What is foam made from?

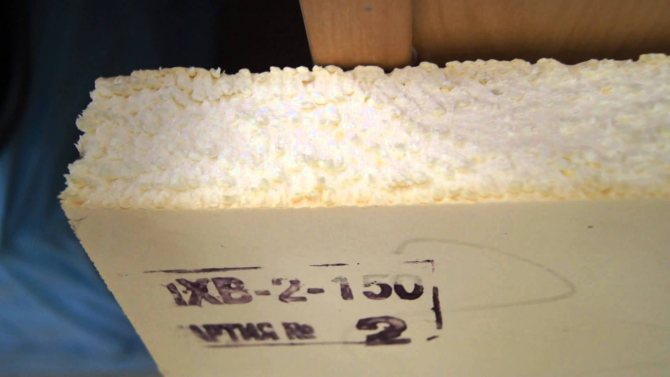

Polyfoam can be made from any polymers (plastics). The most famous raw materials are polyurethane, polyvinyl chloride, phenol-formaldehyde, polystyrene and others. But what kind of plastic the material would not be made of, there is only 2% of it in the material, the rest is atmospheric air. Domestic building material is produced in accordance with GOST 15588-2014 and is indicated by the general marking of PSB, to which numbers and letters are added, which indicate additional properties: low density, self-extinguishing, universal and others. Raw materials for expanded polystyrene look like translucent beads with a diameter of 0.2 to 3.7 mm. The material is produced in several stages:

- Foaming.

- Drying.

- Stabilization.

- Cutting.

- Maturation.

- Baking.

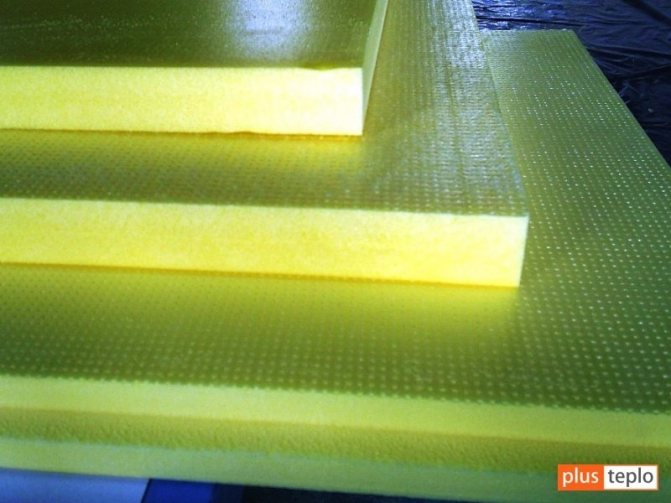

One of the methods assumes, after stabilization, the transition to baking, bypassing the 2 previous stages. Not so long ago, a modern version of the material appeared on the market - extruded foam. It differs from the classical one in the smaller size of the cells and their complete closure. Such a material was recognized as more technological, but ordinary polystyrene foam is still the most in demand, it can be used as a heater for walls made of any materials: wall blocks, concrete monolith, wood, brick and much more.

With him it will get warmer everywhere

The range of properties of foam plastic as a heater allows it to be used when carrying out work on energy saving of building structures, elements, linear objects:

- Vertical, horizontal, inclined;

- Foundations, walls (partitions), ceilings, roofs;

- Balconies and loggias;

- Tracks, roads, runways.

The foam is installed close to the insulated surfaces.

Now, knowing what foam is, we can say with confidence that the properties of new heat-insulating materials will not be able to significantly surpass the characteristics of foam as a heater for a long time. And every time you meet with him, you will remember your carefree childhood.

Photo of a happy construction worker with a Styrofoam sheet.

