Warm floor is really a blessing of civilization. It is especially relevant if it is installed on the first floors of residential buildings or in apartments located above the basement. Underfloor heating can make your home cozy. Unfortunately, like any other electrical system, such floors can also fail, at one point stopping heating the room. Of course, the system needs careful testing and troubleshooting. And immediately after installation, even before pouring the screed and laying the finishing, it is important to find out its performance. How to check underfloor heating?

How to check underfloor heating

Types of electric underfloor heating

Underfloor heating malfunctions

A malfunction of the infrared floor heating system is an unlikely event, but a possible event. The most common reason for this is a mistake made during installation. In this article, we will look at ways to find the cause of the failure.

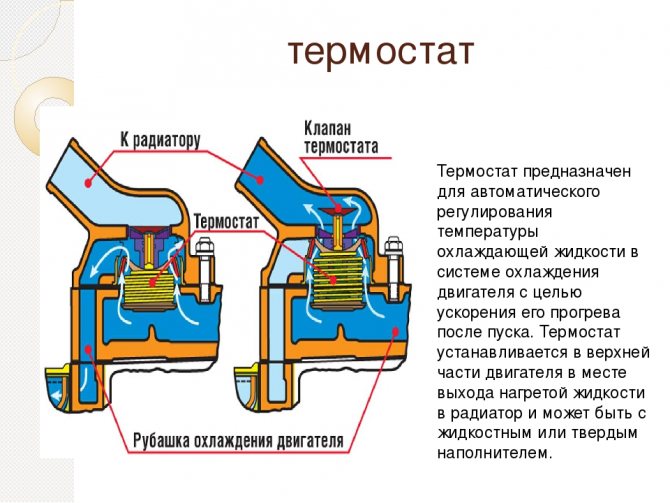

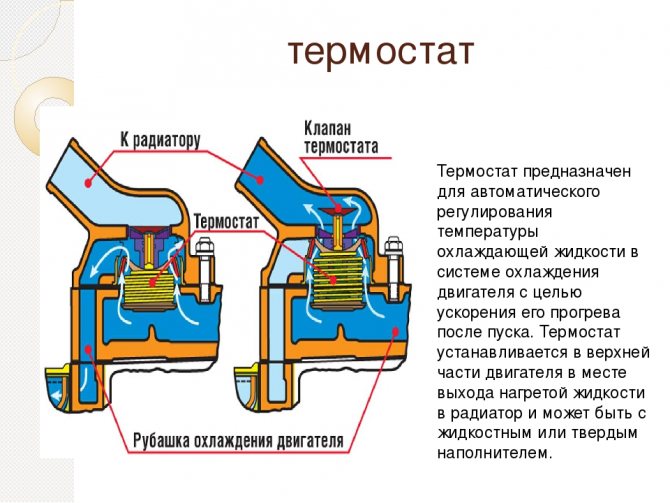

First of all, it is necessary to identify the faulty item. The main elements that may be incorrectly connected or fail are the heating element itself, connecting wires, thermostat and temperature sensors.

The main elements of the heating system of the film warm floor

Make sure the thermostat is powered and configured correctly. If power is on, but there is no effect, the next step is to check if the wires are connected to the thermostat. Refer to the instruction manual or the pin markings on the back of the thermostat to make sure all pins are connected correctly. If everything is in order here, then we proceed to check the heating elements themselves.

In most cases, the heating film breaks down due to improper installation. This may be an error in connecting the wires to the film, their break during laying, or an incorrectly calculated cross-section.

There are two ways to check the health of the heating foil.

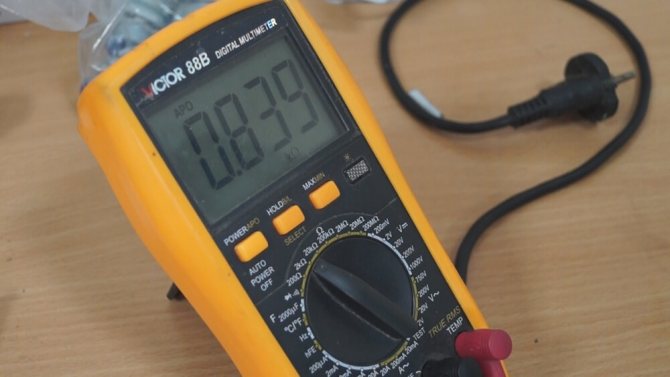

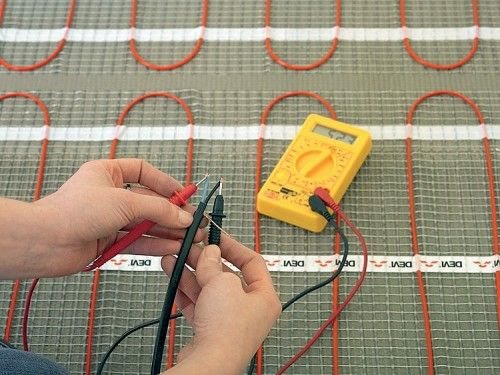

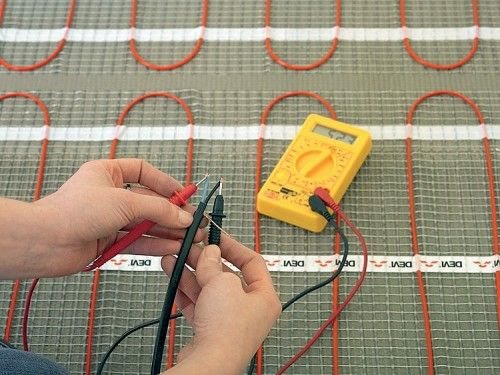

Resistance measurement

The first method is to measure the resistance of the floor and compare it with that indicated in the passport. The resistance value can be calculated using the formula R = U / P. When using multiple heating elements, the resistance of each can be checked separately.

Signs of malfunction of the film underfloor heating:

- If the reading is zero, the system is most likely short-circuited.

- If the reading is equal to infinity, the heating element may break in the system.

In any case, if the measured resistance does not correspond to the passport, the cause of the malfunction lies in the film. It is necessary to check the integrity of the wires and the correctness of their connection to the heating elements.

Heating foil connection

The second way is to connect the power supply to the warm floor directly, bypassing the thermostat. If the film starts to heat up, then the problem is in the thermostat. Otherwise, it is necessary to check the film and the wires connected to it.

