Building a brick house is quite popular throughout the Russian Federation, because brick walls have many advantages. They are reliable, fire resistant and can last for years. But there are also disadvantages, for example, they do not retain heat efficiently enough. The problem can be easily eliminated if additional external insulation of the brick walls of the house is carried out with special materials. Almost every owner thinks about how to insulate a brick house from the outside.

In the process of building a brick house, you have to spend a lot, which is why very often the question arises of how to carry out work on the house insulation with your own hands. Everything is quite simple and if you thoroughly approach the issue, study all the nuances and choose the right material, insulate the house from silicate bricks, it will work without the involvement of hired specialists. The answer to the question of how to insulate a brick house from the outside, knows any seller of a hardware store.

There are a lot of insulation technologies, for a start we will consider a type of insulation for siding.

The choice of material for insulating a brick house outside for siding

The question, what is the best way to insulate a brick house from the outside, is very common in specialized forums. It is worthwhile to thoroughly study all the information provided, and choose what suits you. The main division of insulation for walls occurs according to the principle of installation, there are those that require additional finishing, and which do not need it. There are simply a huge number of varieties of materials for insulation and sound insulation, many of them are similar in characteristics, and differ only in price and manufacturer.

- Mineral insulation (Minvata). It is very often used, due to the fact that the price for it is quite low, and the characteristics are suitable. For example, its thermal conductivity is 0.04 W / (m * K). In addition, it is quite environmentally friendly and even an inexperienced person can mount it. Minvata is capable of burning, so it has a low level of fire safety, which can be considered a minus, and during installation it will be necessary to additionally carry out work related to the moisture insulation of the walls, tk. the material absorbs condensation well.

- Expanded polystyrene (styrofoam). Thermal conductivity 0.036 W / (m * K). Lightweight, practical, with high moisture resistance. Just like mineral wool, it is environmentally friendly. The disadvantages of insulating a brick house outside with expanded polystyrene are toxic emissions during combustion, fragility, vapor resistance.

- Extruded polystyrene foam (penoplex), a warm brother of ordinary polystyrene. But it is produced using a different, fundamentally new technology. Due to this, it has improved characteristics of heat and sound insulation, as well as steam and water permeability. House insulation with penoplex is very popular.

- It is possible to insulate a brick house from the outside using modern methods, using foaming technology. Mounting polyurethane foam. The product is new, but has already conquered most of the market. Perfectly insulates and protects against moisture ingress. Minus, the application is carried out using special equipment.

insulation of a brick house from the outside by spraying polyurethane foam

How to choose a heater?

After the method of warming the walls of the house has been chosen, you need to decide what material this event will be held with. When choosing a heat insulator, you should pay attention to some parameters. It should be borne in mind that not every insulation for brick walls is suitable for outdoor use.The same goes for internal insulation. One of the main properties to focus on are density and thermal conductivity. From them you can determine how much material is required for installation. Depending on the type, you will need a different amount of insulation, since each material is characterized by its inherent properties.

If you plan to insulate a brick house from the outside with your own hands, then attention is paid to such a parameter as the resistance of the material to external influences.

and internal insulation, it is worth choosing materials that are resistant to mold. One of the important parameters is the coefficient of thermal conductivity, which you should pay attention to when choosing. You can be guided by the following proportion: the lower this coefficient, the thinner the thermal insulation can be. Attention is also paid to the moisture absorption coefficient. The lower it is, the more preferable the use of this material.

Particular attention should be paid to the flammability class. Security will depend on this in the future. The choice should be made in favor of heaters that belong to the first class of flammability. It is they who are able to stop burning in the absence of a source of fire. Do not lose sight of the durability of thermal insulation, which will be used for wall insulation. The importance of this parameter lies in the fact that it directly depends on how long the service life of the heat-insulating material will be. If the insulation is made from the inside, then attention should be paid to the vapor transmission capacity. There are a number of other parameters that are less important.

Heat insulating materials

Next, it is worth considering what materials can be used to insulate a house:

- Mineral wool. Refers to the most common heat insulators. The material is endowed with good indicators of moisture absorption and thermal insulation, but it is preferable to use it for interior work. One of the main disadvantages of mineral wool is that when moisture gets in, its technical characteristics deteriorate.

