During the construction of private houses and apartment renovation, a wide variety of materials are used, including insulation. For the purpose of arranging thermal insulation, mineral wool, foam plastic and extruded polystyrene foam are actively used today.

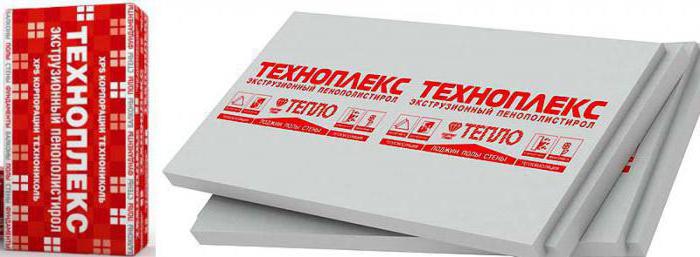

The latter type includes such an innovative product as Technoplex (50 mm). The characteristics of the material allow you to use it at any stage of repair and construction, so we suggest that you familiarize yourself with it better.

Description and features of the material

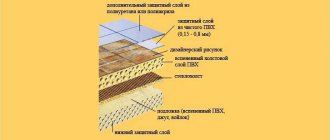

Insulation "Technoplex" is made of polystyrene granules, which are mixed with a special foaming compound and graphite under the influence of high temperature and high pressure. The viscous mass is sent to molds of a certain size, where it solidifies and is cut into sheets of standard parameters.

The final product is smooth and firm. The structure of the sheet consists of a large number of small closed cells that do not allow air to pass through. Due to this, the characteristics of "Technoplex" (50 mm) are quite high. Graphite additives significantly improve the thermal insulation properties and enhance the strength of the boards.

The products are sold in rectangular packaging, the size and weight of which depends on the size of the material.

Technoplex expanded polystyrene production technology and scope

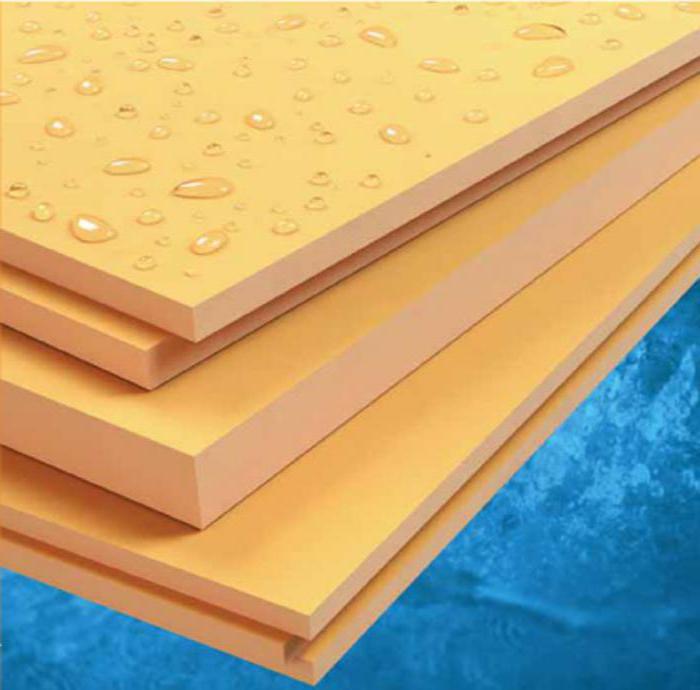

Insulation Technoplex has a cellular structure and is resistant to moisture. And also does not shrink, which makes it a more optimal material for insulation than ecowool.

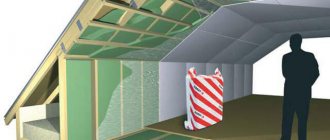

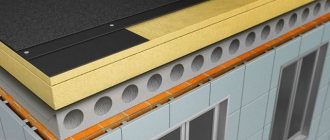

The scope of the material is insulation of balconies, outbuildings, private houses, repair of living quarters and internal insulation (for example, if the facade is lined with sandwich panels, insulation is installed under them). Also Technoplex slabs are used as a substrate for a "warm water floor". Installation is carried out on polystyrene foam glue. The glued insulation provides reliable thermal insulation.