Attention!

All work is carried out with the power supply disconnected! The contacts on the thermostat may differ, follow the instructions for use and markings on the thermostat.

Connecting the film to a network without a thermostat for a long time can lead to its failure.If, when connecting the heating film, the machine directly knocks out, a short circuit or a malfunction of the machine is possible, in this case it is necessary to measure the resistance of the heated floor, it should not tend to zero.

How to check the performance of the thermostat

Thermostat malfunctions can be associated with both the device itself and the remote temperature sensor.

If the thermostat fails, the relay or capacitor is most often to blame. Considering the cost of repairing it, it is more advisable to purchase a new thermostat. To check the functionality of the thermostat, you must:

- set the minimum temperature on the thermostat,

- apply voltage to the thermostat and measure it (should be 220 V),

- turn the toggle switch to the ON position,

- set the maximum temperature on the thermostat. When the temperature rises, a click is heard at a working thermostat (the relay switches). The voltage at the load contacts (wires going to the heating elements) should be 220 V.

- when the thermostat is set to the minimum temperature, the relay re-activates, disconnecting the voltage supply to the load contacts.

Temperature measurement sensor test

To check the health of the floor temperature sensor, it is necessary to measure its resistance using a multimeter. Each sensor has a declared factory resistance indicated in the passport. When the temperature sensor heats up, its resistance decreases. If the resistance differs by more than 5 kΩ, or is equal to 0, then the sensor is faulty and requires replacement.

Note

In programmable thermostats, in the event of a temperature sensor malfunction, a corresponding message is displayed on the panel.

How to check floor resistance

The most common reason for the lack of heating in an underfloor heating system is a faulty or incorrectly calculated and installed underfloor heating resistance.

In this regard, the current issues of how to identify a malfunction and, if possible, independently eliminate a defect in work without attracting highly paid labor of qualified specialists, will be considered below.

Breakage options

If there is unevenness or lack of heating in the electric floor heating system, there are not many reasons for breakdown.

Do not panic if all the parameters of the correct installation were observed during installation, then most likely it will not be difficult to get rid of the problem.

It is necessary to check the supply of power to the system, the health of the sensor and the integrity of the load cable system.

The simplest reasons for the lack of heating are malfunctions in settings or a breakdown of the thermostat.

No. Possible reasons What to do

| 1 | There is no electricity in the network | Make sure that the thermostat is in good working order: the indicator light should be on |

| 2 | Lost or changed settings | Check and restore settings |

| 3 | No mains voltage | Measure the voltage in the network by disconnecting the thermostat and connecting the device to the L and N terminals, the value should be 220 V. |

Thermal sensor malfunction

Do not rush to open the floors, check first if the temperature sensor is working

In order not to open the screed ahead of time, check the serviceability of the temperature sensor. Its cable is a two-core wire.

For testing, you need to measure the resistance between the wires. Typically, the resistance values are in the range of 5 - 120 kOhm, the exact value is indicated in the technical data sheet for the thermostat.

Resistance test:

- the multimeter is switched to ohmmeter mode,

- parameters are set,

- the resistance value is measured.

If the resistance value during the check does not correspond to the passport value, then the sensor is faulty and requires replacement.

Disconnect the power supply before checking

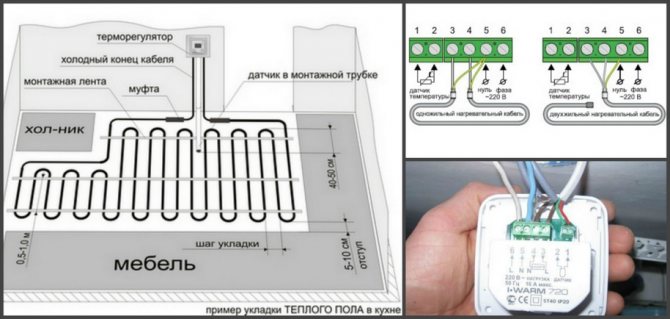

You can check the electric underfloor heating and make sure that the heating system itself is working properly by connecting the power directly to the floor wires. This requires:

- Turn off the power in the electrical network of the apartment or house (unscrew the plugs on the electrical panel).

- Connect the power wires directly to the shield, bypassing the thermostat: contact No. 1 with contact No. 3, and contact No. 2 with contact No. 4.

- Turn on the electricity supply, wait half an hour until the floor heats up.

If, with this connection, the system warms up, then the thermostat unit itself is faulty. If, after carrying out all the activities, the floor does not work and the cause could not be eliminated, the problem is much deeper in the literal sense.

Load cell problems

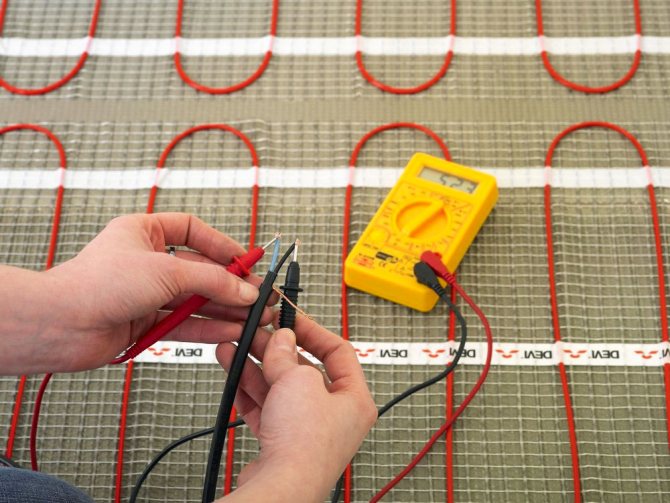

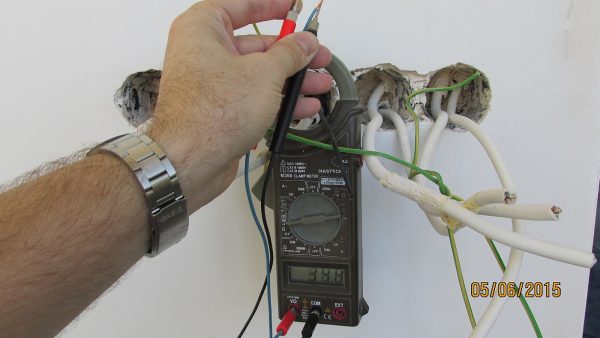

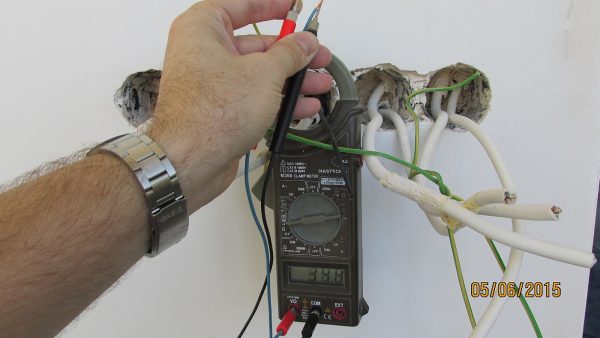

Check the underfloor heating resistance with a multimeter

If no problem is found in the power supply and the regulator, then the integrity of the load wires is broken.

