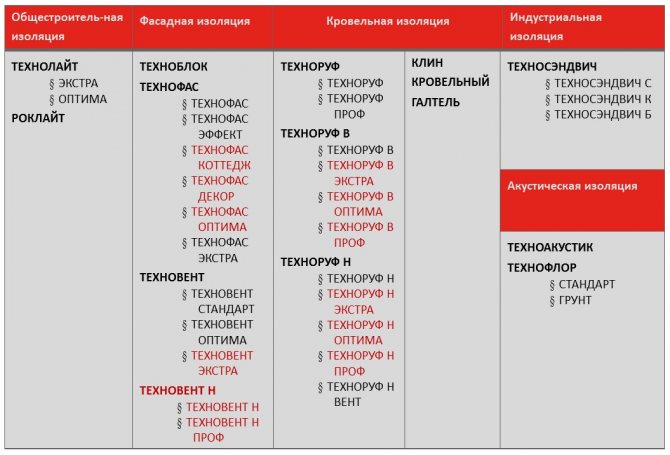

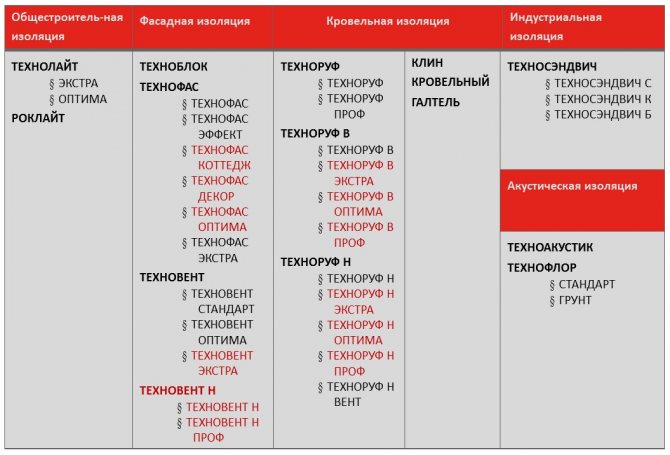

A building can lose up to 1/5 of the heat through the roof, which means that this is an Achilles' heel in the thermal insulation of the room. And if a pitched roof is created in order to retain the cold, due to a large air gap (attic), a flat one is deprived of such an opportunity. To solve problems, mainly insulation of a flat roof, the TechnoNikol insulation of the Technoruf series has been developed.

The quote taken on the official website of the manufacturer clearly indicates the scope of the material:

Purpose of Technoruf

Although, it is worth noting that it is also possible to insulate pitched roofs with this material.

General features

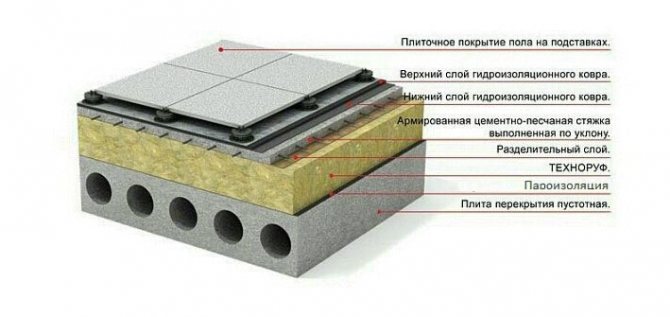

Technoruf is a mineral wool insulation in the form of rigid slabs. Hard because the minimum density is 121 kg per cubic meter. Given the density, the conclusion immediately suggests itself that the material is intended for highly loaded surfaces requiring insulation. For example, such an area is an exploited flat roof. Insulation can be fixed on a metal or reinforced concrete base, and a concrete screed before or after the material is not a prerequisite. Below in the plate are the summary technical characteristics of Technoruf. If you are already a professional and are only looking for numbers, we will not delay you with unnecessary explanations.