To provide thermal insulation of foundations in cottage construction, Carbon (XPS Carbon) is used.

In the production of insulation of this brand, extruded polystyrene foam is used, the granules of which are mixed with a foaming agent. This process requires high pressure and temperature.

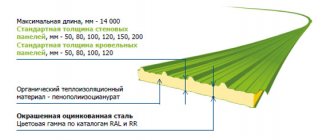

Dimensions of extrusion insulation

In order to correctly determine the required number of slabs, you should study in more detail the characteristics of Technoplex 50 mm. How many plates are in the package, and what size they are, you can, of course, check with the seller, but it is better to have this information in advance.

So, from the information from the manufacturer, we know that the described slabs are of two types:

- with dimensions 118 x 58 cm;

- size 120 x 60 cm.

Also, insulation sheets can have different widths (from 20 to 100 mm). But since slabs with a width of 50 mm are considered the most versatile, our article is devoted to them. One package contains 6 plates of the same size.

Technoplex dimensions

In the manufacture of the technoplex, certain standards for finished products are observed. Therefore, regardless of the manufacturer, the insulation has the same size and sheet thickness. It looks like this:

- Length - 1 180 - 1 200 mm

.

Width - 580 - 600 mm

.

Thickness - 20/30/40/50/100 mm

.

It should be clarified that thick slabs are used only in the construction of industrial buildings and road works. Meanwhile, the characteristic L-edge profile is absent on products with minimum thickness.

Positive features of the material

Technical characteristics of "Technoplex" (50 mm thick) indicate that this material can significantly save the budget, as it has improved thermal insulation properties. In comparison with ordinary foam, the capabilities of this product are twice as high, and if you look at the thermal insulation performance of fiberglass plates, it becomes clear that their capabilities are 1.5 times less.

In addition, a number of positive properties of the material should be noted:

- Increased strength. Extrusion material is more than 5 times stronger than foam.

- High density indicators. "Technoplex" is able to withstand heavy loads, which makes it possible to use it when arranging the floor.

- Resistant to moisture. The dense and solid structure of the material does not allow moisture to pass through itself, while the foam is able to absorb liquid, albeit in small quantities.

Despite the fact that the Technoplex material (50 mm) has rather high characteristics, it still has one drawback - poor vapor permeability. This fact must be taken into account when buying extrusion plates for certain jobs.

Strength indicators

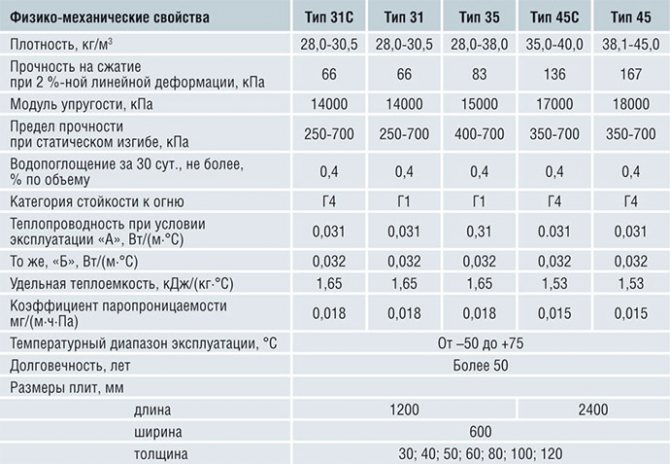

If you cannot decide which is better - penoplex or technoplex, then you can pay attention to the mechanical strength. The materials described have practically the same compressive strength with a deformation of 10%, the figure is 250 kPa. If we talk about the ultimate strength when exposed to static bending, then for penoplex this figure, depending on the type, will vary from 0.4 to 0.7 MPa. This indicator for the Technoplex is less and is only 0.3. From this we can conclude that penoplex exhibits more impressive resistance to bending and is able to withstand a large load.

