The market of thermal insulation materials is replete with offers for every taste. Mineral wool, polystyrene and polyurethane foam have long established themselves as reliable and safe thermal insulators. However, science does not stand still, and manufacturers always strive to expand their market share through new products.

A relatively "young" thermal insulation material is XPS insulation (eXtruded PoliStyrene). This name was given to extruded polystyrene foam. Due to the unique combination of characteristics, the material has gained recognition among a large number of buyers.

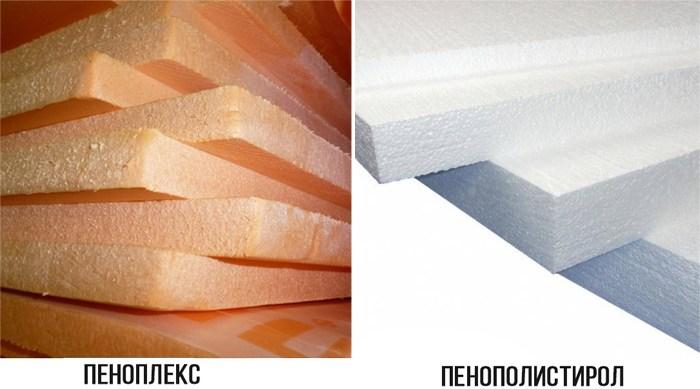

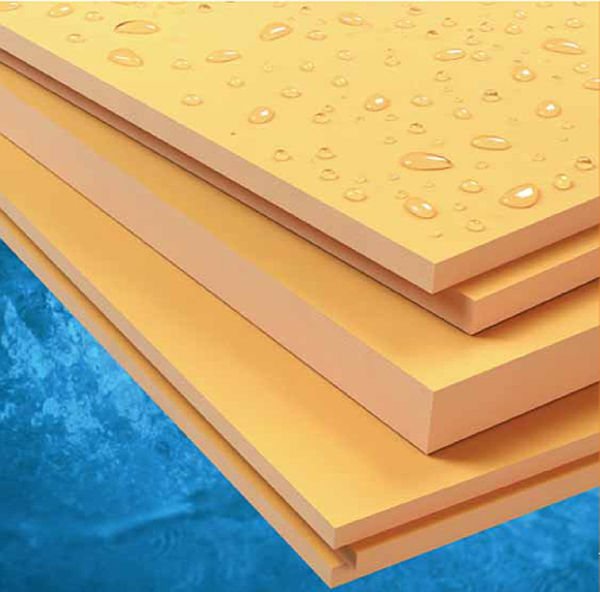

Extruded or extruded polystyrene foam is expanded polystyrene foam that is produced by extrusion. In essence, it is a plastic with a uniform fine-mesh (0.1-0.2 mm) closed structure. The fundamental difference is contained in a more advanced technology for foaming polystyrene granules, as a result of which the output is a material that is fundamentally different from the usual ball-shaped foam. Despite the fact that these two heaters are made from the same raw materials, the set of properties of finished products has significant differences.

Analogues and competitors

TechnoNIKOL is a large company engaged in the production and supply of high quality building and insulation materials

The most popular among the tile insulation made of expanded polystyrene are the products of the Penoplex (Penoplex) and Technonikol (Technoplex) companies. These two heaters are widely used, are analogues and ardent competitors.

Is there a difference between Penoplex and Technoplex and is it critical for choosing one or another product? To answer this question, you should compare the characteristics of these tile heaters.

What should you opt for

As mentioned above, there are no big differences between heaters, so the choice remains with the buyer and his personal preferences. However, penoplex appeared on the market much earlier than the technoplex and has already managed to gain the trust of the masters. But many, due to the difference in price, consider it unreasonably expensive and, if possible, purchase a technoplex.

Therefore, the main selection criterion is the intended use. Technoplex is declared as an internal insulation, penoplex - as a universal one.

Thus, the answer to the question - what kind of insulation to choose from extruded or extruded polystyrene foam is superficial. It all depends on the scope of its application and customer confidence.

What is extrusion

The heat-retaining properties of extruded polystyrene foam are an order of magnitude higher than that of a related foam that has not passed through the extruder

More than half a century ago, American engineers developed a technology for extruding polystyrene, which is now successfully used in the production of building materials with high thermal insulation properties.

Polystyrene granules under high pressure and temperature are mixed with foaming agents (a mixture of non-toxic light freons).

The material obtained at the exit of this process has a cellular structure. Freon residues in the cells are quickly replaced by air. Microscopic closed cells are evenly distributed throughout the entire volume of the slab.

Various additives (graphite, flame retardant additives) are added to the expanded polystyrene produced by extrusion, which enhance the useful properties of the material.

Insulation of the outer walls of a residential building

If, when insulating the outer walls of the house, you make a choice of material, then it would be better to take just the foam, and not the foam, because the foam is cheaper and has greater air permeability, which in many cases makes it possible not to separately make the internal vapor barrier with expensive materials, while getting completely breathable »Wall.