| Obsolete name | Density | Thickness, mm | Thermal conductivity A25 | Water vapor permeability, not less than mg / (m h Pa) | Organic matter content, no more,% | Compressive strength at 10% deformation, not less | |

| Technoruf 45 | 126-154 | 50-150 | 0.038 | 0.3 | 4.5 | 45 | |

| Technoruf Technoruf PROF | 145-175 | 20-100 | 0.038 | 0.3 | 4.5 | 60 | |

| PROF with | 145-175 | 30-250 | 0.038 | 0.3 | 4.5 | 60 | |

| Technoruf N30 | 100-130 | 50-200 | 0.038 | 0.3 | 4.5 | 30 | |

| N OPTIMA | H35 | 100-120 | 50-250 | 0.038 | 0.3 | 4.5 | 35 |

| H EXTRA | 90-110 | 50-25 | 0.037 | 0.3 | 4.5 | 30 | |

| Technoruf B60 | 165-195 | 40-50 | 0.038 | 0.3 | 4.5 | 60 | |

| IN OPTIMA | 165-195 | 20-100 | 0.041 | 0.3 | 4.5 | 70 | |

| In PROF | B80 | 175-205 | 20-100 | 0.041 | 0.3 | 4.5 | 80 |

| IN EXTRA | B70 | 155-185 | 40-50 | 0.038 | 0.3 | 4.5 | 65 |

| EXTRA with | 155-185 | 20-100 | 0.04 | 0.3 | 4.5 | 65 |

Features of roofing tiles

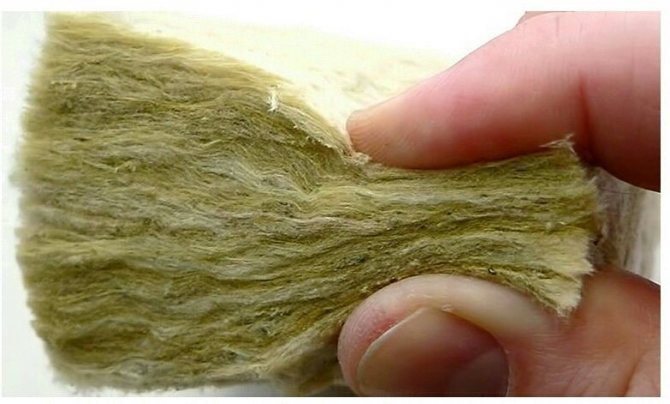

Insulation composition. The picture shows the fibers of molten basalt at high temperature

TechnoRuf prof are plates with thermal and sound insulation. They are made of mineral wool, which is based on the basalt group of rocks. In addition, it is a non-flammable material that retains heat well.

The density of such a slab is 121 kg per m3. This means that it can be used to insulate highly loaded exploited surfaces. Insulation can be laid on different bases: metal, reinforced concrete, using a concrete screed and others.

Scary numbers in titles

As is customary in any company, the indices in the names of the models are for informational purposes. In the case of our material, numbers from 30 to 60 indicate the material's ability to resist stress. This value is indicated in Kilopascals. Previously, numbers up to 80 were used, however, recently these indices have become not quite accurate to convey information. For example, Technoruf B70, called in the past, is now called B PROF and has a density index of 65, and the B50 index is not used at all. The type of marking Technoruf 50 does not exist at the moment either. If the manufacturer had left the previous index, it would not correspond to reality. It should also be noted that the Technoruf N PROF index does not exist. There is only Technoruf PROF (without the letter H) and it does not need a second, additional bottom layer.

Insulation types

Varieties of insulation and scope

Technoruf N Extra has a density of 100 kg / m3, is used for the device of the lower insulating layer in a multilayer structure when insulating a flat roof. The non-combustible material has a compressive strength of 30 kPa, a thermal conductivity of 0.039 W / m · s.

Technoruf N 30 has a density of 115 kg / m3. The technical characteristics of the Technoruf H30 insulation indicate a compressive strength of 30 kPa and a thermal conductivity of the material of 0.041 W / m · s.It is used as the first layer with two-layer thermal insulation on reinforced concrete or corrugated sheet, combined with Technoruf V.

Technoruf 45 characterized by a density of 140 kg / m3, is used in the form of a lower layer for multilayer roof insulation with a protective dry or wet screed. Ultimate strength - 45 kPa, thermal conductivity in the range of 0.038 - 0.041 W / m · s.