Technical and physical characteristics of the material

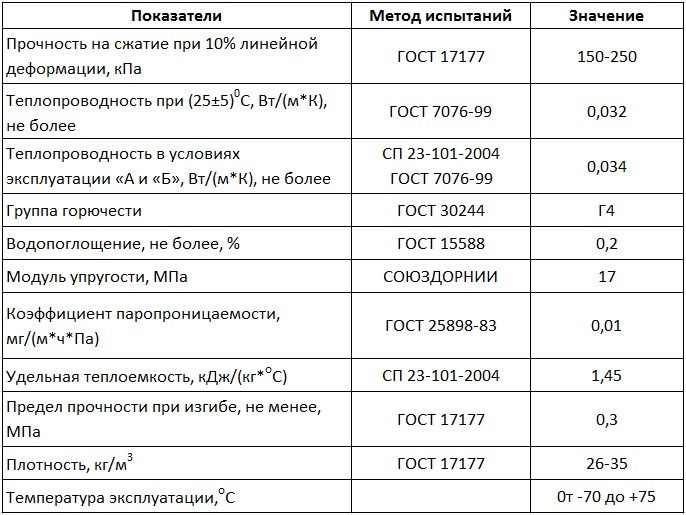

The manufacturer indicates the operational and other properties of the insulation on the packaging. Having carefully studied the instructions, you can understand that the technical characteristics of Technoplex (50 mm) look like this:

- sheet thickness - 50 mm;

- average material density - 26-30 kg / m³;

- compression resistance - up to 25 tons / m²;

- indicator of water absorption of the material (per day) - 0.2% of the total;

- use in the temperature range - from -70 to + 75 ° С;

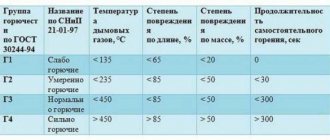

- flammability class - G4;

- heat capacity index - 1.45 kJ;

- vapor permeability coefficient - 0.01 m / h / Pa;

- bending strength - not less than 0.3 MPa.

As you can see, with a low weight and minimum thickness, the material has the ability to withstand heavy loads, which significantly expands the scope of its application. It is also important that this type of insulation is not prone to decay, rodent and fungus colonization. During operation, it does not emit harmful substances into the air and remains resistant to most chemical compounds (except for gasoline and organic solvents).

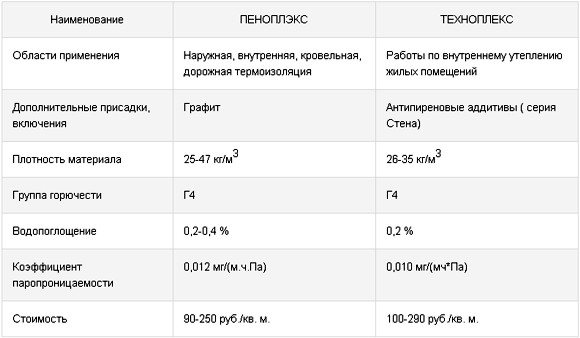

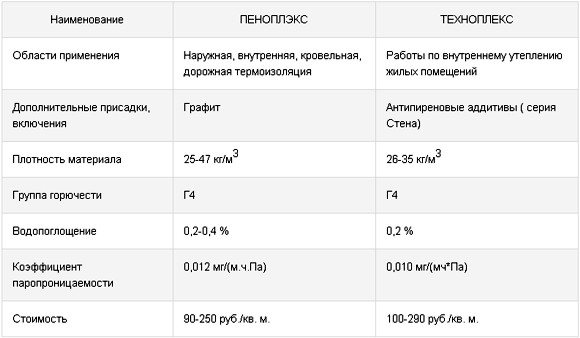

Comparing Technoplex and Penoplex

In fact, the composition of technoplex and penoplex is much more complex, it includes stabilizers, flame retardants, antioxidants and substances that slow down secondary polymerization. The difference can be in temperature, pressure and use of the blowing agent.