Specifications

| Parameters | The values | Comments (1) |

| Compressive strength at 10% linear deformation | 0.05 to 0.16 MPa | Strength indicators directly depend on the polymer from which the foam is produced. For example, phenol-formaldehyde have higher strength values. |

| Thermal conductivity | 0.038 to 0.043 W / mGrad | The parameter also depends on the brand of building material. |

| Frost resistance | Up to 200 cycles - normal Up to 500 cycles - extruded | The characteristic values depend on the brand |

| Water absorption | 1% per day | Tests have shown: 3% of the volume for 1 month of full immersion in water. The parameters are insignificant, however, if moisture gets into the expanded polystyrene, then it can subsequently freeze when the cold weather sets in. |

| Water vapor permeability, coefficient | 0.03mg / mchPa | This building material does not form a natural air exchange between premises and streets. |

| Fire resistance | Flammability G3-G4 Flammability B2-B3 Smoke formation D3 | Expanded polystyrene is considered a difficult flammable material |

| Foam cost | On average, 3 thousand rubles per 1 m3. | Styrofoam is quite available, the price depends on the brand and thickness. |

| Soundproofing | Depending on the thickness, it can increase the protection up to 32 dB | Expanded polystyrene is characterized by high performance, but inferior to other materials, for example, mineral wool |

| Environmental friendliness | Safe | It has no radioactivity, it is completely utilized, since no toxic raw materials are used in the production and a minimum of energy is expended. |

| Life time | 13 to 80 years old | The value of the indicator depends on the manufacturer, production technology and raw materials. |

| Foam density | 11 to 40 kg / m3 | The characteristic depends on the brand. |

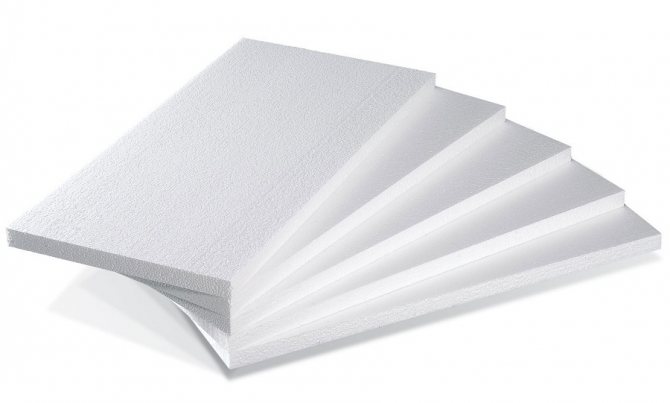

Standard foam sizes - thickness varies from 20 to 100 mm, length and width: 1000 * 1000, 1000 * 1200, 1200 * 1200. How much the foam costs depends on the size parameters.

Myth number 3. expanded polystyrene burns well

Indeed, expanded polystyrene, like any materials with polymer additives, is a combustible material. However, correct use with the fulfillment of all existing installation and operation rules, fire safety requirements make it possible to successfully use it in construction.

Combustible building materials are divided into four groups: G1 (slightly combustible), G2 (moderately combustible), G3 (normally combustible), G4 (highly combustible). "Analyzing the results of the experiments, we can say that with a certain chemical treatment of expanded polystyrene, the degree of its flammability can reach the indicators G1, G2, G3," - assured Boris Serkov, deputy head of the fire certification body of the Academy of the State Fire Service. For comparison: mineral wool, an equally popular thermal insulation material, if tested according to the method of testing expanded polystyrene plates, belongs to the G4 flammability group.

The temperature of spontaneous combustion of polystyrene foam is +491 ºС. This is 2.1 times higher than the ignition temperature of paper (+ 230 ºС), and 1.8 times higher than that of wood (+260 ºС). Thermal energy, during combustion, polystyrene foam emits from 1000 to 3000 MJ / kg. For comparison, burning dry wood produces 70008000 MJ / m3. Thus, expanded polystyrene gives a slight increase in temperature, unlike other materials involved in a fire (furniture, linoleum, etc.). Fire resistance (combustibility) of expanded polystyrene plates is determined not only by their physicochemical properties, but also by their "neighbors". These are combinations with other building materials, as well as the availability of the necessary protective layers. Subject to fire safety rules, PSB-S polystyrene is less dangerous than other widespread building materials.