Technoruf Prof it has a density of 160 kg / m3, it is used as the main or top layer in multilayer insulation. Strength at 60 kPa, thermal conductivity 0.41 W / m · s.

Technoruf B 60 has a density of 180 kg / m3, is used when arranging the last layer or as the main insulation material for roll roofs with or without screed. The tensile strength is 60-65 kPa, the thermal conductivity of the material is 0.041 - 0.043 W / m · s.

Technoruf Galtel represents insulating strips with a triangular cross-section. They are made of basalt wool and are used for insulation at the junction of horizontal and vertical areas. Strips 1.2 m long have legs 0.1 m long.

Technoruf N 30 Wedge is produced in the form of slabs with a slope of 1.7%. The area of application is the area of the slope on the roof to remove water.

Marking

Indices in the names of mineral wool boards carry information about the insulation. Figures from 30 to 60 indicate the compressive strength of the material, the unit of kilopascal (kPa) is used. Previously, there were numbers 80 and 50, but in the latest modifications they are not used. There is no index in the name Technoruf Prof, Extra, Optima, but their ultimate strength corresponds to a given value of 60 kPa.

The letters indicate the parameters of laying in an insulating structure:

- H - speaks of the purpose in the lower layer.

- B - insulation is used for the upper layer.

Modifications that do not contain a letter designation are used as the main material and are placed in 1 layer.

The Great Mystery of All Time: V or H

As is the case with numbers, the letters indicate the parameters of the ruler. Some representatives of the line can only be used in two-layer insulation systems. In this case, one is laid as the bottom layer and is designated by the letter "H", and the second, respectively, as the top "B" (yes, yes, not "second", but "top"). Materials that do not have an "H" or "B" index are intended for single-layer insulation, for example, Technoruf 45 or PROF insulation. Now try to say to yourself, say, what is hidden behind the H30 index. For those who skipped the previous paragraph, titles like "Extra" and "Optima" were used instead of numeric indexes.

What is behind the H30 index?

Basic properties

You now know the characteristics of Technoruf B60 insulation, but you can also familiarize yourself with the main properties. The material consists of short thin basalt fibers, which determines its characteristics. The distance between the elements is filled with air, which provides low thermal conductivity. The same feature allows the material to act as a noise barrier.

The production technology provides thermal insulation with increased strength, it helps to maintain its original shape even under the influence of stress. Having considered the technical characteristics of "Technoruf B 60" (50 mm), you should pay attention to other advantages of the material, among them you should highlight:

- durability;

- resistance to chemical attack;

- easy stacking;

- low coefficient of water absorption.

Another plus is that the insulation does not attract rodents. However, its cost is slightly higher compared to other offers on the market. The price is justified by the resistance to compression and long service life.

And one more thing for a snack

For complete clarity in the names, we just have to learn three names:

WEDGE

These are slabs with a slope, which are designed to create a slope of the roof;

Technoruf KLIN

FILLET

Insulation elements for the transition from a horizontal to a vertical insulation surface. For example, for thermal insulation of a parapet.

Technoruf GALTEL

N VENT

This type of slab has special channels for draining water. This technology is intended for the treatment of flat roofs disease - the formation of fungus and disturbance of the indoor microclimate.

Technoruf N VENT

Composition and purpose

The material mentioned above acts as one of the varieties of mineral wool. He has all the benefits. It has a low coefficient of thermal conductivity, and also acts as a noise barrier. But this insulation is made for flat roofs. On such structures, thermal insulation has to undergo an impressive impact. Therefore, Technoruf B60, the technical characteristics of which you should know before purchasing the material, has increased strength.

It is used even in reinforced concrete and corrugated sheets. However, if we compare it with the "Ursa" insulation, then the described "Technoruf" is non-combustible. It is made from natural raw materials, therefore it is environmentally friendly. It can be used in childcare facilities, residential buildings and hospitals. A vapor barrier is placed between the thermal insulation and the roof. A polymer membrane is strengthened from the inside, it excludes the penetration of moisture into the insulation.