Test the heating element yourself, for this you need to measure the resistance of the heated floor with a multimeter.

Connect the measuring device to contacts No. 3 and No. 4. The resulting figure must correspond to the value declared in the manufacturer's passport. For more information on the resistance of a warm floor, see this video:

In a situation with a film floor, it is sufficient to measure the resistance in an unheated area.

Multimeter Indicator Options

No.IndicatorsBreakage

| 1 | No resistance, or close to zero | a short circuit has occurred in the system, most likely due to an incorrectly calculated cable cross-section. |

| 2 | Above passport | the insulation of the heating element is broken |

| 3 | Below passport | there was a break in the floor system |

Any of the above situations will entail additional work to identify the location of the defect and eliminate it. For a warranty period of service, contact the company that carried out the installation. Post-warranty breakdowns will also be easier to fix for the company that installed the warm floor, since they have retained the necessary documentation, including the installation diagram.

gurupola.ru

Answers from experts

Sergey Popov:

In no case. The foreman obviously bred you. The warm floor heats up immediately. If the floor is electric, then the open circuit or the regulator does not work.

Agonda:

Warm floors are different. The electric one immediately starts heating. Watery longer. On our large area (the entire first floor, about 100 sq. M.), A water-heated floor, turned on for the first time, was heated for the day. And that's a lot. A cheater is your foreman or a clumsy one. He screwed up, most likely, now he thinks how to get rid of and dump. I don’t want to fix it at my own expense ...

Evolutionary:

Well, about the moisture, he bent it. What is your gender (cable or mat)? If the cable is in a tie, then it can really heat up for a long time. And check: you can disconnect the wires of the floor itself from the thermostat and measure the resistance with a tester or by email. counter. Disconnect all email. appliances, and then turn on the floor email. the counter should start "spinning".

Andrew:

The foreman claims that to check the correctness of the work, you need to wait a month, says that there is still moisture under the tiles and it interferes with heating .... you need to trust people, we do not live in the forest for tea, support this holy man and tell me what prevents not only warming, but also paying for all his work, he himself suggested waiting a month, so go to meet this absolutely honest man ....

Winds:

I support Andrey. Offer to either fix the malfunction or get money when the floor works.

Any electrical appliance. Generates heat, if it works, regardless of humidity. And if the foreman himself said that he laid the cable on a damp base or a laminate on a wet bulk, demand money from it and for damaged materials, a violation of technology

Dmitry Ostankov:

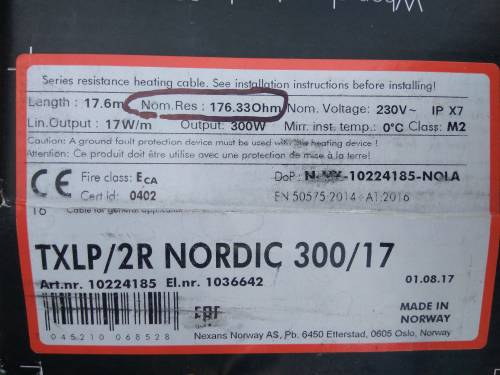

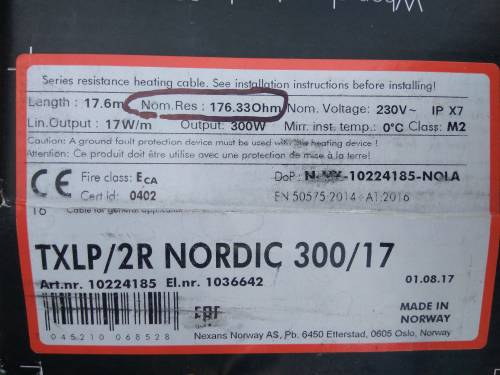

You need to check two indicators: 1) the resistance of the heating core of the mat (using a multimeter). It must correspond to that indicated in the passport for the product.permissible deviations: + 10% / -5% of the specified indicator. The multimeter terminals are connected to the leads of the heating conductor at both ends. 2) insulation resistance (using a megohmmeter). Between the leads of the heating vein from both ends of the mat, the megohmmeter should show "0", that is, K / Z. , since these veins are closed. Between any of the cores and the screen, the device should show "infinity" - "8" on the side. This is the main indicator. It indicates the integrity of the mat insulation. This indicator is especially important after filling. And do not trust the electricians who only checked the resistance with a Chinese tester and say that everything is in order.

Andrey Volkov:

They check it in the store with you, when you buy it. - they look at the resistance with the device And it is better to roll it into the screed

And glue the tiles on a flat surface - under a comb so that there are no voids under it

Alexander Bakushev:

you can turn it on for a few seconds, if it gets warmer, it means a worker!

Stas Shabanov:

Check with a tester, it should show 60-70 Ohm ..

Troubleshooting Techniques

There are two ways to check the functionality of the installed floor heating system:

- Visual inspection of the cable and system elements for visible damage. Suitable for burnt-out equipment, lack of power from the mains or broken connections in the structure. The method is not very informative, so they proceed to the second one;

- Using a multimeter for testing allows you to measure the voltage in the network. The regulator is removed and the voltage is measured with special probes. If the voltage level is 220V, then the malfunction is caused by the breakdown of one of the system elements.

Determination of resistance with a multimeter

The serviceability of the heating system and a cold floor mean a malfunction outside the structure. There is a way to find out the operation of the underfloor heating sensor using a multimeter - a resistor with its own resistance.