Features of the

This building material is widely used due to the following qualities:

- ease of processing of building materials allows you to create structures of any geometry, even the most complex;

- low strength and high compression density;

- it maintains the stability of the structure in a wide temperature range: from -170 to +80 degrees;

- high resistance to many chemicals and biological factors;

- high thermal insulation allows us to consider foam insulation as an excellent building material, for example, for the construction of modern multi-layer house structures;

- environmentally friendly building material, since it does not contain substances from a series that is toxic and harmful to human health;

- easy to handle and install, also with conventional building adhesives.

- the price of non-extruded foam is lower than that of EPS.

Disadvantages:

- limited mechanical strength necessitates the formation of protection after installation;

- collapses upon contact with paints and varnishes and nitro paints;

- building material can be damaged by rodents, so it must be covered with substances less attractive to animals;

- the material almost does not allow air to pass through, which makes it necessary to equip the building with ventilation systems;

- Plastering on polystyrene foam requires preliminary preparation to ensure the best adhesion.

What is already known about him

What is Styrofoam? The basic properties of foam have been known for a long time and to almost everyone. Lightweight, white, rather dense, not quite durable. It is often used for packaging household appliances, other goods, and making promotional items. It can be used to increase the buoyancy of ships, or it can be used as a seal.A less visual, but no less important application of polystyrene is the insulation of buildings and structures, both newly erected and put into operation. Many people have views on it, deciding to insulate the house, but not many know so much about it to make an informed decision.

Scope of application

This material is widely used in various spheres of human activity: packaging for products, furniture manufacturing, tailoring, outdoor advertising, shipbuilding, electrical engineering and radio. But expanded polystyrene is most in demand in the construction industry:

- Polyfoam is a building insulation material that can be used to insulate the walls of a house from the outside.

- Thermal insulation of roofs and floors.

- As an insulation of engineering communications.

- For soundproofing between floors or rooms.

- Polyfoam for insulation is used on the plinth, closing it with cladding, as well as for thermal insulation of the foundation.

Why - foam as insulation?

It's time to put everything on the shelves: flies - separately, cutlets - separately.

Hello!

Some of my subscribers ask - is it possible to replace the foam in our technology "My own home 2.0" with a more "harmless" insulation?

Foam plastic for the "My own home 2.0" technology was not chosen by chance. If you have been looking for insulation for your future home for a long time, you probably noticed that in the network of positive and negative materials about the two main types of insulation - all kinds of fiber and foam - about 50x50.

I am in no way going to find fault with various types of fiber insulation, since I am not the manager of a foam manufacturer.

Just foam for the "My Own Home 2.0" technology is more suitable for the following reasons:

1. According to technology, we need a solid insulation.

2. We need a durable wall (it is not an easy task to ensure that mineral wool does not sag or get wet for decades).

3. We do not want to complicate (read - rise in price!) The structure of the wall - to mount a ventilated facade - is almost a mandatory thing for fiber insulation.

4. Polyfoam is cheaper than fiber insulation.

5. I had to personally communicate with experienced builders (from the Moscow region, Krasnodar, Nizhny Novgorod and Ufa). The priority insulation for them is definitely polystyrene. They also use Minvata when developers insist on it (I think so - they were scared by the myths walking on the Internet!).

When it comes to styrofoam, basically, people cannot navigate three aspects, three alternatives:

1. Harmfulness - harmlessness.

2. Flammability - non-flammability.

3. Breathes - does not breathe.

Let's take a look at these three aspects one by one. Today we will consider item 1:

1. Harmfulness - harmlessness.

Disputes regularly arise on the Internet about the dangers of using heat-insulating material in the construction of a house - expanded polystyrene. Let's try to figure it out without emotion, based on facts.

But first of all, let's try to figure it out: are polystyrene and expanded polystyrene the same thing?

Various plastics can be foamed. But, since basically polystyrene is now made from polystyrene, there will be no big mistake in this definition:

Polyfoam is a common household name for all expanded polystyrene - both foamed and extruded. Simply - not everyone will pronounce this long word - expanded polystyrene, and "styrofoam" is both shorter and more familiar.