The Layers Question

Why might there be a need for two-layer insulation? It is no secret that Technoruf slabs, like any mineral wool slabs, retain heat mainly due to air. It is gas that is much less conductive of heat than solid. The more air in the plate, the lower the thermal conductivity, BUT, and the lower the rigidity. Look again at the table just above. Find in it, for example, Technoruf V EXTRA (Technoruf B70). Its density is from 155 to 185 kg per cubic meter and the coefficient of thermal conductivity is 0.038. Compare this indicator with Technoruf N EXTRA. 90-100 kg per m3 and 0.037. The difference in numbers is small, but it is there. And on large areas, a loss of one thousandth in the coefficient of thermal conductivity translates into hundreds of thousands of rubles for heating.

Instructions for roofing made of bitumen-polymer roll materials produced by TechnoNIKOL. Part 3. Thermal insulation.

3.1. Installation of thermal insulation Thermal insulation - a layer of the insulation system of the external structure (including the roof), which ensures the preservation of heat inside the building. The surface of the insulation can act as a base for the roof, provided that it is used - TECHNOROOF stone wool slabs with a compressive strength at 10% deformation of at least 60 kPa or TECHNONICOL polyisocyanurate foam slabs (PIR). The following types of TECHNONICOL thermal insulation are used for the installation of the thermal insulation layer of roofs in the presented TECHNONICOL systems: • stone wool - TECHNOROOF, TECHNOROOF N 30, TECHNOROOF V 60; • extruded polystyrene foam –XPS TECHNONICOL CARBON PROF; • polyisocyanurate foam - TECHNONICOL PIR. In the case of a monolithic or prefabricated screed on a slab insulation based on stone wool, plates with a compressive strength at 10% deformation of at least 0.040 MPa (40 kPa) are used. General information on the installation of the thermal insulation layer In this section, the installation of thermal insulation is considered on the example of using a slab insulation based on TECHNOROOF stone wool. Install the thermal insulation boards on the finished vapor barrier layer. The surface of the vapor barrier must be dry.

- When installing thermal insulation from two or more layers of TECHNOROOF heat-insulating slabs, place the seams between the slabs "sprawling", ensuring a snug fit of the slabs to each other. - Fill the seams between the insulation boards over 5 mm with heat-insulating material *.* When installing panel insulation based on XPS TECHNONICOL CARBON PROF extruded polystyrene foam or polyisocyanurate (PIR) foam, you can also use polyurethane foam. - In places of intensive movement of people, as well as carts with materials and equipment, lay out temporary footpaths made of sheet materials (OSB plywood, chrysotile cement sheets, cement particle boards of the TsSP –1 brand). IMPORTANT! TECHNOROOF mineral wool insulation soaked during installation must be removed and replaced with a dry one. Insulation plate: - Lay the insulation TECHNOROOF, TECHNOROOF N 30, TECHNOROOF B 60, start from the corner of the roof. Laying the first (lower) layer of TECHNOROOF N: - Lay the boards in the direction "towards you". This will reduce damage to the slabs during installation. Laying the second (top) layer of TECHNOROOF B:

- When laying, the thermal insulation boards are additionally cut so that the joints of the boards of the 1st and 2nd layers do not coincide.

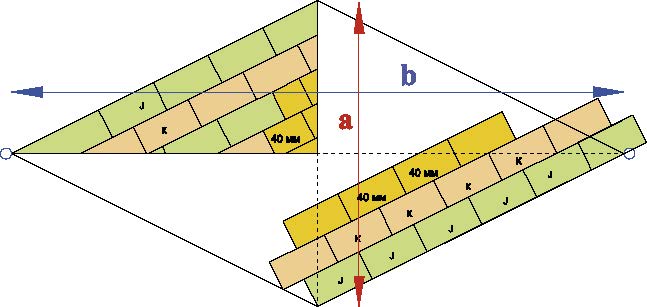

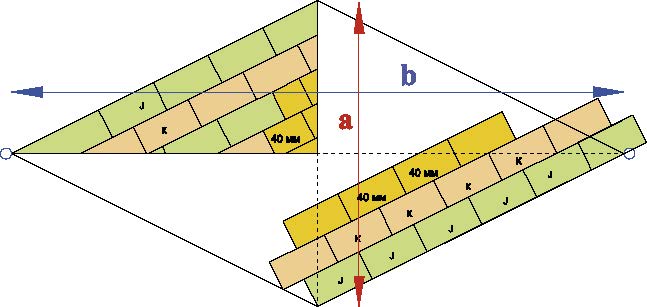

To simplify the installation of slab insulation in oblique corners, it is recommended to use the following method for cutting slabs:

- Place the insulation board in the corner of the roof. The long side of the slab should be parallel to one side of the corner. - Place the second on the first slab so that the long side of the slab coincides with the second side of the corner. Cut the lower TECHNOROOF N plate along the line as shown in the figure. - Lay the first and second row of thermal insulation boards from the obtained elements. IMPORTANT! In accordance with SP 17.13330.2017, the “roofs” on the coatings of buildings with a height of more than 75 m due to the increased effect of wind load, the thermal insulation plates must be completely glued to the vapor barrier.

Ballast method of fixing the thermal insulation layer Free laying of panel insulation TECHNOROOF, TECHNOROOF N 30, TECHNOROOF V 60 is used in case of loading by overlying layers capable of withstanding wind load: over thermal insulation; • arrangement of protective layers of the exploited roof, arrangement of gravel ballast, etc. Laying of thermal insulation boards is carried out in accordance with paragraph 2.3.1 - When installing a cement-sand screed base over the thermal insulation, a separating layer must be provided. Roofing material should be used as a separating layer. This will reduce the damage to the plates and the wetting of the insulation during the subsequent construction of the structural layers. A cement-sand screed can also be made along a slope-forming layer of backfill material or insulation slabs. - When installing inverted roofs, thermal insulation boards with low water absorption are used - XPS TECHNONICOL CARBON PROF. On top of the thermal insulation, backfilling with gravel or the device of protective layers of the exploited roof is performed along the separating and drainage layer. IMPORTANT! In accordance with SP 17.13330.2017 “roofs”, the thermal insulation layer of inverted roofs must be single-layer. Adhesive method of fastening thermal insulation boards The adhesive method of fastening thermal insulation boards is used in systems where roofing carpet is melted directly onto thermal insulation.

- Oil roofing bitumen BNK 90/30 * is used for gluing heat-insulating plates. Bitumen is heated in bitumen cookers (BEMT or analogs) with a mixing device and temperature control. The temperature of the heated mastic should be 150–180 C. * Hot mastic MBKG or TECHNONICOL mastic No. 41 (Eureka) can be used as alternative materials

- Application of hot mastic is done pointwise, or "snake". And it must ensure the gluing of the thermal insulation board at least 30% of the area of the board. - Thermal insulation boards TECHNOROOF, TECHNOROOF N 30 are laid immediately after applying the adhesive layer. Insulation boards are laid starting from the corner of the roof.In the case of a multilayer insulation system, the boards are glued together in a similar way. IMPORTANT! It is necessary to use thermal insulation boards with a laminated glass fiber surface - TECHNONICOL PIR CXM / CXM or TECHNOROOF V PROF s. Mechanical fixation of thermal insulation boards Mechanical fixation of thermal insulation boards is used in systems with laying roofing carpet on thermal insulation. - Fasten the top insulation plate to the supporting base with fasteners. The fasteners must be installed at a distance of at least 100 mm from the edge of the board. - When installing a roof by the method of mechanical fixation, the fastening of the TECHNOROOF, TECHNOROOF B 60 plates with dimensions of 1000x500 mm and 1200x600mm is carried out at the rate of 2 fasteners per top plate, a plate of 2400x1200 mm, 6 fasteners per plate. - When installing the roof by the method of continuous gluing to the surface of thermal insulation, the fastening of the TECHNOROOF, TECHNOROOF V 60 plates with dimensions of 1000x500 mm and 1200x600mm is carried out at the rate of at least 5 fasteners per top plate, 1200x1200 mm plates, at least 9 fasteners per plate. 3.2. Formation of a slope on the roof Slopes are needed to drain water from the roof. For complete drainage of water from the surface of the roofing carpet through external and internal drains, it is recommended to observe a slope of at least 1.5%. As a slope-forming layer, backfill insulation (expanded clay gravel, perlite, etc.), light concrete mixtures (foam concrete, expanded clay concrete, perlite concrete), cement-sand compositions or wedge-shaped insulation slabs CARBON PROF SLOPE or TECHNORUF N 30 KLIN can be used. The device of the slope-forming layer of backfill insulation The traditional method of arranging slopes from bulk materials: Before starting work, it is recommended to make a separating layer (for example, from roofing material, glassine) on the insulation plates.