Experts point to an error related to the floor temperature: 5 degrees of heat on a multimeter is equal to 22 kΩ, and 40 degrees is 6 kΩ. In any case, the sensor and its resistance should not go beyond the manufacturer's standards; if the deviation is 5 kOhm, the device is considered broken and replaced.

Diagnostics of the thermostat

Visual inspection of the device is useless, a multimeter is required. The test begins after identifying problems with the thermostat - first, the heaters are turned off, and then they are started up to the maximum temperature.

The terminals without a cable are measured with a multimeter, if the regulator operates, then the relay should turn on and the voltage will be reflected on the device. The regulator is set to minimum heating, the relay should turn off the system and the multimeter reading drops and disappears.

POWER OF HEATED FLOOR PER SQUARE METER

Regardless of whether it is mats or a cable, an underfloor heating is usually chosen so that for each square meter of the heated surface there is, on average, 150 W of electrical power. Depending on the purpose of the room and the purpose of the installation, this value can vary:

- from 100 - 130 W, when it is enough just to make the temperature of the coating on the surface comfortable, for example, floor tiles in the bathroom or in the kitchen;

- from 130-180 W, when it is necessary to supplement the main heating system, it is most often used. It can heat up the flooring quite strongly, thereby additionally warming up the room during cold periods;

- from 180 - 250 W, when the warm floor is used as the main source of heating, or, it is a full-fledged part in the general heating system of places where it is especially cold, for example, a balcony;

- On average, the power of a running meter of a heating cable for a warm floor is 10 - 20 W / m.p .;

Thus, after measuring the resistance, you must estimate the approximate installation area and proceed with the calculations:

Example: Let's say you have a corridor in an apartment in which about 6 square meters are heated. By measuring the resistance of the heating cable with a multimeter, you got a result of 55 ohms. It remains to calculate how much this is enough for such an area:

First of all, we determine the total power:

P = U2 / R = 220 2/55 = 880 W

Then the power of 1 square meter:

Psq.m. = 880/6 = 146.7 W / sq.m. - which, taking into account the error, corresponds to the standard, most common power of electric floor heating. If the calculated value is too low or high, then you will understand that it is the heating cable that is the cause of the malfunction, and you can repair it.

As you can see, measuring the resistance of an electric underfloor heating cable is the main diagnostic method. Heating mats or cables, after they are installed in a screed or tile adhesive, cannot be reached and inspected without complete dismantling. And to measure its resistance with a multimeter in everyday life is available to everyone and is not an impossible task. Having learned that the floor conductors are not broken, do not short-circuit and have sufficient power to heat up, you can continue to look for the cause of the malfunction in other components.

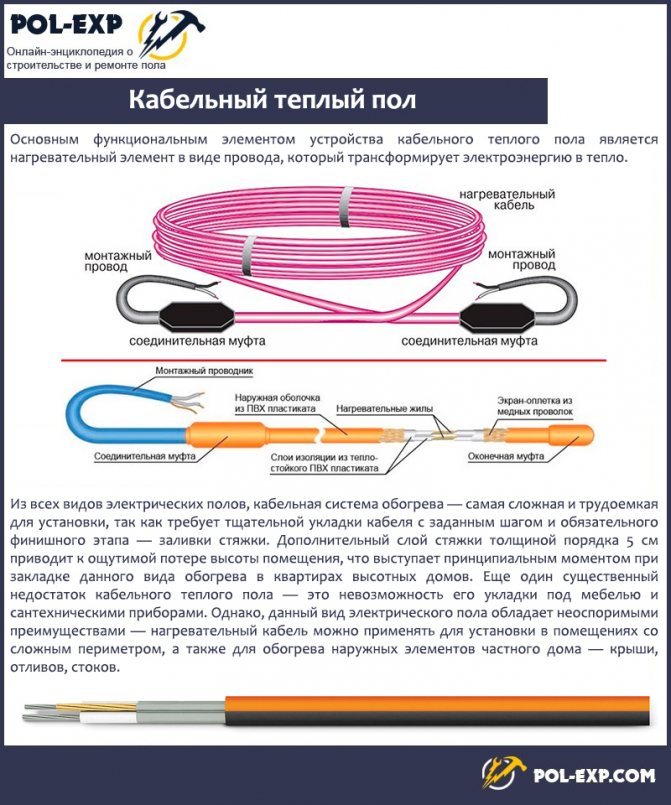

What is included in underfloor heating?

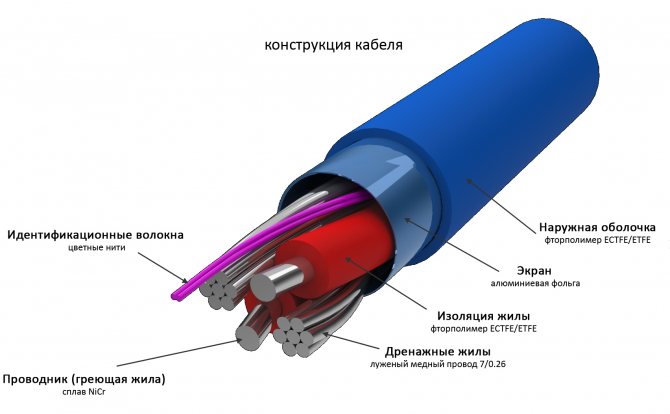

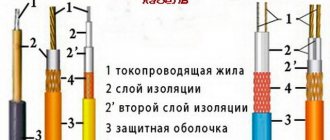

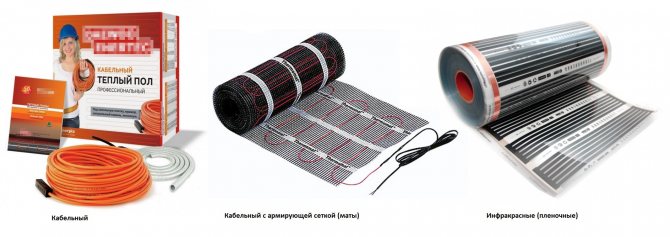

Heated floors are made of electric cables or with infrared foil. The system includes the following elements:

- Heating cable - heat source;

- Thermal sensor for cable heating control;

- The thermostat connecting the elements to the structure starts or stops heating depending on the temperature parameters.

Features of using the thermostat

The thermostat automatically adjusts the voltage applied to the wires. It is connected to a conventional power grid through the phase and neutral wires and looks like a small switch. Its heating is monitored by a sensor located next to the wires.