- Expanded polystyrene. Compared to mineral wool, it is less popular. But at the same time, it is possible to insulate the walls from the outside with expanded polystyrene, as well as from the inside. The material is resistant to moisture and has good thermal insulation properties. The disadvantages include flammability and low steam transmission ability.

- Extruded polystyrene foam. The material is characterized by almost the same properties as for the above-described insulation, but the difference is in its higher strength. A good option for indoor and outdoor insulation.

- Warm plaster. It has a number of advantages. These include high sound insulation, good vapor permeability, combustion resistance, low moisture absorption. Of the shortcomings, it is worth noting the need to apply a layer no more than 5 cm thick. If you insulate the house with such plaster, then the weight will be considerable, which requires strengthening the foundation without fail. Today, many who are faced with the question of how to insulate a brick wall from the inside or outside prefer this option.

This is not a complete list of materials that can be used as insulation for a brick house. The above list can be supplemented with such heat insulators as polystyrene, cork, fiberglass, etc. To answer the question of which insulation is better for the walls of a brick house, you need to decide whether a material is needed for internal or external thermal insulation.

So, for internal installation, you can use foam, mineral wool, warm plaster or extruded polystyrene foam. These heaters are endowed with all the necessary parameters that are especially important for internal thermal insulation. For outdoor work, the same materials can be used as for indoor.Before deciding what is better to insulate a brick house from the outside or from the inside, it is necessary to consider all the pros and cons of each material and take into account the conditions under which they will be used.

Two types of insulation that do not require additional finishing

- Another method of insulating a brick wall from the outside, using a thermal panel for a brick, is a fairly new technology. The main advantage is that there is no need to hide such panels under the siding. They have a beautiful appearance.

Thermal panels for brick

- insulation for a brick house using warm plaster, an innovative look. In our country, it is gaining more and more popularity due to its simplicity and low cost.

Insulation for a brick house using warm plaster

For internal thermal insulation

We will find out what types of insulation are suitable for this method of protecting the walls of a building from cold weather.

The most popular thermal insulation materials for the internal insulation of the walls of a brick house today are:

- foam and other insulation based on it;

- mineral wool;

- plaster with insulation.

More about these species

Styrofoam and expanded polystyrene

Today it is the most popular and effective way to insulate brick walls internally. The positive properties of the material include its moisture resistance, which eliminates the problem of mold formation on the walls. A small level of thermal conductivity of foam and polystyrene foam materials reliably protects a brick building from cold weather, even if the house is located in northern latitudes.

Styrofoam for insulating the house from the inside

The lightness of the material allows for installation without unnecessary effort and additional hands. The material is durable and reliable. It has high strength characteristics, and is dense enough so that the finishing interior decoration of the house can be carried out directly on the insulation plates - without the need for additional lathing. But how to use reinforced foam for the facade, and why such material is good, you can learn from this article.

Mineral wool

This material has been known for a long time, and is widely used in construction and finishing works. Cotton wool is usually used to insulate the inner surface of brick walls if they are supposed to be subsequently clad with plasterboard. There are also such names for mineral wool as stone or basalt. Essentially, they are all the same.

Mineral wool

Cotton wool reliably protects the building from frost and winds, it will also help muffle annoying noises from the street. This material has many positive qualities, but there is also a significant disadvantage - cotton wool strongly absorbs moisture, which over time can lead to a deterioration in its thermal insulation properties. However, if initially the installation was carried out taking into account all the necessary requirements, the shelf life of the material is at least 10 years.

Warm plaster

Despite the fact that it is still plaster, it is quite capable of acting as a heater. However, please note: apply this material to the walls in a layer of no more than 5 cm, as otherwise the coating may peel off.

Using warm plaster

Warm plaster is recommended to be used for internal insulation of a brick house, only if there is also an external one. Alone, this material cannot achieve the necessary comfortable microclimate in the home.

This material has good sound insulating properties, allows wet steam to pass through, and does not burn. But due to the significant weight of the plaster, additional strengthening of the base of the house is sometimes required. But what warm facade plaster looks like, and how to apply it, you can learn from the article.

Bung

This safe natural material is a great option for interior insulation of brick walls.The downside is that the plug is flammable. This disadvantage can be minimized by treating the material with refractory solutions. But how cork soundproofing of walls is carried out can be found in the article.

