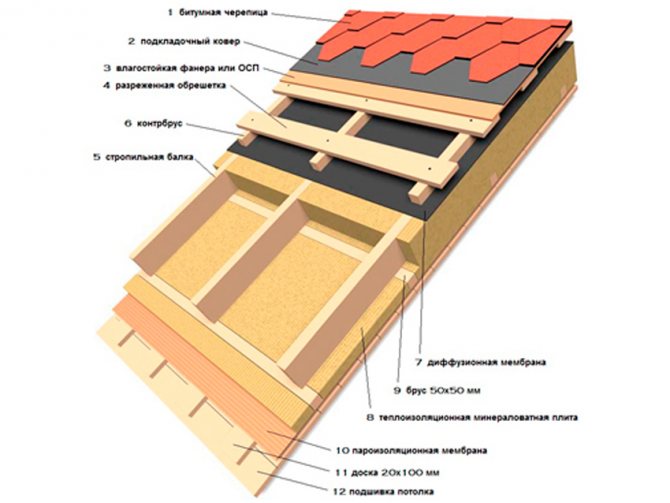

The Right Roofing Pie

The design for soft tiles is complex. So that he does not lose his qualities, during installation it is necessary to follow all the rules specified by the manufacturer. Thanks to a warm roof, you can insulate a cold attic, as well as increase the area of the room, while incurring small material costs.

But if during the repair work break the device "pie", then this can worsen the thermal insulation characteristics of the roof. As a result, the microclimate indicators in the room will deteriorate. There is a high chance of leaks, which will lead to many other problems. In order for the roof to meet the necessary indicators, it is necessary to take into account everything that affects it.

- Precipitation. The roof must be free of leaks. The installation method directly depends on the angle of inclination of the slopes. It is also worth taking care that snow does not penetrate into the space under the roof.

- Dynamic loads. They are temporary (wind, snow, etc.) and permanent (roof weight). When calculating the rafter system and choosing the coating materials, it is important to take into account the maximum values of the complex loads. A special safety factor must be added to this indicator.

The microclimate in the attic must be stable. It should not be influenced by external factors. If the temperature difference between the indoor and outdoor air is large, then this will cause increased heat transfer and heat loss. To avoid this, an insulated roof is created, consisting of a large number of layers.

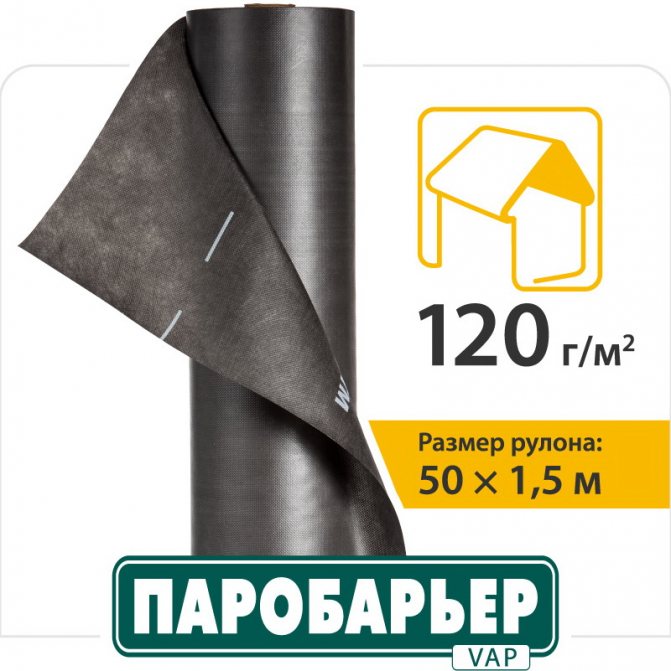

Vapor barrier

Indoor installation. Its main task is to prevent mineral wool from wetting. Modern membranes (an expensive option) or a simple plastic film can serve as a vapor barrier. If you use polystyrene or expanded polystyrene, then you can do without a vapor barrier. These materials are resistant to moisture, do not absorb it, thermal conductivity indicators do not increase due to them.