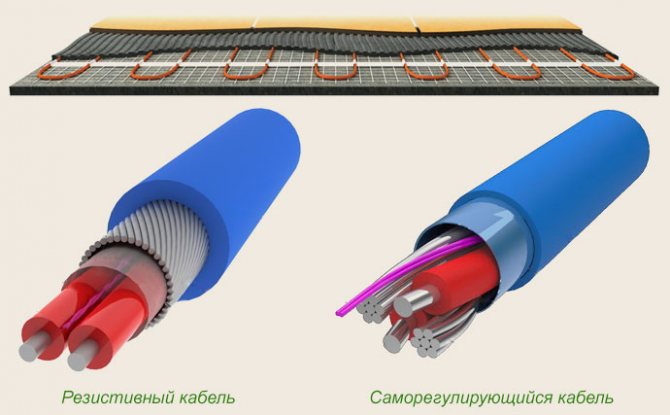

The person sets the minimum temperature, upon reaching which the heating system starts. A cable in such a design can be resistive or self-regulating fluctuations in heat degrees and resistance level.

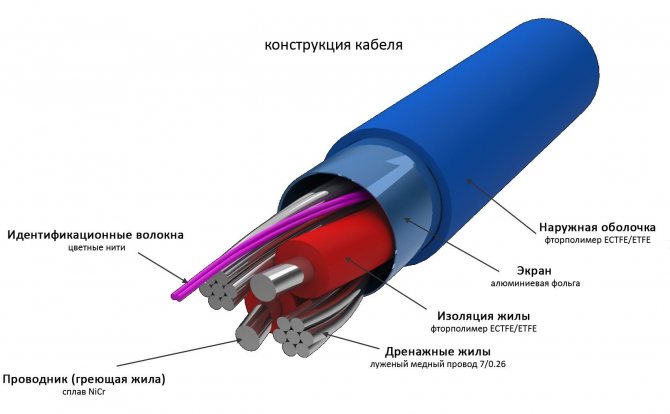

Which cable is suitable for the heating system?

The calculations of the heating system largely depend on the length of the cable, changes in which will subsequently disrupt the functioning of the entire structure and damage the insulation.

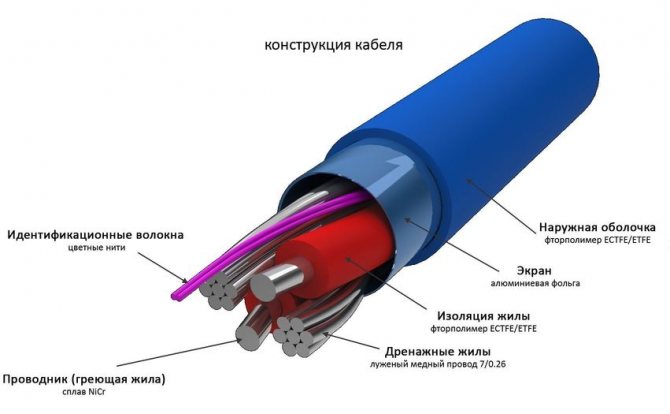

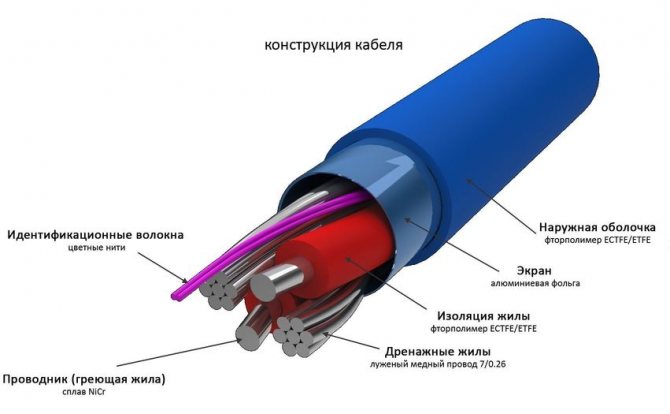

Two-core cables or a pair of single-core cables are used. A wire with two cores cannot be cut or mounted in places with a load on the floor, single cores are more versatile.

The method of checking the warm floor for performance

To determine the malfunction of the heating system, two methods can be used: visual and the method of measuring the main parameters. And if in the first case the consumer can only rely on external signs (blackening, insulation melts, etc.), then the second option gives a more accurate assessment of the damage to the system.

Checking underfloor heating with a multimeter

The first step is to make sure that there is a supply voltage at the terminals of the thermostat. For this, by moving the multimeter to the position for measuring alternating voltage, you need to make sure that the network is available. You must first remove the protective cover from the temperature controller.

The next step is to measure the resistance of the heating cable (film). For this, the entire system should be de-energized and, having moved the multimeter to the position for measuring resistance, apply the probes of the device to the terminals of the heating elements (after disconnecting them from the terminals of the thermostat).

Resistance values may vary depending on the power of the device. Well, in order to accurately determine the correctness of the measurements (knowing the power of your warm floor), you can use the following relationship:

P = U2 / R,

And then, substituting the available values, you can determine the correctness of the measurements.

For example, if the multimeter showed a resistance value of 100 Ohm, then the power of your warm floor according to the given formula will be P = 2202/50 = 480W.

By the way, if there are no passport data for a warm floor, then the average power of the heaters can be taken in the ratio of 150W per 1 square meter of floor area.

By comparing the measurement results with the available characteristics, it will be possible to find out about the quality of the heater. If the measurement results differ significantly from the passport data (more than 10 - 15%), then we can talk about damage to the heating element.

Exceeding resistance - short circuit of the circuit;

Reduced (zero) resistance values - cable break.

Of course, further repair of the warm floor will require the involvement of specialists for dismantling and subsequent installation of heating elements.

Thermistor check

In case the heaters are intact, the next thing to look out for is the thermistor. Its integrity can also be checked with a multimeter.

However, it should be understood that the value of electrical resistance for a given element can vary significantly depending on the ambient temperature. And the same sensor will show 20kΩ or more at t = + 5⁰С and 5kΩ at t = + 35⁰С. At this point, you should pay attention and additionally check the process of changing the resistance when the temperature sensor is warming up.

As mentioned above, replacing a thermistor is a very simple undertaking. And if necessary, the consumer will be able to perform the specified procedure on his own.