Wall insulation plug

Cellulose cotton wool

The material is intended exclusively for internal insulation. Possesses high ecological qualities: natural and safe. However, cellulose wool is too exposed to moisture and, in addition, does not cope well with mechanical stress: it does not have high strength.

Cellulose cotton wool

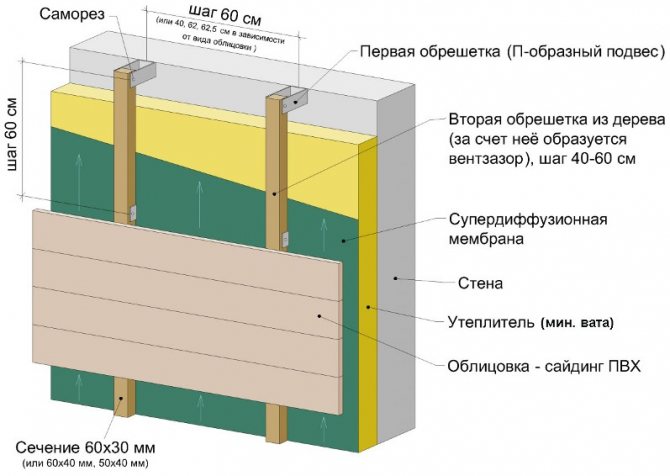

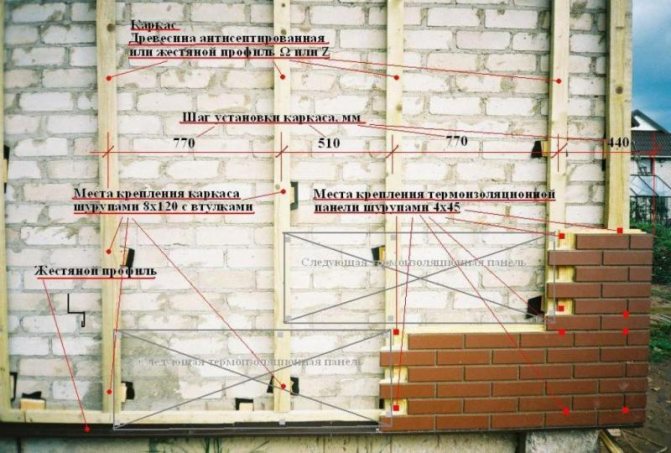

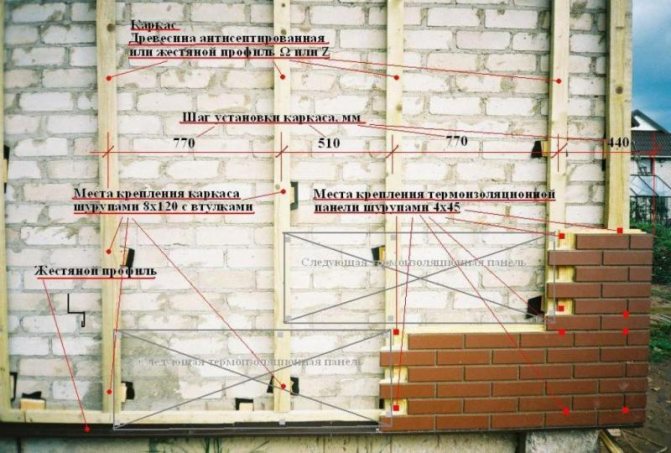

Installation scheme for siding

Surely not everyone knows how to properly insulate a brick house from the outside, or rather how exactly to mount the insulation. Installation, a group of heaters for siding, is fundamentally similar for all types of materials in this group. Before insulating a brick wall from the outside, it is necessary to expose the frame for the subsequent installation of siding. To do this, you will need to have:

- A hammer drill with an 8 mm drill, or an impact drill with a drill of the same diameter.

- Screwdriver.

- Construction level.

- Building corner.

- Roulette, hammer.

As a material for the manufacture of the frame, you can use a metal profile 60 * 27mm., Or wooden bars with a section of 50 * 50 mm.