Moisture can penetrate into the structure of the "roofing cake" if there is a difference in the partial pressure of water vapor in the room and outside. The materials from which the vapor barrier is made must be highly durable and practically impermeable to steam. This minimizes the risk of humid air entering the insulation.

If the vapor barrier is carried out incorrectly, then moisture will condense in the thickness of the cotton wool. If the temperature is low, then the water in the state of steam is much less than if the temperature is high. Condensation starts to form in the top layer of the cotton wool, where the dew point is. But further, due to the action of gravity, water penetrates downward. As a result, all mineral wool gets wet. Because of this, the heat protection index decreases, and decay processes begin to develop.

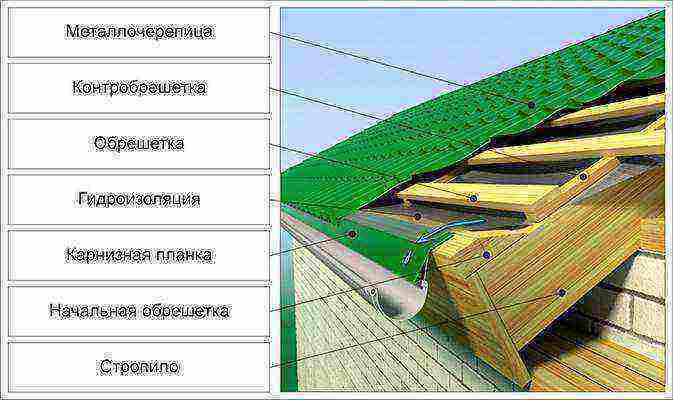

Why a vapor barrier is not needed for a cold roof

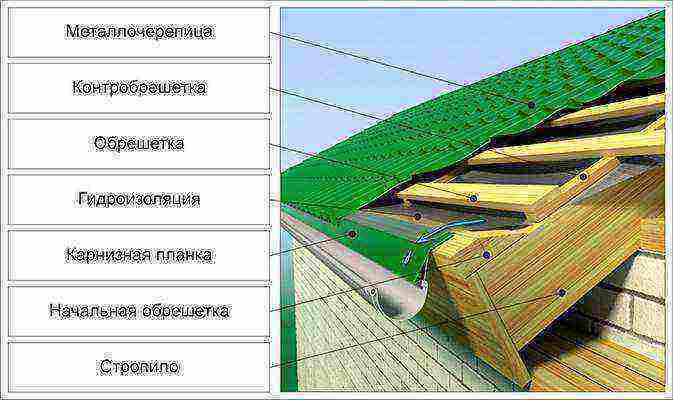

A cold roof is a rafter system on which a waterproofing material is laid. It will prevent moisture from entering the under-roof space and protect the rafter system from premature destruction. Then a counter-grill is mounted to ensure natural ventilation: the air flow enters the roof and removes excess moisture. A bar of 50 * 50 mm is usually used.

Next, the lathing is installed and directly the roof itself. The main feature of such a roof is the absence of insulation, the presence of ventilation outlets under the ridge and on the slopes.

Since there are no significant temperature changes in the roofing "pie", the dew point will be shifted to the insulation of the last floor (warm air will condense in the insulation in front of the attic), therefore, vapor barrier in the cold roof is not needed, but it will be needed in front of the insulation on the last floor, in front of the attic.

Materials and tools for installing a soft roof

As stated above, soft roofing is easy to install. And there is.If you strictly follow all the technologies, then you can mount a two-layer warm roof yourself. The main thing is to have at least a little experience in construction. In addition, you will not need to incur additional material costs for the purchase of additional materials and tools. Any home craftsman can always find everything you need.

Before proceeding with the installation of shingles, you need to prepare the following set of tools:

- saw on wood;

- jigsaw;

- a hammer;

- pencil, chalk;

- level;

- knife for cutting shingles;

- putty knife;

- roulette;

- Master OK;

- nail puller.