Methods for checking the health of a warm floor

There are only two ways to check the performance of the underfloor heating system. One of them is visual inspection of the cable and components for damage... But it will reveal only those defects that can be seen - burnt (blackened) equipment, broken cable, lack of electricity in the house, etc. The method is the simplest and does not require the use of any devices, but it is not very informative and will not always be able to help in identifying the cause of the lack of floor heating.

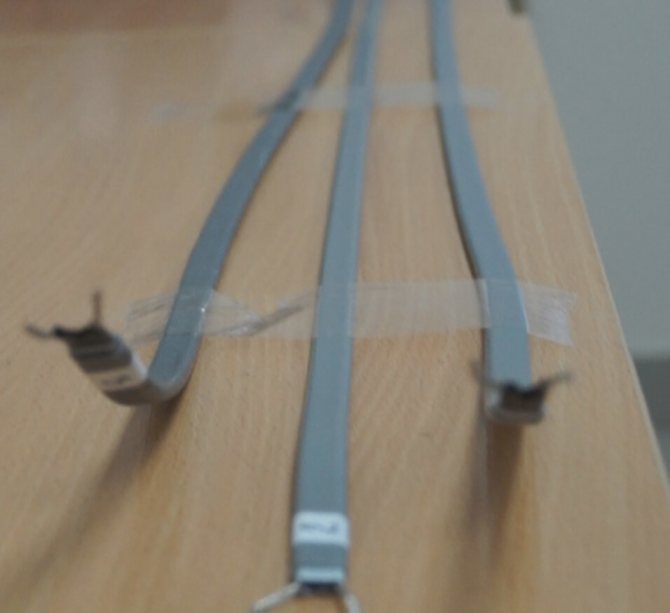

Invalid rotation of the heating mat after the factory coupling. During cable operation, permanent deformation of the outer sheath occurs

The second way is determination of the main parameters of the system power supply using a multimeter... It will help you find out more precisely what is the reason for the lack of working capacity of the floor. Using the device, you can measure the mains voltage - just remove the thermostat from the wall and, using special probes on the terminals, measure the mains voltage. It should be 220 V. If the indicator is normal, then one of the elements of the entire underfloor heating system is clearly to blame.

The first step is always a visual inspection. It is important to make sure that the lack of heat is not due to a lack of electricity throughout the house. Next, you can look for the presence of melted or burnt parts of the system. If nothing suspicious is found, then it's time to pick up a multimeter.

A multimeter is also used to diagnose the underfloor heating system. The resistance of the cable is measured and divided by the value of 220 V (this is an indicator of the voltage in the mains). The resulting figure shows the master the amount of current flowing through the floor system. Further, this indicator is multiplied by the voltage - this is how the power consumption indicator is revealed. It is she who must correspond to the capacity of the system, which is usually indicated in the passport. If the power value is higher than necessary, then there are short circuits in the system - somewhere the cable insulation is damaged.

Attention! This type of malfunction can also be noticed due to overheating areas of the floor in some places.

Infrared floor heating - electricity consumption

If the power value is less than indicated in the cable passport, then there is a wire break somewhere. Because of this, the system is unstable.

Advice! If all the documentation regarding floor heating equipment is irretrievably lost, then the power according to the passport is assumed to be conventionally equal to 150 W / m 2.

Let's figure it out further: if the resistance indicator on the multimeter is 0, then, most likely, it was out of order by a short circuit that had arisen somewhere. It will be extremely difficult and expensive to fix the equipment. And it will be difficult to find the damaged place when it comes to the cable field. If an infrared floor is used for heating, then it is enough to lift the finish, find the damaged area and change it.

Cable designs and location

According to the principle of operation, the cable in the construction of a warm floor can be:

- self-regulatory;

- resistive.

Self-regulating cable in the operating mode changes its resistance with temperature drops. The resistance value of the resistive cable is independent of temperature. If the work on the installation of the cable is carried out in compliance with all requirements and recommendations, then the cable will not be damaged by temperature. The main requirement for cable laying is a certain length of time. If the cable turns out to be long during laying, it must not be shortened, as this will cause a change in the current characteristics and heating, which will lead to the destruction of the insulation. In practice, 2 types of heating cables are most often used:

- single two-core;

- 2 single cores in parallel.

A single two-core cable is a wire mesh, plugged on one side. Such a cable is mounted in a concrete screed. The selection of the mesh is carried out strictly according to the area of the room, free of plumbing and furniture, since it cannot be cut.

The parallel arrangement of 2 separate cores of the cable is also mounted in a screed, but differs from the previous cable in that its length can be changed without fear of insulation.

A film floor based on infrared heating differs from cable structures in that it is a chain of active resistances. The advantage of the film is its low thickness and the possibility of using it with almost all floor coverings. It is allowed to change the area of the film, but only according to special marking marks.

The main working elements of the warm floor

To identify the cause of the malfunction of the warm floor, it is necessary to know the main constituent elements of the system, which may not affect its operation. So, in general, the electric floor heating system consists of:

- thermostat,

- temperature sensor,

- and directly the heating element itself, which can be a heating cable, a heating mat (a cable fixed on a grid with a certain pitch), an infrared film.

The floor functions as follows: a current flows through the heating element, after which heat radiation occurs. The temperature data is received by a special sensor, transmitting the obtained values to the thermostat.

The work of the thermostat is to control and maintain the temperature: the desired temperature is set manually, and the thermostat activates / deactivates the underfloor heating system to establish the desired temperature regime. In order to check the serviceability of each of the elements of the general system of a warm floor, there are a number of actions.

The first step is to determine the performance of the warm floor

The operation of the underfloor heating may be disrupted due to a malfunction in the heating element itself. To check its operation, you need to connect the floor to the network without a thermostat. After connecting, you need to wait a while and check if all parts of the warm floor are heating up. If the floor heats up evenly and no malfunctions were detected, then the thermostat of the warm floor or its sensor is not working.

What should be the resistance of an electric floor heating

Underfloor heating is most often produced in the form of a heating cable or mats:

Heating mats represent a heating cable laid in a certain way and fixed in this position. In addition to the fact that this option has a much simpler installation, it has a fixed power per square meter, which does not change.

But the power per square meter of a floor made with an ordinary cable can vary greatly, depending on how it is placed on the surface, with what density, how many turns are made and what is the distance between them.