- Work is carried out in dry weather. It is not allowed to perform work during precipitation (rain, snow, etc.). - Install the beacon rails on the base according to the level-adjusted marks with a step of 2-3 m.

- Fill in and align the material with the lighthouse rails. Loose material must be dry. - On the slope-forming layer, lay a reinforcing mesh made of wire Вр3 with a mesh size of 150x150 mm. Reinforcing mesh allows further work on bulk material without breaking slopes. IMPORTANT! The main disadvantages of slopes made from backfill insulation: • violation of design slopes due to displacement of backfill material during installation. • Additional loads on the supporting structure of the roof.

Installation of a slope-forming layer of wedge-shaped thermal insulation plates The fastest and most convenient way to create a slope is to use wedge-shaped insulation boards with a given slope. Slope-forming boards TECHNONICOL CARBON PROF SLOPE and TECHNOROOF N 30 WEDGE should not be considered as an alternative to thermal insulation boards. The fixing of the wedge-shaped plates is performed in the same way as the heat-insulating layer. IMPORTANT! Advantages of using wedge-shaped thermal insulation boards CARBON PROF SLOPE and TECHNOROOF N 30 WEDGE: • reducing the load on the supporting structure of the roof; • saving labor costs for the implementation of slopes; • reduction of time for work execution.

Wedge-shaped slabs for the formation of the main slope on the roof: - Extruded polystyrene foam TECHNONICOL CARBON PROF SLOPE 1.7% (XPS CARBON PROF SLOPE 1.7%): plates from the set "A" and "B" create the main slope on the roof from the valley to the ridge equal to 1.7%. The slabs are laid on the top layer of the main thermal insulation. - Begin to collect the slope from the lowest point of the roof - from a funnel, valley or overhang. As an additional slab, when forming a slope, use extruded polystyrene foam boards with a thickness of 40 mm. Wedge-shaped slabs for forming the slope in the valley and counter-slope

- Extruded polystyrene foam TECHNONICOL CARBON PROF SLOPE 3.4% (XPS CARBON PROF SLOPE 3.4%): plates from the set "J" and "K" form a slope of 3.4% between the funnels in the valleys, a counter slope from the parapet, skylights, ventilation shafts and other elements. - Extruded polystyrene foam TECHNONICOL CARBON PROF SLOPE 8.3% (XPS CARBON PROF SLOPE 8.3%): slabs are designed for deflectoring between funnels in valleys, counter slopes on the roof with a main slope of more than 3%. - The first row is laid with “J” plates, the second - with “K” plates.Further, if required, install a 40 mm thick extruded polystyrene foam board and repeat the layout of the boards: first, row of boards "J", then row of boards "K". The ratio of the long (b) diagonal of the rhombus to the short (a) should be b / a <3. Recommended ratio: b / a = 3.

To create the main slope on the roof, form a slope in the valley and counter slopes, wedge-shaped slabs TECHNOROOF N30 WEDGE (1.7% and 4.2%) or TECHNONICOL PIR SLOPE (1.7% and 3.4%, 8.3% ) 3.3. Installation of the base for the roof 3.3.1. Installation of a base for roofing material on a horizontal surface of a cement-sand screed The foundation is made of a cement-sand screed, it takes place along the finished slope-forming layer of backfill material or insulation slabs. Before starting the installation of the base under the roof, it is recommended to make a separating layer (for example, from roofing material, glassine) along the wedge-shaped insulation plates. - Lay a reinforcing mesh made of wire Вр3 with a mesh size of 150x150 mm. Place mesh patterns with an overlap of at least 1 cell. In the place of the overlap, tie the mesh patterns with a knitting wire with a pitch of 300 mm (3 cells). - Install the beacon rails with a step of 1.5–3 m. To maintain the slope and thickness of the screed, set the rails according to the marks that have been leveled. For convenience, select the height of the rail profile equal to the thickness of the required screed. For backfill insulation (expanded clay gravel, perlite sand, etc.) and for thermal insulation slabs (TECHNOROOF stone wool, TechnoNICOL XPS CARBON extruded polystyrene foam, TECHNONICOL PIR polyisocyanurate foam), cement-sand screeds with a thickness of at least 50 mm are arranged.