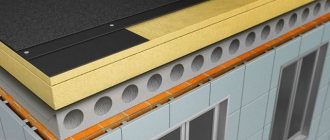

Types of bases for a flat roof cake

To overlap a building where a flat roof is supposed to be arranged, reinforced concrete slabs, corrugated sheets or wood are used. The choice of material depends on the size of the span to be covered, the purpose of the roof structure.

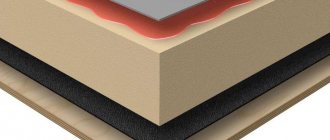

Flat roof pie on a reinforced concrete slab

Reinforced concrete floors are considered classic for flat roofs. Plates must be used when arranging an operating structure. Such a base can withstand heavy loads. A ramp is arranged on top of the slabs. Arrangement of a cold roof structure provides for the installation of waterproofing immediately. For a warm roof, a vapor barrier is laid on the screed of the slope. Its edges are made with a margin so that they are wrapped to the height of the installed insulation. The final layer is waterproofing.

Flat roof pie on a metal profile

A base of a metal profile is used for an unexploited roofing structure. The profiled sheet serves as an element of overlapping spans. For rigidity, metal beams are laid under it. Pie layers are standard for warm roof structures. If the roof is cold, then the profiled sheet is the final coating.

Flat roof pie over hardwood floor

A wooden base is similarly used for an unexploited roof structure. The flooring material is often chipboard or plywood. Sheets are laid on wooden beams. From above, the base of the cold roof is protected with waterproofing, roofing. For a warm roof, a standard set of layers is mounted on a wooden floor using insulation.

Waterproofing films

It is not only steam from the inside of the room that can get into the thermal insulation layer. There is a high probability of moisture formation on the outside. This happens, as a rule, as a result of leakage of the main coating or when condensation occurs. In both cases, a waterproofing film will help protect the thermal insulation from the ingress of unwanted moisture.

Most of these products are made reinforced, based on the above-mentioned polyethylene and polypropylene. At the same time, the properties of waterproofing materials can have significant differences, therefore, they must be chosen especially carefully and deliberately.

No vapor barrier film, even of the highest quality, is capable of providing a 100% level of protection against unwanted moisture from entering the insulation. Some steam still gets into the insulation. Excess moisture should not accumulate in it, and for this it must be provided with an unhindered exit opportunity, which can be provided by high-quality waterproofing.

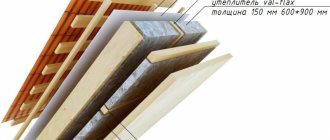

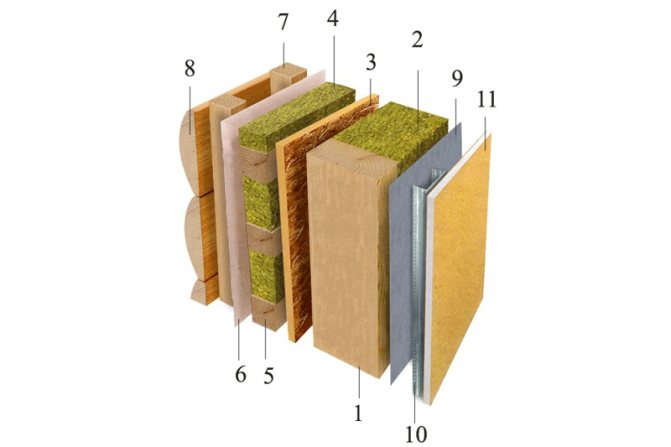

The wall of a frame house - the correct order of layers

When building a residential building, the correct placement of layers guarantees not only the high quality of the building, but also its durability, low frequency of repairs, and practical features of operation. The correct pie of the "Canadian" frame house is assembled in a few weeks and requires skills in working with different types of materials: wood, plastic oilcloth (waterproofing), facing materials (drywall, wall paneling, stone), and so on.If we consider the device of a standard wall from the room to the outside, then it will have the following structure:

Finishing with OSB (oriented strand board), plasterboard, less often with clapboard and other types of assembly wall cladding;