What is the difference between expanded polystyrene

What is the difference? A powder or liquid gas-forming agent can be better mixed and distributed over the volume of polystyrene granules, therefore, such materials for insulation have more stable thermal insulation characteristics.

But this is not the only reason why in modern production of technoplex and penoplex they refuse to use freon:

- Freon gas remains in the sealed cells of new, not yet used material for some time, which is formally considered safe, but in practice it is better to get rid of it, since it often leads to lung problems, especially in children;

- Over time, the gas is displaced by air and water vapor. If for the production of expanded polystyrene, not the purest raw materials with styrene residues were used, then gradually part of the contents of the cells of the Technoplex will be squeezed out into the environment.

For "technical" brands of EPS, for example, penofol, such processes are not of particular importance. According to the manufacturer, it is better to use penofol for insulating foundations, basements of a building, for use in the construction of highways, therefore, a mixture of freon and carbon dioxide is used for its production. The contact compressive strength of penofol is approximately equal to the strength characteristic of the Technoplex.

Often, contractors recommend that developers use foam insulation, motivating their offer with a low price. To understand which is better, penoplex or expanded polystyrene, it is worth recalling the production technology.

The use of the extrusion process allows to obtain a linear-oriented structure and very dense elongated pores. As a result, extruded polystyrene foam resists water and water vapor much better, has a higher bending and compressive strength. Therefore, all extruded polymeric polymers used for insulation - penofol, technoplex, penoplex, have the best strength characteristics than they differ from expanded polystyrene, or, in other words, polystyrene.

The main characteristics of Technoplex and Penoplex

The most reliable way to determine which insulation is better is to compare their main characteristics. The most important parameter is thermal conductivity, for foam, the coefficient is 0.029-0.030 W / m ∙ K, for technoplex - 0.030 W / m ∙ K. The difference is negligible, so both materials retain heat equally well.

The second characteristic concerns strength. According to reviews, penoplex is cut better and less deformed during installation. The flexural strength of the technoplex is almost two times lower than that of the penoplex, but its manufacturer initially declares that its products are better used for internal thermal insulation, and the penoplex better withstands the pressure from the heaving of the soil and the mass of the concrete foundation.

The third characteristic concerns water absorption. In this part, penoplex resists water better than TechnoNIKOL products, almost twice - 0.1% versus 0.2%. But both indicators are much better than foam plastic -0.5% and mineral wool - almost 10%. In addition, extruded polystyrene foam practically does not change characteristics even after thousands of freeze-thaw cycles.

The last factor is the price of the insulation, in this case the technoplex looks better, its cost per square is 10-15% lower than the competitor.

Comparison of expanded polystyrene with other types of insulation

The main competitors of foamed polystyrene foam are mineral felts and fiber mats. When asked which is better, penoplex or mineral wool, it can be argued that for private one-two-story buildings it is better to use penoplex as the most effective heat insulator. For exterior decoration of high-rise buildings, it is better to use mineral wool, for one reason - absolute fire safety. Expanded polystyrene, even with additives of a fire retardant, can emit a large amount of toxic gases during high-temperature heating, so for high-rise buildings it is better to avoid unnecessary risks.

On the other hand, it is better not to use mineral wool for damp basements and semi-basements, since the fiber instantly absorbs water. In addition, in the production of certain grades of mineral or basalt wool, phenol-formaldehyde resin is used, which is highly toxic and carcinogenic. It is better, in general, not to use such brands for insulating living quarters.

One of the competitors for the Technoplex is Isolon, a material based on foamed and modified polyethylene. Izolon, of all the materials listed, is best suited for insulating walls and ceilings inside residential premises. The coefficient of thermal conductivity and water absorption of polyethylene foam of the PPE brand is practically equal to the analogous characteristics of the technoplex.The PPE layer can withstand prolonged heating up to 80 ° C for 24 hours. Izolon PPE has good sound and noise insulation, and the main advantage is that the environmental friendliness and safety of such thermal insulation is better than that of the most expensive EPPS brands.