And what do the regulations say?

According to GOST R 52953-2008, expanded polystyrene (foam is not mentioned here at all), depending on the production method, is divided into expanded polystyrene foam (EPS) and extruded (XPS). These two types of polystyrene foam have differences in physical characteristics.

Extruded polystyrene foam has the Russian name "Penoplex". It is stronger than expanded polystyrene, a little heavier and, of course, more expensive, three or four times.

Penoplex has scanty water absorption and increased strength, and therefore I used it earlier and will use it - when building a granddaughter's house - only to insulate the foundation along the outer contour.

Well, now let's try to find out - how harmful is expanded polystyrene - to run from it like from the plague, or accept it as a neutral participant in everyday life? It is not so neutral, but very even useful, since it makes it possible to save a lot on heating the house. It should be borne in mind that a better insulation than expanded polystyrene has not yet been invented by mankind.

Let's deal with the myth about the harmfulness of expanded polystyrene - flies separately, cutlets - separately.

Expanded polystyrene is made from polystyrene.

The raw material for the production of polystyrene is styrene monomer.

We look at GN 2.1.6.1338-03 and classify styrene as a substance of the 2nd hazard class.

The Kristall detergent is also assigned to the same hazard class. We washed our clothes, put them on and wear them on ourselves. Nobody yells: “I don’t want to live in chemistry!”. "Tide (THEN WE ARE COMING TO YOU! - from advertising)" and most other detergents are classified as hazard class 3, a little more harmless, but we are in constant contact with them and the amount of detergents you have to deal with is several orders of magnitude more than the theoretical presence of styrene in the insulation of the house.

Is there a lot of residual styrene in expanded polystyrene? Expanded polystyrene was invented in 1951 by BASF (Austria). At that time, according to the then technology, the amount of non-polymerized styrene in polystyrene was about 2-3%. For 63 years, production has been greatly modernized and today the share of styrene in raw materials, polystyrene granules, is no more than 0.05%.

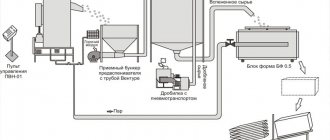

In the process of production of expanded polystyrene foam: polystyrene granules enter the blowing machine, where they are converted by steam into expanded EPS granules ("balls"), which in turn are dried, then fed into a block mold and sintered again at a high temperature.

With these manipulations, the main part of the residual styrene (0.05%) in the production of EPS simply evaporates and is removed during the production cycle into the ventilation.

The result is expanded polystyrene - a material consisting of 2% polystyrene and 98% air.

In addition, after production, expanded polystyrene lies, until it is bought, in the open air, erodes (if there is anything to erode!). Then, being laid in the wall, through leaks in the joints, the polystyrene also erodes. If some kind of poison remains in the expanded polystyrene after its manufacture, then there is no chance of remaining in the insulation by the time the house is finished building.

In addition, we are separated from expanded polystyrene in the thickness of the wall (according to the project "My Own House 2.0") by a blind monolithic wall made of expanded claydotopil column concrete with a thickness of 100 mm.

Sometimes you can hear statements that polystyrene foam decomposes over time with the release of styrene.

The Austrian company BASF (the inventor of expanded polystyrene) regularly checks a sample of expanded polystyrene installed in real conditions of operation more than 50 years ago and notes the complete absence of decomposition. Therefore, statements about "decomposition with the release of harmful substances" are gossip.

Those who spread gossip about the dangers of expanded polystyrene are somehow silent about the fact that styrene is used, in addition to the previously mentioned washing powders, also in the production of car tires, electronic housings, shoes, etc.

And that the main raw material for the production of the vast majority of water-dispersion paints, which are widely used in the repair and decoration of premises, is styrene-butadiene binder (GOST 28196-89).

And no one rushes to the forum to find out whether it is harmful to wash and wear shoes, or to use water-dispersion paint, which is widely used for repairs in apartments, which is made with the participation of such a "suspicious" material!

Why, then, are people afraid to live in a house insulated with expanded polystyrene?