- A vapor barrier layer that protects the remaining layers from the penetration of gaseous substances. This is a necessary layer that will completely protect the insulation from the negative effects of various kinds of liquids (including condensate). Mineral wool is capable of accumulating moisture and straying into tight lumps, which disrupt the thermal insulation process and significantly reduce the overall warmth of the house. A vapor barrier layer is necessary in any type of wall with mineral wool-based filler (basalt, glass wool, etc.);

- These two layers are attached to a wooden frame from a bar or board. Installation is carried out using a construction stapler or special staples. The outer trim can be drilled either directly to the frame or to the counter-lattice. In this case, the space between the counter-lattice and the frame is filled with sound insulation or a layer of foam (a type of cross-insulation);

- The third layer (inner) is insulation. In frame houses, rolls or blocks of mineral or basalt wool, glass wool or combined compositions are used. Stowed in special niches - the space between the vertical and horizontal frame beams. Mineral wool practically does not attach to the wood in any way - during the installation process, it straightens out and fills all the available space. This allows you to achieve maximum insulation. At the same time, the frame becomes a vulnerable spot - the tree is a "cold bridge", therefore, a cross frame is more often used - another layer of insulation, one third thinner than the main one.

After the main layer of insulation, an OSB plate follows, which holds the insulation from the street side. Fastened with screws or nails. When installing between the plates, it is necessary to leave a small gap - literally 1-3 mm. Sooner or later, the stove will pick up a little water and swell, the gap, as such, will disappear. The thickness of the slab should be several centimeters - for better protection against adverse environmental factors.

A layer of moisture and wind protection is also often laid between the OSB board and the insulation. The cake of a frame house with a thick OSB outside is completely protected from kinetic effects - shocks, falls, etc. (for example, from falling branches).

When treated with special means, the house will be resistant to fire.

The next layer is wood lathing. This is a horizontal or vertical lattice made of timber or a cheap board, which serves as a fastener for the next layers. Fastened to nails, self-tapping screws, less often - square brackets. Often, wood lathing serves as a frame for the outer layer of insulation - high-density cotton wool, less often - foam.

A thick layer of moisture and wind protection. This is a special membrane, which is the main line of protection of the entire frame from external influences. Attaches to industrial staples or nails with large heads. Membrane layers should be overlapped, the corners of the house must be closed with a single piece of VVZ.

Another layer of lathing made of thin beams, planks or planed boards. Serves as the basis for the installation of decorative finishes. Fastened at an angle of 90 ° to the previous layer.

The last layer is the exterior finish. As a rule, these are lining, sheets of corrugated board made of plastic or metal, decorative panels.

It is worth noting that for more complex exterior finishes, it is necessary to make changes to the original design of the house. So, if the customer wants to make a beautiful brick finish, not only the foundation, but also the frame will have to be seriously strengthened. Lining frame houses with stone is a very complex technique, but it allows you to create an imitation of a brick house for three times less.

The order of installing the layers is as follows:

- Frame;

- Cross-insulated frame;

- Filling external niches with insulation;

- VVZ membrane, OSB outer plate;

- The second layer of insulation;

- Vapor barrier layer, installation of interior decoration;

- External lathing, installation of external finishing;

- Cosmetic work (painting, putty, etc.).

Stages of the device of the operated roof

· Cleaning the base from debris and dust, sealing cracks and chips.

· Vapor barrier device.

· Installation of thermal insulation in 2 layers with mechanical fastening to the base.

· Roof slope device with cement-sand screed by 1-2 degrees.

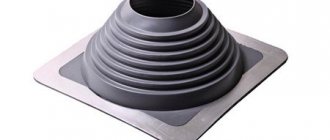

· Installation of parapet and two-level gutters with reinforcement with waterproofing patches.

· Installation of a separating layer from geotextile.

· Installation of waterproofing on a horizontal plane and places of abutment to the parapet, ventilation shafts, pipes and other protruding elements of the roof.

· Installation of topcoat.

*The order of placement of insulation and waterproofing depends on the type of roof.