If you know what the power of the kit is, by measuring its resistance, it will not be difficult for you to check its serviceability and efficiency:

It is enough to use Ohm's law, namely the following formula:

P = U2 / R, where P, Watt - power; U, Volt - mains voltage, usually 220 Volts are taken into account; R, Ohm - Resistance;

Example: Thus, knowing that a heating mat with a total power of 800 W is flooded in the screed, and the multimeter showed a resistance of about 60 Ohms, you can check how the actual indicators correspond to the declared ones:

P = 220 2/60 = 806.7 W - which is very close to the nominal value, which means the floor is working properly.

If you do not know the power of the installed electric heating system, you only roughly understand the surface area that it heats and where it is installed, diagnostics should be carried out as follows:

How to check a warm floor without a thermostat and a multimeter?

If it happens that there is no multimeter at hand, then the check can be performed without it.

The integrity of the heating vein can be checked by applying a voltage of 220V for a few minutes.

A working cable will become warm. The integrity of the insulation between the heating core and the grounding screen can be checked by connecting the section to a power supply line that is equipped with a current leakage protection device (RCD).

If the RCD does not work, then the warm floor is operational. However, such a check should be carried out only in the absence of measuring instruments.

If you still have questions: how to check a warm floor without a thermostat? How to check the warm floor with a multimeter? This site has free consultation from specialists

.

Please contact our managers, they will be happy to answer all your questions.

You can find the phones on any page of the site or order a "call back".

Also on the site there is a large selection of warm floors at an excellent price. Trust us, we have the best prices.

Enjoy your shopping.

too much resistance

Posted by shatl on Feb 28, 2020 in Underfloor heating (electric)

Create an account

Register in our community. It's very easy!

Already have an account? Sign in.

Or sign in with one of these services

Google recommends

Our recommendations

What is it for?

Phoenix posted a topic in Tools and Equipment, Jan 15, Topic

I propose to warm up, who is interested.

Who has any guesses about what this is for?)

Birch suvel

Sano posted a blog post in Slab Furniture, Jan 23, blog post

Here is a cut of birch suveli brought to the workshop, while we are planning to make a coffee table in advance.

The procurement of such material itself was not the easiest thing, not only was it found in the forest, it was also taken with difficulty, then the suvel was cut into pieces, but after that, using a special technology, it was cooked for a couple of weeks, and then dried for a couple of years.

In general, this is a whole epic, and in view of the fact that so much has been done only for the workpiece, and based on the size, the price of such material is already becoming very high. And this is not the table itself.

It is necessary to carefully approach the work, and make a flat tabletop with minimal losses in the thickness of the workpiece.

Yin and yang ceilings

ramon posted a topic in Our works, December 12, 2008, topic

One of our first works supported the oriental theme with a branch of sakura

Slab table.Hoffmann swallows

Sano posted a blog entry in Slab Furniture, Sunday at 20:28, blog entry

I make a table to order, I make a table top from elm slabs or otherwise elm.

In one of the slabs there is a rather extensive and in places through crack. I cleaned it, and also filled it with epoxy, it will seal the crack, and also level the surface of the countertop.

As an additional blockage against crack opening, Hoffmann's swallows are embedded, which not only enhance, but also create a decorative effect.

Someone will say that they spoil the appearance, and they should have been placed on the back side of the countertop. But the fact of the matter is that they just cannot be put there because of the peculiarities of the table top.

I personally like these swallows, and besides, their presence was approved by the table customer.

They were made from scraps of the same table top, two dark swallows lay on the light half, and one light one was cut into the dark half of the table top.

A brief excursion where this furniture element came from. For me, this Homfan did not invent anything, but simply took what has been used for centuries in carpentry and not only art. In fact, this is the same dovetail connection.

Let's leave it on the conscience of the author, besides, this name is a swallow or a Hoffmann butterfly stuck to this type of connection, as, for example, all copiers are called Xerox.

In 1985, while still a student at Harvard University, Thomas Hoffman developed a system for joining parts made of wood and chipboard (MDF and chipboard), which was named "Swallow Hoffmann" and was soon adopted throughout the woodworking industry.

DIY heating cable repair

You have found a broken or broken wire. Now you need to carefully remove the tiles above this place. To repair the cable with your own hands, you need to remove only a few tiles, or, if possible, cut out part of the tile and then reinstall it in the same place.

It usually requires no more than 10-25 cm of heating wire to cover the sleeve.

If the problem with the heating cable passing outside the premises (for example, the heating system of roofs, balconies, stairs, etc.) occurred during the cold season, then it is better to postpone the cable repair with your own hands for the summer. In low temperature and high humidity environments, it is difficult to provide dry areas for safe repairs. However, if you decide to contact YouDo service specialists, then the problem will disappear by itself - professional craftsmen are able to provide repair work at any time of the year.

In order to make the correct repair of the heating cable with your own hands, it is necessary to clean its ends with a ledge.

Common malfunctions of warm floors

The reason for the breakdown of the warm floor may be incorrect installation of equipment, or the exit from standing of individual elements of the system.

Thermostat

As mentioned above, it is responsible for maintaining the floor temperature in a given range. And also it is a switching link on which all the circuits of the heated floor are assembled (power supply, load, temperature control).

And if all connections are made according to the diagram, then the reason for the malfunction of the thermostat lies in its element base. Of course, you can try to restore the specified block. But as practice shows, most often the repair of a thermostat comes down to replacing it.

temperature sensor

Refers to easily replaceable elements, due to the fact that it is located in the corrugation (laid in the floor screed). The durability of this element directly depends on the quality of the materials from which it is made, as well as on its correct location relative to the heating cable (see manufacturer's recommendations).

Heating cable

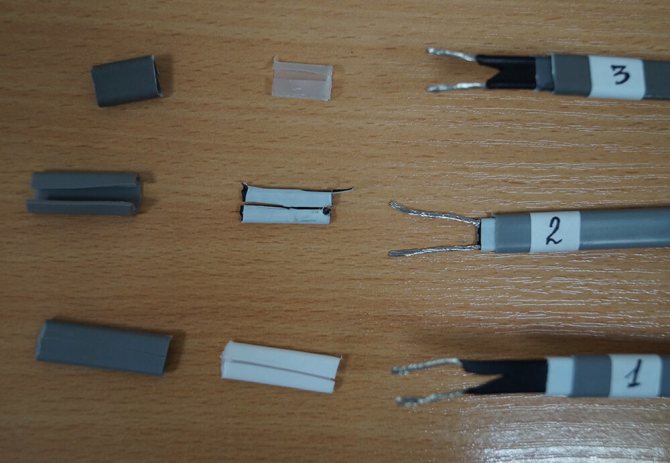

A fairly reliable element of the system, which most often fails due to improper installation.Moreover, the most "problematic place" of the heating cable is the connecting sleeve (through which the power is supplied)

In view of this, with self-repair, first of all, you should pay attention to this particular unit.