- Fill the strips formed by the laths with cement-sand mortar. Align the laid mortar with a rule, moving along the guide rails. - After the screed gains strength, dismantle the slats and fill the cavities from the slats with a cement-sand mortar. For the convenience of work, you can first fill the strips bounded by laths with a cement-sand mortar through one. Then align the laid mortar with the rule, moving along the guide rails. After gaining strength, the lighthouse strips should be dismantled and the intermediate unfilled strips should be filled with mortar. Align the laid mortar with a rule.

3.3.2. Arrangement of the base for the roofing material on a horizontal surface from the prefabricated screed. The base arrangement of the prefabricated screed occurs along the finished layer of insulation plates. The base is laid in two layers. IMPORTANT! The mass of the prefabricated screed must provide protection against tearing of the roof due to wind action. Otherwise, the prefabricated screed must be mechanically fastened to the supporting base. The number of fasteners is determined by the calculation for the wind effect, taking into account the bending strength of the prefabricated screed sheets.

- Before installing the base from the prefabricated screed, prime the prefabricated screed sheets on both sides with TECHNONICOL Bituminous Primer No. 01. - Lay the prefabricated screed sheets with a gap in the joints so that the top layer sheets overlap the bottom layer seams by at least 500 mm. - Fasten the sheets together with rivets or self-tapping screws. - Fasteners should be evenly distributed over the entire surface of the sheet. The fastener pitch should be 250–300mm. 3.3.3. Arrangement of a base for roofing material on a horizontal surface made of thermal insulation boards The surface of heat-insulating boards can serve as a base for a roofing carpet. The following types of TECHNONICOL thermal insulation are used for installing the base under the roof: • Mineral wool slabs TECHNOROOF V, with a compressive strength at 10% deformation of at least 0.060 MPa (60 kPa). They are used for roofing with mechanical fixation. • Mineral wool slabs TECHNOROOF V PROF s, with a laminated glass fiber surface and compressive strength at 10% deformation not less than 0.060 MPa (60 kPa).They are used when constructing a roof with mechanical fixation or with fusion on thermal insulation. • Boards made of polyisocyanurate foam - TECHNONICOL PIR. They are used when constructing a roof with mechanical fixation or with fusion on thermal insulation. Fusion on thermal insulation made of polyisocyanurate foam is possible in the case of using boards with a laminated glass fiber surface (PIR CXM / CXM). IMPORTANT! The polystyrene concrete surface cannot be the base for the roofing carpet.

3.3.4. Device for local lowering in the places where the funnel is installed IMPORTANT! The local lowering of the roof at the places where the funnels of the internal drainage are installed should be 20–30 mm at a distance of 500 mm from the center of the funnel. This can be accomplished in several ways.

1 way

- Place a wooden box on the vapor barrier. The height of the wall should be equal to the thickness of the insulation. - Put the insulation in the box and close the top with two sheets of chrysotile cement pressed sheets. - Install a reinforced mesh between the sheets. - After installing the thermal insulation layer, install a slope-forming layer, with the lower slope mark matching the level of the sheet. - Then the cement-sand screed is poured to the sheets. 2 way - Local lowering can be achieved by reducing the thickness of the slope-forming layer of backfill material. - Then fill in the cement-sand screed. 3 way

- Lowering is carried out when the slope is arranged to the funnel, using wedge-shaped insulation plates. - Then fill in the cement-sand screed. 4 way This method is typical in the case of using a heat-insulating layer of stone wool.