Work should begin with cleaning the wall from anything that would interfere with the installation of the frame. Dismantle ebbs and slopes from windows. Then you can start installing the extreme bars. If the wall to be insulated is flat enough, then the frame can be made of wood, and the bars can be fastened with a dowel - nails, through and through. For exterior walls with irregularities, it is better to use a metal profile.

The extreme bars are installed, using a building level, strictly vertically. After that, between them, for convenience, a lace is pulled, it is convenient to control the installation of the remaining bars along it. All installed bars should be at a distance of 60 cm from each other in the same plane.

Insulation, cut into pieces of the required length and fit between the bars. It should be fixed using dowels - nails for insulating materials, having previously drilled holes for them in the wall.

If additional vapor barrier is necessary, it is mounted before installing the bars, directly on the wall, and only then proceed to the installation of the frame bars. If a metal profile is used as a frame, the whole scheme looks about the same, only instead of bars, profiles are installed using special suspensions.

Insulation with polyurethane foam

The process of insulating the brick walls of the house from the outside, using polyurethane foam, is slightly different in the order of work. You should start by cleaning the wall and removing anything that will interfere with the correct installation of the frame. The next stage is marking and installation of hangers on the wall for mounting profiles. After mounting the suspensions, they start applying the polyurethane foam. The last step after applying the foam is the installation of the profiles. As in the case of the bars, the extreme profiles are first installed, and then the lace is pulled and the rest are mounted with it. The profiles must be in the same plane.

Important: Before applying the foam, the hangers should be bent in such a way that they are ready for the installation of profiles in them, if this is not done, then after applying the foam, this will not work.

Siding installation

After installing the frame and insulation, the next stage is the installation of siding. The installation scheme depends on the type of siding panels, but general points are worth noting.

- Installation is carried out starting from the bottom of the house.

- Installation of the first panel is carried out strictly horizontally using a level.

- Each next panel is mounted in the previous one.

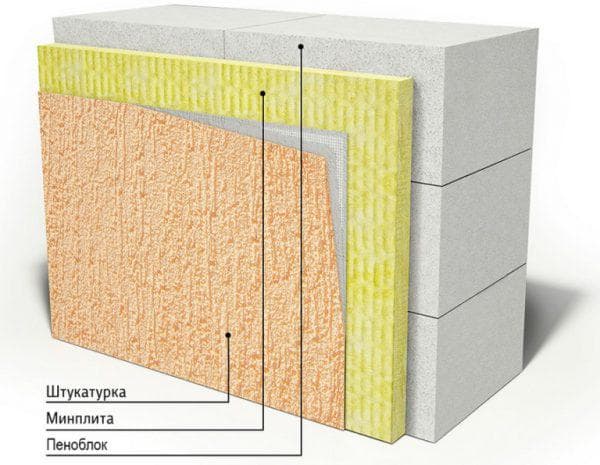

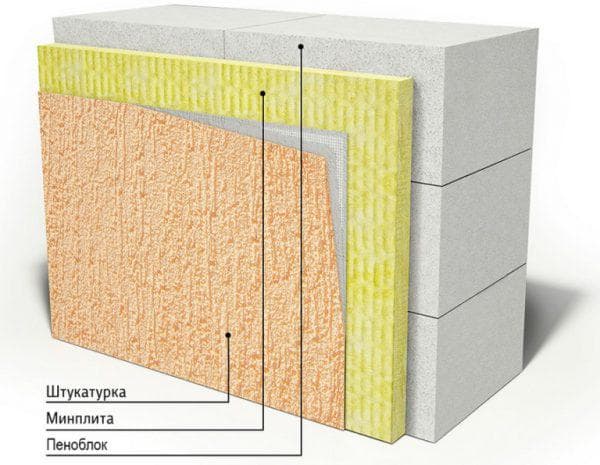

Finishing the facade of a brick house can be carried out using other technologies. For example, mount plates of mineral insulation (mineral wool) and then plaster and paint the surface. Or insulate the walls from the outside with foam and brick it.

The choice of insulation for the outer walls of a brick house

Are you here

Table of contents:

When building a house, walls are often made of bricks. And, despite its many positive properties, it needs high-quality insulation. It is usually done outside. For good heat conservation inside the house, you will need a high-quality outdoor insulation for a brick house.

Why insulate brick walls?