By the way, the method of choosing a heating cable for a warm floor can be found here.

Why measure the resistance in front of the underfloor heating screed?

When installing the underfloor heating system, before the screed, experts measure the resistance of the heating cable with a multimeter. The works are carried out in the following sequence:

- Examine the passport or cable label indicating the resistance. A maximum change of 10% in any direction is allowed;

- The multimeter is switched on to the measurement mode;

- Probes are placed on the wires leaving the system;

- Resistance is watched on the screen. This value must be the same as that specified by the manufacturer.

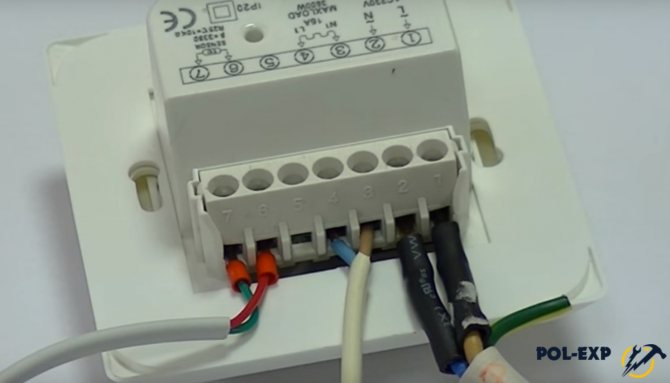

How to check the performance of the thermostat

Let's look at an example of how you can check if the thermostat is working using a regular light bulb.

Step 1. The thermostat is connected to the network in compliance with all the rules. That is, the phase wire is connected to terminal L, and the zero wire is connected to terminal N. The temperature sensor and a regular light screwed into the socket are also connected. It will be a load indicator.

Step 2. The thermostat connected to the network is turned on with a toggle switch.

Step 3. The lever responsible for increasing the temperature is set to maximum.

Step 4. If the thermostat is working properly, the lamp will light up.

Step 5. Using this circuit, you can also check the temperature sensor. To do this, it is taken into the hand, and the temperature controller is set to an average value.

Step 6. The temperature regulator is again turned to higher values. The light will turn on again. But when the sensor heats up to the temperature of the human body, it will go out.

Step 7. After that, the system can be left alone. After a while, the light will turn on again when the temperature sensor cools down and gives a signal to the thermostat.

Diagnostics of the thermostat

The thermostat is also checked with a multimeter. To make sure that the cause of the malfunction is in it, you need to turn off the floor heating element itself. Further, the floor heating level regulator is turned to the maximum. After that, the terminals without wires are diagnosed with a conventional multimeter. According to all the rules, in this case, the relay is triggered and the device shows the voltage level. With the regulator set to the minimum heating level, the relay will de-energize and the voltage will disappear.

Checking with a resistance tester

Repair of thermostats

It's no secret that sometimes thermostats fail, and at the most inopportune moment. There are several reasons for this sad event. The most common one is incorrect installation: an error in the wiring diagram (such as: mixing up wires and terminals, too much load), painting the installed thermostat with paint, installing the thermostat in a damp room. With such errors, the thermostat either immediately fails, or its service life is significantly reduced. Have the thermostat installed by a professional electrician.

The second reason is related to the design features of the thermostats. The fact is that basically their power supplies are built according to a transformerless circuit with a ballast capacitor (almost all regulators from such companies as: OJ Electronics, Eberle, Raychem, some DEVI), or according to a key stabilizer circuit such as Devireg D530, Devireg D535 , Veria B45, Veria T45.

Such thermostats are sensitive to impulse noise on the power supply, which occurs when devices such as a welding transformer, a hammer drill or an electric lawn mower are turned on next to the regulator, which is often the case in country houses.In such conditions, it is better to use regulators with transformer power supplies that do not allow impulse noise (for example, NTC100 Busch Jaeger regulator).

If your regulator is out of order, do not rush to throw it away. In most cases, the regulator can be repaired.

Our company carries out warranty repairs of thermostats purchased through our network of stores or through our dealers, as well as non-warranty repairs of any regulators.

The cost of such repairs is fixed - 1000 rubles.

Underfloor heating does not work! What to do?

A typical customer case! You decided to make a warm floor at home, and the builders who are doing the repairs say “That from early childhood they put the floor. More than 1000 warm floors have been installed and everyone is happy. Why put there? ”As a person who sincerely trusts your builders, for fear of showing doubts about their professionalism, you entrust them with the installation of underfloor heating. From this moment on, the headache begins! The builders completed the repairs and left for their homeland. The burned-out tiles are laid, the cold has come, and the warm floor does not work! We proceed to search for the cause of the malfunction.

Debugg

How to replace the underfloor heating sensor

If the results of testing the "warm floor" system showed that the cause of the malfunction is the temperature sensor, then it can be replaced with a new one, but only if the design of the thermostat itself allows it. But keep in mind that you need to purchase a sensor of the same type and with the same resistance as the previous one. Such a replacement will not hit the pocket, since the prices for temperature sensors range up to 600 rubles. If you need help in choosing the appropriate sensor for your thermostat, you can seek advice from the specialists of our company at the contacts indicated in the header of the site. The consultation is free.

How to replace the underfloor heating thermostat

If the cause of the malfunction lies in the fact that the underfloor heating thermostat has stopped working, then the best option is to purchase a new device.

Replacement of the thermostat for the temperature of the warm floor can be carried out on the universal models Terneo ST and Terneo Pro. These models are combined with various devices and heating systems, they can operate according to the set time modes, due to which you can significantly save on energy consumption.

You can also look at other models of thermostats from our catalog "Thermostats".

If you are having difficulty choosing a thermostat model or do not know which temperature sensor is suitable for replacing a failed one, the specialists of our store can always help you. To get professional free advice from our managers on all issues related to the "warm floor" system and its components, call us at the numbers indicated in the header of the site, write by e-mail, or contact an online consultant.