- When installing a roofing carpet on a base made of heat-insulating slabs, a local drop in the places where the funnel is installed can be achieved by reducing the thickness of the heat-insulating layer by 20-30 mm at a distance of 500 mm from the center of the funnel. - Heat-insulating mineral wool boards in this area must be replaced with XPS TECHNONICOL CARBON PROF extruded polystyrene foam.

- Chrysotile cement pressed flat sheet 10 mm thick, primed on both sides, is laid on top of the extruded polystyrene foam. The sheet is fixed to the supporting base. IMPORTANT! To create an airtight connection, glue the XPS to the vapor barrier using TECHNONICOL # 45 butyl rubber sealant. If you use several layers of XPS to insert, then you need to glue the boards to each other using a sealant.

3.3.5. Installation of a base for roofing material on a vertical surface In vertical surfaces of monolithic reinforced concrete structures:

- Level the surface of the monolithic reinforced concrete base (walls, parapets) with cement-sand mortar grade not lower than M150.

In vertical surfaces of precast concrete structures:

- Seal joints of vertical reinforced concrete structures (walls, parapets) with TECHNONICOL 2K two-component polyurethane sealant. - Level the surface of the reinforced concrete base (walls, parapets) with cement-sand mortar grade not lower than M150.

Vertical structures made of piece materials:

- Vertical surfaces of structures made of piece materials (bricks, foam concrete blocks) must be plastered with cement-sand mortar M150 on the entire surface of the establishment of an additional waterproofing layer.

- Vertical surfaces of structures protruding above the roof and made of piece materials (bricks, foam concrete blocks) can be sheathed with chrysotile-cement pressed flat sheets or cement-bonded particle boards of the TsSP-1 brand on the entire surface of the establishment of an additional waterproofing layer.

- On the horizontal plane of the parapet, create a slope of 3% towards the roof.

In order to read the entire instruction, follow the links below:

Part 1Part 2 Part 3Part 4 Part 5 Part 6 Part 7 Part 8 Part 9

You can purchase all the required materials for organizing roofing carpet and repairing roofs by calling us, or by making an application in the online store on our website. You can also pick up the material from our warehouse.

Helpful !!! We recommend watching on our YOUTUBE channel a series of videos on organizing work on the installation of roofing carpet on flat roofs using insulation materials of the Technoelast, Uniflex, Linokrom series, thermal insulation mineral wool boards TECHNOROOF, TECHNOROOF N 30, TECHNOROOF V 60 and other building insulating materials produced by the TechnoNICOL corporation. Organization of installation work on the device of roofing carpet on flat roofs www.youtube.com/TK CentroStroy

What do they use?

The most popular in construction are Technoruf H30 and B60 insulation... Their use is optimal in the middle regions of Russia. H30 is used for the bottom layer, and the upper layer, which is subjected to high stress, is covered with Technoruf 60 insulation. Technoruf 45, the density of which is 126-154 kg per m3, is also in demand as a single-layer insulation.

We hope that this short description of the TechnoNicol roofing line will help you in insulating a flat roof or other roof. Or maybe, as some enthusiasts, you decide to use the material even for facade insulation. In any case, do not forget to look at the manufacturer's instructions, drink more hot tea in winter and look at the stars more often.

Features of the material and its properties

Mineral insulation Technoruf has proven itself and is popular in the construction industry. Heat-insulating plates are made on the basis of basalt fibers, which are located in the horizontal and vertical directions, forming a multilayer structure. An organic substance is used as a binder. The technological process provides for the impregnation of the material with a water-repellent composition, giving the boards high hydrophobic qualities. As a result, the products are characterized by:

- a good indicator of heat and sound insulation;

- low water absorption;

- incombustibility (class NG);

- resistance to mechanical stress;

- stability of size, volume, shape.

Technoruf slabs are used for the installation of an insulating layer during construction and reconstruction of industrial facilities and housing. Due to its excellent strength characteristics and density, the insulation is suitable as the main insulating layer when installing roofs of any structure.

Mineral slabs are laid on reinforced concrete floors and metal foundations made of profiled sheets. Along with thermal insulation qualities, the material is resistant to fire, increasing the fire safety of the building.