Vapor permeability

Polyfoam in comparison with penoplex has a slightly higher vapor permeability, which is not always good.

By the way, it is useful to listen to the opinion of a specialist about the vapor permeability of foam, because many people swim in these matters, and the brands of foam are different, so I recommend watching this small, but quite informative video:

General properties of heaters

According to experts, both penoplex and technoplex are innovative, safe, non-combustible materials and they are practically eternal.

The products of the two competing companies have similar properties:

- have the form of slabs of various sizes - their thickness ranges from 20 to 120 mm;

- high thermal insulation properties due to the cellular air structure;

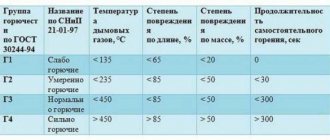

- high degree of fire safety - the material does not support combustion processes;

Note: different products from the same company may have different degrees of fire resistance. Check this information on the product packaging.

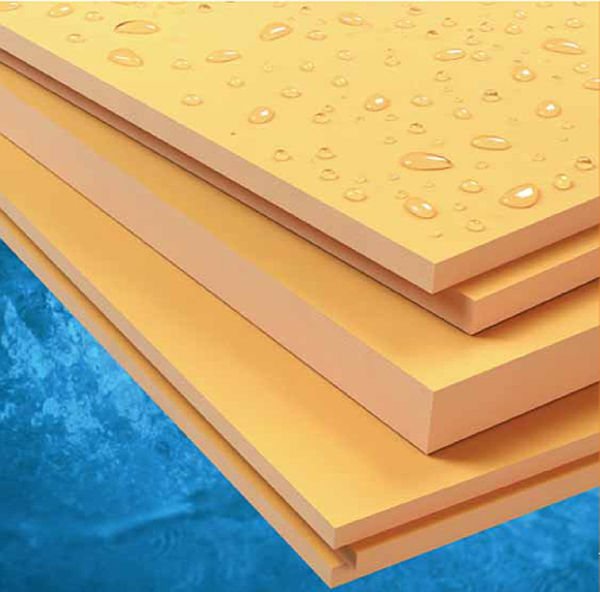

- environmental friendliness, chemical and biological inertness. Expanded polystyrene boards do not rot, do not decompose, do not dissolve in water and soil. Their water absorption and thermal conductivity indicators are extremely small;

- the possibility of installation in any weather conditions;

- high strength and elasticity, both products have a long service life;

- easy handling and installation. The low weight of the slabs greatly facilitates the installation process;

- good sound absorption.

Take a note: you can use an ordinary clerical knife to cut the expanded polystyrene plates.

Ceiling insulation ↑

Any of the materials in question can be used. Penoplex, perhaps, will be even the best solution, since in this case it is possible not to make additional coatings on the attic floor and walk directly on the penoplex - its density and strength allow this.

Floor insulation

Any material will do. Whether foam or penoplex is an excellent choice. They will benefit from the notorious low thermal conductivity, compressive strength, and water resistance. We make a rough floor along the logs. You can use a simple unedged board in two layers diagonally. We put penoplex or expanded polystyrene on top. Directly on the plates we pour a screed of 1-2 cm. And on the screed any finishing material to your liking.

Life time

According to Andrey Eliseev, the service life of polystyrene and polystyrene foam differs. However, his arguments did not seem convincing enough to me. He assures that foams crumble faster and, accordingly, lose their heat-saving qualities more quickly. Penoplex keeps thermal insulation longer.

Fire safety

This is not an idle question in construction. There are always many complaints about foam in this particular part. In its neutral state, the material is not environmentally hazardous to others. But if, God forbid, a fire happens, then the foam becomes dangerous. The fact is that this material is flammable, and at the time of combustion it emits extremely harmful substances. As for the penoplex, it also ignites and also contains the same harmful substances, but is self-extinguishing, and this is its advantage over its older brother. At the same time, referring to the fire hazardous properties of polystyrene, one should not absolutize and interpret literally such concepts as "non-spreading fire", "self-extinguishing" - today this reflects only particular definitions in relation to certain specific studies and is often unreasonably used by marketers in advertising purposes.

Price

If we talk about the price, then penoplex is more expensive.So thermal insulation work using foam is a more expensive undertaking than the option with traditional foam (again, I'll make a reservation, depending on which foam to take, because it has a lot of brands and all differ somewhat from each other in characteristics). If it is very important to save money, then it is more advantageous to take polystyrene.

Fedor Orlov (C)

* The information in the article, including attempts at comparative analysis, is largely ambiguous, so I ask you to take it as the author's personal experience.