A single-layer brick wall with a thickness of 40-65 cm provides a level of thermal insulation three times lower than is necessary for a comfortable life. As a result, the walls have to be insulated. It is important to carry out competent external insulation. For this, the following materials are used:

- Styrofoam.

- Expanded polystyrene.

- Mineral wool.

At the same time, they will not affect the appearance of the facade, because in the future the structure can be sewn up with drywall or siding.

Note! Styrofoam and polystyrene foam are cheaper than mineral wool. But the latter has complete resistance to combustion.

It seems to many that heaters for walls outside a brick house will make being in it during the summer heat unbearable. But this is not the case. Any heat-insulating material is designed so that the warmth in the winter remains inside the premises, and in the summer they are dominated by the saving coolness. In addition, modern insulation makes it possible to remove steam and moisture in one direction. They do not let them into the house and do not absorb them.

Interestingly, about 40% of the electricity is spent on maintaining a normal temperature in the house. Thanks to competent outdoor insulation, you will get rid of such problems. The choice of insulation for the walls of a brick house is carried out according to the following scheme: 10 cm of insulation must correspond to the qualities of 1 m of brickwork. With this approach, you don't have to use air conditioners in the summer and spend extra money on heating your home in the winter.

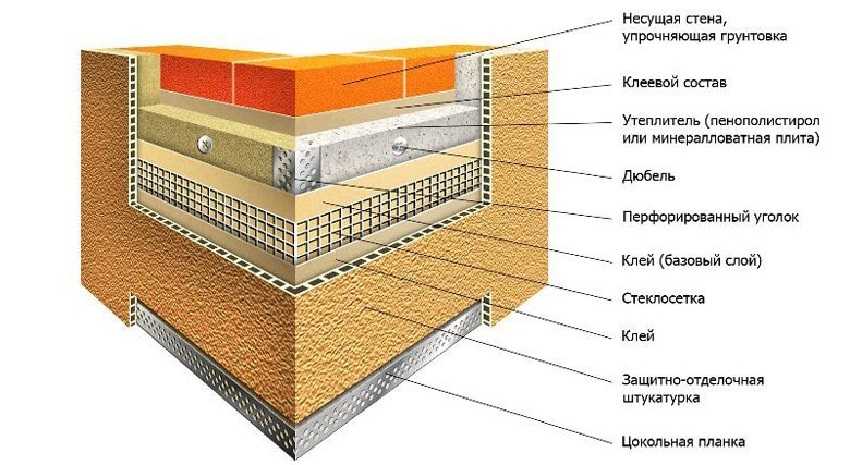

When insulating a brick house outside, the following systems are used:

- Multilayer system.

- Ventilated facades.

Multilayer thermal insulation system

- If you prefer this option for your home, it is important to properly prepare the surface of the walls for work. The facade must be cleaned of dirt. If defects are found in the plaster, they must be eliminated.

- Insulating material is installed. If you are using Styrofoam, you will need a special adhesive to fix the boards. It must be applied evenly to the surface of the insulating board. When the composition is set, the foam can be fixed to the wall. For this, umbrella dowels are used. The seams are sealed with the same mixture on which the foam was installed.

- After that, the reinforcement is installed. This operation is carried out using a plaster plastic mesh, on top of which a layer of plaster is applied. After it dries, the finishing plaster is applied. When the surface is ready, it can be painted with a special facade paint.

