Nissan hydrogen fuel cell

Every year, mobile electronics are improving, becoming more and more widespread and more accessible: PDAs, laptops, mobile and digital devices, photo frames, etc. All of them are constantly being updated with new functions, large monitors, wireless communications, stronger processors, while decreasing in size ... Power technologies, unlike semiconductor technology, do not go by leaps and bounds.

The available batteries and accumulators to power the achievements of the industry are becoming insufficient, so the issue of alternative sources is very acute. Fuel cells are by far the most promising direction. The principle of their operation was discovered back in 1839 by William Grow, who generated electricity by changing the electrolysis of water.

How to connect?

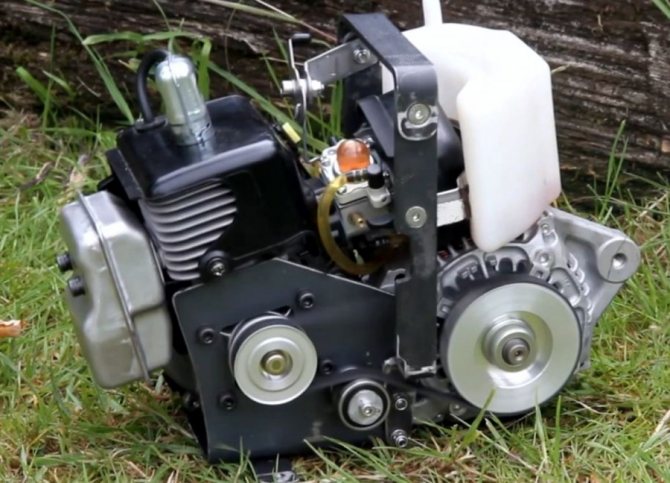

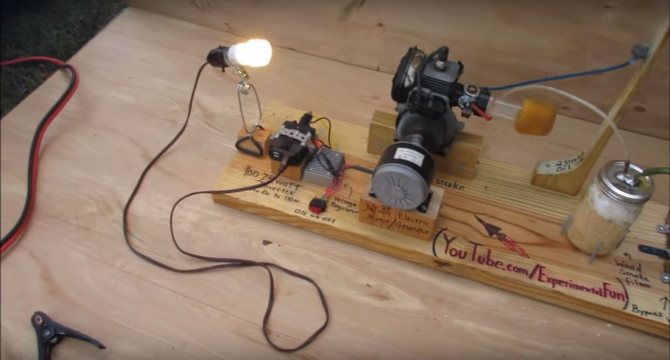

The optimal solution is to make a special removable block that can be quickly connected to the saw, and just as quickly dismantled. In this case, such a device is easy to take on a hike, as its versatility will come in handy. For fastening, either an old saw bar or a homemade bracket is used. The optimal connection is a belt connection, since the chain drive is too noisy, and even requires lubrication. The belt must be chosen so that the electric generator (it's easy to make it with your own hands) is located as close as possible to the saw itself.

The principle of operation of the generator

As an energy carrier, hydrogen really has no equal, and its reserves are practically inexhaustible. As we have already said, when burned, it releases a huge amount of thermal energy, incomparably greater than any hydrocarbon fuel. Instead of harmful compounds emitted into the atmosphere when using natural gas, when hydrogen burns, ordinary water is formed in the form of steam. One problem: this chemical element does not occur in nature in a free form, only in combination with other substances.

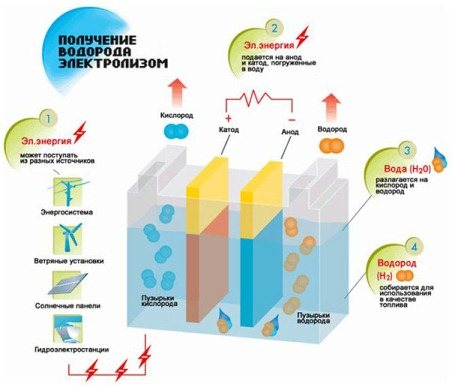

One of these compounds is ordinary water, which is completely oxidized hydrogen. Over the years, many scientists have worked on breaking it down into its constituent elements. This is not to say that it was unsuccessful, because a technical solution for the separation of water was still found. Its essence is in the chemical reaction of electrolysis, as a result of which water splits into oxygen and hydrogen, the resulting mixture was called explosive gas or Brown's gas. Below is a diagram of a hydrogen generator (electrolytic cell) powered by electricity:

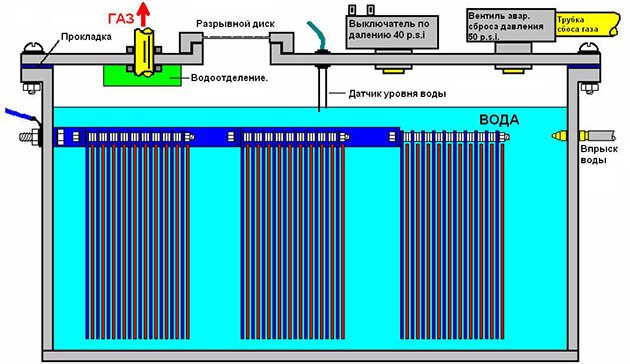

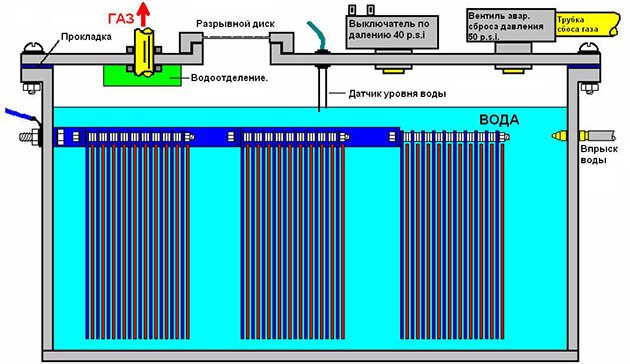

Electrolyzers are produced in series and are designed for gas-flame (welding) work. A current of a certain strength and frequency is applied to groups of metal plates immersed in water. As a result of the ongoing electrolysis reaction, oxygen and hydrogen are released mixed with water vapor. To separate it, the gases are passed through a separator and then fed to the burner. In order to avoid a kickback and explosion, a valve is installed on the supply, allowing the fuel to pass only in one direction.

To control the water level and timely replenishment, the structure provides a special sensor, at the signal of which it is injected into the working space of the electrolyzer. The excess pressure inside the vessel is monitored by an emergency switch and a relief valve. Maintaining a hydrogen generator consists of periodically adding water, and that's it.

Technology - Youth 1964-03, page 20

I met Vasily Lavrovsky in Omsk. The conversation began with the most general topics, and then he suddenly asked:

- Have you ever seen electric generators that do not have a single meter of wire, but can provide a current with a capacity of hundreds of thousands of kilowatts? Do you think it's impossible? So I'll tell you now about an electric generator that can be built without copper, insulating materials, with an insignificant amount of electrical steel, without step-up transformers for transmitting current over long distances.

And I heard a story similar to a fantastic story ...

LONGLY FORGOTTEN

For the first time, electricity was obtained by friction. It was on this principle that electrostatic machines were built. And then these machines almost ceased to be used - only some of their varieties are used in nuclear physics, electronics and other fields. The fact is that although they give a very high voltage current, the current strength is negligible.

What if these high-voltage machines are given more power? After all, then you get a generator with unlimited possibilities ...

But how? To many, such a task seemed almost insoluble. However, scientists did not lose hope. "It seems to me quite possible," wrote Academician AF Ioffe more than twenty years ago, "electrostatic generators for thousands and tens of thousands of kilowatts ..."

Meanwhile, until CIS times, electric current continued and continues to be obtained with the help of complex, expensive generators that operate on the principle of electromagnetic induction. ,

GENERATOR FROM CONDENSER

The oppositely charged capacitor plates are mutually attracted. To push them apart in different directions, it will be necessary to expend a mechanical force, which must exceed the force of electrical interaction. The expended mechanical energy will go to increase the potential difference across the capacitor plates. The capacitance of the capacitor will decrease, and the voltage across its plates will increase.

It was this principle that served as the basis for the creation of Lavrovsky capacitive generators.