Areas of use

With external wall insulation, Penoplex expanded polystyrene plates should fit as tightly as possible to the base and to each other

Penoplex and Technoplex insulation boards can be used in the widest range of construction works and are generally interchangeable:

- civil and industrial construction;

- Walling;

- floor insulation in a private house, ceiling insulation;

- internal thermal insulation and external insulation of facades;

- insulation of basements and foundations;

- roof erection;

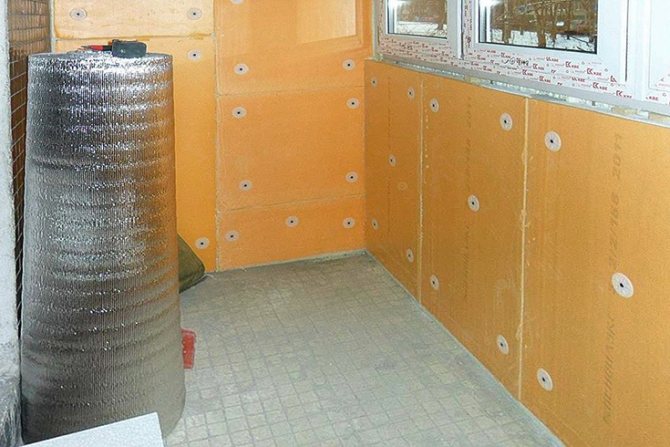

- insulation of loggias and balconies;

- arrangement of terraces, verandas;

- arrangement of refrigerating chambers;

- isolation of septic tanks and pools;

- thermal insulation of soil in road construction, including railway;

- arrangement of gas pipelines and oil pipelines;

- any construction work in permafrost regions;

- thermal insulation equipment for airports and runways.

Foam polystyrene insulating plates are irreplaceable when installing a warm floor system. It should be noted that the smooth and rough surface of the slabs provides excellent adhesion to finishing materials.

Application of Penoplex and Technoplex boards

Penoplex is used for floor insulation in a bath. Read how to do this here. Maybe,

Penoplex or mineral wool?

Penoplex is a polystyrene derivative, a product of organic chemistry. Mineral or basalt wool is a product of thermal processing of mineral raw materials. Both materials are successfully used in the creation of heat-insulating layers, but there are features of the use of each of them, this is explained by some physical indicators.

Physical indicators of mineral wool:

- density - varies widely and can be from 10 to 300 kg / m3;

- thermal conductivity (with a density of about 35 kg / m3) - 0.040-0.045 W / m * K;

- moisture absorption - more than 1% (depends on the density);

- vapor permeability - 0.4-0.5 mg / hour * m * Pa;

- maximum holding temperature 450 C and above.

The analysis of these values shows that the worst indicators of thermal conductivity of mineral wool are compensated by better vapor permeability, resistance to high temperatures and incombustibility. Using min. cotton wool is justified precisely in those conditions where the listed parameters are important. The use of glass wool insulation is advisable to use in garages, workshops, industrial facilities, wherever there is an increased risk of fire. It is better to insulate damp rooms, such as saunas, baths and swimming pools with the help of mineral insulation, so in this case the vapor permeability of the insulator is important.

Environmental safety of insulation based on polystyrene and mineral wool depends on the conditions of use. Polystyrene derivatives can sustain combustion in the event of fires, while emitting toxic fumes. Mineral heat insulators are resistant to high temperatures and do not degrade, but over time they can age and release dust in the form of microfibers that make up the material. The outdoor method of wall insulation with basalt wool is safe in this regard.

The thermal insulation design must take into account the possible impact of water. Mineral materials are susceptible to more fluid accumulation, while their thermal conductivity will be increased.

What is the difference between materials

Penoplex and Technoplex are similar thermal insulation materials. The main difference between them is the selling price

- Some differences in the operational properties of Penoplex and Technoplex are due to slightly different production technology, different methods of cooling the extruded material. According to the manufacturer TechnoNIKOL, Technoplex is produced without the use of freon mixtures.

- The addition of various additives to enhance the properties of the insulation boards Technoplex is distinguished by the presence of graphite nanoparticles in its composition, which increase the overall strength of the material.

- The mechanical bending strength of Penoplex can reach 0.7 Pa versus an average value of 0.3 Pa for Technoplex. It should be borne in mind that these are serious values, both materials perfectly withstand the normal load.

- The declared operating temperature of Penoplex starts from -70 ° C, Technonikol guarantees the preservation of the properties of its product at a temperature of -50 ° C. The difference, of course, is significant, but irrelevant for central Russia.

- There is a slight difference in the price of these products, but it is not absolute and depends mainly on the region and the manufacturing plant.

Table

| Penoplex | Expanded polystyrene |

| What do they have in common? | |

| Both materials are made of polystyrene foam, in many cases interchangeable | |

| Comparable in terms of vapor permeability | |

| What is the difference between them? | |

| Manufactured using press extrusion | Manufactured without extrusion pressing |

| The structure of the material is represented by small cells | The structure of the material is represented by significantly larger cells |

| Has lower thermal conductivity | Has a higher thermal conductivity |

| Has a higher density | Has a lower density |

| Has less water absorption | Has great water absorption |