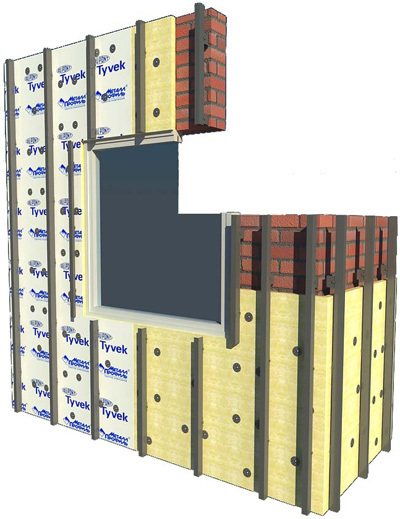

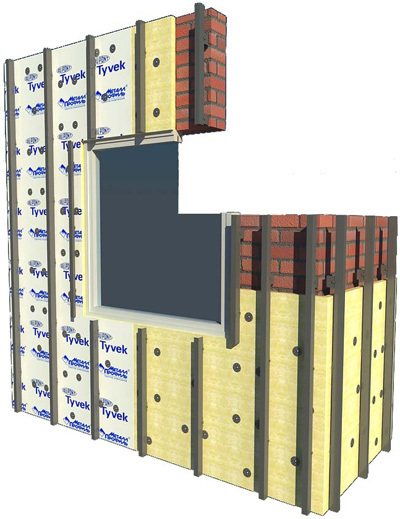

Ventilated facades

Before you start insulating a brick house from the outside, you need to decide on the device of ventilated facades. They include several layers. Typically, the following layers are used:

- Outer layer represented by a cladded screen.

- Lathing.

- Ventilation gap.

- Heat insulator.

The following stages of ventilated facades are distinguished:

- First you need to properly prepare the surface for work. Clean the facade from dirt and eliminate possible defects.

- Then it is necessary to install load-bearing surfaces, which are constructed from a metal profile. The frame can also be made of wooden blocks, but its service life will be significantly lower.It is important to leave equal gaps between the elements of the system so that the insulation for the outer walls of a brick house is located "in tightness" with some tension.

- At the next stage, the heat insulator is laid. To fix it, use dowels and special adhesives.

- It is important to create a hydro-barrier. This will protect the insulation from wind and moisture.

- At the final stage, finishing is made, which can be tile, siding or other materials.

Features of facade insulation with foam plastic for siding

If siding is used for exterior wall cladding, give preference to insulation materials such as EPS or foam. The latter material is the most popular because it has a lower cost.

If you plan to install insulation under siding for a brick house, use one of the following methods:

- Glue the styrofoam.

- Install it on the fasteners.

The use of foam for insulating brick walls for siding is the best solution. This is due to the high speed of work and their lower labor intensity.

Styrofoam sticking process

When installing with glue, the following sequence of actions is used:

- The walls are cleaned of dirt and, if necessary, leveled.

- Then a deep penetration primer is applied to them.

- A horizontal rail is installed at the bottom of the wall, which will be used as a support for the foam sheets during the gluing process.

- Then, vertical posts made of wooden bars or a metal profile are exposed. It is important that the step between them corresponds to the width of the insulation sheets.

- It is necessary to walk on the surface of the plates with a needle roller.

- A special adhesive is applied to the center and perimeter of the canvases. You can use dry mix, cans of polyurethane glue or special foam glue. Any of these compositions allows you to carry out high-quality wall insulation for siding.

- The first row of insulation boards is fixed with support directly on the horizontal rail.

- The second row of slabs is laid in relation to the first in a checkerboard pattern.

- When the glue is completely dry, the siding can be installed.

Video about polystyrene - outdoor insulation for a brick house

Note! It is better not to use a cement-sand composition for attaching foam plastic to external brick walls. It will not fully adhere to the heat insulator.

The process of installing foam with fasteners

If you plan to attach the insulation under the siding using fasteners, you need to buy dowels with wide caps. This is a more reliable method that will require much more labor. The following stages of work are carried out:

- The walls are cleaned of dirt and, if necessary, leveled. If there are no large differences in height, there is no need for alignment.

- A horizontal rail is installed at the bottom of the wall, which will act as a starting guide. Then beacons are stretched from stretched cords, which serve as a guide in the process of laying the slabs.

- Set up vertical racks of wooden bars or metal profiles. It is important that a step remains between them, corresponding to the width of the thermal insulation sheets.

- The foam sheets are fixed with five dowels. Four dowels are installed in the corners and one in the center.

- Then the siding is installed.

How to insulate brick walls with mineral wool?

This material is optimal for internal insulation of brick walls. This is mainly due to its environmental safety and easy work with it. But mineral wool can also be used in external insulation of brick walls. To carry out work on external insulation, it is better to use pressed plates.

Insulation from the outside will require the arrangement of a ventilated facade. Due to the fact that rock wool is a hygroscopic material, a gap must be left to separate it from the exterior. This will allow moisture to evaporate efficiently. From above, mineral wool is additionally covered with a vapor-tight membrane.

You must perform the following sequence of actions:

- A lathing made of wooden bars or a metal profile is installed on the surface of the load-bearing wall.