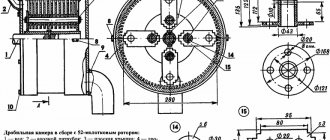

If we make a model on which one capacitor plate remains stationary, and the second rotates clockwise, and we attach an exciter to the collector and the stationary plates, then ...

Take a look at the picture. You can make sure that when removing the plate "a" from the plate "g" and decreasing the capacity from Cmax. To C min. the tension will increase as many times as Smake. RELATED TO SMNN. So, if the pathogen gives 1 OOO in,

and the capacitance ratio is 50, then the generator will give 50 thousand volts to the load.

But ... such machines will be good only in space, but for their successful operation you need an absolute vacuum. On the ground, the small dielectric constant of the air interferes. A discharge occurs between the plates or rings, the accumulated charges disappear.

In vacuum, the breakdown voltage reaches 100 million volts per cm of distance between the plates. Under these conditions, high voltages can be used to obtain and hold large charges.

To push the capacitor plates apart. force must be applied.

GENERATOR OF VASILY

Vladimir STRELKOV, our specialist correspondent Fig. I. KALEDINA

In terrestrial conditions, Lavrovsky suggested using a material with a high dielectric constant - barium titanate.

... But again the air interfered, this time due to its other peculiarity. The smallest air gap between the rotor and the stator made of barium titanate nullified the wonderful properties of ceramics: on the one hand, it has an ultra-high dielectric constant, high polarization of the medium, and on the other hand, it is a good insulator. The air was almost not polarized, and the generator worked with negligible efficiency. And yet Lavrovsky found a way out.

RELEASES THE PEACEFUL ATOM ...

Ionized gas is an excellent medium for polarization!

If the air in the rotor-stator gap is ionized, then it acquires a high dielectric constant, sufficient for good machine operation.

To do this, it is necessary to cover the sections of the rotor and stator with a radioactive isotope with alpha decay. Then the required polarization will appear in the gap. Particles with alpha decay will allow you to abandon complex and expensive protection.

As the air becomes thinner, the amount of ionizing isotope to be applied to the gap will decrease. And in order to reduce the amount of radioactive substances to the limit and ‘at the same time increase their efficiency, it is possible to use a“ rough vacuum ”in the gap — 5-10 mm Hg.

… PLUS PLASTIC

But barium titanate is a ceramic. Its strength is much less than steel. The barium titanate rotor cannot be given a large number of revolutions - it will fly to pieces.

vacuum 5 ″ l (lft.

Causative agent

• METAA.COVERED AND PROTECTIVE TIPS WITH RAASH SHOP NZ PLASTICS

And for generators that are installed in power plants, speeds up to 3 thousand rpm are required.

Causative agent

TITANATE BARIUM

LOAD

This is how the simplest model of a capacitive generator for operation in space can be built.

LOAD

Ceramics came to the rescue.

It turned out that you can not rotate heavy ceramics. The "former" ceramic rotor is made stationary. A metal n-wheel with plastic insulating inserts is placed between it and the stator. When the insert during movement is against the isolated obli-