Everything is very simple. In Russia, a vicious practice has developed when low-paid managers of trading companies, in order to earn their percentages on sales, compensating for their own illiteracy, are spreading rumors about competing products, slandering competitors, creating an information product, which is commonly called the bad word "Gossip".

And then the "OBS" mechanism turns on (One Grandma Said) - and this gossip went for a walk on the forums, acquiring more and more terrible details. So gossip turns into a myth.

A few words about houses made of SIP panels (Canadian technology)... In general, there is a house (both walls and floors), everything is made of expanded polystyrene (plywood is glued to it from the outside and from the inside). Millions of such houses have been built all over the world, including Russia.

Any more or less large city in Russia (and Surgut too!) Certainly has a firm for the production of SIP panels and builds houses from them.

People living in these houses do not complain about harm, but about other shortcomings. For example - poor noise absorption. And in the event of a flood (as it was in 2013 in the Khabarovsk Territory), a light house “for some reason” floats to a neighboring site.

In Europe, expanded polystyrene is very widely used in construction and there is no talk of a ban even.

When applied, all established European standards are strictly observed and this does not cause any negative consequences.

In Russia, unfortunately, you can spread any kind of gossip, because judicial attempts to punish this occupation are still completely futile.

Health safety is also confirmed by the fact that expanded polystyrene is used for food packaging (in accordance with the Hygienic Norms GN 2.3.3.972-00). Who does not know Doshirak noodles, mashed potatoes and other products in disposable polystyrene dishes? The semi-finished product is poured with boiling water and the contents are eaten (placed in expanded polystyrene!) - for a sweet soul!

And what do they bring in fish from Norway? In boxes made of expanded polystyrene. You can also add styrofoam bee hives to this list. And the certificate to the bees - to the bulb! They use only material that is harmless from their point of view. The list goes on and on.

It is interesting that birds and other animals, unaware of "the dangers of expanded polystyrene", devour (or peck) it godlessly - for fun! (I suppose - because there is not a single sales person among them - there is no one to spread gossip).

As for me personally, for 15 years I have been living in a house insulated with expanded polystyrene and I do not feel any harm. (In our village, every second house is insulated with expanded polystyrene).

In general, the debate about the harmlessness of expanded polystyrene reminds me of the beginning of the 20th century. Then everyone shied away from the "smoking monsters" - cars. The then "fighters for the environment" unambiguously advocated "environmentally friendly" horse transport. Time has put everything in its place.

We always cite Europe as an example of environmental friendliness. There is definitely nothing harmful to produce and will not be used!

But, if we take only Germany, then more than 80% of the used wall insulation is precisely expanded polystyrene

ny heaters.

Now in Russia the energy consumption of heating systems is 60-75% higher than in the Nordic countries. And one of the reasons for this is the low level of use of modern thermal insulation materials.

So in Russia there is only 50 square meters per 1000 people. meters of thermal insulation against 600 sq. meters in Sweden, while polymers in our country account for only 20%, while in Sweden 60%.

I hope I convinced you that expanded polystyrene is not so terrible as it is painted. As one friend of mine said:

“Living is harmful! They die from this! "

In our technology "My own home 2.0" for building a house kind of key with your own hands (even if you have never been involved in construction!), The most effective insulation today is used - expanded polystyrene. In any case, a more effective insulation has not yet been invented by mankind.

In the next letters, we will continue to explore the properties of expanded polystyrene, in particular in terms of flammability - do not forget to open my letters.

I remind you that tomorrow, December 24, the Sun turns into spring (1 minute is added in the longitude of the day!) And in connection with this event - the beginning of the construction season is inevitably approaching (!), We decided to provide you with the opportunity to receive our courses at a very low cost. Don't miss this chance, be sure to open tomorrow's letter!

Best regards, Sergey Lapko.

P.S.

I also remind you that the entry into the early list for receiving the course "Mobile lift with scaffolding" is open - a course - for those who want to make construction a sheer joy, and not "hard labor", as well as for those who know how to count money.

Tweet