- Then mineral wool is laid.

- A membrane is fixed on top.

- It is important to provide ventilation ducts with a width of 4-6 mm.

- Finish is installed on top.

Video about mineral wool - insulation for the outer walls of a brick house

If you insulate a brick house in this way, mineral wool will serve flawlessly for many years.

Thus, a heat insulator for external insulation of a house allows you to keep warm inside the premises, however, do not forget also about the insulation of windows, because a lot of heat goes through them. In addition, this will significantly reduce the cost of air conditioning in summer and heating in winter. As a result, you get a well-insulated structure.

How would you insulate a brick house? Let us know in the comments.

www.rutvet.ru

Clinker panel installation diagram

Insulation of the facade of a brick house using a clinker thermal panel has a fundamental difference from the installation of mineral wool and other similar types of insulation. It consists in the fact that the installation of the frame and, accordingly, siding is not required. The pattern of clinker panels can be different, there are panels for brick, natural stone, etc.

Before installation, as in the case of conventional insulation, the wall must be cleaned of dust, dirt and anything that might interfere with installation. The clinker panel is installed from the bottom up. The process from the outside resembles the assembly of a puzzle. First, the corners and the base are collected, then the inside of the wall is gradually filled. Fastening takes place using dowel nails for insulating materials, as well as a small amount of mounting foam, which is applied under the insulation and then glues it to it.

The specifics of thermal insulation of a private brick house

Carrying out such thermal insulation work with mineral wool from the outside, it should be remembered that the insulation of the wall of a house made of brick is a whole complex of measures, which should include not only work with the walls, but also the protection of the foundation, floor and roof. This is the only way to ensure maximum protection of the room from the cold. The walls of the house can be made of hollow or solid bricks. Also, the masonry may have additional air pockets, which improve the thermal insulation performance of the room.

The choice of one or another heat insulator must be made based on the type of brick, wall thickness and type of brickwork.

Warm plaster

Abroad, for a long time, this type of insulation of the outer walls of a brick house is considered one of the best and is used almost everywhere. In Russia, the advantages of warm plaster have not yet been properly appreciated, although many builders are already using it in practice.

Warm plaster, has a composition almost the same as ordinary plaster, only instead of sand, bubbles of foam plastic, or perlite or vermiculite are added to it.

Polyfoam is a good insulation, even anyone unfamiliar with construction technologies knows this. The use of plaster with the addition of polystyrene will allow you to insulate the house without high costs, and in a short time. Plastering does not require special preparation of the walls. Simply moisten with water and the mixture can be applied. Thermal insulation using warm plaster is quite effective becauseno joints, cracks or other defects remain on the wall through which heat can escape. Another indisputable advantage is the complete incombustibility of the plaster and the absence of the need to replace the slopes on the windows, which also allows you to save on finishing.

In addition to the article, watch the video:

Use of mineral wool

It is possible to preserve the ventilation qualities of a red brick building with the help of mineral wool.

Any type of this insulation is not suitable for such an event. You should stop your choice on basalt wool. It does not rot or mold. Even when wet, this siding insulation continues to retain its high thermal insulation properties. Using mineral wool, it is possible to insulate houses using the ventilated facade technology.

Thermal insulation of a brick wall with basalt wool is carried out as follows:

Brick wall insulation scheme with stone wool.

- The wall is being prepared for work. All protruding objects, pipes and wires are removed from it. The working surface is treated with an antiseptic.

- Marking is applied to the wall. Provides for the creation of a wooden or steel frame. The mesh size should be slightly smaller than the size of the mineral wool slabs.

- A vapor barrier film is attached to the wall. It is intended for the free release of excess moisture from the house. The membrane can be fixed on rails or steel profiles with a stapler.

- A frame is assembled to accommodate mineral wool and fasten siding strips. Slabs of basalt wool are laid inside it. Another layer of membrane film is attached on top of the insulation.

- Siding is installed on the frame. It is advisable to use the plastic option. This material is strong enough, resistant to moisture, temperature extremes and ultraviolet light.

When working with siding, you should avoid tightly tightening the self-tapping screws that fix the panels. Plastic has a fairly high coefficient of thermal expansion. Incomplete tightening of the fasteners will allow the panels to move when the temperature changes.