16

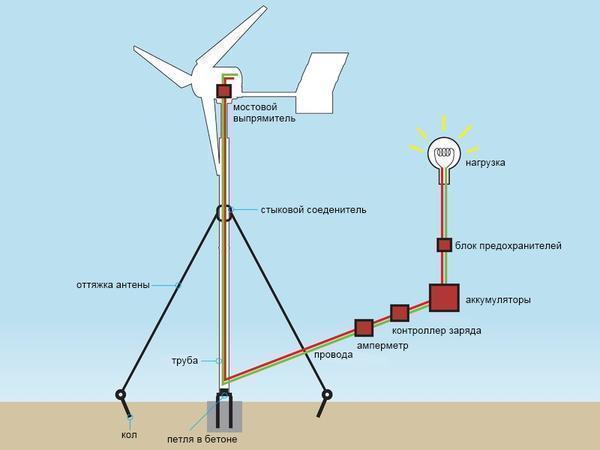

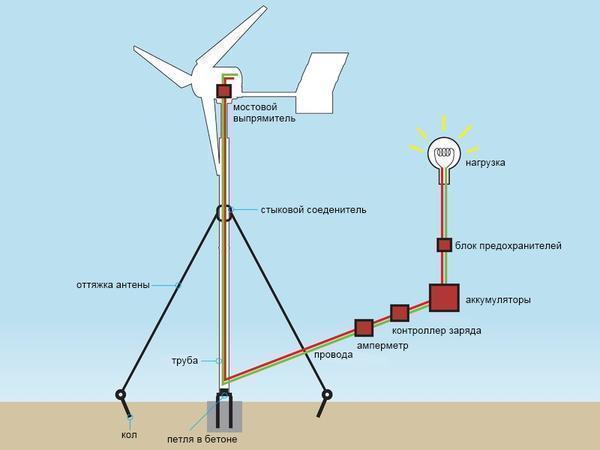

Wind turbine characteristics

Despite the fact that a wind generator may well be installed on the site without any claims from the state, problems may arise with neighbors, for example. It may happen that he will interfere with other people, which will cause complaints and possible complaints. For these reasons, it is necessary to pay great attention to some parameters, both when purchasing and when making it yourself.

- Mast height. When assembling a wind generator, you need to remember that there are height restrictions for individual buildings. If there is an airport, tunnel or bridge nearby, then the height of the building cannot exceed 15 meters.

- Equipment noise. Naturally, the rotor and blades will generate some noise during operation. To measure this parameter, there are special devices. After the measurement, the results obtained must be documented. They should not exceed noise standards.

- Interference on the air. During the arrangement of the wind turbine, it is necessary to take care that it does not interfere with the air. This is only relevant for those places where the generator is, in principle, capable of creating such troubles.

- Environmental component. Rarely, but still there may be claims from this service. They can be presented only if the wind generator for the house is located on the migration path of birds, which will interfere with them. However, this is extremely rare.

If the device is made by hand, then these parameters need to be given special attention. If the wind turbine is purchased, then it is worth checking its technical data sheet to familiarize yourself with all the characteristics.

Pros and cons of the device

If everything became clear with how to make a wind generator of such a model, then it is worth considering what the pros and cons the assembled structure will have. If all the work was done in the exact sequence and accurately, then everything will work properly and without problems. If you connect a converter, for example, for 1000 W and a battery for 75 A, to such a windmill, then the power will be enough not only for connecting household appliances, but also for burglar alarms or for a video surveillance system. Among the main advantages are the following points:

- profitability;

- all elements are quite simple and cheap, which means that they can be easily repaired or simply replaced with new ones if necessary;

- there is no need to create special working conditions;

- the device is quite simple, and therefore reliable;

- during operation will not make a strong noise.

There are not many negative sides, but they are still there. The performance is not too high for such installations, and also depends quite strongly on wind gusts. Too strong wind can blow off a homemade propeller quite easily.

DIY wind turbines for 220 V

In order to assemble the scoop we need: a 12 volt generator, batteries, a 12 v to 220 volt converter, a voltmeter, copper wires, fasteners (clamps, bolts, nuts).

The manufacture of any wind turbine assumes the presence of such stages as:

- Manufacturing of blades. The blades of a vertical wind turbine can be made from a barrel. You can cut parts using a grinder. The screw for a small wind turbine can be made from a PVC pipe with a cross section of 160 mm.

- Manufacturing of a mast. The mast must be at least 6 meters high. At the same time, in order for the twisting force not to break the mast, it must be fastened to 4 stretch marks. At the same time, each stretch must be wound on a log, which should be buried deep in the ground.

- Installation of neodymium magnets. The magnets are glued to the rotor disc. It is better to choose rectangular magnets, in which the magnetic fields are concentrated over the entire surface.

- Winding generator coils. Winding is carried out with a copper thread with a diameter of at least two mm. At the same time, there should be no more than 1200 skeins.

- Fixing the blades to the pipe with nuts.

In the presence of powerful batteries and an inverter, the resulting device will be able to generate such an amount of electricity, which will be enough for using household appliances (for example, a refrigerator and a TV). Such a generator is perfect for maintaining the operation of lighting, heating and ventilation systems of a small country house, greenhouse.