Polyethylene foam, even with strong heating, does not emit toxic decomposition products. The main drawback of the material is its excessive flexibility and softness. Isolon laid on the wall requires additional finishing with hard plates, for example, drywall or MDF. It is impossible to put a layer of plaster on the isolon or stick wallpaper, therefore it is better to use it in tandem with external EPS insulation.

Scope of application

In what kind of work can Technoplex 50 mm be used? The characteristics and dimensions of the material practically do not limit the scope of its application, therefore it is very popular in many works.

So, "Technoplex" was actively used in the insulation of facades. For this purpose, it is mounted on a special glue (like polyurethane foam). Since extrusion plates do not lose their properties even underground, they are also used when creating a heat-insulating layer on foundations, and as a heater for underground utilities.

The material is no less actively used in the process of interior decoration. It is mounted both on vertical surfaces and in the floor screed.

Installation features

The process of assembling the material itself is simple and will require from the performer minimal construction knowledge and skills in using the tool. To carry out the installation, we need the following tools and consumables:

- puncher;

- hammer and spatula;

- sharp knife;

- roulette and level;

- marker;

- directly technoplex of the required brand and thickness;

- special plastic dowels with a wide head;

- adhesive mixture for expanded polystyrene;

- metal support profile.

When the materials and tools are ready, you can proceed with the installation. To begin with, it is worth preparing the surface. Most often, technoplex is used for external insulation of a facade or foundation, so the surface should be sufficiently flat (it is not necessary to display it with millimeter accuracy) and clean. Some professionals recommend additional priming of the wall or foundation for better adhesion of the adhesive. This step will not be superfluous, although it is not required.

After preparing the surface, you can proceed to the installation of the Technoplex. To begin with, a lower horizontal rail from a metal profile is set and attached to the level. When choosing a rail, it is necessary that its width coincides with the thickness of the insulation plate. Then we attach the top rail.

We begin to lay polystyrene foam plates between the guides. To do this, grease the surface with glue and press it against the wall (foundation). By level, we check the correctness of installation. Given that the solution hardens for a certain time, it is possible to slowly adjust the location of each plate relative to the level to achieve the desired result.

After the glue is completely dry (usually after 2-3 days, depending on the brand of the mixture), we proceed to additional fixation of the plates. To do this, use a puncher to drill holes in the surface through the insulation and insert plastic dowels. Due to their design, they have a hollow body and teeth on the outside of the nail. We hammer a steel rod into a special hole, which deforms the dowel from the inside and makes it firmly hold in brick or concrete.

As a rule, 5 dowels are driven into one slab - 4 at the edges so that the head fixes the adjacent slabs and 1 in the center. Sometimes, in order to save money, they are content with less.

Installation is complete, now you can proceed to the external surface finish.

"Technoplex" 50 mm: characteristics and customer reviews

At the end of this topic, let's say a few words about how consumers relate to the Technoplex material. If you study a huge number of reviews, you can understand that most of the specialists are attracted by the ease of installation of this insulation. They note that with his help, work on the arrangement of thermal insulation is carried out very quickly.

Many people emphasize ease of use, which is explained by the low weight of the material and the ease of processing. Among builders, slabs are valued for their lack of shrinkage and preservation of their original qualities for a long period of time. An ordinary buyer is attracted by the democratic cost - 990 rubles per package.

Based on all that has been said, one conclusion can be made - Technoplex plates are a fairly popular material, which has already won the sympathy of a domestic manufacturer. It can be used almost everywhere, which means that the popularity of this insulation will continue to grow continuously.

Comparison of heaters by cost

If you still cannot decide which is better - penoplex or technoplex, then you should also pay attention to the price, because it is sometimes the decisive factor before purchasing thermal insulation, like any other material. Penoplex is somewhat cheaper. However, the price difference does not exceed 10%. If you decide whether penoplex or technoplex is the difference, then it is worth considering that, depending on the manufacturer and regions, the cost may change, but the trend in the difference will remain the same. Making a conclusion, it can be noted that both materials are similar and do not differ too much from each other. The main difference is only in the cost of materials.